In Amazon’s warehouses, the stages of the conversion process (from storing, to picking and packing

operations for shipping products) are managed through an ICT-based system, which serves to

register incoming goods, track the exact position of all stored goods, and collect all data on current

production processes.

It is also used as a digital control system to monitor the employees’ activities – where they are, how

many articles they handle in a given period of time, and how their performance compares to that of

their colleagues.

Each picker (whose job is to collect the goods from various shelves) has a hand barcode scanner

equipped with a microphone and a camera, that determines the route the worker has to take

through the warehouse, and serves as a kind of time card for clocking the time spent to perform the

task.

Similarly, each packing station (where the job consists in preparing and labelling packages for

shipping) is equipped with a monitor which shows what order has to be handled and how.

Amazon has issued a pair of patents for a wristband system that monitors and tracks warehouse

workers’ position in relation to a given inventory bin

Bracelets that can emit ultrasonic sound pulses or radio transmissions to let a receiver system get a

fix on where the workers’ hands are, in relation to an array of inventory bins.

A method for verifying that the correct items are being processed.

The system’s sensors triangulate on the wristband’s signals to determine where a worker’s hand is

positioned, and software matches that position with the inventory item that’s supposed to be

processed.

In addition to picking up signals, the system could send signals back, setting the band abuzz with a

burst of “haptic feedback” to let workers know their hands are heading for the right bin.

Amazon released the following statement about its patents for a wristband tracking system, saying

that such a device is aimed at making it easier for warehouse workers to do their jobs.

“The speculation about this patent is misguided. Every day at companies around the world,

employees use handheld scanners to check inventory and fulfill orders. This idea, if implemented in

the future, would improve the process for our fulfillment associates. By moving equipment to

associates’ wrists, we could free up their hands from scanners and their eyes from computer

screens.”

Amazon, like many companies, routinely files high-tech patents exploring the frontiers of

technology. As we’ve pointed out previously, many of those patents undergo significant refinement

before a product is brought to market, and many more never come to fruition. For example, there

are no smartphone airbag systems or drone-dispensing airship warehouses on the horizon. So

�breathe easy: Amazon won’t be using wristbands to track employees’ bathroom breaks anytime

soon..

Previously: Amazon has been issued a pair of patents for a wristband system that monitors whether

warehouse workers are putting their hands in the right places.

The patents, published today, cover bracelets that could emit ultrasonic sound pulses or radio

transmissions to let a receiver system get a fix on where the workers’ hands are, in relation to an

array of inventory bins.

Amazon doesn’t typically comment on its patents, but if the technology makes economic sense, it

could conceivably be picked up for use in the Seattle-based online retailer’s hundreds of fulfillment

centers.

This isn’t the first time the concept has come to light: When the applications for the patents were

published last fall, there was a spate of stories about “buzzing wristbands that bosses can use to

track workers and order them around.”

It’s true that the idea of wearing a monitoring bracelet evokes a modicum of creepiness, akin to the

idea of wearing an ankle bracelet during house arrest. But you won’t find a hint of that in the patent

documents. The concept is laid out instead as a labor-saving measure:

“Existing approaches for keeping track of where inventory items are stored … may require the

inventory system worker to perform time consuming acts beyond placing the inventory item into an

inventory bin and retrieving the inventory item from the inventory bid, such as pushing a button

associated with the inventory bin or scanning a barcode associated with the inventory bin. …

Accordingly, improved approaches for keeping track of where an inventory item is stored are of

interest.”

The patents, filed in 2016, suggest that the wristbands provide a no-muss, no-fuss method for

verifying that the correct items are being processed. The inventors say the system circumvents the

need for “computationally intensive and expensive” monitoring by means of computer vision, a la

Amazon Go.

And the inventors know their way around computer vision: The patent for the ultrasonic wristband

was filed by Jonathan Cohn, senior technical program manager for Amazon Go. The radio-frequency

wristband system was proposed by Tye Brady, chief technologist for Amazon Robotics.

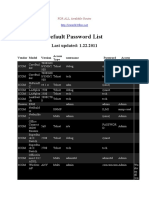

�Radio-based wristband system

This diagram illustrates how sensors could track the position of a wristband that sends out radio

signals. (Amazon Illustration via USPTO)

The system’s sensors triangulate on the wristband’s signals to determine where a worker’s hand is

positioned, and software matches that position with the inventory item that’s supposed to be

processed.

In addition to picking up signals, the system could send signals back, setting the band abuzz with a

burst of “haptic feedback” to let workers know their hands are heading for the right bin.

It’s not clear if or when Amazon might actually turn the wristband concept into a reality. But since

Amazon employs tens of thousands of workers at its fulfillment centers, it doesn’t take much to

guess where the system could be put into effect. So if boxes of wristbands start turning up at a

warehouse near you, be sure to let us know.

�The working process at Amazon's warehouses, as described in the provided text, can be analysed

based on the following points:

Social Structure (Technical Knowledge):

Amazon's social structure is characterized by the use of advanced technology to optimize its

warehouse operations.

The technical knowledge involves the development and use of the patented wristband tracking

system, which utilizes ultrasonic sound pulses or radio transmissions to improve the efficiency of

warehouse work.

1. Storing:

- Workers responsible for receiving and storing incoming goods.

- They may use handheld scanners and other equipment to log the arrival of products and place

them in designated storage locations.

- This role involves maintaining an organized and efficient inventory system.

Animalising and comparing whit each elements of the social structure:

Who: no

Where: warehouses

How: to store

2. Picking:

- Pickers are responsible for retrieving products from storage locations as per customer orders.

- They use handheld barcode scanners equipped with microphones and cameras to identify and

pick the correct items.

- The goal is to efficiently gather the ordered items while following the most optimal route within

the warehouse.

Who: picker, personal responsible for picking whose relationship among each one, no direct

interactions among the pickers

Where: amazon warehouse, best predetermined path (best in terms of time)

How: barcode scanners keypad by a camera

When: shortest time possible

3. Packing:

- Packing station workers are tasked with preparing and packaging the gathered items for

shipment.

� - They utilize monitors that provide information about the orders, guiding them in packaging the

products correctly and labeling them.

- Quality control and accurate packaging are essential in this role.

4. Shipping:

- Workers involved in the shipping stage ensure that packages are appropriately labeled and sent

out for delivery.

- This may involve coordinating with carriers and logistics providers to ensure timely dispatch and

tracking of shipments.

- Accuracy in labelling and timely shipment is crucial for customer satisfaction.

In this social structure, different teams or individuals have distinct roles and responsibilities related

to the various stages of the warehouse operations, ensuring the smooth flow of products from

storage to shipping.

Who (Knowledge about Working Devices, Tools):

Warehouse workers are the primary individuals involved in the process.

They use various devices and tools, including handheld scanners, wristbands, and monitoring

equipment.

Where (Knowledge about the Object of Transformation):

The object of transformation in Amazon's warehouses is physical products (goods) that need to be

stored, picked, and packed for shipping.

The work occurs within the warehouse facilities of Amazon's fulfilment centres.

When (Knowledge about the Regulation of Work):

The regulation of work is not explicitly detailed in the text, but it is evident that Amazon aims to

improve the work process for warehouse employees.

The mentioned technology could free up employees' hands from scanners and their eyes from

computer screens, potentially improving the efficiency and convenience of their work.

How (Working Tools, Devices, Equipment, and Machinery):

The working process involves the use of handheld barcode scanners equipped with microphones and

cameras by pickers.

�Packing stations are equipped with monitors to provide order information.

The patented wristband system utilizes ultrasonic sound pulses or radio transmissions to track the

position of workers' hands in relation to inventory bins.

The system includes sensors and software to determine hand positions and provide haptic feedback.

Training, Rewards, Selection, Career Paths, Expertise, Skills, and Knowledge Possessed:

The text does not provide specific information about training, rewards, selection, career paths, or

the expertise and skills of workers.

However, it does highlight the potential benefits of the wristband system in making work easier for

fulfilment associates, indicating a focus on improving the work environment and processes.

In summary, Amazon's working process in its warehouses involves the use of advanced technology

to optimize the handling and tracking of physical products. The primary actors are warehouse

workers who utilize various devices and tools to improve the efficiency of their tasks. The focus

appears to be on enhancing the work environment and processes to benefit employees. Specific

details about training, rewards, and career development are not mentioned in the provided text.