0% found this document useful (0 votes)

59 views11 pagesChapter Twenty Three

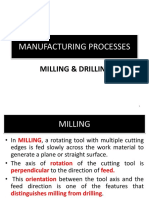

The document discusses various machining operations used to produce different shapes like milling, broaching, and sawing. It describes milling operations like peripheral milling and face milling. The key parameters for milling and face milling are also defined. An example calculation for material removal rate, power, torque, and cutting time for slab milling of mild steel is also shown.

Uploaded by

abdullaammar090Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

59 views11 pagesChapter Twenty Three

The document discusses various machining operations used to produce different shapes like milling, broaching, and sawing. It describes milling operations like peripheral milling and face milling. The key parameters for milling and face milling are also defined. An example calculation for material removal rate, power, torque, and cutting time for slab milling of mild steel is also shown.

Uploaded by

abdullaammar090Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

/ 11