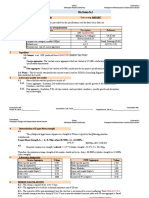

EPC PEMBANGUNAN OPEN ACCESS RU VII KASIM

QC

Proportions for Normal Concrete (ACI 211.1-91)

Method by Volume Isian Pancang

STEPS ITEM CALCULATION OR REFERENCE VALUE

1 1.1 Mix Identification 03/C31/Bula/VI/2024 Ps.Bula

1.2 Cubical Strength F'c (Mpa) 29

ACI 318-95, Table 5.3.2.2 - Required average compressive strength when

1.3 Margin 4,5 8

data are hot availeble to establish a standard deviation

1.4 Target Mean Strength (Cylinderical) F'cr (Mpa) = F'c+sd*1.645 37

1.5 Cement Conch Original Portland Cement (OPC) Type I

1.6 Aggregate Characteristics Gravel 1 Gravel 2 (Waelola) Sand (Manado)

Specific Gravity 2,65 2,65 2,52

SPGR 2,65 -

% Water Absorption 1,03% 1,02% 1,98%

Fineness Modulus 6,80 6,70 2,80

Dry Rodded Unit Weight 1402 1402 -

Average 1.402 Kg/m3 1,680 Kg/m3

2 Mess Concrete Temperature Scope Of Work 35 ⁰C

3 Target Slump 160 ± 20 mm

Table 6.3.3 - Approximate mixing water and air content requirements for

Nominal Size of Aggregate different slumps and nominal maximum sizes of aggregates 20,0 mm

Entrapped Air in non-air entrained concrete Measured in accordance with ASTM C 231, C 173, or C 138. 2,0%

†Air-content tolerance is ±1-1/2%.

Required Mixing Water 195 kg/m3

Because it uses an admixture that reduces water Water Reducing 25,0 %

consumption (Water) 48,75 kg

Admixture Type D 0,40% Dosage 0.15% - 0.5% by Weight of Cement ASTM C 494 1,80 kg/m3

Admixture Type F 1,10% Dosage 0.8% - 2% by Weight of Cement ASTM C 494 4,95 kg/m3

Mixing Water Corrected 153 kg/m3

Table 6.3.4(a) - Relationship between water - cement or water cementitious

4 Water/Cement Ratio 0,34 %

materials ratio and compressive strength of concrete

5 Cement Content 153,0 /0,35 450 kg/m3

Silica Fume - dosage 3% s/d 15% 5% ACI 234 R-96 Sheet 23 - 5.3.7 Sulfate Resistance 23 kg/m3

Cementitious 450 kg/m3

6 Quantity of Coarse Agg. Per unit vol. of concrete Table 6.3.6 - Vol.of coarse agg. per unit of vol.of concrete 0,670

* The required Dry Mass is , therefore 0,67 x 1402 939,3 kg/m3

Volume Correction faktor Dry Rooded CA 939,34 x 1 939,3 kg/m3

7 Required Fine Aggregate * With the quantity of Water, Cement & Coarse Agg established

7.1. The Sand Content can be Calculated by Absolute Volume Basis

Volume of ingredients of the concrete per cubic meter is Volume of water 153,00 x 1000 0,153 m3

calculated as follows Solid volume of cement 450,00 / 3,14 x 1000 0,143 m3

Solid volume of Fume 22,50 / 2,2 x 1000 0,010 m3

Solid volume of Admixture Type D 1,80 / 1,16 x 1000 0,002 m3

Solid volume of Admixture Type F 4,95 / 1,17 x 1000 0,004 m3

Solid volume of Coarse aggregate 939,34 / 2,7 x 1000 0,354 m3

Volume of entrapped air 0,020 x 1 0,020 m3

Total solid vol. of ingredients except fine agg. Sum = 0,687 m3

7.2. Solid volume of fine aggregate is therefore 1 - 0,687 0,313 m3

7.3. Required weight of fine aggregate 0,313 x 2,52 x 1000 789,3 Kg

8 Batch masses per cubic meter of concrete Water (net mixing) 153 Kg

Amount of Cement 450 Kg

Silica Fume 23 Kg

Admixture Type D 1,6 L

Admixture Type F 4,2 L

Combined - Particle Size - 30.5mm 0% Weight coarse aggregate(G1) - Kg

- Particle Size - 19.0mm 100% Weight coarse aggregate(G2) 939 Kg

Over Size % Comulative passing sieve 9.5mm 100% Weight fine aggregate Sand 789 Kg

% Comulative passing sieve 9.5mm 100% Weight fine aggregate Dust - Kg

Table 6.3.7.1 - First estimate of weight of fresh concrete 2360 Kg/m3

Prepared and Tested by Witnessed and Checked by Witnessed and Approved by

Date Sign Date Sign Date Sign

Name Name Name