PROJECT NAME & DETAILS

REF:

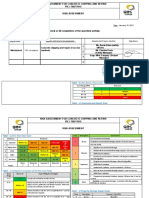

RISK ASSESSMENT FOR CONCRETE WORKS - SUBSTRUCTURE REV: 00

DATE:

RISK RISK

RESIDUAL RISK

CONSEQUENCES/ EVALUATION LEVEL ACCEPT

S.N. ACTIVITY HAZARD CAUSES OF HAZARD IMPLEMENTED CONTROL MEASURES

IMPACT Y/N?

P S H/M/L P S H/M/L

1 Delivery and Untrained Unsafe maneuvering of Fatality, injury Ensure all personnel,

mobilization Personnel concrete truck and damage to operators/drivers has HSE

of equipment property, accident orientation/Pre-job meeting

on site between trucks Ensure that the truck roads are

to be identified and location of pumps to

be marked in the drawings

Trained flag man/ signal man to

control vehicle maneuvering

4 4 16 Trespassing of personnel on the 1 4 4 Y

route is to be monitored

Reverse alarms for trucks is to

be operational while reversing

Unauthorized personnel or other

workers are to be restricted from trucks

movement path.

Safe distance to be maintained

between trucks.

2 Concrete Miss handling of Failure to follow the usage of Hand burn, injury Use of proper hand gloves

testing and concrete during proper P.P.E due to chemicals

4 3 12 Training and safety procedures 1 3 3 Y

placing on testing and to be followed

slab placing

3 Pumping Equipment, Improper inspection of joints Fatality, injury Ensure spill precautions by

concrete and unskilled operators and putting polythene sheets and timely

Failure of pumps

mechanical failure removal to designated place

3 4 12 Proper clamping of hose pipe of 1 4 4 Y

pump

Competent Operator License

Ensure pump has valid certificate

4 Pouring Failure of Load can fall (Concrete) Severe personal Make sure competent operator

concrete with concrete bucket injury, Property and rigger are assigned

bucket damage Use certified equipment / lifting

tackles

Use third party certified buckets

4 5 20 Use tag line 1 5 5 Y

Follow the SWL

Inspect the bucket during use

Cordon off the area

Close supervision

Page 1 of 5

� PROJECT NAME & DETAILS

REF:

RISK ASSESSMENT FOR CONCRETE WORKS - SUBSTRUCTURE REV: 00

DATE:

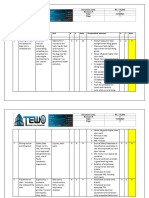

5 Placing Miss handling of Failure to deploy trained Fatality, injury The personnel handling the hose

concrete on concrete hose personnel and barricading the pipe is to be trained and use of higher

columns& area while cleaning process in diameter nylon rope as for guiding the

slabs progress, working at height 3 4 12 hose while concreting 1 4 4 Y

Controlling and cleaning of pump

Use of full body harness

6 While placing Slips and trips Improper housekeeping and House keeping to be maintained

Fracture,

concrete negligence of the personnel penetrating or Re-enforcement placing top and

puncture injury 3 4 12 bottom bars are to be tied properly to 1 4 4 Y

avoid unbalance while personnel walking

over the steel

7 While placing Fall of personnel Failure to follow the rules on Fatality, injury of Use appropriate working plate

concrete from height working at heights person form with abdicate fall protection system

Ensure that the edge protection

4 4 16 handrails system of the shuttering is 1 4 4 Y

properly fixed and in place.

Use job specific PPE like, ie:

goggle, hand gloves, gum shoes and mask

8 While placing Collapse of Failure in the structural design Fatality, injury of Ensure the formwork supplier is

concrete formwork with respect to the load the person and to assess the supporting system is

calculations property damage adequate according to the design.

Certification to be given to Main

Failure in provision of back

Contractor prior to the Consultant

propping system as per design 3 5 15 1 5 5 Y

inspection for concerting.

standards

Ensure a carpenter team must

be made available while casting to check

the back propping system is not

disturbed/ altered

9 Use of Repeated No proper training in usage of Corporeal syndrome Work cycle method / rotation

vibrator vibratory vibrator (white finger system in usage of vibrator for placing of

equipment use disease) for 2 4 8 concrete 1 4 4 Y

personnel Control repetition work

10 Usage of Unsafe use of No proper maintenance of Electrocution of Periodic check of electrical

electrical electrical electrical equipments/ personnel equipments/ machineries

machineries machineries machineries 3 4 12 1 4 4 Y

Electrical connection of power

Failure to deploy skilled supply/ cable management and

electricians arrangements

11 Concreting Sunstroke Failure to follow the local and Sunburn Adequate drinking water supply

on day ministerial regulations along with dehydration supplement like

Collapse of

3 4 12 ORS… 1 4 4 Y

personnel

First Aid facility is made

available throughout

12 Concreting at Slips & trips Failure in providing proper Personnel injury, Proper lighting facilities provision

night illumination fracture 4 4 16 1 4 4 Y

Approval / NOC for night

Page 2 of 5

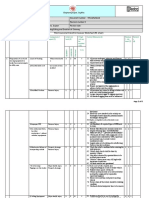

� PROJECT NAME & DETAILS

REF:

RISK ASSESSMENT FOR CONCRETE WORKS - SUBSTRUCTURE REV: 00

DATE:

concreting

Implement HSE concrete pouring

checklist

13 Concreting Soil collapse Heavy vibration from pump Buried by soil, Confirm soil test report

activity and vibrators asphyxiation,fatal, recommendation

3 3 9 1 3 3 y

Temporary shoring erected

Persons in danger

Workers undertaking the work

Persons passing the site location/ truck routes, e.g. members of the public and persons in the Vehicles.

Personal protective equipment

Safety Helmet, Gum Boot, Proper Gloves & Safety Goggles

Information, instruction and training

All personnel in the team are to be made aware of the safe systems of work.

Ensure that good house keeping standard is maintained through out.

Training and experience for personnel to use electrical equipments and vibratory equipments.

Educate the personnel to handle chemicals such as concrete…

Emergency procedures

Site emergency procedures should make provision for the rescue of individuals from heights.

First-aid facilities should be available to cope with any significant injuries that may arise from the work.

Monitoring and review

Work should be monitored by Foreman and charge hand who are trained to ensure that any additional precautions or equipment required are

provided.

Page 3 of 5

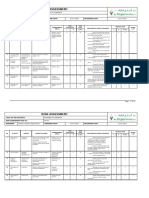

� PROJECT NAME & DETAILS

REF:

RISK ASSESSMENT FOR CONCRETE WORKS - SUBSTRUCTURE REV: 00

DATE:

RISK ASSESSMENT COMMITTEE: Project Manager/ Project Engineer

Safety Manager/ Safety Officer

Reviewed by: (Safety Officer) Approved by: (Project Manager)

RISK MATRIX

Risk Rating (RR) – Severity x Likelihood

LIKELIHOOD

(PROBABILITY)

Likely

(P) Rare Unlikely Possible Almost certain

Could happen often (on

Remote possibility (once Could happen but rare Could happen occasionally Could happen frequently

average once a month or

every 3 years or more) (typically once in a year) (on average quarterly) (once a week or more)

more)

SEVERITY 1 2 3 5

4

(IMPACT)

(S)

Low Low Low Low Medium

Insignificant 1

1 2 3 4 5

Low Low Medium Medium Medium

Minor 2

2 4 6 8 10

Low Medium Medium Medium High

Moderate 3

3 6 9 12 15

Low Medium Medium High High

Significant 4

4 8 12 16 20

Medium Medium High High High

Major 5

5 10 15 20 25

Page 4 of 5

� PROJECT NAME & DETAILS

REF:

RISK ASSESSMENT FOR CONCRETE WORKS - SUBSTRUCTURE REV: 00

DATE:

RISK BASED CONTROL PLAN

RISK LEVEL ACTION AND TIMESCALE

Quick, easy controls should be implemented immediately and further action planned for when resources permit. Monitoring required

1-4

ensuring controls are maintained. Manage through routine procedures. Go for economic improvements where possible. Incident

Low

report must be completed.

Aim to reduce risks but costs of prevention may be limited. Undertake a risk assessment of the situation / task and implement the

appropriate actions. Actions should have a timescale and should be monitored. Where the risk involves work in progress undertake

5-12 a risk assessment as soon as possible to ensure the safety of the situation or task. Work should not start until the risk is

Medium reduced to an acceptable level. Considerable resources may have to be allocated. Contact your Manager and Risk Manager by

telephone about the actions that should be taken to reduce the risk/s. incident report must be completed. Incident must be added

to service risk register.

Do not commence the activity until a risk assessment has been completed to ensure the safety of the situation or task. If it is

15-25 not possible to reduce or eliminate the risk even with unlimited resources, work must remain prohibited. Inform your relevant

High Director, your Manager and the Risk Manager immediately by telephone. Incident report must be completed. Incident must be

added to service risk register.

Page 5 of 5