Assessing risk using a risk matrix approach

What is risk assessment?

Risk assessment is the process of estimating and communicating workplace safety

risk, and deciding whether this risk is acceptable.

The main reasons for conducting a risk assessment for any hazard are to:

use the risk assessment to prioritise the risk control activities

use the risk assessment as a guide as to how the risk is to be controlled

justify the control activities based on the level of risk reduction.

A risk assessment must be undertaken considering the following factors that may be

contributing to the risk:

the work premises and working environment (including the layout and condition)

the number of people and how frequently those people could be exposed to risk

the capability, skill, experience and age of people ordinarily undertaking the work

the systems of work being used

the range of reasonably foreseeable conditions

the number and type of workplace and/or industry incidents.

OHS information available that is relevant to the particular hazard including:

OHS information provided by a supplier of any plant, equipment or substance

material safety data sheets (MSDS) for any hazardous substance

the label of any hazardous substance

results of any biological monitoring

results of any atmospheric monitoring

information contained in any specialised OHS reports provided or available

information about previous injuries, illness and dangerous incidents

standards, code of practice and guidelines.

Conducting a risk assessment involves making a value judgement based on this

information and any available evidence within the workplace and industry. This may

include numbers of current and past incidents, severity of injuries from the identified

hazard, lost work time from injuries and number of people involved in incidents.

Specific information such as environmental measurements of hazards, eg noise

levels, dust levels, Legionella, and comparisons made between the workplace

measurement and the legally required measurement can also assist in the risk

assessment process.

1

�The risk matrix

Risk matrixes are available from state/territory WorkCover authorities or the Risk

Management Standard: AS/NZS 4360:2004. You may also find that other state

authorities or event and industry associations may have developed sample matrixes.

The risk matrix records the level of risk which is determined by the relationship

between the likelihood of an incident occurring from the hazard, and the

consequence caused by the hazard. This is recorded as either a numerical or

alphabetical code. The relationship between likelihood and consequence determines

how dangerous the hazard is.

The level of risk or code that is determined is referred to as a risk priority rating. This

priority rating allows employers to prioritise the hazards identified to ensure that the

hazards with high potential of creating an incident are eliminated or controlled first.

Controlling a hazard may involve inspections, investigations and/or monitoring control

activities with managers, supervisors and work teams involved as appropriate

depending on the circumstances.

A hazard posing a low level of risk should not automatically be assessed as

acceptable. If there is a means of further reducing or eliminating this risk then this

must be done.

Risk matrixes, while staying true to the OHS authorities design, can be and are often

modified to suit a particular work environment or work task.

Modified risk matrixes can be reviewed within industry specific standards, codes of

practice, guidance notes and fact sheets from the state/territory OHS authorities or

risk management policies and procedures from event associations or companies.

2

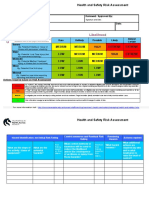

�Sample risk matrix (example 1)

This risk matrix has been designed and adapted from the Australia/New Zealand

Standard for Risk Management: AS/NZS 4360:2004. The risk priority rating on this

matrix is represented by an alphabetical code as the key below outlines.

Consequences

Severe Major Medium Minor Negligible

Likelihood

(1) (2) (3) (4) (5)

Almost certain

E H H M M

(A)

Likely

H H M M L

(B)

Possible

H M M L L

(C)

Unlikely

M M L L T

(D)

Rare

M L L T T

(E)

Key to the risk rating

E Extreme risk — Immediate action required; this level of risk needs detailed research

and planning by senior management.

H High risk — Action plan is required as soon as practicable by senior management.

M Moderate risk — Action plan is required by Area/Department Manager.

L Low risk — Managed by routine procedures and employees under supervision.

T Trivial risk — Unlikely to need specific application of resources.

The numbers and letters associated with the criteria for ‘likelihood’ and

‘consequences’ reflect accuracy in the rating. For example a risk rating may be “H”

but does that represent — ‘possible and severe’ or ‘likely and severe’ or ‘likely or

major’ etc. It is a way of explaining the reasoning behind the risk priority rating. It also

recognises that there are a few versions of the same rating just with different criteria

being assessed.

3

�Sample risk matrix (example 2)

This risk matrix has a risk priority rating represented by a numerical code as the key

below outlines.

How likely is it to be that bad?

++ Very likely + Likely = Unlikely – Very unlikely

How severely

could it hurt could happen could happen could happen may happen but

someone or anytime at some time but very rarely probably wont

how ill could it

make someone?

Kill or cause

permanent 1 1 2 3

disability or ill

health

Long term

illness or 1 2 3 4

serious injury

Medical

attention and 2 3 4 5

several days off

work

First aid needed

3 4 5 6

Key to the risk rating

1 and 2 The hazard has a high risk of creating an incident. It requires immediate

executive management attention to rectify the hazard. Control action must be

immediately implemented before working in the area or carrying out the work

process.

3 and 4 The hazard has a moderate risk of creating an incident. It requires

management attention in a reasonable timeframe to prevent or reduce the

likelihood and severity of an incident. Control action of a short term nature would

need to be taken immediately so that work could still be carried out with further

long term action taken to ensure that the hazard was fully controlled.

5 and 6 The hazard has a low risk of creating an incident. It requires supervisor and

employee attention in a reasonable timeframe to prevent or reduce the likelihood

and severity of an incident.

4

�Using the risk assessment matrix

A risk matrix identifies the relationship between the likelihood of an incident occurring

from the hazard, and the consequence caused by the hazard. This should still be the

case even with a modified matrix. Regardless of the matrix used the risk rating for a

particular hazard should still reflect the same outcome. Following are examples of

risk assessments of a range of hazards. They are recorded as either a numerical or

alphabetical code.

Hazard assessed: Operation of a fork lift at an event (alphabetical code)

To accurately assess this hazard and its potential associated risks consideration has

been given to:

the specific use of the fork lift

the number of people in the area of the fork lift use

the design and set-up of the event area in which the fork lift is used

experience of and licence requirements for people operating fork lift

regulatory and operational requirements of the fork lift.

Consequences

Severe Major Medium Minor Negligible

Likelihood

(1) (2) (3) (4) (5)

Almost certain

E H H M M

(A)

Likely

H H M M L

(B)

Possible

H M M L L

(C)

Unlikely

M M L L T

(D)

Rare

M L L T T

(E)

Risk rating = E

Extreme risk — Immediate action is required; detailed research and planning by

senior management.

5

�Acting on the risk rating

In this example the risk rating priority of E requires immediate action and detailed

research and planning by senior management to rectify the hazard. The action must

be developed before the activity is undertaken.

In this risk assessment particular consideration has been given to the number of

other people who will potentially be in the vicinity during the operation of the fork lift.

It is important to remember that risk assessments on the same or similar hazards can

differ if there are used in different work environments. For example, an assessment

of fork lift operations within a warehouse where access by people is limited may

record a risk rating of H.

Hazard assessed: Operation of a fork lift at an event (numerical code)

How likely is it to be that bad?

++ Very likely + Likely = Unlikely – Very unlikely

How severely

could it hurt could happen could happen could happen may happen but

someone or anytime at some time but very rarely probably wont

how ill could it

make someone?

Kill or cause

permanent 1 1 2 3

disability or ill

health

Long term

illness or 1 2 3 4

serious injury

Medical

attention and 2 3 4 5

several days off

work

First aid needed

3 4 5 6

Risk rating = 1

The hazard has a high risk of creating an incident. It requires immediate

executive management attention to rectify the hazard. Control action must be

immediately implemented before working in the area or carrying out the work

process.

6

�Acting on the risk rating

A risk rating priority level of 1 requires immediate executive management attention to

rectify the hazard. Control action would need to be immediately implemented before

working in the area or using the fork lift. This may include ensuring that all operators

are currently licensed, checking that the fork lift is in good working order and/or

barricading the area where the fork lift is being used so as to avoid an excess of

pedestrian traffic.

Hazard assessed: Leads lying around on stage (alphabetical code)

To accurately assess this hazard and its potential associated risks consideration has

been given to:

the layout of the stage area

the number of people on stage at any one time

the number and type of leads of leads (voltage, coverings)

experience of the stage crew and artists

regulatory and operational requirements of electrical leads.

Consequences

Severe Major Medium Minor Negligible

Likelihood

(1) (2) (3) (4) (5)

Almost certain

E H H M M

(A)

Likely

H H M M L

(B)

Possible

H M M L L

(C)

Unlikely

M M L L T

(D)

Rare

M L L T T

(E)

Risk rating = M

Moderate risk — Action plan is required by Area/Department Manager.

7

�Acting on the risk rating

In this example the risk rating priority of M requires an action plan to be developed

prior to stage preparation being carried out to either eliminate or reduce the risk of

tripping and falling.

Hazard assessed: Heat exhaustion (numerical code)

To accurately assess this hazard and its potential associated risks consideration has

been given to:

the supply of and access to shaded areas

the number of people working in the outdoors or in a high heat areas

the number and type of cooling facilities provided

the length of shifts for workers and length of exposure to heat

type of clothing provided for workers

the type of work undertaken.

How likely is it to be that bad?

++ Very likely + Likely = Unlikely – Very unlikely

How severely

could it hurt could happen could happen could happen may happen but

someone or anytime at some time but very rarely probably wont

how ill could it

make someone?

Kill or cause

permanent 1 1 2 3

disability or ill

health

Long term

illness or 1 2 3 4

serious injury

Medical

attention and 2 3 4 5

several days off

work

First aid needed

3 4 5 6

Risk rating = 5

The hazard has a low risk of creating an incident. It requires supervisor and

employee attention in a reasonable timeframe to prevent or reduce the likelihood and

severity of an incident.

8

�Acting on the risk rating

A risk rating priority level of 5 records the hazard as a low risk of creating an incident.

It requires supervisors and employees attention in the form of monitoring work

conditions and personnel and/or their own physical state to prevent or reduce the

likelihood and severity of an incident.

Control actions would still need to be implemented when setting up the work area

such as providing sufficient shading, rotating shifts to avoid lengthy period in hot

areas etc. Also as temperatures can fluctuate continual monitoring during the event is

required.

Recording risk priority ratings

Once the risk matrix has been used to identify the risk priority rating, it must be

recorded. Once the risk rating has been assessed, control measures can be

determined.

The following event hazards have been risk assessed to demonstrate the recording

format using both formats.

Hazard Safety risk Possible outcomes Risk Risk

rating rating

People working at Falling Death

height to install rigging Climbing equipment Permanent injury

and equipment

E 1

failure

Use of fork lift with Person being hit by Death

other people in the vehicle Permanent injury

event area

E 1

Exhaust fumes from Exhaust build-up Exhaust inhalation

exhibition display, eg Crowd crush Death or Injury

cars

H 2

Boxes left in main Trip hazard Medical attention

doorway required

M 4

Wet floor from spilled Slips and falls First aid

liquid Burns if liquid is corrosive L 5

The accuracy of the risk priority ratings will depend on the workplace situation and is

only offered as guide.