Fault Code 135: Primary Shift

Device (J1939)

J1939: SA 3 SPN 751 FMI 2, 9, 11, 12, 13, 14, 19

Overview

The Transmission Control Module (TCM) receives a

primary shift mode request messages from the

OEM Driver Interface Device over the Primary Data

Link. The TCM also receives a secondary shift

mode request signal from the OEM Driver Interface

Device over a separate circuit. The secondary shift

mode request allows a driver to engage the

transmission into gear in the event the primary shift

mode request message is not available. The

primary and secondary shift mode requests are

contained within the 20-Way TCM Vehicle Harness.

Note: Freightliner chassis (OEM Supplied Driver

Interface Device) does not have a secondary shift

device and must be configured (ACN 19) to J1939

CAN Device (w/o secondary).

Detection

The TCM monitors the Primary shift mode request

message. If an invalid message is received, the

TCM sets the fault code active.

Conditions to Set Fault Code Active

FMI 2 – Data Erratic: Primary shift mode request

message out of range for 5 seconds.

FMI 9 – Abnormal Update Rate: Primary shift mode

request message not received for 5 seconds.

FMI 11 – Root Cause Unknown: Primary and

Secondary shift mode requests do not match.

FMI 12 – Bad Intelligent Device: Shift mode request

into a gear that is in the opposite direction of

vehicle travel at a speed greater than allowable

shuttle shifting speed (Service).

FMI 13 – Out Of Calibration: Primary shift mode

message not available.

FMI 14 – Special Instructions: Shift mode request

into a gear from Neutral received but delayed

acceptance of mode request (Service).

FMI 19 – Received Network Data In Error: Primary

shift mode request message received but in error

for 5 seconds.

Fallback

FMI 2, 9, 11, 19:

Amber warning lamp on

Manual shifting not available

If fault codes 135 and 145 are active:

- Engine may not crank

- Transmission stays in current gear

- PTO mode prohibited

- Hill Start Aid prohibited

If the vehicle is moving and the transmission

is configured:

- Red stop lamp on

FMI 12:

Transmission stays in current gear

FMI 13:

Amber warning lamp on

Engine cranking prohibited

FMI 14:

Non neutral modes prohibited

PTO mode prohibited

Conditions to Set Fault Code Inactive

FMI 2: Primary shift mode request message in

range for 10 seconds.

FMI 9: Primary shift mode request message

received for 10 second.

FMI 11: Primary and Secondary shift mode requests

match for 10 seconds.

FMI 12: Key cycle.

FMI 13: Driver Interface Type properly configured

or condition no longer exists.

FMI 14: Neutral mode re-selected and achieved.

FMI 19: Primary shift mode request message valid

for 10 seconds.

Possible Causes

FMI 2, 9, 19:

Vehicle Wiring (power supply and J1939 Data

Link)

- Wires shorted to ground, shorted to

power or open

- Terminals bent, spread, corroded or

loose

Driver Interface Device

- Internal Failure

FMI 11:

Vehicle Wiring (power supply, J1939 Data

Link and secondary shift mode request)

- Wires shorted to ground, shorted to

power or open

- Terminals bent, spread, corroded or

loose

Driver Interface Device

- Internal Failure

FMI 12, 14:

TCM

- Software issue

- Internal failure

FMI 13:

TCM

- Driver Interface Device not configured

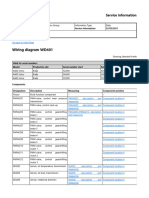

Component Identification

1. 20-Way TCM Vehicle Harness Connector

2. Transmission Control Module (TCM)

3. 9-Way Driver Interface Device Connector

4. 9-Way Type 2 Diagnostic Connector (In Cab)

1. Transmission Control Module (TCM)

2. 20-Way TCM Vehicle Harness Connector

3. 9-Way Driver Interface Device Connector

4A. 9-Way Type 2 Diagnostic Connector (OEM-Specific

Primary Data Link FG)

4B. 9-Way Type 2 Diagnostic Connector (OEM-Specific

Primary Data Link CD)

Fault Code 135

Troubleshooting

Purpose: Check for Active or

A Inactive fault codes.

1. Set vehicle parking brake and chock wheels.

2. Record the transmission fault codes, FMIs,

occurrences, and timestamps from the Service

Activity Report created during the Diagnostic

Procedure.

If Fault Code 135 is Inactive and

there are other Active vehicle or

transmission fault codes,

troubleshoot all Active fault codes.

Go to Step V

If Fault Code 135 FMI 2, 9, or 19 is

Active or Inactive, Go to Step B

If Fault Code 135 FMI 11 is Active

or Inactive, Go to Step E

If Fault Code 135 FMI 12 or 14 is

Active or Inactive, contact Eaton

Cummins Automated

Transmission Technologies at +1-

800-826-4357 for further

diagnostic instructions. Go to Step

V

If Fault Code 135 FMI 13 is Active,

configure Driver Interface Device

using ServiceRanger. Test

complete.

If Fault Code 135 FMI 13 is

Inactive, Driver Interface Device is

configured. Test complete.

Purpose: Verify power and

ground supply at the 9-Way

B Driver Interface Device

Connector.

1. Key off.

2. Disconnect the 9-Way Driver Interface Device

Connector.

3. Inspect the 9-Way Driver Interface Device

Connector, verify the connector is free from

contamination and corrosion; the terminals are

not bent, spread or loose; and there is no

damage to the connector body.

4. Key on.

5. Measure voltage between 9-Way Driver

Interface Connector Pin 1 (TCM supplied 12v)

and Pin 2 (TCM supplied ground). Record

reading in table.

Note: Refer to OEM wiring diagrams.

6. Compare reading(s) in table.

If readings are in range, Go to

Step C

If readings are out of range, refer

to OEM guidelines for repair or

replacement of the Driver

Interface Device power supply

circuits between the 9-Way Driver

Interface Device Connector and

20-Way TCM Vehicle Harness

Connector. Go to Step V

Pins Range Reading(s)

1 to 2 11–13 V

Purpose: Verify voltage of

the J1939 Data Link at the 9-

C Way Driver Interface Device

Connector.

1. Key on.

2. Measure voltage between 9-Way Driver

Interface Device Connector Pin 7 (J1939 Data

Link High) and 9-Way Diagnostic Connector

Pin A (ground). Record reading in table.

Note: Refer to OEM wiring diagrams.

3. Measure voltage between 9-Way Driver

Interface Device Connector Pin 8 (J1939 Data

Link Low) and 9-Way Diagnostic Connector Pin

A (ground). Record reading in table.

4. Compare reading(s) in table.

If readings are in range, Go to

Step D

If readings are out of range, refer

to OEM guidelines for repair or

replacement of vehicle J1939

Data Link. Go to Step V

Pins Range Reading(s)

7 to A 2.25–2.75 V

8 to A 2.25–2.75 V

Purpose: Verify fault code

D status.

1. Key off.

2. Reconnect all connectors and verify that all

components are properly installed.

3. Key on.

4. Connect ServiceRanger.

5. Retrieve and record the fault codes, FMIs,

occurrences and timestamps.

If Fault Code 135 is Active, refer to

OEM guidelines for repair or

replacement of the Driver

Interface Device. Go to Step V

If Fault Code 135 is Inactive, no

problem was found. The

intermittent nature of the fault

makes it likely that the problem is

with the:

- Driver Interface Device

- J1939 Data link wiring to the

Driver Interface Device

- Power and ground supply

wiring to the Driver Interface

Device from the 20-Way

TCM Vehicle Harness

Connector

- Refer to OEM for further

diagnostic instructions.

Purpose: Verify power and

ground supply at the 9-Way

E Driver Interface Device

Connector.

1. Key off.

2. Disconnect the 9-Way Driver Interface Device

Connector.

3. Inspect the 9-Way Driver Interface Device

Connector, verify the connector is free from

contamination and corrosion; the terminals are

not bent, spread or loose; and there is no

damage to the connector body.

4. Key on.

5. Measure voltage between 9-Way Driver

Interface Device Connector Pin 1 (TCM

supplied 12v) and Pin 2 (TCM supplied

ground). Record reading in table.

Note: Refer to OEM wiring diagrams.

6. Compare reading(s) in table.

If readings are in range, Go to

Step F

If readings are out of range, refer

to OEM guidelines for repair or

replacement of the Driver

Interface Device power supply

circuits between the 9-Way Driver

Interface Device Connector and

20-Way TCM Vehicle Harness

Connector. Go to Step V

Pins Range Reading(s)

1 to 2 11–13 V

Purpose: Verify continuity of

the secondary shift mode

F request circuit and not

shorted to ground.

1. Key off.

2. Disconnect 20-Way TCM Vehicle Harness

Connector.

3. Inspect the 20-Way TCM Vehicle Harness

Connector, verify the connector is free from

contamination and corrosion; the terminals are

not bent, spread or loose; and there is no

damage to the connector body.

4. Measure resistance between the 9-Way Driver

Interface Device Connector Pin 4 and 20-Way

TCM Vehicle Harness Connector Pin 9. Record

reading in table.

Note: Refer to OEM wiring diagrams.

5. Measure resistance between the 9-Way Driver

Interface Device Connector Pin 4 and Ground.

Record reading in table.

6. Compare reading(s) in table.

If readings are in range, Go to

Step G

If readings are out of range, refer

to OEM guidelines for repair or

replacement of the secondary

shift mode request circuit

between the 9-Way Driver

Interface Device Connector and

the 20-Way TCM Vehicle Harness

Connector. Go to Step V

Pins Range Reading(s)

4 to 9 0.0 –0.3 Ohms

4 to Ground Open Circuit (OL)

Purpose: Verify fault code

G status.

1. Key off.

2. Reconnect all connectors and verify that all

components are properly installed.

3. Key on.

4. Connect ServiceRanger.

5. Retrieve and record the fault codes, FMIs,

occurrences and timestamps.

If Fault Code 135 is Active, refer to

OEM guidelines for repair or

replacement of the Driver

Interface Device. Go to Step V

If Fault Code 135 is Inactive, no

problem was found. The

intermittent nature of the fault

makes it likely that the problem is

with the:

- Driver Interface Device

- Secondary shift mode

request circuit between the

Driver Interface Device and

20-Way TCM Vehicle

Harness Connector.

- J1939 Data link wiring to the

Driver Interface Device

- Power and ground supply

wiring to the Driver Interface

Device from the 20-Way

TCM Vehicle Harness

Connector

- Contact OEM for further

diagnostic instructions.

V Purpose: Verify repair.

1. Key off.

2. Reconnect all connectors and verify that all

components are properly installed.

3. Key on with engine off.

4. Connect ServiceRanger.

5. Go to “Fault Codes”.

6. Select “Clear All Faults”.

7. Operate vehicle and attempt to reset the fault

code or duplicate the previous complaint.

8. Check for fault codes using ServiceRanger.

If no fault codes set and the

vehicle operates properly, test

complete.

If Fault Code 135 sets Active

during test drive, Go to Step A

If a fault code other than 135 sets

Active, troubleshoot per the Fault

Code Isolation Procedure Index.