0% found this document useful (0 votes)

15 views83 pagesCasting - Part-II

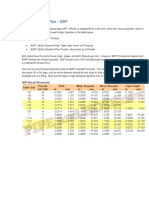

The document covers various aspects of metal casting, including principles of molten metal flow, solidification time, and design considerations for risers and molds. It discusses the application of Chvorinov's Rule for solidification and the importance of directional solidification to minimize shrinkage. Additionally, it introduces different casting processes such as shell molding, investment casting, and die casting, along with potential casting defects.

Uploaded by

PRASHANT'S WORLDCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

15 views83 pagesCasting - Part-II

The document covers various aspects of metal casting, including principles of molten metal flow, solidification time, and design considerations for risers and molds. It discusses the application of Chvorinov's Rule for solidification and the importance of directional solidification to minimize shrinkage. Additionally, it introduces different casting processes such as shell molding, investment casting, and die casting, along with potential casting defects.

Uploaded by

PRASHANT'S WORLDCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 83