Manual Cleaning Process

Uploaded by

infoManual Cleaning Process

Uploaded by

info⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯

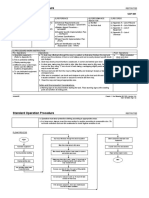

Standard Operating Procedure for Manual Cleaning Processes

Manual Cleaning Processes SOP

This page intentionally left blank

Rev 0.1 January 5, 2024 ii

Manual Cleaning Processes SOP

UNIVERSITY OF NEW MEXICO

Casey Hall Victor Tovar

Director of Environmental Health & Safety Manager of Custodial Services

Matt McKernan

Matt McKernan (Jan 10, 2024 14:13 MST) James Todd (Jan 10, 2024 11:34 MST)

Matthew McKernan Jim Todd

Manager of Sports Facilities Director of Recreational Services

Dee Goines

Dee Goines (Jan 10, 2024 15:32 MST)

Dee Goines Dennis-Ray Armijo

Manager, Residence Life & Student Housing Assoc. Director Business Operations, SUB

Rev 0.1 January 5, 2024 iii

Manual Cleaning Processes SOP

DOCUMENT REVISION LOG

Rev. No. Effective Date Revision Description Pages Replaced Completed by:

0 7/6/2023 Initial implementation of SOP N/A

0.1 1/5/2024 Updated title for Dennis-Ray Armijo on signature N/A ZP

page.

Rev 0.1 January 5, 2024 iv

Manual Cleaning Processes SOP

UNM’S COMMITMENT TO SAFETY

Safety is a core value of the University of New Mexico. UNM is committed to creating and fostering a

culture of safety within the community. To learn more visit https://ehs.unm.edu/culture-of-safety.html.

ACRONYMS & DEFINITIONS

EHS Environmental Health and Safety

Dilute Make liquid thinner or weaker by adding water.

Floor buffer A piece of industrial cleaning equipment that allows cleaning professionals

to strip or remove the wax from a facilities floor.

Musculoskeletal Injury An injury that affects the bones, muscles, ligaments, nerves, or tendons

resulting in pain.

Overshoes A kind of shoe or boot of rubber or fabric, worn over the regular shoe to

protect against cold or dampness.

Microfiber cloth A synthetic fabric consisting of ultra-fine fibers.

PPE Personal Protective Equipment

SDS Safety Data Sheets

SOP Standard Operating Procedure

Rev 0.1 January 5, 2024 v

Manual Cleaning Processes SOP

TABLE OF CONTENTS

1. Introduction .......................................................................................................................................... 1

2. Scope ..................................................................................................................................................... 1

3. Roles & Responsibilities ........................................................................................................................ 1

3.1. Supervisors .................................................................................................................................... 1

3.2. Environmental Health & Safety .................................................................................................... 1

3.3. Employees ..................................................................................................................................... 1

4. Training Requirements.......................................................................................................................... 1

5. Records.................................................................................................................................................. 2

6. Cleaning Tasks ....................................................................................................................................... 2

6.1. Vacuuming .................................................................................................................................... 2

6.1.1. Applicable Equipment: .......................................................................................................... 2

6.1.2. Potential hazards when vacuuming: ..................................................................................... 2

6.1.3. Required PPE: ........................................................................................................................ 2

6.1.4. Recommended PPE ............................................................................................................... 2

6.1.5. Check equipment daily.......................................................................................................... 2

6.1.6. Check equipment weekly ...................................................................................................... 3

6.1.7. Backpack vacuum: ................................................................................................................. 3

6.1.8. Wet-Dry Shop Vacuum:......................................................................................................... 3

6.1.9. Proper ergonomics for a backpack vacuum:......................................................................... 3

6.1.10. Proper ergonomics for an upright and Wet-Dry Shop Vacuum:........................................... 3

6.2. Restroom Cleaning ........................................................................................................................ 4

6.2.1. Applicable Equipment: .......................................................................................................... 4

6.2.2. Potential hazards when cleaning restrooms......................................................................... 4

6.2.3. Required PPE ......................................................................................................................... 5

6.2.4. Recommended PPE ............................................................................................................... 5

6.2.5. Ergonomic Considerations .................................................................................................... 5

6.2.6. Chemical Safety ..................................................................................................................... 5

6.2.7. Restroom Cleaning Checklist................................................................................................. 6

6.3. Mopping and Other Floor Cleaning............................................................................................... 6

6.3.1. Equipment: ............................................................................................................................ 6

6.3.2. Potential hazards when mopping: ........................................................................................ 6

Rev 0.1 January 5, 2024 vi

Manual Cleaning Processes SOP

6.3.3. Required PPE: ........................................................................................................................ 6

6.3.4. Recommended PPE: .............................................................................................................. 6

6.3.5. Proper ergonomics when mopping: ..................................................................................... 6

6.3.6. Applying floor finish using a mop.......................................................................................... 7

6.3.7. Applying floor finish Using an Applicator with a Reservoir on the Handle ........................... 7

6.3.8. Procedure for automatic scrubbers and Strippers: .............................................................. 7

6.3.9. Buffer: ................................................................................................................................... 8

6.4. Sweeping ....................................................................................................................................... 8

6.4.1. Equipment: ............................................................................................................................ 8

6.4.2. Potential hazards when sweeping: ....................................................................................... 8

6.4.3. Required PPE: ........................................................................................................................ 8

6.4.4. Recommended PPE: .............................................................................................................. 9

6.4.5. Proper ergonomics when sweeping: .................................................................................... 9

6.4.6. Sweeping procedure: ............................................................................................................ 9

6.5. Lifting or Moving Furniture ......................................................................................................... 10

6.5.1. Equipment: .......................................................................................................................... 10

6.5.2. Potential hazards when lifting or moving furniture:........................................................... 10

6.5.3. Required PPE: ...................................................................................................................... 10

6.5.4. Proper ergonomics for lifting or moving furniture: ............................................................ 10

6.5.5. Lifting Procedure: ................................................................................................................ 10

6.6. Trash Disposal ............................................................................................................................. 10

6.6.1. Equipment: .......................................................................................................................... 10

6.6.2. Potential hazards when disposing trash: ............................................................................ 11

6.6.3. Recommended PPE: ............................................................................................................ 11

6.6.4. Proper ergonomics when disposing trash: ......................................................................... 11

6.6.5. Disposing trash procedure: ................................................................................................. 11

6.7. Dusting ........................................................................................................................................ 11

6.7.1. Equipment: .......................................................................................................................... 11

6.7.2. Potential hazards when dusting:......................................................................................... 11

6.7.3. Required PPE: ...................................................................................................................... 11

6.7.4. Recommended PPE: ............................................................................................................ 11

6.7.5. Proper ergonomics when dusting: ...................................................................................... 11

6.7.6. Procedure: ........................................................................................................................... 12

Rev 0.1 January 5, 2024 vii

Manual Cleaning Processes SOP

7. Equipment Maintenance .................................................................................................................... 12

8. Diluting Chemicals............................................................................................................................... 12

8.1. Potential hazards when diluting chemicals: ............................................................................... 12

8.2. Safety controls when diluting chemicals: ................................................................................... 13

Rev 0.1 January 5, 2024 viii

Manual Cleaning Processes SOP

1. INTRODUCTION

With over eight million square feet of building space to clean, and just under 2,500 bathrooms, the

custodial staff perform a critical function in providing clean and healthy facilities for our students, staff,

faculty and guests. The Manual Cleaning SOP will outline how to properly conduct the many cleaning

tasks performed by the custodial staff.

2. SCOPE

This program applies to all UNM employees that perform custodial and cleanup functions.

3. ROLES & RESPONSIBILITIES

3.1. Supervisors

• Implement and enforce this program.

• Instruct their employees to the content of this program.

• Ensure that formal training is provided as required by this program.

3.2. Environmental Health & Safety

• Implement and maintain this program.

• Provide PPE training.

• Provide Ergonomic training.

3.3. Employees

• Adhere to the requirements and restrictions set forth by this program.

• All stakeholders have the right to stop work if an unsafe condition arises within the work

environment.

4. TRAINING REQUIREMENTS

Training should include:

• Hands-on performance of job tasks and related activities

• Proper equipment use.

• Maintenance and storage

• Safety procedures

• Proper use of personal protective equipment (PPE) as required

• Instruction in proper body mechanics

• Verbal, written and illustrative materials.

Training should be provided to all employees in their dominant language. Translators should be utilized

when necessary.

Rev 0.1 January 5, 2024 1

Manual Cleaning Processes SOP

5. RECORDS

All written programs should be easily available.

Training records shall be maintained for the duration of employment.

6. CLEANING TASKS

The following section will detail cleaning tasks performed by the Custodial Team. Each task will be

described with equipment required and proper use listed, as well as potential hazards, safety

considerations, and PPE for each cleaning task.

6.1. Vacuuming

Vacuums are used by virtually every cleaning facility, so it is necessary to utilize the right equipment

with the correct ergonomic technique. Because of the many moving parts and constant current of

electricity associated with machinery, it is important to exercise extra care.

6.1.1. Applicable Equipment:

• Backpack vacuum

• Upright vacuum

• Wet-Dry Shop Vacuum

6.1.2. Potential hazards when vacuuming:

• Electrical Shock

• Muscular Skeletal Injury

• High Noise Levels

• Inhalation of fine dust particle

6.1.3. Required PPE:

• Overshoes (when vacuuming liquids)

• Reinforced toe, non-slip shoes

6.1.4. Recommended PPE

• Hearing Protection (Ear plugs, Canal Caps, or Earmuffs)

• Coated fabric gloves

• Dust mask

• Safety Glasses

6.1.5. Check equipment daily

• Paper filter: Check and shake out every two hours. Replace as needed due to wear and tear.

• Cloth filter: Check and shake out every two hours. Replace as needed.

• Cord: Check the cord before each use for damage. If damage is found, tag and lockout the

equipment, and notify your supervisor. Do not use equipment with damaged cords

• Check the cord before each use for damage. Replace it if needed.

Rev 0.1 January 5, 2024 2

Manual Cleaning Processes SOP

• Plug: Check before each use for damage. Do not use until replace damage is found, tag and

lockout the equipment, and notify your supervisor. Do not use equipment with a damaged plug.

• Storage: Store equipment in a designated area.

6.1.6. Check equipment weekly

• Dome Filter: Rinse and dry out. Return to proper location on the vacuum.

• Foam filter: Rinse and dry out. Return to proper location on the vacuum.

• NOTE: Always verify outlet is in proper working condition prior to plugging a cord into it.

6.1.7. Backpack vacuum:

• Ensure the harness fits properly by loosening the straps, then fastening and tightening the waist

belt. The weight of the vacuum should rest on the hips, allowing the legs to carry the weight of

the unit, not the back.

• Adjust and tighten the shoulder straps so the unit sits close to the body, but not to the point of

shifting the weight to the shoulders.

• Adjust the sternum strap for a snug fit as your last step before starting to vacuum.

6.1.8. Wet-Dry Shop Vacuum:

• When responding to flooded spaces, follow FM Procedure 5080: Entering a Flooded Space

• Wear overshoes when using a Wet-Dry Shop vacuum to pick up liquids.

• Keep intake connection clean and lightly lubricated to eliminate sticking.

• When using two bladed wet pick-up tools, tilt it slightly one way in a forward motion and slightly

the opposite way in backward motion. This prevents the blades from sticking to the floor. (This

procedure is not necessary with the single-bladed tool).

• Be careful not to overflow the tank.

• Empty the wet-dry vacuum immediately after use. Rinse inside and clean with all-purpose

cleaner.

• Keep accessories clean and dry.

6.1.9. Proper ergonomics for a backpack vacuum:

• The padded waist belt should fasten snugly around the hips, allowing shoulder straps to fit

comfortably but loosely. The primary weight of the unit should rest on the hips, not the

shoulders, since shoulder straps serve mainly to balance the pack and prevent load shifting.

• Use the side-to-side vacuuming technique.

• Backpack users should never have to bend their back for any reason, and the upper torso should

be kept erect with very little twisting or sudden sharp movements while operating the vacuum.

• When you need to bend over, remember to bend with your knees and use the support of your

legs, not your back

6.1.10. Proper ergonomics for an upright and Wet-Dry Shop Vacuum:

• Mind your posture. Line up your body with the path of the vacuum. Do not twist your back.

Minimize hunching over, use your legs as often as possible.

Rev 0.1 January 5, 2024 3

Manual Cleaning Processes SOP

• Be mindful of over-extending your reach. Keep the wand close to the body. The further you

move the wand from the body, the more likely your arms will become fatigued.

• Alternate vacuuming between two hands. Switching between hands helps aid in the resting of

frequently used muscles and body parts without losing productivity time.

6.2. Restroom Cleaning

6.2.1. Applicable Equipment:

Restroom Cart: The restroom cart is a useful tool to hold the supplies needed for building housekeeping.

The restroom cart is used to carry tools, supplies, PPE, and action card for cleaning restrooms. Below are

the supplies that can be found for on the restroom cart:

• Wet floor sign

• Pac cutter

• Putty knife

• Wooly duster

• Note pad with pencil

• Grabber tool

• Scraper/ Razor

• Mop bucket/Mop handle

• Flat mop bucket Flat mop handle

• Sponge/pad

• Keys

• Disinfectant brush & caddy

• Johnny mop & applicator

• Microfiber cloth

• Glass cleaner

• Disinfectant

• All-purpose cleaner

• Floor cleaner

Color of Microfiber Cloth Use only for

Yellow Microfiber Dry Dusting

Red Microfiber Disinfectant

Blue Microfiber Glass cleaner

Green Microfiber GS extra strength all-purpose cleaner

NOTE: Never leave the restroom cart unattended. Restock the cart daily with cleaning clothes, paper

towels, toilet paper, hand soap, and trash can liners. Clean the caddy, pail, and mops in the appropriate

container for laundering at the end of the shift. Never place food or drinks on the cart. Never place

personal items on the cart.

6.2.2. Potential hazards when cleaning restrooms

• Slippery or wet floors

Rev 0.1 January 5, 2024 4

Manual Cleaning Processes SOP

• Overexertion & Fatigue: Pushing or pulling carts, especially in tight areas or when overloaded.

Bending and twisting pulling with one arm.

• Struck by: Objects, coworkers, or guests if cart obstructs your view.

• Pinch Points: Hands and fingers caught between cart and walls or doorways

• Bloodborne Pathogens Exposure (when cleaning materials that contain blood)

• Chemical splash

• Musculoskeletal Injury

• Infectious Waste

6.2.3. Required PPE

• Reinforced toe, non-slip shoes

• Rubber gloves

• Goggles / Safety Glasses

• Respirator mask (as required by chemical Safety Data Sheet (SDS))

6.2.4. Recommended PPE

• Kneepads OR a kneeling pad

6.2.5. Ergonomic Considerations

• Set up carts as instructed. Do not overload them.

• Keep your hands and fingers away from the outer edges of the cart when going through

doorways or close to walls.

• Squat or kneel to stock or remove lower items. Do not bend at the waist.

• Use a mat or towel to protect the knees when kneeling.

• Alternate between left and right hands when scrubbing.

6.2.6. Chemical Safety

• Always read the instructions and the safety data sheets for each product.

• Ensure that SDS are accessible, and employees are aware of the location. Periodically review

your SDS sheets to ensure that they are current and reference chemicals that are currently in

use.

• Know what you are using. Do not use chemicals from unmarked bottles or containers.

• Measure all chemicals. If the directions say to use two (2) ounces in one (1) gallon of water,

measure the water and the chemical correctly. A weak solution may not provide the proper

cleaning power. A solution that is too strong will not only waste supplies but will damage the

surface on which you use it. It may also have the potential to cause injury to yourself or others.

• Do not smell chemicals as a means of identification.

• Always secure bottle caps and lids before the container leaves your hands.

• Always use proper ventilation.

• Do not bring chemicals from home.

• Do not mix chemicals in an area where food is consumed.

Rev 0.1 January 5, 2024 5

Manual Cleaning Processes SOP

6.2.7. Restroom Cleaning Checklist

• Empty waste receptacles and change liners.

• Restock dispensers: soap, paper towel, toilet tissue and sanitary napkins.

• Thoroughly scrub and disinfect toilets and urinals.

• Flush toilets and urinals.

• Spray disinfectant and wipe sinks, mirrors, doors, and dispensers starting from the top working

your way down.

• Dust mop and wet mop floors with disinfectant solution.

• If hard water deposits exist, see supervisor for controlled cleaning solutions.

6.3. Mopping and Other Floor Cleaning

Mopping is an important task performed by custodians. UNM has many different surfaces and using the

right mop can make the floor last longer.

6.3.1. Equipment:

• Wet Mop

• Mop bucket

• Wet floor sign

• Flat mop

• Finish applicator

• Automatic Scrubber (battery operated; Electric cable operated)

• Buffer

• Extractor

6.3.2. Potential hazards when mopping:

• Slip, Trip, & Fall: in areas that have been mopped due to the wet surfaces.

• Fatigue

• Musculoskeletal Injuries

• Electric Shock (Scrubber)

• Struck-By (Scrubber)

6.3.3. Required PPE:

• Reinforced toe, non-slip shoes

6.3.4. Recommended PPE:

• Coated fabric gloves

6.3.5. Proper ergonomics when mopping:

• Take necessary breaks to stretch and change positions to avoid overworking certain areas

• Work backwards towards the exit to avoid walking in the wet areas

• Bend your knees and keep your back straight as you push the mop wringer down.

• Face the wringer lever

Rev 0.1 January 5, 2024 6

Manual Cleaning Processes SOP

• Use a mop bucket raised off the floor to reduce the bending force required to wring out the

water.

• While squeezing the mop, place your foot in front of the wheel to prevent the bucket from

moving.

• Use mop sink and avoid lifting filled mop bucket.

• NOTE: Floor drains can only be utilized for dumping mop bucket if no chemicals are present in

the water.

6.3.6. Applying floor finish using a mop

• Always use a wet-floor sign when applying floor finish.

• Check the floor area carefully and remove all trash and other debris.

• Apply finish solution to a small enough area so that edges will not dry before the next are

started. If the finish does dry, lap marks can be caused.

• Work quickly from one area to another to prevent lap marks caused by drying.

• Place the amount specified on the finish solution packet into the bucket????

• Immerse the mop in the bucket of finish solution and wring slightly (the mop should not be

dripping). Wring slowly to prevent foam.

• Start from the outer end of the room and fill in the area with a figure eight pattern.

• On the first coat keep 6” away from the walls. The second coat should be applied to the edge of

the floor. This procedure eliminates lap marks.

• Each coat of the finish solution should be the thickness of a sheet of waxed paper.

• Keep floor finish solution from overfilling onto the screen.

6.3.7. Applying floor finish Using an Applicator with a Reservoir on the Handle

• Fill tank with floor finish.

• Saturate applicator with finish.

• Adjust valve to allow proper amount of finish to flow onto leading edge of the applicator (no

puddles).

• Walk back in a straight line. Overlap the previous pass slightly.

• Rinse tank, hose, and applicator thoroughly.

6.3.8. Procedure for automatic scrubbers and Strippers:

• Before using the automatic scrubber, dust mop the area.

• Plan a cleaning pattern to use time and solution efficiently.

• Fill the solution tank with proper amount of water and detergent for scrubbing or stripping.

• Be sure to check that the recovery tank is empty.

• Fill batteries with distilled water before charging.

• Use either single pass or double pass method for scrubbing.

• Apply rinse with spray tank. This method saves time and always uses a clean rinsing solution. (A

mop bucket method will contaminate the rinse).

• Use clear water to rinse when scrubbing. Use a neutralizing solution to rinse when stripping.

• Pick-up rinse solution with mop or automatic machine. Use only the squeegee. Do not scrub

when picking up rinse solution.

Rev 0.1 January 5, 2024 7

Manual Cleaning Processes SOP

Single pass scrubbing method:

• Install scrubbing pad.

• Fill machine with properly diluted solution.

• Dispense solution.

• Scrub and pick up solution in same pass.

Double pass scrubbing method:

• Install scrubbing or stripping pad.

• Fill machine with properly diluted solution.

• Dispense solution. Scrub with squeegee in up position.

• Scrub a second time without dispensing solution unless necessary lower squeegee to pick up

solution during this second pass. (This method allows the chemical time to work).

6.3.9. Buffer:

• Floor buffing should be performed regularly to restore shine to the floors.

• Dust mop and damp mop the floor.

• Place wet floor signs.

• Use a buffer pad for the buffing machine.

• Add the correct amount of finish solution to the mop bucket and mix with water. Carefully

follow the directions on the bottle.

• Apply a thin coat of finish solution to the floor using a figure eight motion. Avoid splashing.

• Buff slowly side-to-side with the low-speed buffer. Buff while walking in a straight line with the

high-speed buffer.

• Allow the floor to dry.

• Buff slowly side-to-side with the low-speed buffer. Buff while walking in a straight line with the

high-speed buffer.

• Dust mop the floor again.

6.4. Sweeping

6.4.1. Equipment:

• Push broom

• Angle broom

• Dustpan

6.4.2. Potential hazards when sweeping:

• Airborne Particulate

• Slip/Trip/Fall

• Musculoskeletal Injury

6.4.3. Required PPE:

• Reinforced toe, non-slip shoes

Rev 0.1 January 5, 2024 8

Manual Cleaning Processes SOP

6.4.4. Recommended PPE:

• Coated fabric gloves

• Dust mask

6.4.5. Proper ergonomics when sweeping:

• Keep your upper arms close to your body, as if they were attached to your side, and move the

handle by moving your feet. This technique will limit the turning and twisting of your spine.

• Keep proper posture of the spine and move through your legs.

• Always face your work directly. Turn by moving your feet.

• Alternate hands.

• Keep your upper arms close to your body and move the handle by moving your feet.

6.4.6. Sweeping procedure:

• Drag the head of the broom along the ground using short, deliberate strokes. Hold the broom in

both hands, with one hand at the top and the other near the middle and move it from the

outside of your body inward. As you do, the bristles will push whatever kind of debris that’s

found its way onto the floor in the direction you’re sweeping.

• The shorter your strokes, the more control you’ll have. The idea is to get all of the debris into

one central place.

• Do not sweep too fast or too forcefully. Doing so can spread clouds of dust up in the air, only to

settle back down on the section you just swept.

• Start at the edges of the room and work your way towards the center. Draw the debris away

from the baseboards and out into the open, where you can shape it into a small pile that will be

easy to collect later on. You may need to angle your broom when you get to corners, cabinet

bottoms, or low-lying pieces of furniture to make sure that the bristles reach back into the

deepest recesses.

• It’s also a good idea to proceed from the far side of the room towards the door or entrance.

That way, you won’t be forced to track back through the piles of debris that have already been

swept.

• For particularly large rooms, try dividing the floor up into smaller sections and treating each

section like a self-contained space.

• Pause periodically to clean your broom. Items like hair, lint, and dust tend to get caught in

broom bristles. When this happens, hold the broom over a trash can and loosen the stuck-on

substances by hand.

• Make sure you wash your hands after handling anything that’s been on the floor.

• Sweep the pile you’ve been forming into your dustpan for disposal. Once you’ve gone around

the edges of the room, turn your attention towards coaxing the accumulated debris into your

dustpan. Then, pick up the dustpan carefully, empty the contents into the nearest trash bin.

• Consider switching to a compact hand sweeper at this point to manipulate small piles with

greater precision.

• Sometimes after sweeping a pile of debris into your dustpan, you’ll notice a thin line of dust left

behind at the front edge. When this happens, raise the handle up at a steep angle while keeping

Rev 0.1 January 5, 2024 9

Manual Cleaning Processes SOP

the lip pressed firmly into the floor. This will allow you to brush the dust up over the threshold

and trap it in the dustpan.

• Alternatively, you can simply vacuum or wipe up dust lines that you’re having difficulty corralling

with your broom.

6.5. Lifting or Moving Furniture

6.5.1. Equipment:

• Dolly

6.5.2. Potential hazards when lifting or moving furniture:

• Musculoskeletal Injury

• Pinched fingers or toes

6.5.3. Required PPE:

• Reinforced toe, non-slip shoes

• Coated fabric gloves

6.5.4. Proper ergonomics for lifting or moving furniture:

• Ensure the load is stable

• Keep the load close to your body

• Lift heavy items with a partner

• Bend your knees not your back

• Ensure a good grip on load

• Frequently handled loads should be located waist to chest level

• Avoid twisting the spine during lifting activities.

6.5.5. Lifting Procedure:

• Always ask for help when needed.

• Plan the lift and talk to your partner.

• Make sure your lifting partner understands the plan.

• Use lifting equipment wherever possible.

• When furniture is heavy or awkward, it may be necessary to pivot the furniture by lifting and

pivoting one end at a time in a zigzag pattern.

6.6. Trash Disposal

6.6.1. Equipment:

• Trash bins

• Trash liners

• Dumpster

• Trash compactor (depending on location)

Rev 0.1 January 5, 2024 10

Manual Cleaning Processes SOP

6.6.2. Potential hazards when disposing trash:

• Back strain

• Needle Stick

• Laceration

• Bloodborne Pathogens

6.6.3. Recommended PPE:

• Nitrile Gloves

6.6.4. Proper ergonomics when disposing trash:

• Lift with your knees and keep your back straight.

6.6.5. Disposing trash procedure:

• Trash cans may contain sharp or dangerous items that could stab, pierce, or cut someone’s

hand. Never reach directly into the trash can instead, carefully dump the contents of smaller

cans into larger ones or tie the top of the bag and lift it out.

• Wash any soiled trash cans, especially if soiled with food products.

• Use ramp or steps provided when throwing trash into dumpsters.

• Do not throw bags over your head and get help if bags are too heavy to safely lift.

6.7. Dusting

Microfiber dust cloths can be used for most light dusting. Heavy dust build-up may require the use of a

vacuum cleaner.

6.7.1. Equipment:

• High duster

• Microfiber cloth

6.7.2. Potential hazards when dusting:

• Falling debris and dust in eyes

6.7.3. Required PPE:

• Reinforced toe, non-slip shoes

6.7.4. Recommended PPE:

• Coated fabric gloves

• Dust mask

• Safety glasses/Goggles

6.7.5. Proper ergonomics when dusting:

• When dusting keep the wrist straight.

• Get close to the work area to avoid unnecessary bending and reaching.

Rev 0.1 January 5, 2024 11

Manual Cleaning Processes SOP

6.7.6. Procedure:

• Wipe horizontal surfaces such as window ledges, sills, files, counter tops, and desks with a

microfiber dust cloth.

• Utilize eight-fold process, and replace the dust cloth when all eights sides have been utilized.

7. EQUIPMENT MAINTENANCE

Equipment that is in safe working order allows for healthier work practices, greater productivity and

reduces the risk of injury.

• Check equipment before each use.

• Perform preventative maintenance.

• Make sure broken or malfunctioning equipment is tagged, reported to your supervisor, removed

from service, and repaired as soon as possible to maintain productivity and prevent employee

injury.

8. DILUTING CHEMICALS

Diluting concentrated cleaning solution with water in proper proportions is efficient and practical.

• Without diluting the cleaning solution concentrate you can damage the surfaces being cleaned,

harm your skin, make too many suds, and waste the cleaning solution.

• Too little concentrate can result in improper cleaning of surfaces, waste of material, and energy.

• Check the cleaning solution concentrate package for proper ratios.

Ratio: Amount of concentrate: Amount of water:

4 to 1 32 oz Per gallon

5 to 1 26 oz Per gallon

10 to 1 13 oz Per gallon

15 to 1 8 ½ oz Per gallon

20 to 1 6 ½ oz Per gallon

25 to 1 5 ½ oz Per gallon

30 to 1 4 1/3 oz Per gallon

40 to 1 3 1/3 oz Per gallon

60 to 1 3 1/3 oz Per gallon

85 to 1 1 ½ oz Per gallon

128 to 1 1 oz Per gallon

256 to 1 ½ oz Per gallon

8.1. Potential hazards when diluting chemicals:

• Skin irritation

• Skin sensitization

• Carcinogenicity

• Flammability

Rev 0.1 January 5, 2024 12

Manual Cleaning Processes SOP

• Corrosion

• Explosive

• Eye damage

8.2. Safety controls when diluting chemicals:

Utilize Engineering controls and wear PPE in accordance with the chemical’s SDS sheet.

Rev 0.1 January 5, 2024 13

Manual Cleaning Processes SOP Final R0.1

Final Audit Report 2024-01-16

Created: 2024-01-10

By: Zachary Peterson (zpeterson@unm.edu)

Status: Signed

Transaction ID: CBJCHBCAABAAtbeTDJ8BY9ubzZklCEjIXJVSdt1l8jsf

"Manual Cleaning Processes SOP Final R0.1" History

Document created by Zachary Peterson (zpeterson@unm.edu)

2024-01-10 - 6:24:36 PM GMT- IP address: 174.28.177.127

Document emailed to Victor Tovar (vtovar@unm.edu) for signature

2024-01-10 - 6:26:04 PM GMT

Document emailed to mckmatt@unm.edu for signature

2024-01-10 - 6:26:04 PM GMT

Document emailed to James Todd (jtodd@unm.edu) for signature

2024-01-10 - 6:26:04 PM GMT

Document emailed to dgoines@unm.edu for signature

2024-01-10 - 6:26:05 PM GMT

Document emailed to Dennis-Ray Armijo (drayarmijo@unm.edu) for signature

2024-01-10 - 6:26:05 PM GMT

Document emailed to Casey B Hall (cbhall4@unm.edu) for signature

2024-01-10 - 6:26:05 PM GMT

Email viewed by James Todd (jtodd@unm.edu)

2024-01-10 - 6:33:41 PM GMT- IP address: 129.24.32.163

Document e-signed by James Todd (jtodd@unm.edu)

Signature Date: 2024-01-10 - 6:34:00 PM GMT - Time Source: server- IP address: 129.24.32.163

Email viewed by Casey B Hall (cbhall4@unm.edu)

2024-01-10 - 8:42:50 PM GMT- IP address: 129.24.33.94

Document e-signed by Casey B Hall (cbhall4@unm.edu)

Signature Date: 2024-01-10 - 8:42:56 PM GMT - Time Source: server- IP address: 129.24.33.94

Email viewed by mckmatt@unm.edu

2024-01-10 - 9:13:16 PM GMT- IP address: 104.28.85.157

Signer mckmatt@unm.edu entered name at signing as Matt McKernan

2024-01-10 - 9:13:39 PM GMT- IP address: 174.218.18.178

Document e-signed by Matt McKernan (mckmatt@unm.edu)

Signature Date: 2024-01-10 - 9:13:41 PM GMT - Time Source: server- IP address: 174.218.18.178

Email viewed by dgoines@unm.edu

2024-01-10 - 10:32:14 PM GMT- IP address: 64.106.113.215

Signer dgoines@unm.edu entered name at signing as Dee Goines

2024-01-10 - 10:32:29 PM GMT- IP address: 64.106.113.215

Document e-signed by Dee Goines (dgoines@unm.edu)

Signature Date: 2024-01-10 - 10:32:31 PM GMT - Time Source: server- IP address: 64.106.113.215

Email viewed by Victor Tovar (vtovar@unm.edu)

2024-01-11 - 4:59:18 PM GMT- IP address: 129.24.109.146

Document e-signed by Victor Tovar (vtovar@unm.edu)

Signature Date: 2024-01-11 - 4:59:31 PM GMT - Time Source: server- IP address: 129.24.109.146

Email viewed by Dennis-Ray Armijo (drayarmijo@unm.edu)

2024-01-16 - 11:28:15 PM GMT- IP address: 129.24.191.51

Document e-signed by Dennis-Ray Armijo (drayarmijo@unm.edu)

Signature Date: 2024-01-16 - 11:28:24 PM GMT - Time Source: server- IP address: 129.24.191.51

Agreement completed.

2024-01-16 - 11:28:24 PM GMT

You might also like

- SN-QC-SOP-042 SoP For Cleaning & Sanitization of Pharmaceutical Facility100% (2)SN-QC-SOP-042 SoP For Cleaning & Sanitization of Pharmaceutical Facility14 pages

- SOP 003 Wooden Bench Deep Cleaning ProcessNo ratings yetSOP 003 Wooden Bench Deep Cleaning Process7 pages

- Ops Ms - 003 - Cleaning and Janitorial Services - HealthcareNo ratings yetOps Ms - 003 - Cleaning and Janitorial Services - Healthcare83 pages

- Product End-of-Life Disassembly InstructionsNo ratings yetProduct End-of-Life Disassembly Instructions35 pages

- SOP For Cleaning and Sanitation of Microbiology Section With Disinfectants75% (4)SOP For Cleaning and Sanitation of Microbiology Section With Disinfectants3 pages

- Standard Operation Procedure Cleaning Offices and Out UnitsNo ratings yetStandard Operation Procedure Cleaning Offices and Out Units11 pages

- VAL 215 Cleaning Validatio Master Plan Non Sterile Solid SampleNo ratings yetVAL 215 Cleaning Validatio Master Plan Non Sterile Solid Sample5 pages

- Cleanroom Cleaning Process Guide-PEGASUSNo ratings yetCleanroom Cleaning Process Guide-PEGASUS12 pages

- ASEAN TMHS GMP Training Chapter 4 Annex 8 SOP On Cleaning of Equipment and Acce PDFNo ratings yetASEAN TMHS GMP Training Chapter 4 Annex 8 SOP On Cleaning of Equipment and Acce PDF3 pages

- Sample Housekeeping SOP: Standard Operating Procedure Template (Simple Guide)No ratings yetSample Housekeeping SOP: Standard Operating Procedure Template (Simple Guide)7 pages

- MAN 015 Factory Cleaning Procedure SampleNo ratings yetMAN 015 Factory Cleaning Procedure Sample4 pages

- CLEANING SOPS OF Semi Automatic Dropper Filling MachineNo ratings yetCLEANING SOPS OF Semi Automatic Dropper Filling Machine2 pages

- Cleaning and Hygiene SOP Lucky EngineersNo ratings yetCleaning and Hygiene SOP Lucky Engineers2 pages

- Fibo Wallpanel Installation Instructions Inlay All Markets Fibo INL WP 0624 SSA LQNo ratings yetFibo Wallpanel Installation Instructions Inlay All Markets Fibo INL WP 0624 SSA LQ2 pages

- Buku Murid Bahasa Inggris - Student's Book My Next Word For Elementary School Unit 9 - Fase BNo ratings yetBuku Murid Bahasa Inggris - Student's Book My Next Word For Elementary School Unit 9 - Fase B13 pages

- Victor 899 MFL68005568 06 190902 EN+SP+FC Full 1No ratings yetVictor 899 MFL68005568 06 190902 EN+SP+FC Full 1172 pages

- Zak Mckracken: Between Time and Space: English WalkthroughNo ratings yetZak Mckracken: Between Time and Space: English Walkthrough10 pages

- After The Breakup He Washed Away The Memories Lazy Girl TranslationsNo ratings yetAfter The Breakup He Washed Away The Memories Lazy Girl Translations1,461 pages

- Copia de ENGL120 Grammar 2 1 Present Simple Continuous100% (1)Copia de ENGL120 Grammar 2 1 Present Simple Continuous16 pages

- Bank Mandiri Jayapura Interior Renovation BOQNo ratings yetBank Mandiri Jayapura Interior Renovation BOQ58 pages

- A Course of English Grammar - Kechyan - The VerbNo ratings yetA Course of English Grammar - Kechyan - The Verb188 pages