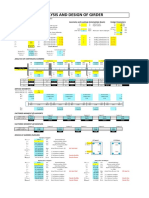

Girder Mark : 2G-1

Analize and Design by : Engr. Marvin A. Bensig

Geometry and Loadings (Girder) Design Parameters

f'c = 20.7 Mpa

b= 0.2 m width of girder fy = 275 Mpa

h= 0.5 m height of girder Main ø = 16 mm

Top Bars at Support

Mdemand = 75.00 kN-m Demand Moment At Support At Midspan

n= 4 pcs Assume number of bars

As = 804.247719319 mm2 Total Area of Rebar S = 1 layer

a= 62.8497081025 mm Depth of compression fiber d = 482 4 pcs 1 pcs

c= 73.9408330618 a = 0.85c

fs = 3311.23534892 Mpa Actual Stress (fs must > fy) OK, Steel Yield

Actual T = 221.168122813 kN

cb = 330.514285714 mm "c" at balance condition S = 1 layer 5 pcs 5 pcs

ab = 280.937142857 mm "a" at balance condition d = 482

0.75ccb = 741.463354286 kN CC at Balance Condition Pass for Ductility

Mcapacity = 89.687573294 kN-m Beam Moment Capacity Pass for Flexure

Bottom Bars at Support Bottom Bars at Midspan

Mdemand = kN-m Demand Moment Mdemand = 57.00 kN-m Demand Moment

n= 5 pcs Assume number of bars n= 5 pcs Assume number of bars

As = 1005.30964915 mm 2

Total Area of Rebar As = 1005.31 mm 2

Total Area of Rebar

a= 78.5621351281 mm Depth of compression fiber a= 78.56214 mm Depth of compression fiber

c= 92.4260413272 a = 0.85c c= 92.42604 a = 0.85c

fs = 2528.98827914 Mpa Actual Stress (fs must > fy) OK, Steel Yield fs = 2528.988 Mpa Actual Stress (fs must > fy) OK, Steel Yield

Actual T = 276.460153516 kN Actual T = 276.4602 kN

cb = 330.514285714 mm "c" at balance condition cb = 330.5143 mm "c" at balance condition

ab = 280.937142857 mm "a" at balance condition ab = 280.9371 mm "a" at balance condition

0.75ccb = 741.463354286 kN CC at Balance Condition Pass for Ductility 0.75ccb = 741.4634 kN CC at Balance Condition Pass for Ductility

Mcapacity = 110.154729623 kN-m Beam Moment Capacity Pass for Flexure Mcapacity = 110.1547 kN-m Beam Moment Capacity Pass for Flexure

DESIGN OF GIRDERS (SHEAR)

Top Bars at Support

Mdemand = 75.00 pcs Demand Moment At Support At Midspan

n= 4 pcs Assume number of bars

As = 804.247719319 mm2 Total Area of Rebar S = 1 layer

a= 78.5621351281 mm Depth of compression fiber d = 482 4 pcs 1 pcs

c= 92.4260413272 a = 0.85c

fs = 2528.98827914 Mpa Actual Stress (fs must > fy) OK, Steel Yield

Actual T = 276.460153516 kN

cb = 306.437086093 mm "c" at balance condition S = 1 layer 5 pcs 5 pcs

ab = 260.471523179 mm "a" at balance condition d = 482

0.75ccb = 687.44946755 kN CC at Balance Condition

MPROBABLE RIGHT= 122.39414403 kN-m Nominal Moment Capacity

Bottom Bars at Support

Mdemand = 0.00 pcs Demand Moment Ve

n= 5 pcs Assume number of bars

As = 1005.30964915 mm 2

Total Area of Rebar T1 = 1.25AsFy

a= 98.2026689102 mm Depth of compression fiber T2 = 1.25AsFy

c= 115.532551659 a = 0.85c

fs = 1903.19062331 Mpa Actual Stress (fs must > fy) OK, Steel YT1 = 1.25A MPROBABLE LEFT MPROBABLE RIGHT

Actual T = 345.575191895 kN

cb = 306.437086093 mm "c" at balance condition Ve

ab = 260.471523179 mm "a" at balance condition L1/2 L2/2

0.75ccb = 687.44946755 kN CC at Balance Condition

MPROBABLE LEFT= 149.599039417 kN-m Nominal Moment Capacity

L1 = 5 m Length Max

L2 = 1 m Length Min

Ve = 271.993183442 kN Shear Force based on probable moments

Vg = 93 kN Shear Force Due to Gravity Loads

Vp = 364.993183442 = Ve + Vg

VuAnalysis = 112 kN Shear Force generated based on Analysis

Vu = 364.993183442 kN Governing Factored Shear (assume to be @ distance d from the support)

Vud < ØVn ØVn = Ø(Vc + Vs)

(f'c)^0.5*b*d = 438.59 kN

ØVc = Ø1/6(f'c)^0.5*b*d = 54.82 kN Factored Shear Capacity of Concrete

ØVc / 2 = 27.41 kN No need for Stirrups if this value is greater than Vu Notes: Stirrups is Needed

Vs = (Vu-ØVc)/Ø 413.56 kN Required Shear Strength for Stirrups

s = Avfyd/vs 41.56 mm Computed Spacing of Stirrups based on the Shear Required

Ø2/3(f'c)^0.5*b*d = 219.30 kN This value must be greater than Vs, to limit bursting and crushing of concrete

Ø2/3(f'c)^0.5*b*d is < Vs therefore, Not Safe

1/3(f'c)^0.5*b*d = 146.20 kN If this value is greater than Vs, max spacing is S = d/2 s= 225 or 600mm

1/3(f'c)^0.5*b*d = 146.20 kN If this value is less than Vs, max spacing is S = d/4 s= 100 or 300mm

1/3(f'c)^0.5*b*d is < Vs therefore, max spacing of stirrups is = 100 mm

Additional Provisions for Eathquake Resistant Structure -Section 418

Actual width Minimum Width

Beam Dimension Limits =

200 > 250 Fail NSCP 418.6.2.1b

reinforcement ratio Limitations

Longitudinal Reinforcement

Limits= 0.00834 < 0.025 Pass NSCP 418.6.3.1

d/4 = 120.5 mm

Hoop Reinfocement at twice 6db = 96 mm

depth from the face of the support

= = 150 mm

governs = 90 mm

Stirrups Spacing

S1 = 25 Computed Spacing of Stirrups based on the Shear Required

S2 = 100 Maximum spacing of stirrups

S3 = 90 Hoop Reinforcement

governs (sh) = 25 mm

�2h = 1000 Sh = 90 mm 11 pcs

3h = 1500 St = 150 mm 10 pcs

Schedule of Stirrups/Hoops : 1 @50mm, 11 pcs @ 90 mm, 10 pcs @ 150 mm, Rest @ 225 mm