0% found this document useful (0 votes)

25 views8 pagesPM Schedule For The Month of Jan-25

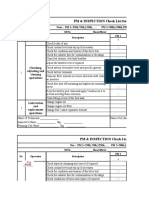

The document outlines the planned preventive maintenance (PM) job schedule for January 2025, detailing various mechanical and electrical tasks across different units. It includes specific tasks such as lubrication, cleaning, seal replacements, and inspections for equipment like the log pusher unit, main press, and die oven. Additionally, it lists required items and quantities for maintenance activities.

Uploaded by

mishraankit943Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

25 views8 pagesPM Schedule For The Month of Jan-25

The document outlines the planned preventive maintenance (PM) job schedule for January 2025, detailing various mechanical and electrical tasks across different units. It includes specific tasks such as lubrication, cleaning, seal replacements, and inspections for equipment like the log pusher unit, main press, and die oven. Additionally, it lists required items and quantities for maintenance activities.

Uploaded by

mishraankit943Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

/ 8