Zhejiang Tianhong Machinery Co.

, Ltd

FAT (Factory Acceptance Test)

The FAT of the Machine is arranged at the Factory before the machine ready for

delivery to customer side.

The details of the machine, the product, and installed and tested by Engineers for

the machine.

User (Company Name) Conversant technology co.,ltd

Machine model Automatic capsule filling machine,

model NJP-1200C

Machine serial number

Dispatch date

Installation Engineer

Capsule Producer

Powder product for testing

The machine will be tested in the test room under the following condition:

1) Room Temperature: 14°C

2) Room Relative Humidity (RH): 56%

3) Capsules: For the capsules, do not add any lubricant powder.

4) Fill weight: According to powder.

Before the FAT, we will check the following of the machine.

1) The Performance of the machine is neatness, slick, cleaning.

2) Inside the machine, there is no dead corner, easy to clean.

3) The connect part with the total machine is under the

machine running requirement.

4) The power supply is meeting the machine requirement.

5) The test materials such as the powder and empty capsules

under the machine specification.

After we finish the above performance of the machine, we will check the machine

spare parts under the Sale Contract

1

� Zhejiang Tianhong Machinery Co., Ltd

The main components of the equipment of NJP-1200C

Item Specification Qty. Brand

Touch screen 6AV6/648-0CC11-3AX0 1 SIEMENS

PLC S7-200 CPUST20 1 SIEMENS

AC contactor 3TS32 10-OXMO 2 SIEMENS

Inverter speed

ATV320U15N4C 1 SCHNEIDER

controller

Thermal relay 3US5040-1G 2 SIEMENS

Button

(2)ZB2-BZ101C/ZB2-BS54C

3 SCHNEIDER

ZB2-BA5C

Transfer switch LM30-40/300010 1 GAOQIAO

Air Switch 5SN6325-7CN

2 SIEMENS

5SN6110-7CN

LED Alerter AL50E-RGM-2321 1 GAOQIAO

Power Switch LRS-100-24 1 MEANWELL

Relay

RXM2LB2BD 6 SCHNEIDER

Protection relay XJ3-G 1 CHINT

Main motor MTD37-Y1.5 1 OMT

Cam indexing box RU-100DS-10 RU-100DS-6 2 DAOJIN

Vacuum pump (water)

SK-0.5A 1 YULONG

Dust Cleaner

XLJ-220 1 TIANHONG

Linear bearing

LM10UU 80 SAMICK

Linear bearing

LM12UU 8 SAMICK

Linear bearing

LM20UU 8 SAMICK

Needle roller bearing

CF12B 5 IKO

2

� Zhejiang Tianhong Machinery Co., Ltd

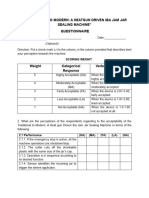

Some Main technical features of equipment according to the contract:

No Technical features Pass or Fall Remark

1 Machine model with

Fixed upper mould

2 The nozzles for supply

of compressed air at the

station for removal of

capsules

3 Ability to control the

supply of empty

capsules from the panel

display

4 Parts which contact with

product mage SS316L,

other parts of machine

are made SUS304

5 Powder hopper with

auger feeder and both

are made SUS316L; the

speed of auger feeder

can be adjusted;

6 Touch screen based on

PLC, in russian and

English

General Visual Inspection

Inspection Items Inspection Result Pass or Fall Remark

1 All kinds of technical

documents are intact

accurate

2 All of the marks are

made correctly

The connection of

3 electricity and air is the

a the diagram;

The switch for

electricity and air meet

3

� Zhejiang Tianhong Machinery Co., Ltd

requirements

PLC control, stepless The touch screen is in

4 speed adjusting with

both Chinese and

frequency conversion,

operating language on English

touch screen in English

5 Safe earthing

6 All the connections are

firm

7 All the wires are

reasonable

Inspection Items Inspection result Pass or Fall Remark

Surface board is not

Appearance distorted.

No serious nick on

the surface

Remark for the pipe

connection is correct

Transmission part can

run normally

Air pressure shows

accurately while

Running working

One button for stop

the machine while

urgency

Safety guard and

alarm system when

few material

After we have checked all the specification and technical we will test the following:

The weight of capsule with powder

Rotate Time 20

2min 5min 10min 30min Finish

speed Item min

4

� Zhejiang Tianhong Machinery Co., Ltd

Appearanc comp comp comp comp comple qualified

e lete lete lete lete te

Capsul

Average …mg …mg …mg …mg …mg qualified

e NO.

weight

0#

Filling ≤..% ≤...% ≤..% ≤...% ≤..% ≤..%

level

difference

Test Materia: _________ powder

Mesh: 200 meshes

Fluidity: Normal

Running Test Conditions

1. Vacuum: 40M3/Hr Real Pressure: 40M3/Hr

2. Power Supply: 380v 3phase Real:380v 3phase

3. Dust Collector: working fine

Final Inspection and Test Report

Inspection Items Standard Inspection Pass or fall Remark

result

Capacity Max.800 capsules/min

Material

Capsule Marking Rate 100%(empty capsule)

≥99%(full capsule)

Filling Error ≤±5%

Working temperature 18-26 degree

No.of segment bores 6

Noise ≤80db

5

� Zhejiang Tianhong Machinery Co., Ltd

Running steadily and good

smooth

Equipment appearance The surfaces of inside

and outside are smooth

with the inside surface

is finished to be Ra

≤0.8u

Extra Observation and Comment:

Date: Company:

Manufacture Factory

Product Manager:

Design Manager:

Installation Engineer:

Date: