0 ratings0% found this document useful (0 votes) 179 views19 pagesErection Method For Steel Structure

Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content,

claim it here.

Available Formats

Download as PDF or read online on Scribd

(wind) B CONSORTIUM WIKA CHENGDA

LA)

PLTU Kalimantan Selatan 2 x 65 MW

ISSUE DATE DOCUMENT NO. REV

5-Oct-10 WC-GD-KSL-2-063 00

PREPARED BY | CHECKED BY

Da {i WIKA CHENGDA ENGINEERING

7

Nye

‘SIGNED BY

JASEN

Revision

Revol

Rev-02

(BOP)

Rev-

Rev-04

Rev-0s

| ERECTION METHODE for STEEL STRUCTURE

Rev-06

Related Section

Review

COPY FOR

foarte

pare

loare

pare

DATE:�Page 2of 19

<> uaa wo

ERECTION METHOD for STEEL STRUCTURE

Project : PLTU Kaleel 2 x 65 MW Asam-asam

TABLE OF CONTENT

4 PURPOSE ......

PREPARATION WORK ..

ERECTION WORK ...

FINAL CHECK .........

MISCELLANEOUS STRUCTURAL STEEL ...

See ee eee

DAMAGE CAUSED DURING ERECTION’

CORRECTION OF ERRORS

Se PPR Ercietatodeseasee Pov 01 Tut: sop so10�Page 3of 19

PT. BANGUN SARANA BAJA WQA

‘ripatn anit onsen sete fete

ERECTION METHOD for STEEL STRUCTURE pute

fev:

Project : PLTU Kalsel 2.x 65 MW Asam-acam

1. PURPOSE

The purpose of erection method for steel structure is as a guide in performing the work, to obtain

optimal results, in accordance with the wishes of the client, namely : a strong steel structure with

precision accurate & secure installation.

Il, PREPARATION WORKS

4. Engineering Preparation

Purpose :

‘© Determine the type and capacity of tools and equipments that will be used

© Determine a safe point for components to be installed

‘© Determine the type of stiffener to components to be used when needed

2. Site Preparation

Purpose :

© Determine the order based on the installation instructions

* Determine the area of dismantling & placement of components will arrive at site

‘* Determine the operational area of work equipment

3. Monitoring of materials or components to be installed in accordance with the initial or working order

3. Request for materials / components must be installed according to working order

5, Prepare and check equipment or equipment to be used, especially mobile cranes, chain blocks,

single Shackle, clamps (see the data needs of working equipment)

6. Determining the position of the rope / slings that will be used to lift material when installed

7. Checking the anchor position and condition of the rope / slings

ase FILPREectoenodersiSneZe Rovio Tete: oA 010�Page 40f 19

> pamoum sanana nasa wos

cao gee

ERECTION METHOD for STEEL STRUCTURE Reeta

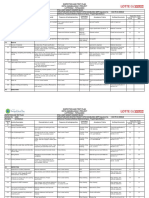

114, Plan of Work Equipments to Use for Erection (For Example)

z

&

Mesin Las

Kabel lastsiang las @ 50m

Kap Las

Biander Potong (kompit) @50m (LPG besar)

Elpiji besar

Oksigen

Bor Tapping screw ( Screw Driver )

Borpistol

Kabel Supply

Kunci Momen 7200

Kunci Momen 3000

2 |srek3T

3_|Seling Kain 5 T

i4_|Segel 25mm

15 |

6

Jonis Jumlah | Unit |

1

1

|

ofa ~/o)a)a|ols

|

'Seling untuk labrang 10mm

Jarum keres 16mm

| Segel 12mm

"Tali Tambang 5/8 (200m)

Kiem Seling 10mm

[Kiem Seling &mm

[Segel 10mm

‘Tiang Replan

Langi, paju, palo, palu

Container z oe

27 |Kotekait fe [2 |

"28 |sabukPengaman (Hamest) 2s

29 | Kaca Mata safety ; 25

30_[Sarung Tangan Kain a)

290-Fu PRU Eondaadersnlcheo va 01 a, + soAgt-010�Page Sof 19

See WOA

spcimamcacara Some

ERECTION METHOD for STEEL STRUCTURE

LTU Kalsel 2 x 65 MW Asam-asam

Rev: 0

11.2, Prepare Location for Material Storage

Materials which have been received from the fabrication placed in the area near the location of the

site for efficiency installation.

ll, ERECTION WORK

ERECTION OF PRIMARY AND SECONDARY STRUCTURAL

GENERAL INFORMATION

Many methods and procedures are in use for erecting the structural portion of metal buildings. For

‘example, the techniques of raising frames vary all the way from erecting small clear spans and end

wall frames in units, to erecting the larger clear spans and modular frames in sections. The erection

methods used depend sttictly on the type of buildings, the available equipment. the experience level

of the crews. and the individual job conditions.

The variation in these factors precludes the establishment of a firm or specific set of erection rules

and procedures. Consequently, the erection operation must be tailored, by the erector himself, to fit

individual conditions and requirements. However, there are certain erection practices. pertaining to

structural members, which are in general use and have proven sound over the years. Description of

these follow.

The erector shall have all the lifting equipment. cranes, forklifts, spreader bars, slings, guy wires,

come-a longs, and hand tools necessary to erect the building.

SB FILPRECrdioMatodesalsence a 08 a. a + f.4e42010,�Page 6 of 19

> PT. BANGUN SARANA BAJA, WQA

ERECTION METHOD for STEEL STRUCTURE aa

ee

Project : PLTU Kalsel 2 x 65 MW Asam-asam

4. For Anchor Bolt Installation

* Installation starts by determining the coordinates / axis columns (to get an accurate position,

coordinated by the civilian workers)

Anchor Installation which is made based on the mall plate, adapted to the column has been

inserted in the track to determine the level of the base plate

‘* After the anchor position is correct, then the tip of the anchor is strengthened by a strong

column, binding using welding wire (or depending on the expertise WELDER) to strengthen the

beam

2. Erecting The Frames

Instructions are directed to a single-span structure.

Review erection drawings. Determine which bay includes permanent bracing. Set columns for

braced bay. Do not include endwall columns in this initial phase. Set a minimum of four interior

frame columns. Tighten anchor bolts and nuts sufficiently to prevent columns from rocking,

Install all sidewall girts between each pair of columns. Install permanent bracing as indicated in

erection drawings.

Assemble rafter section on wood blocking. Place flange stays in position on rafter.

so PuPRaerecirteodersiaaee fel 01 Talat = tA co10�Page 7 of 19

BANGUN SARANA BAIA Wa

ERECTION METHOD for STEEL STRUCTURE oe

ev

Project : PLTU Kalsel 2 x 65 MW Asam-asam

Install all bolts in rafter splice to the proper tension, using tun of nut method or torque wrench.

Al buildings require temporary bracing which shall be attached to the rafter before itis lifted into place,

then tied off to prevent buckling of the rafter.

Raise rafter into position at top of columns.

Hold in place with hoisting equipment while required bolts are installed through the column caps, tighten

to snug fit

Tie off first frame with cables extending lengthwise of the building.

‘The quantity and location of this temporary bracing will vary with the size of the structure.

CAUTION : ALL BUILDINGS MUST BE BRACED DURING ERECTION. THE DEGREE OF

BRACING BEING DEPENDENT ON THE SIZE OF THE BUILDING AND LOCAL WEATHER

CONDITIONS. DO NOT COMMENCE ERECTION IF WEATHER CONDITIONS ARE UNSETTLED OR

‘STRONG WINDS IMMINENT.

Using above procedure. assemble second rafter. Place it on top of second set of columns,

Bolt to columns. Continue to hold second rafter with rig until a minimum of a quarter of the purlins are

installed,

Release rig. Between erected rafters. place remaining roof purlins at every purtin location.

Install permanent rod bracing between rafters. Bolt flange stays in position.

noe Fu PRucnceomonadeielscte Reva ot Ta. et: Soap 2010�Page 8 of 19

RANOUM SARANA BAIA Woa

Ti ast sao voce re

ERECTION METHOD for STEEL STRUCTURE ae

ev

Project : PLTU Kalsol 2 x 65 MW Asam-asam

| chine &

| SeLUMe os,

PERMANENT

Roo SRACING

Use the temporary braces to pull the columns into plumb.

When all columns of the first bay are plumb. tighten all anchor bolts. eave strut bolts. girt bolts.

and column to rafter bolts.

Resume erection of columns. rafters. and purlins in same manner in successive bays.

ESS PRE ErcirMahodesiasuuID evs 01 Tate: tog 2010�Page 90f 19

PT. BANGUN SARANA BAJA WQA

Ga eprinemmecnnncam™ oe

“op toe ater set 70

ERECTION METHOD for STEEL STRUCTURE

Project : PLTU Kalsel 2x65 MWAsam-asam by : |

Use additional temporary bracing as work progresses.

As each frame is erected. plumb columns tighten anchor bolts. eave strut bolts. purlin bolts and fix

flange braces.

After completing all main frames the end walls can be erected. Follow details from standard erection

drawing. ensure that high strength bolts are used where indicated.

‘Complete installation of girts. sag rods and bracing. Install door frames and extra window framing. if

any.

Make a final check of structural frame for alignment and plumb.

Check all connections to be sure that all bolts have been installed. and that all high strength bolts are

tensioned to correct requirements.

These instructions can be used for any of the different types of buildings. For specific details

refer to the appropriate standard erection drawing.

NOTE: The same principles apply for both clear span buildings as well as multi-span buildings with

internal columns, With very wide buildings the rafters may be lifted in segments. making sure that

sufficient guy wires are fixed until the full rafter is completed. In addition. be particularly careful in

selecting the correct size of spreader bar when lifting long sections of rafter.

Incorrect lifting methods could distort the rafter.

SSE FLFR ErcrNetodSiaSauee Revs 01 Taw » 19.2040�Page 10 of 19

<> PT. BANGUN SARANA BAJA WQA

“iy otis occ are

ERECTION METHOD for STEEL STRUCTURE

Project : PLTU Kalsel 2 x 65 MW Asam-asam

Rev: 0

TIGHTENING BOLTS.

Preparation Work

‘© Preparation equipment and tools for tightening bolts, all he tools certificate checked for

completeness, especially Torque wrench. (Attachment)

* Preparation ladder and scaffolding in position around the bolt and check with the lead scaffolder

erector, mark a place that is ready to tighten.

© Must use safety equipment to cover the entire body, safety shoes, safety helmet, gloves and

earmufs.

© Tightening bolts addressed in the joint structures, which are included in the joint use of the

connection requirement specification ASTM A 325.

ightening Bolt

* Bolts installed in accordance connection to ensure the completion of joint washers and the

appropriate dimension or quantity.

© For the first time, the bolts are tightened by hand, in the order from the center to the edge position

by using a paint mark from the top plate bolts to the joint connection.

© For the second tightening bolts using the electric impact wrench, according to the sequence from

the middle position to the edge, to ensure the bolt can be moved 120 ° from the first line mark.

© Check all bolts with a torque wrench tightening, according to the capacity and dimensions, and in

the order of the position of the center to the edge.

20 FLFR ErcirNaodeceatcten Rava 01 Tata: sop 2010�Page 11 of 19

-BANGUN SARANA BAJA Wor

“op tte foes So

ERECTION METHOD for STEEL STRUCTURE

Project : PLTU Kalsel 2 x 65 MW Asam-asam

HIGH STRENGTH BOLTS

© Tur of nut methods is the normal practice of tightening high strength bolts,

© Turn of nut method -All nuts in the connection shall be snug tight (the effort of one man using the spud

wrench). all nuts in the connection shall then be tightened a further 1/3 rum.

© To be sure of correct nut rotation. match-mark the nut and bolt after snugging all nuts and prior to final

tightening.

* High strength bolts may also be tightened by means of impact or manual wrench in accordance with the

table below.

1 25.4 51 226 635 861

| 789 | 1069

[ta 347) 74 37 one | 1508

- rae) 360 8 378 1405 |= (1985

4-172 | 381 | 103 459 1937 2623

9b. PR) Ecterlehacersnlscice oa: Tele: song 010�Page 12 of 19

27, PT. BANGUN SARANA BAJA WQA

ERECTION METHOD for STEEL STRUCTURE aety

ev

Project : PLTU Kalsel 2 x 65 MW Asam-asam

IMPORTANT

No loads shall be supported from the purlins unless the building has been designed for additional loads. In

such cases the loads shall not be supported from the purJins until the roof sheets have been installed and

fully screwed.

The following sketches show correct and incorrect methods of support from rafters and purlins.

YES

NO YES

Bo0-U PRA ErecterlohadttBrce el :08 Tain: 9A—s2010�Page 13 of 19

<>"! PT. BANGUN SARANA BAJA WOQA

Bear orheeetipecte Saito

ERECTION METHOD for STEEL STRUCTURE

STRUCTURAL FASTENERS

The chart below identifies the most commonly used bolts in Steel Building and indicates where they are used

in connecting the various components.

OD FMPRS Erecietebodociaisiucve eva 01 aL Teni : oAetc010�Page 14 0f 19

PT. BANGUN SARANA BAJA WQA

‘ren Gahone Hi Goh 18) Soa

ERECTION METHOD for STEEL STRUCTURE

Project : PLTU Kalsel 2x65 MWAsam-asam

3. Sheeting

GENERAL NOTES

‘Always use a chalk line for accurate driling and screwing. This gives better appearance and less risk

of leakage due to misdriling.

* At the end of each working day clean the roof with a soft brush. Sweep off old drill bits, pop rivets,

swart from driling or cutting. These items can cause rusting if they are not removed,

Roofings screws shall be fixed in the high-ribs. Wall fasteners shall be fixed in the low ribs.

* When walking on the roof. do not stand on high ribs. stand only on the low ribs.

preferably over the purlin line. Standing on high ribs can cause severe damage which could lead to

possible leakage.

Note that stitch screws are required at sidelaps on roof sheets.

* Do not walk on skylights.

Mark out the sheeting along the length of the building. this will give correct overlap and avoid creep.

SELF TAPPING SCREWS

TOO LOOSE TOO TIGHT CORRECT

Touch-up any damaged paint on the main frame prior to sheeting.

Dso-rirnscrcioarodtSeesinie ove! 08 Ta wn: AOA 2010�Page 15 of 19

<>" ee Woa

ERECTION METHOD for STEEL STRUCTURE

Project : PLTU Kalsel 2 x 65 MW Asam-asam

COMMERCE WALL SHEETING FIRST

Check condition and dimension of incoming material for roofing and siding by Subcontractor’s QC/ Material

Control.

Check and make sure condition of steel framing by Subcontractor QC or Supervisor. Touch-up any damaged paint

cn the main frame prior to sheeting.

Fix the base angle to the concrete by means of HILT! (or similar) masonry nails. 4

Align the girts by means of wood biocking, one above the other between the girts, at mid bay. Two bays can

be done in this way and the timber blocks moved to the next bays after sheeting, this makes a straight girt

line and more accurate fixing

Mark the notch at 900mm centres as an aid to keeping the correct sheet coverage. Take note of the starting

dimension shown on the erection drawing.

WALL SHEETING-WITHOUT INSULATION

Start wall sheeting at the opposite end to the prevailing wind, or the most viewed direction so that the sheet

overlaps are not visibile.

Install the inside foam closure level with top of base angle before screwing the panels.

Check for correct starting dimension as per erection drawing. Check the panel is vertical. Repeat the vertical

check as each panel is erected

Note: The bottom screw shall pass through and hold the foam closure in position.

Se PMLPRE CeciaNatodeSeesstee oi -08 Tot et: 012010�Page 160f19

<> PT. BANGUN SARANA BAJA WQA

i tnensughonn foc eH ol ae

ERECTION METHOD for STEEL STRUCTURE

Project : PLTU Kalsel 2x 65 MW Asam-asam

OUTSIDE FOAN

/~ closure

INSIDE FoAtt—y

CLOSURE,

ROOF SHEETING-WITHOUT INSULATION

Place the first roof sheet to the given dimension for the overhang at the eave. (See Erection Drawing) Use a

string line as a guide for keeping the tail-line of the sheeting straight.

Start at the eave and work up the roof towards the ridge. from both sides of the building. The ridge sheet is

placed last. be sure that the endlap mastic is placed correctly. without gaps.

SHEETING-WITH INSULATION

‘The same procedure shall follow for lining and plumbing. with or without insulation.

Wall and roof insulation shall be cut to lengths as indicated by the erection drawings. Wall insulation shall be

clamped at the eave-strut or secured with double-faced tape. and pulled tight before screwing the panel.

‘Successive ‘drops' of insulation shall be stapled to the previous by the side tabs. (See Drwg. for Detail). This

is important to complete the vapour barrier seal.

Roof insulation shall be fixed or clamped at one eave strut and stretched as tight as possible before fixing at

the other eave strut. On average sized buildings one roll of insulation will span the full width. but on wider

buildings it may be necessary to splice. this shall be done on a purlin. After the roof sheets have been

placed. the next run of insulation can be stapled at the side tabs and work continue.

SonrMPRecrcierNetodeseasnetee evil ot Teta «0g z010�Page 17 of 19

PT. BANGUN SARANA BAJA WQA

‘ene Suni ora ems

“ap aise co Sra

ERECTION METHOD for STEEL STRUCTURE pata

ev

Project : PLTU Kalse! 2x 65 MW Asam-asam_

TRIMS AND ACCESSORIES-GENERAL NOTES

Keep it neat -keep it straight. the neatness of trimming and installation of accessories is of paramount

importance to give the finished building the quality look.

Use the proper tools for cutting: aviation snips for cutting trims. nibbler and shear for cutting sheets.

Use a chalk line to keep things straight. Use a spirit level to keep things plumb. Always clean-off your work,

Study the standard drawings supplied, these indicate correct trims, and fixing details for each application.

Take note of spacing of screws and rivets or the number of fasteners per item.

Observe where foam closures have to be installed.

Be sure that sealant or mastic is applied where required. Read all the notes on the drawing, they are

important.

Follow manufacturers instructions for installation of Roll-up-door, Personnel doors or Special Accessories.

\

QS

SOS

Use the correct tools

WRONG.

SBE PRS crecieNebednsisniaue eval sot Tet: og 2010�Page 18 of 19

Kd PT. BANGUN SARANA BAJA WOQA

ERECTION METHOD for STEEL STRUCTURE aera

ev

Project : PLTU Kalsel 2 x 65 MW Asam-asam

IV. FINAL CHECK

© After completing al rims and accessories a final inspection of the building shall be made

@ Allbracing in position and tightened

* Allbolts in place and high strength bolt tightened to correct tension.

© Check that roof and gutter are clear of debris and ferrous metals

© Check for mis-driled screws.

‘© Check al roof penetrations for weather tightness.

© Check operation of all doors.

© Touch-up any damaged paint

© Clean up the site work

V. MISCELLANEOUS STRUCTURAL STEEL ( e.g Stairway Handrail, Ladder, Cage Ladder,

Grating and Flooring installation)

STAIRWAY AND HANDRAIL

© Construct pedestal for column of stairway (including Anchor bolts)

Install Stee! column, frame etc which shall be erected in sequence manner.

Install Stair Boom left side and right side until column of building which already installed and all

bolts shall be tightened utilizing torque wrench after plumb.

© Install Balustrade frame structural steel 1" level flight, 2nd level flight and make sure that elevations,

connection of stee! member are structurally correct

© Check the structural steel frame for alignment and plumb by Subcontractor’s QC and witnessed by

Contractor QC.

‘@ Tightening bolts and check all connections to be sure that all bolts have been installed, where washer, lock

washer are called for, they shall be checked and that all high strength bolts are tensioned to correct

requirements by Subcontractor’s QC or Supervisor and witnessed by Contractor QC.

‘© Install Toe Plate and Handrail post

‘© Install handrail and accessories

‘* Install the Galvanized treads from bottom to the top level and tighten the bolts

* Install Grating for Balustrade 1" level, 2nd level

sSoeUPRIraceronaetrntSrucite oval 08 asta: 19.402019�Page 19 of 19

<> Raman sanana an wpa

ERECTION METHOD for STEEL STRUCTURE

Project : PLTU Kalsel 2 x 65 MW Asam-asam

Rev: 0

LADDER AND CAGE LADDER

Assemble the Ladder close to the location as indicated at the drawing

Setting out center line of the ladder

‘¢ Install by section complete sets of ladder to the steel ladder boom

‘© Install cage ladder by section refer to the ladder the above mentioned

© Alignment the straightness of ladder similar with steel ladder boom

© Fixing the complete ladder permanently

GRATTING AND FLOOR INSTALLATION

© Make sure that all Joist are properly constructed and bolt tightened

* Grouping and select type and dimension based on Marking for erection sequence and purpose.

Transporting and install to the designated position

* Fixing the corner of each grating connected properly and shall be jointed by designated clamp

or bolt

© Clean-up (collect and dispose the rubbish and waste material if any)

VL DAMAGE CAUSED DURING ERECTION CORRECTION OF ERRORS

* Allunplanned mosification has to be done for conforming to the situation and conaltion at site e.g. misfit

reasoned by improper fabrication, incomplete fabrication, damage caused during erection, etc., and shall

be recorded and rectified as per approved Field sketch issued by Contractor.

© If there is found improper weld on the structural steel joint, Subcontractor shall carry out repair at site with

reference to the qualified field welding procedure and Field Sketch issued by Contractor.

B50. PRL Ceteronacartnalsciee Revs ot Taste: soa a010