Title: Assembly Line 3 Downtime reduction

A3 - Structured Problem Solving

ID: Sponsor: PM:

Project Team: S Johnson, M Williams, E, Smith, J Brown, L Miller Start Date: 10/29/2023 Last Updated: 11/14/2024

A. Describe Problem / Issue C. Solve Problem / Issue

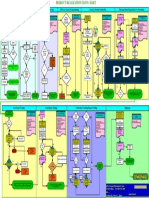

1. Problem Description / Current Condition / Containment Actions 5. Corrective Action

3. Key-Questions Is Is Not

Over the past three months, machine downtime on Automotive Assembly

Line No.3 has increased by 30%. This has predominantly affected the What Increased Affecting all

assembly line workers and leads, leading to production delays and higher What is the machine machinery on

labor costs. problem/defect? downtime by 30% the floor

Current Condition:

Average downtime is currently 90 minutes per day per machine, causing a

delay in the production of approximately 40 cars per day. Where? Automotive Present in

Containment Actions:

assembly line assembly

Temporary overtime shifts have been added to meet production goals,

Where is the No.3 lines No.1 and

leading to an increase in labor costs. problem? No.2

2. Goal Statement / Target Condition When? Over the past 3 An issue that

months has been

Our goal is to achieve at least a 20% reduction in machine downtime on Automotive

Assembly Line No.3, lowering it from 90 minutes to no more than 72 minutes per day consistent

When is the problem

per machine, within the next 60 days. This will be accomplished through the observed over the

implementation of a weekly preventive maintenance schedule and upgrading critical years

machine components. This reduction is crucial for increasing productivity and reducing How? Through Through

labor costs, aligning with our overall business objectives.

interruptions in supply chain

the assembly or external

How is it a problem?

process factors

Who? Affects assembly Affecting

line workers and administrative

leads staff

Who is involved?

B. Find Root Cause of Problem / Issue D. Validate Solution and Standardize

4. Technical & Systemic Root Cause 6. Effect Confirmation

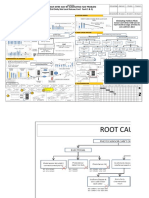

5 Whys Analysis for Lack of Assembly Line 3 Downtime (minutes)

Preventive Maintenance

1. Why are machines not serviced 90

regularly? 85

There is no established schedule for 80

preventive maintenance.

2. Why is there no established schedule 75

for preventive maintenance? 70

Management has not prioritized creating 65

a preventive maintenance plan. 60

3. Why has management not prioritized

creating a preventive maintenance plan? 55

They are under the impression that it 50

would be too costly and time-consuming. 45

4. Why do they think it would be too 40

costly and time-consuming? 0 0 0 0 0 0

There is a lack of data showing the long- 10 15 20 25 30 35

45 45 45 45 45 45

term benefits and cost-savings of

preventive maintenance. 7. Read Across / Preventive Action / Lessons Learned

5. Why is there a lack of data showing

the long-term benefits and cost-savings Lessons Learned:

of preventive maintenance? Cost of Inaction: Neglecting regular maintenance can lead to more significant downtimes and, in turn, higher costs in terms of production losses and emergency

The organization has not invested in repairs.

tracking this kind of data, focusing Training is Crucial: Ensuring that the maintenance team is well-trained and updated with the latest best practices is essential for machine longevity and optimal

performance.

instead on immediate, short-term gains. Data-Driven Decision Making: Using data to analyze the problem helped in understanding the gravity of the situation and drove the decision-making process.

Continuous monitoring post-implementation helped validate the effectiveness of the solutions.

Importance of Early Detection: By identifying and addressing potential issues early on, many machine-related problems can be nipped in the bud, preventing

larger, more costly issues down the line.

Stakeholder Buy-in: Securing management's buy-in was essential for the success of the preventive maintenance plan. Their support was crucial in terms of

resources, approvals, and company-wide implementation.

Continuous Improvement: Even after implementing solutions, the need for continuous review and improvement is paramount. What works today might need

adjustments tomorrow based on evolving business needs and challenges.

Learnleansigma.com

� Title:

A3 - Structured Problem Solving

ID: Sponsor: PM:

Project Team: Start Date: Last Updated: 11/14/2024

A. Describe Problem / Issue C. Solve Problem / Issue

1. Problem Description / Current Condition / Containment Act 5. Corrective Action

3. Key-Questions Is Is Not

What

What is the

problem/defect?

Where?

Where is the

problem?

2. Goal Statement / Target Condition When?

When is the problem

observed

How Big?

How many objects

have the problem?

Who?

Who is involved?

B. Find Root Cause of Problem / Issue D. Validate Solution and Standardize

4. Technical & Systemic Root Cause 6. Effect Confirmation

7. Read Across / Preventive Action / Lessons Learned

Learnleansigma.com