0 ratings0% found this document useful (0 votes)

278 views51 pagesTransducer Notes

Measurement and instrumentation

Uploaded by

Ajay kumarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

0 ratings0% found this document useful (0 votes)

278 views51 pagesTransducer Notes

Measurement and instrumentation

Uploaded by

Ajay kumarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

You are on page 1/ 51

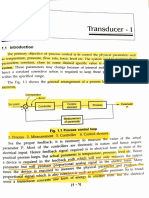

Transducer is a device which converts one form of energy to another form.

Another name of transducer is Pick up.

The main application of transducer is in the measurement of non electrical

quantities. It is used in the detector stage of instrumentation system.

Sometimes i

electrical signal.

Non

jectrical

Electrical ——>|

Transducer

Energy

is also defined as a device which converts a Physical quantity into an

Electrical

Energy

‘The reasons for transforming a physical phenomenon into electrical form are:

Electrical amplification and attenuation can be done easily

Mass inertia effects associated with mechanical systems are absent

vvv

Easy to control electrical signal.

Electrical signals can be easily used, transmitted and processed for further data

acquisition systems.

If the transducer covers entire detector transducer stage, the transducer may be

consisting of two stages:

y

Sensing element: it is that part of a transducer which responds to a physical

physical phenomenon, The response of the sensing

phenomenon or change i

element must be closely related to the physical phenomenon.

> Transduction element: A transduction element transforms the output of sensing

element to an electrical output.

Note: The above two stages can be considered as primary and secondary transducer.

The transducers can be classified as :

> On the basis of transduction form used- Resistive, capacitive , inductive,

piezoelectic ete

> As primary and secondary transducers ~ Bourdon tube and LVDT for measurement

of pressure, load cell and strain gauge for measurement of force.

> As passive and active transducers

> Asanalog and digital transducers

> As transducers and inverse transducers.

Primary transducer:

>

It forms first stage of transduction. It converts non electrical quantity to another

form which is compatible for next transducer. Mechanical device acts as primary

‘transducer,

ex: Bourdon tube, Diaphragm, Bellows, Load cell

The output of primary transducer is given to secondary transducer and it converts

into electrical signal compatible for data acquisition systems.

Ex: Strain Gauge, POT, LVDT

Passive transducer:

> Passive transducers derive the power required for transduction from an auxiliary

power source. They also derive part of the power required for transduction from

the physical quantity under measurement. They are known as “Externally powered

transducers”

ex: POT, Strain gauge, LVDT

Active transducer:

> Active transducers does not require an auxiliary power source to produce their

output. They are also known as “Self generating type transducers”

ex: Thermocouple , Piezoelectric crystals , Photovaltaic cells

Analog transducer:

> These transducers convert input quantity into an analog output which is a

continuous function of time.

Ex: Thermocouple , LVDT, Thermistor

Digital transducer:

> These transducers convert the input quantity into an electrical output in the form

of pulses.

Ex: Glass scales

Transducer:

> A transducer is a device which converts non electrical quantity into electrical

quantity

Inverse transducer:

> An inverse transducer is a device which converts electrical quantity into non

electrical quantity

Ex:

iezoelectric Crystal

Resistance Transducers

> The resistance of a metal conductor is expressed by an equation that involves a

few physical quantities.

pl

R-2t

A

where R= Resistance

P = Resistivity of conductor material

L= length of conductor

A= Area of conductor

‘Any method of varying one of the quantities in the above equation can be the

design basis of Resistive Transducer

> Potentiometer, Strain gauge, RTD, Thermistor are the examples of Resisti

transducers

Potentiometer ( POT )

POT: are suitable for measurement of linear and angular displacements

POT consists of resistive element provided with a sliding contact known as wiper.

‘The motion of the contact may be translatory (linear) or rotational.

‘Some of the POTS use both combination of translatory and rotational motions ,

they are known as HELIPOTS.

poenent

+ al

“a

Advantages of POT

Y Simple to operate and inexpensive

Y — Suitable for measurement of large amplitudes of displacement

v

In wire wound potentiometer the resolution is I

ed and metal film

potentiometers the resolution is infinite.

Disadvantages of POT

Y — Itneeds larger force to move their sliding contacts.

¥ Sliding contacts are viable for wear out, misalignment and introducing errors

Strain Gauge

If a metal conductor is stretched or compressed, its resistance changed on account

of the fact that both length and diameter of conductor changes.

‘There is a change in the value of resistivity of the conductor when it is strained and

property is called Piezoresistive effect.

Strain gauges are used for measurement of strain and associated calculation of

stress,

Strain gauges also useful es secondary transducer in many of the sensors like Load

cells, Pressure gauges, accelerometers and flow meters etc.

If a strip of clastic material is subjected to tension or pi

ively strained, then

length increases and diameter decreases ( lateral dimension ), It results

ito

increase in resistance of gauge.

Ifa strip of elastic material is subjected to compression or negatively strained, then

length decreases and diameter increases { lateral dimension ). It results into de

crease in resistance of gauge.

¥ — Sometimes, the change in resistance of strained conductor is more than what can

be accounted for a change in resistance due to dimensional changes. It is due to

change in resistivity ( Piezoresistive effect).

Types of Str

Gauges:

4. Un banded metal strain gauges

2, Bonded metal wire strain gauges

3. Bonded metal foil strain gauges

4, Sputter deposited thin metal strain gauge

5, Semiconductor strain gauges

Semiconductor Strain Gauges:

“High sensitivity strain gauges needs higher gauge factor. A high gauge factor means

arelatively higher change in resistance for the applied strain.

¥ Semiconductor strain gauges will have higher gauge factor | + 130) due to

Piezoresistive effect ( i.e the change in value of resistance due to change in

resistivity),

¥ Silicon and Germanium are used as resistive materials for semiconductor gauges.

Advantages :

> High gauge factor

y

‘Smallin size

> Hysteresis characteristics are excellent

Disadvantages:

> Very sensitive to temperature variations

Non linear characteristics. The gauge factor varies with strain.

Rosette:

>

ra

>

It is the combinaton of strain gauges, called Rosette.

Itis may consist of two gauges or three gauges.

In practical applications, an element may be subjected to stresses in any

direction and hence it is not possible to locate the direction of principal

stress. Therefore it is not possible to orient the strain gauge along the

direction of principal stress.

There is a necessity to evolve a strain measurement system which

measures the values of principal strain and stresses with out actually

knowing their directions.

Special points on strain gauge:

>

Change in resistance in strain gauge will be measured by Wheatstone

bridge.

If only one active gauge is used in bridge, it is known as Quarter Bridge .

To increase sensitivity and for temperature compensation, half and full

bridge configurations are to be followed.

In the half bridge , two active bridges shall be employed. The output

voltage of half bridge is two times that of quarter bridge.

In the full bridge , four active bridges shall be employed. The output

voltage of full bridge is four times that of quarter bridge.

Effect of Temperature on strain gauge:

Temperature change acts as spurious signals and cause change in

resistance in two wayst

(1) the resistance of the wire grid of strain gauge changes with change in

temperature.

(2) a change in resistance occurs due to differential expansion exciting

between the gauge and test surface to which strain gauge is bonded.

Temperature compensation:

The errors due to temperature change can be accounted / cancelled out during

measurement by the following methods:

a) Dummy gauge

b) Half bridge configuration

Full bridge configuration

Resistance Thermometers

The resistance of a conductor changes when its temperature is changed.

The variation of resistance R with temperature T (°K) can be represented

by the following formula:

R=R (4 agT H0gT? + on boT")

where

R, =resistance at temperature T = 0

0,00 ,..0.0, aFe constants

The resistance thermometer uses the changes in electrical resistance of

conductor to determine temperature.

Platinum is specially suited for Resistance Temperature Detector ( RTD ), it

can withstand high temperatures while maintaining excellent

stability.

RESISTANCE THERMOMETERS

>All motals produce a positive change in resistance with tomporature. This, of

course, is the main function of an RTD.

ized when the nominal value of RTD is large. This

>The system erro1

implios a motal with a high value of resistivity should be used for RTDs. Tho

lower is the resistivity of the metal, the more material we will have to use.

mini

>The requirements of a conductor material to be used in RTDs are :

(i) The change in resistance of material per unit change in temperature

should be as large as possible

(i) The material should have a high value of resistivity so that minimum

volume

of material is used for the construction of RTD.

(iii) The resistance of materials should have a continuous and stable

relationship with temperature.

>Tungsten has relatively a high resistivit

, but is reserved for high temperature

applications s it is extremely brittle and difficult to work.

>Copper is used occasionally as an RTD element. Its low resistivity forces the

element to be longer than the platinum element, but its low linearity and low

cost make it an economical alternative,

»The most common RTDs are made of either platinum, nickel or nickel alloys.

The economical nickel wires are used over a limited temperature range. They

are quite non-linear and tend to drift with time, For measurement integrity,

platinum is the obvious choice.

THERMISTORS

>Thermistor is a construction of a term “thermal resistors”,

>Thermistors are generally composed of semi-conductor materials.

>Thermistors have a negative coefficient of temperature resistance i. their

resistance decreases with increase of temperature.

>The negative temperature coefficient of resistance can be as large as several

percent per degree Celsius.

>This allows the thermistors circuits to detect very small changes in

temperature which could be observed with an RTD or a thermocouple.

>In some cases the resistance of thermistor at room temperature may

decreases much as 5 percent for each 1 °C rise in temperature.

>This high sensitivity to temperature changes makes thermistors extremely

useful for precision temperature measurements control and compens:

>Thermistors are widely used in applications which involve measurements in

the range of -60°C to 15°C.

> The resistance of thermistors ranges from 0.5 © to 0.75 MQ.

>Thermistor is a highly sensi

e device.

>The price to be paid off for the high sensi

ty is in terms of linearity.

>The thermistor exhibits a highly non linear characteristics of resistance

versus temperature.

Resistance-Temperature Characteristics of Thermistors: The mathematical

expression for the relationship between the resistance of thermistor and absolute

temperature of thermistor is :

a)

where

R,, =Resistance of thermistor at absolute temperature T, ; °k,

k, and

B =a constant depending upon the material of thermistor, typically 3500 to 4500 °k

Rr, =Resisiance of thermistor at absolute temperature T, :

Applications :

> Measurement of temperature

> Control of temperature

> Temperature compensation

Measurement of thermal conductivity

Materials for thermistors:

> Metall

oxides such as manganese, nickel, cobalt and uranium

> Semiconductor materials

SEEBECK EFFECT

Two metallic strips made of different metals are joined at the ends to form a loop. If

the junctions are kept at different temperatures, there is an electric current in the

loop. This effect is called the Seebeck effect and the emf developed is called the

Seebeck emf or thermo-emf.

THERMOCOUPLES

> Thermocouple is active transducer.

> Thermocouple is the joint of two dissimilar metals.

> Thermocouple produce voltage as its temperature varies as per SEEBECK

EFFECT

>In a thermocouple temperature measuring circuit, the emf setup is measured

by sending a current through a moving coil instrument, the deflection being

directly proportional to the emf.

> Thermal emt is a function of temperature difference A8, the instrument can be

calibrated to read the temperature. The emf may also be measured by a

potentiometer. cogil

Advantages and Disadvantages of Thermocouples :

Advantages:

() Thermocouples are cheaper than the resistance thermometers.

(i) Thermocouples follow the temperature changes with a small time lag and as

‘such are suitable for recording comparatively rapid changes in temperature.

(ii) Thermocouples are very convenient for measuring the temperature at one

particular point in a piece of apparatus.

Disadvantages:

() They have a lower accuracy and hence they cannot be used for precision work.

(i) To ensure long life of thermocouples in their operating environments, they shauld

VARIABLE INDUCTANCE TRANSDUCERS

>The variable inductance transducers work, generally, upon one of the

i) change of self inductance,

following three principles :

) change of mutual inductance,

i) production of eddy currents.

» Transducers working on principle of change of Self Inductance :

‘The self inductance of acoll L=N'/R

where

'N =number of turns, and

R reluctance of the magnetic circuit.

Thereluctance of the magnetic circuit

etnductance b= N? (AQ =NE WG ()

where

it =effective permeability of the medium in and around the coil, H/m

G=AVe =geomettic form factor

‘A =area of cross - section of coil ;m?

and ¢ = length of coil :m.

>it is clear from above equation that the variation in inductance may be

caused by:

(i) chango in numbor of turns, N,

(ii) change in geometric configurations, G,

(iii) change in permeability, p.

> Inductive transducers are mainly used for measurement of displacement. The

displacement to be measured is arranged to cause variation of any of three

variables in Eq(1) and thus alter self inductance L by AL.

Differential Output :

>Change self inductance AL is adequate for detection for subsequent stages

of instrumentation system.

>The transducer can also be designed to provide two outputs one of which is

an increase of self inductance and the other is a decrease in self inductance.

The succeeding stagos of instrumentation system measure the difference

between those output i.e. 2\L. This is known as the differential output.

>The advantages of differential outputs are :

(i) The sensitivity and accuracy are increased.

(ii) The output is less effected by external magnetic fields.

(ili) The effective variations due to temperature changes are reduced.

{iv) Effects of changes in supply voltage and frequency are reduced.

‘Transducers working on principle of change of Mutual Inductance :

An inductive transducer working on the principle variation of mutual

inductance uses multiple coils. The mutual inductance between two coils is

M=KyUjLy

where

L, and L, = seff inductance of two coils,

and K =coefficien t of coupling.

Thus mutual inductance between the coils can be varied by variation of self

inductances or the coefficient of coupling.

>However, the mutual inductance can be converted into a self inductance by

connecting the coi

in sorios.

>The self inductance of such an arrangement varies between L, +L, - 2M to L, +

L, + 2M with one of the coils being stationary while the other is movable.

>The self inductance of each coil is constant but the mutual inductance

_chanaes denendina unon the displacement of the movable coil.

>The differential arrangement, the fixed coil is divided into two parts. The

movement of the movable coil increases the mutual inductance of one part by

AM.

Transducers working on principle of production of Eddy Currents :

> These inductive transducers work on the principle that if a conducting plate is

placed near a coil carrying alternating current, eddy currents are produced in the

conducting plate.

>The conducting plate acts as a short circuited secondary winding of a

transformer. The eddy currents flowing in the plate produce a magnetic field of

their own which acts against the magnetic field produced by the coil. This results

in reduction of flux and thus the inductance of the coil is reduced.

>The nearer is the plate to the coil, the higher are the eddy currents and thus

higher is the reduction in the inductance of the coil. Thus the inductance of the

coil alters with variation of distance between the plate and the coil.

[ LINEAR VARIABLE DIFFERENTIAL TRANSFORMER (LVDT) ]

>The most widely used and popular Inductive transducer to translate the

linear motion into electrical signals is the linear variable differential

transformer (LVDT).

>The transformer consists of a single primary winding P and two secondary

windings S, and S, wound on a cylindrical former. The secondary windings

have equal number of turns and are identically placed on either side of the

primary winding. The primary winding is connected to an alternating current

source. A movable soft iron core is placed inside the former. The displacement

to be measured is applied to the arm attached to the soft iron core.

s, hime

LvoT

>The core is made of high permeability, nickel iron which is hydrogen

annealed. This gives low harmonics, low null voltage and a high sensitivity.

This is slotted longitudinally to reduce eddy current losses.

>The frequency of a.c. applied to primary windings may be between 50 Hz to

20 kHz.

>The primary winding is excited by an alternating current source, it produces

an alternating magnetic field which in turn induces alternating voltages in the

two secondary windings (transformer action ).

>The output voltage of secondary, S,, is E,, and that of secondary, S., is E,, In

order to covert the outputs from S, and S, in to a single voltage signal, the two

secondaries $1 and S2 are connected in series opposition.

>Thus the output voltage of the transducer is the difference of the two

voltages. _pifferential output voltage

E, = Ex, -Esz

When the core is at its normal (NULL) position, the flux linking with both the

secondary windings is equal and hence equal emfs are induced in them. Thus

at null positions : E,, = E,,. Since the output voltage of the transducer is the

difference of the two voltages, the output voltage E, is zero at null position.

¥If the core is moved to the left of the NULL position, more flux links with

winding S, and less with winding S,. Accordingly output voltage E,,, of the

secondary winding S,, is more than E,,, the output voltage of secondary

winding S,, The magnitude of output voltage is, thus, E, = E,, - E,, and the

output voltage is in phase with say, the primary voltage.

If the core is moved to the right of the null position, the flux linking with

winding S, becomes larger than that linking with winding S,. This results in E,,

becoming larger than E,,. The output voltage in this case is E,= E,,-E,, and is

180° out of phase with the primary voltage. Therefore, the two differential

voltages are 180° out of phase with each other.

>The amount of voltage chang er Secondary winding is proportional to

the amount of movement of the core.

>As the core is moved in one direction from the null position, the differential

voltage i.e, the

ference of the two secondary voltages, w

crease while

maintaining an in phase relationship with the voltage from the input source.

> In the other direction from the null position, the differential voltage will also

increase, but will be 180° out of phase with the voltage from the source.

By comparing the magnitude and phase of the output (differential) voltage

with that of the source, the amount and direction of the movement of the core

and hence of displacomont may be dotormined.

Advantages

> High range of displacement ( up to 250 mm)

> Friction and electrical isolation.

>Immunity front external effects.

>High out i.e high sensitivity.

Disavantages

> Sensitive to stray magnetic fields

> Transducer performance is affected by vibrations.

>Further instrumentation system should be capable of receiving a.c signal,

otherwise is to be converted to dc

Applications

> Measurement of displacement

> Acting as secondary transducer in force , weight, pressure measurement.

ROTARY VARIABLE DIFFERENTIAL TRANSFORMER (RVDT)

> RVDT is useful for measurement of angular displacement

itis similar to LVDT but its core is CAM shaped and is rotated botween tho

windings by means of a shaft.

> At NULL position of the core, the output voltage of secondary windings are

equal and in opposition. Thorefore, the net output voltage is zero.

>Any angular displacement from the null position will result in a differential

output voltage.

>The greater this angular displacement, the greater will be the differential

output.

> clockwise rotation produces an increasing voltage of a secondary winding

of one phase while anti clock wise rotation produces an increasing voltage of

opposite phase.

>The amount of angular displacement and its direction may be obtained from

magnitude and phase of the output voltage.

CAPACITIVE TRANSDUCERS

>The principle of operation of capacitive transducers is based upon the

familiar equation for capacitance of a parallel plate capacitor.

Capacitance cacy = a0 (ty

where

‘A = overlapping area of plates ;m?,

d =distance between two plates m,

{9 = permitivily of mediumover lapping area of plates ;F/m,

relative permitivity,

permilivity of free space ;8.85 x 10"? Fim.

>The capacitive transducer work on the principle of change of capacitance

which may be caused by;

(i) change in overlapping area A,

(li) change in the distance d between the plates,

__and_(iii) chanae in dielectric constant

>These changes are caused by physical variables like displacement, force,

and pressure in most of the cases.

>The change in capacitance may be caused by change in dielectric constant

as is the case in measurement of liquid or gas levels.

The capacitance may be measured with bridge circuits.

>The capacitive transducers are commonly used for measurement of linear

displacomont. These transducers uso the following offects :

(i) change in capacitance due to change in overlapping area of plates,

change in capacitance due to change in distance between two plates.

Transducers Using Change in Area of Plates :

> It is evident from the formula that the capacitance is directly proportional to

the area, A of the plates. Thus the capacitance changes linearly with change in

area of plates.

>This type of capacitive transducer is useful for measurement of moderate to

large displacements say from 1mm to several cm.

>The area changes linearly with displacement and also the capacitance.

»Fig shows the variation of capacitance. As mentioned earlier the response is

linear as shown, the initial non- linearity is due to edge effects.

PARALLEL PLATE CAPACITOR

capacitanceis:

cach, =2%F @)

vihere

x =length of overlapping part of plates ;m,

and w = width of overlapping part of plates ;m

Sensitivity $= 8

>The sensitivity is constant and therefore there Is linear relationship between

capacitance and displacement.

Advantages

> Small forces are required for their operation. Hence small power is required

for their operation.

> they have a high input impedance and the loading effects are minimum.

>They have a good frequency response. This response is high as 50 KHz and

hence they are very useful for dynamic studies.

Free from stray magnetic fields

Disavantages

> Guard rings are to be used in order to eliminate effect of stray electric fields.

>The instrumentation circuitry associated with these transducers is complex.

>The capacitive transducers are temperature sensitive and any change in

temperature adversely effects performance.

Applications

>» Measurement of linear and angular displacements

> As a secondary transducer for force and pressure measurement.

Measurement of humidity of gases.

> Measurement of liquid levels, volume and density.

PIEZO ELECTRIC TRANSDUCERS

> A Piezo ~ electric material is one in which an electric potential appears

across certain surfaces of a crystal if the dimensions of the crystal are

changed by the application of a mechanical force. This potential is produced

by the displacement of charges.

>The effect

reversible, i.e, conversely, if a varying potential is applied to the

Proper axis of the crystal, it will change the dimensions of the crystal thereby

deforming it. This effect is known as Piezo-electric effect.

>Elements exhibiting piezo-clectric qualities are called as Electro resi

elements.

>Common piezo-electric materials include Rochelle salts, ammonium

dihydrogen phosphate, lithium sulphate, dipotassium tartarate, potassium

dihydrogen phosphate, quartz and ceramics A and B.

>Excopt for quartz and coramics A and B, tho rest are man-made crystals

grown from aqueous solutions under carefully controlled conditions.

» The ceramic materials are polycrystalline in nature. They are, basically, made

of barium titanate. They do not have piezo-electric properties in their original

state but these properties are produced by special polarizing treatment.

>The materials that exhibit a significant and useful Piezo-clectric effect are

divided into two categories :

(i) Natural group and

(ii) Synthetic group.

>Quartz an Rochelle salt belong to natural group while materials like lithium

sulphate, ethylene diamine tartarate belong to the synthetic group.

>The piozo-oloctric effect can be made to respond to (or causa) mochanical

deformations of the material in many different modes.

>The modes can be : thickness oxpansion, transvorse oxpansion, thickness

shear and face shear.

¥A piezo-electric element used for converting mechanical motion to electrical

signals may be thought as charge generator and a capacitor. Mechanical

deformation generates a charge and this charge appears as a voltage across

the olactrodes. Tho voltago is E = QIC.

> The piezo-electric effect is direction sensitive. A tensile force produces a

voltage of one polarity while a compressive force produces a voltage of

opposite polarity.

>The magnitude and polarity of the induced surface charges are proportional

to the magnitude and

charges depends upon the direction of applied force.

rection of the applied force F. Tho polarity of induced

Properties of Piezo-electric Crystals :

¥The desirable properties of piezo-electric materials are stability, high output

insensitivity to temperature and humidity and the ability to be formed into

most desirable shape.

> Quartz is the most stable piezo-electric material. However, its output is quite

small. On the other hand, Rochelle salt provides the highest output but it can

bo worked over a limited humidity range and has to bo protected against

moisture. The highest temperature is limited to 45°C.

»Barlum titanate has the advantage that It can be formed into a variety of

shapes and sizes since it is polycrystalline. It has also a higher dielectric

constant.

Hall Effect

>If a strip of conducting material carries a current in the presence of a

transverse magnetic field a difference of potential is produced between the

opposite edges of the conductor.

>The magnitude of the voltage depends upon the current, the strength of

magnetic field and the property of the conductor called Hall effect coefficient.

>The Hall Effect is present in metals and semiconductors in varying amounts,

depending upon the densities and nobilities of carriers.

>The resistivity of some metals and semiconductors at low temperatures

changes if exposed to a magnetic field. This effect is known as Magneto

resistance.

Magnetic - resistive elements operate on the law of thermodynamics that

Lorentz forces act upon mobile charge carriers in a magnetic field, causing

electrons to move in an indirect route, thereby lengthening the current path

and increasing resistance.

>The amount of deflection of the electrons depend upon electron mobility.

> The preferred semiconductor materials are Indium antimonide or Indium

arsenide.

You might also like

- Transducer Engineering DR S Renganathan PDFNo ratings yetTransducer Engineering DR S Renganathan PDF158 pages

- To Study Half Wave and Full Wave Rectifier Circuits1No ratings yetTo Study Half Wave and Full Wave Rectifier Circuits14 pages

- Electronic Circuits and Pulse Circuits Lab ManualNo ratings yetElectronic Circuits and Pulse Circuits Lab Manual73 pages

- Network Analysis & Synthesis (KEE 403) Unit-INo ratings yetNetwork Analysis & Synthesis (KEE 403) Unit-I3 pages

- Linear Variable Differential Transformer (LVDT)100% (2)Linear Variable Differential Transformer (LVDT)13 pages

- Chapter # 16: Loud Speakers, Headphones and EarpieceNo ratings yetChapter # 16: Loud Speakers, Headphones and Earpiece12 pages

- Etwork Heorems: Presented by Shashank GuptaNo ratings yetEtwork Heorems: Presented by Shashank Gupta16 pages

- Application of Diodes Rectifier Circuits Clipper Circuits - PPT Video Online DownloadNo ratings yetApplication of Diodes Rectifier Circuits Clipper Circuits - PPT Video Online Download7 pages

- DC Analysis of A NPN BJT Using Voltage Divider Bias100% (1)DC Analysis of A NPN BJT Using Voltage Divider Bias5 pages

- CS-State Space Modeling (Bakshi & Goyal)No ratings yetCS-State Space Modeling (Bakshi & Goyal)58 pages

- Potentiometer and Strain Sensor Experiments100% (2)Potentiometer and Strain Sensor Experiments44 pages

- Digital Voltmeters Can Be Classified in To The Following Broad Categories100% (1)Digital Voltmeters Can Be Classified in To The Following Broad Categories22 pages

- Working Principle of Digital Storage OscilloscopeNo ratings yetWorking Principle of Digital Storage Oscilloscope4 pages

- Multipole Expansion of The Electrostatic PotentialNo ratings yetMultipole Expansion of The Electrostatic Potential16 pages

- Unit-2 - L-12 - Characteristics of LED, Photodiode, and LDRNo ratings yetUnit-2 - L-12 - Characteristics of LED, Photodiode, and LDR9 pages

- State and Explain Barkhausen's Criteria For Sustained Oscillation 1No ratings yetState and Explain Barkhausen's Criteria For Sustained Oscillation 15 pages

- EEE Measurement & Instrumentation GuideNo ratings yetEEE Measurement & Instrumentation Guide116 pages

- Ell100 Lab Report: Single Phase Transformer B-H LoopNo ratings yetEll100 Lab Report: Single Phase Transformer B-H Loop10 pages

- Electronic Measurement and InstrumentationNo ratings yetElectronic Measurement and Instrumentation239 pages

- June 2023 BEE PTU Question Paper With AnswersNo ratings yetJune 2023 BEE PTU Question Paper With Answers19 pages

- B.P. Mandal College of Engineering, Madhepu: Minor Project PresentationNo ratings yetB.P. Mandal College of Engineering, Madhepu: Minor Project Presentation21 pages

- MCQ On Temperature Dependence of ResistivityNo ratings yetMCQ On Temperature Dependence of Resistivity16 pages

- V6 Transmission Gate, Dynamic CMOS, Domino - S CMOS EtcNo ratings yetV6 Transmission Gate, Dynamic CMOS, Domino - S CMOS Etc18 pages

- Variable Inductance Transducer 5th Sem Measurement 2No ratings yetVariable Inductance Transducer 5th Sem Measurement 23 pages

- Transducer & Sensors (5th Sem.. Measurement 2)No ratings yetTransducer & Sensors (5th Sem.. Measurement 2)10 pages