OIL SAMPLING

FUNDAMENTALS

�Outline

• Definition & Objectives

– What is the goal of Oil Sampling?

• Sampling Tools

– What are the best tools for drawing a sample?

• Sampling Methods, Locations and Procedures

– Where is the best location for drawing a sample?

– What is the best method for effective sampling?

• Equipment Specific Sampling

– Where should a sample be pulled from a reservoir?

– Where should a sample be pulled on a circulating system?

• Sampling Frequency

– How to determine how often samples should be pulled?

2

�Oil Sampling Defined

The process of taking a portion of oil from a tank,

reservoir, or oil sump for the specific purpose of

using it for Oil Analysis. This sample should best

represent the oil working area in equipment or oil

turbulent area in a tank or reservoir.

3

�Oil Sampling – The Goal

• Maximize data density

– Samples should reflect the current status of the lubricant and the machine.

Samples should contain the most amount of representative data possible.

• Minimize data disturbance

– Data disturbance or noise in the sample can produce false positives during

testing and analysis. Following best practice for sample extraction, sample

location and the correct oil analysis test slate will help reduce or eliminate

data disturbance.

• Sample at the proper frequency

– Sampling at the proper frequency will allow us to trend the data and identify

problems associated with the lubricant or the machine not just when a limit is

breached, but when an abnormal rate of change is acknowledged.

4

�Oil Sampling – The Goal

Must Reflect: While Maintaining:

• Lubricant condition • Safe environment

• Machine condition • Sample integrity

– Method

– Tools

– Handling

5

�Garbage In = Garbage Out

(Oil Sampling) = (Oil Analysis)

• Poor planning • Poor oil analysis reports

• Poor execution • Improper corrective actions

6

�OIL SAMPLING

TOOLS

�Oil Sampling Ports

• Hydraulic sample ports are used on

smaller tanks or pipes.

• Pipe installation should be on an elbow

with flow coming toward the port.

This style of test port can be installed in a pressurized port up 5000PSI.

8

�Pitot Tube Sampling

• Sample tubes (pitot) are used for non-pressurized applications.

• Used for reaching turbulent zones of oil in larger reservoirs.

• Complete assembly consists of a sample port, sampling tube

and an optional swivel.

• Various lengths and thread configurations to meet the

application needs

• Available in fixed or universal configurations

• Stainless Steel options.

9

�Level Gauge & Pitot Tube Sampling

• Providing multiple solutions in

one port.

• Existing level gauge is removed

and replaced with a modified

sampling unit.

10

�Vacuum Pump

• A vacuum pump is used to extract sample from

non-pressurized and drum sampling. Care must

be taken to ensure that the internals of the

pump are kept in good condition and not

contaminated with oil, dirt, water, etc.

11

�Sample Port Adapter

• Sample port adapters are use to open

the ball valve in the sample ports

allowing fluid to flow through.

• Black caps indicate high flow valves.

12

�OIL SAMPLING

METHODS

�Improper Oil Reservoir Sampling

• Are there safety issues with this type of method?

• Are there concerns with contamination ingression

during sampling?

• Is the sample consistent each time it is taken?

14

�Drain Sampling

Method Pros Cons

Drain Sampling • Inexpensive • Accessibility issues

• No installation required • Risky when sampling

during operation

• Suitable for testing

homogenous properties • Tough to get

representative sample

• Requires significant

flushing

15

�Drop Tube Sampling

Method Pros Cons

Drop Tube • Cost effective • Exposes open system to

Sampling environment

• Difficult to ensure

consistent location

• Risk of tube getting caught

in system while sampling

16

�Sampling Port / Pitot Tube Sampling

Method Pros Cons

Drop Tube Sampling • Cost effective • Exposes open system to environment

• Difficult to ensure consistent location

• Risk of tube getting caught in system while sampling

17

� OIL SAMPLING

PORT / PITOT TUBE

INSTALLATION

METHODS

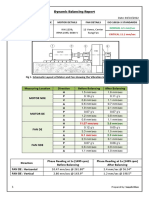

�Circulating Systems Installation

After Component,

Before Return Line

After Pump

Return Before Filter,

Line End After Filter

• Installation of forced lubrication system require the sample

port installed after the component.

• Direction of the path of flow must be known along with

installation of the sample port in a turbulent area.

19

�Hydraulic Method

Pressurized Filtration System

From Filter

Housing

Hose / Tubing from Filter Housing

• Hose or tubing from the fluid flow exit of the filter housing is removed

and replaced by a hydraulic tee and appropriate hardware.

• Sample port is installed so that the flow of the fluid is directed at the

Sample port.

– This creates a turbulent zone for samplings and removes the opportunity

of particle fly-by which is common in laminar flow installations.

20

�Hydraulic Method

Standard Operating Procedure –

Pressurized System

21

�Hydraulic Method

Pressurized Gauge Installation Method

From Gauge Port

Replace Gauge or Sensing Line Connection

• Hose, tubing or the pressure gauge from the main system pressure port

is removed and replaced by a hydraulic tee and appropriate hardware.

• Sample port is installed so that the flow of the fluid is directed at the

Sample port.

– This creates a turbulent zone for sampling and removes the opportunity of particle

fly-by which is common in laminar flow installations.

22

�Hydraulic Method

Pressurized Cooler Installation

• Remove cooler pressure

port plug (if equipped) Fluid Flow Cooler

and replace with the

appropriate size of

hydraulic sample port.

23

�Hydraulic Reservoir Installation

• Installation in a hydraulic reservoir require the

pitot tube to be installed at approximately ½ the

height of the liquid level in a turbulent area.

Watch for baffles internally.

24

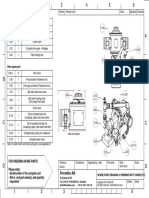

�Gearbox Housing Installation

Using an Alternate or Second Drain Port

Reducer Bushing (if required)

Drain hole size to 1/4 NPT

• Standard sample tube assembly

– Use universal sample port if a substantial bend is required.

25

�Gearbox Housing Installation

Installation of the Pitot Tube

• These units are field fit to ensure

the tube end is off the bottom of

the reservoir and in an area where

oil is circulating.

• Caution is required to ensure tube

assembly does not interfere with

internal gearing.

26

�Standard Operating Procedure –

Non-Pressurized System

27

�Gearbox Housing Installation I

Maintaining a Drain Port

Standard Nipple

Standard Black, Hydraulic

Standard Drain Plug or Stainless Tee

• This method does not require the pitot tube to be removed to

drain the lubricant.

28

�Gearbox Housing Installation II

Sampling Gearboxes

with a Gearbox Kit

29

�Pump Housing Method

Drain Plug

• Ensure pitot tube end is located

off the bottom of the housing but

no higher than ½ the level of the

fluid during operation.

30

�Standard Operating Procedure –

Bearing Housings without

Sampling Devices

31

�55 Gallon Drum Kit

Sampling Stored Oil

32

�Standard Operating Procedure –

55 Gallon Tank

33

�Summary – Sampling Methods

Best Practices Not So Good Practices

• Ensure machines are running and at • Sampling systems that are not running or not

operating temperature. at typical operating temperatures.

• Sample in turbulent area that are • Sampling from drain port.

representative of critical load zones.

• Sampling with a drop-tube.

• Install permanently mounted hardware for

consistent sampling Ex. Pitot Tubes, test • Inconsistent sampling points and methods.

ports, etc. • Sampling shortly after oil changes.

• Flushed sampling valves and sampling • Using tubing more than once causing cross

hardware. contamination of oil.

• Keep the bottles clean. • Sampling without adequate flushing.

• Sampled at proper frequency. • Waiting too long before sending samples to

• Samples forwarded to lab immediately. the lab.

• Follow safety procedures.

34

�Frequency Factors

Frequency depends on many factors but one of the

most important is to base the frequency on the

equipment criticality from an RCM or similar analysis.

• Environmental Severity • Economic Penalty of Failure

– High dust and moisture – Safety risk

– High loads, pressures and speeds – Downtime cost

– High running temperature – Repair cost

– Duty cycle, shocks, or vibration – Mission criticality

– Chemical or radiation contamination

35

�The Roadmap to Success

Oil Sampling

Representative

Sample Location

Oil Analysis

Correct Use of Proper Sample

Sampling Accessories Preparation

Oil Sampling SOP Calibrated Lab Proper Testing

Instruments Methods

Oil Sample

Oil Sample Extraction Certified Lab

Sent to Lab

Techs

36

�Need Help?

• Choosing hardware

• Installation

• Training

Talk to Trico – the team behind Lubricology