0% found this document useful (0 votes)

379 views12 pagesGeneral Engineering PDF

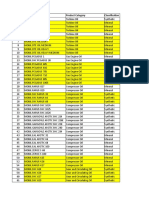

The document discusses Molygraph's general engineering lubricant products, including high temperature greases, extreme pressure greases, multifunctional greases, greases for centralized lubrication systems, high speed greases, water resistant greases, open gear greases, and chain & wire rope grease.

Uploaded by

RUTA TLAXCALA (SHELL)Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

379 views12 pagesGeneral Engineering PDF

The document discusses Molygraph's general engineering lubricant products, including high temperature greases, extreme pressure greases, multifunctional greases, greases for centralized lubrication systems, high speed greases, water resistant greases, open gear greases, and chain & wire rope grease.

Uploaded by

RUTA TLAXCALA (SHELL)Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 12