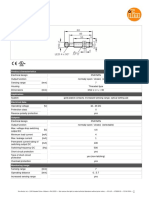

Inductive Sensor

with Increased Switching Distance

I08H003

Part Number Technical Data

Inductive Data

Switching Distance 2 mm

Correction Factors Stainless Steel V2A/CuZn/Al 0,81/0,39/0,42

Mounting flush

Mounting A/B/C/D in mm 0/8/6/0

Mounting B1 in mm 0...1

Switching Hysteresis < 10 %

Electrical Data

Supply Voltage 10...30 V DC

Current Consumption (Ub = 24 V) < 9 mA

Switching Frequency 1070 Hz

Temperature Drift < 10 %

Temperature Range -40...80 °C

Switching Output Voltage Drop <1V

Switching Output/Switching Current 150 mA

Residual Current Switching Output < 100 µA

Short Circuit Protection yes

Reverse Polarity and Overload Protection yes

Protection Class III

Mechanical Data

Housing Material CuZn, nickel-plated

Degree of Protection IP67

Connection M8 × 1; 3-pin

Increased switching distance Safety-relevant Data

Innovative ASIC circuit technology MTTFd (EN ISO 13849-1) 3706,54 a

Integrated error display Function

Error Indicator yes

Minimal mounting clearance thanks to wenglor we-

proTec PNP NO

Connection Diagram No.

Suitable Connection Equipment No. 8

Suitable Mounting Technology No. 200 201

Inductive Sensors with increased switching distances

are distinguished by rugged design, easy installation

and reliable measured values. The large range makes

additional types of sensor superfluous because they

can also be used to implement special applications. In

addition to error-free operation of several sensors in a

very small space, the new generation also provides the

possibility of detecting system errors before it's too late

thanks to ASIC und wenglor weproTec.

Complementary Products

PNP-NPN Converter BG8V1P-N-2M

Inductive Sensors

�1 = Switching Status Indicator

Sleeve M8×1 = 4 Nm

All dimensions in mm (1 mm = 0.03937 Inch)

Legend

+ Supply Voltage + nc Not connected ENBRS422 Encoder B/ (TTL)

– Supply Voltage 0 V U Test Input ENA Encoder A

~ Supply Voltage (AC Voltage) Test Input inverted ENB Encoder B

A Switching Output (NO) W Trigger Input AMIN Digital output MIN

Ā Switching Output (NC) W– Ground for the Trigger Input AMAX Digital output MAX

V Contamination/Error Output (NO) O Analog Output AOK Digital output OK

Contamination/Error Output (NC) O– Ground for the Analog Output SY In Synchronization In

E Input (analog or digital) BZ Block Discharge SY OUT Synchronization OUT

T Teach Input A MV Valve Output OLT Brightness output

Z Time Delay (activation) a Valve Control Output + M Maintenance

S Shielding b Valve Control Output 0 V rsv Reserved

RxD Interface Receive Path SY Synchronization Wire Colors according to DIN IEC 60757

TxD Interface Send Path SY– Ground for the Synchronization BK Black

RDY Ready E+ Receiver-Line BN Brown

GND Ground S+ Emitter-Line RD Red

CL Clock Grounding OG Orange

E/A Output/Input programmable SnR Switching Distance Reduction YE Yellow

Rx+/– Ethernet Receive Path GN Green

PoE ower over Ethernet Tx+/– Ethernet Send Path BU Blue

IN Safety Input B US Interfaces-Bus A(+)/B(–) VT Violet

OSSD Safety Output La Emitted Light disengageable GY Grey

Signal Signal Output Mag Magnet activation WH White

BI_D+/– Ethernet Gigabit bidirect. data line (A-D) RES Input confirmation PK Pink

EN0 RS422 Encoder 0-pulse 0/ (TTL) EDM Contactor Monitoring GNYE Green/Yellow

PT Platinum measuring resistor ENARS422 Encoder A/Ā (TTL)

V0-31.03.2023

Mounting

Specifications are subject to change without notice

IND. CONT. EQ

72HL / E189727

For use in class 2 circuits