MECHANICAL WORKSHOP PRACTICE 2

DJJ20042

MACHINES

DKM3S2

LECTURE NAME :

NAME METRIC NUMBERS

MUHAMMAD SYAHMER BIN JAFRI 13DKM20F1077

IRHAM SYAKIR BIN ZAMRI 13DKM20F1061

INTRODUCTION

In this lathe machine project, we as a student to take knowledge to understand how to work

or use the lathe machine with correctly. The lathe is one of the most important machines in

any workshop. Its main objective is to remove material from outside by rotating the work

against a cutting tool. Though a lathe is used to produce cylindrical work, yet it may also be

used for many other purposes such as drilling, threading, grinding, milling etc.

TOOLS EQUIPMENTS

1) Lathe machine

�2) Vernier Caliper

3) Adjustable Spanner

4) Spanner

�5) Chuck

6) T Hander Tap Wrench

7) Center Punch

�SAFETY PRECAUTIONS

1) Wear PPE example : safety shoes and jacket.

2) Do not make a joke with friend when project was start.

3) Do not start any work without permission.

4) Always think about safety when project was start.

5) Clean the machine when finish our project.

6) Always check power supply when not use the machine.

7) Do not change gears while the lathe is running.

8) Never walk away from a lathe when it is operating.

9) When the work is complete, shut of power and clean the machine.

PROCEDURE

1) Using power hacksaw cut the workpiece of length 65 mm

2) Hold the workpieces in the chuck

3) Facing

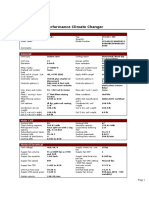

4) Parallel turning ( ø48x30mm )

5) Drilling ( ø35x15mm )

6) Boring ( ø38x15mm )

7) Swap the workpieces ends in the chuck and faced the other end to length (60mm)

8) Marking out the new eccentric axis and circle

9) Setting on the for jaw chuck referring to the new axis

10) Parallel turning ( ø30x40 )

11) Groove, fillet turning and chamfering

12) Drilling ( ø13.5 )

13) Chamfering on the three jaw chuck

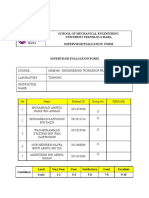

RESULTS

�DISCUSSION

1.Why it very important to practice safety procedure during workshop practice? Discuss.

Answer- because of important to practice safety procedure:

1) To prevent accident during a work.

2) Always take reasonable care before starting the work.

3) Make us more secure when doing a work in workshop.

2. Boring is the most difficult task in this project. List main precaution should be taken so

that the good boring pattern is obtain.

Answer- list of precaution:

1) Do not touch the drill when drilling was start.

2) Put some oil on the workpiece and drilling tool.

3) Do not force the the drill.

4) Avoid from waste workpiece.

3. Study case of sample given , describe the error defects and how to overcome them. Base

on this project , many error made on workpiece because negligence and lack of experience .

from this case , need to take a knowledge before starting a work.

REFERENCE

1. https://www.scribd.com/doc/118466277/LATHE-MACHINE-PROJECT-SEMESTER-2