Doc. No.

QSP-12

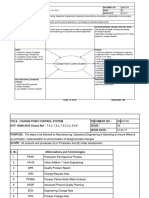

TURTLE DIAGRAM

Issue No./Date 01/01-08-17

Rev. No./Date 01/10-01-23

Title: Process Change Control

OMNI AUTO LTD. Page 1 of 1

With What (Material / With Whom (Competency,

Equipment?) ?Training,Skill)

Computers,Printers - - Knowledge on design, Process

:Process Owner & Product

Drawings - - Document control

Standards- .Head Engg Knowledge on APQP, PPAP, SPC,

Instruments&Tools- MSA, FMEA etc.

Engineering Softwares- - Change Management

Defined Input Desired Output

-Customer requirement Improved process -

Improved quality and cycle -

- Customer Complaint time

-Process Change /Kaizen Process

Cost saving -

- Ergonomics Issue Process change Revised documents like -

- Layout Change - Major control CP,PFMEA PFC

Change Review & update of process-

-Improvement of documents for process change

performance / Quality ( Kaizen) .Changes as per customer req -

- ECN ,

-Statutory /Regulatory req. Intended Result (Process

Measures / Functional or

How? Department Objectives)

(Method/Technique/Procedur Effectiveness:

e) Interacting Process Nil

Production , QA , Maint. ,

As per the procedure of PPC Efficiency:

Process change control QSP - -Average time taken to

implement ECN

12

Non-Conformity, Improvement : Process

:Corrective&Preventive Action improvement

-CAPA on ECN issues .

Review

MRM

Risk Associated with the Process: Risk Associated with the Process is identified and monitored MR/F/04

Format No MR/F/07

Prepared by Approved by

THIS DOCUMENT CONTAINS CONFIDENTIAL INFORMATION. Its use is restricted to employees with a need to know and third parties with a need to

know and who have signed a non-disclosure agreement.

� Doc. No. QSP-12

QUALITY SYSTEM PROCEDURE

Issue No./Date 01/01-08-17

Rev. No./Date 02/22-02-24

Title: Process Change Control

OMNI AUTO LTD. Page 2 OF 2

Process Name

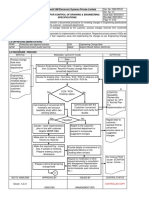

1.0 Objective The objective of this procedure is to establish and maintain a documented procedure to control and react to changes related to process

2.0 Scope The scope of the procedure applies to manufacturing process in the Omni Auto.

3.0 Mapping

Output with

Sl.# Key Inputs Activity How Resp. When Documented

information ref.

1) Customer requirement , Change in drawings ,

specifications

Based on input

2) Customer Complaint

trigger from

3)Process Change /Kaizen/CIP Before initiating any process Engineering Change

1 Customer,Internal Requestor

4)Layout Change - Major Change Raise Engineering change request deviation,

change Note

5)Improvement of performance / Quality

kaizen ,ECN

6)Internal & external deviation

NO Conduct

Feasibility & Risk

Feasibility & DH PE After Process modification

2 Engineering Change Note

Risk

As per Process modif

CFT request note approval

study

analysis

YES

Customer approval / communication (for internal Email / drawing Before initiating any process

3 Engineering Change Note change req.) Requestor

change

Customer approval

Sign off by Approved Process

Before initiating Process

4 Engineering Change Note Internal communication & ECN approval Concerned HOD Requestor

modification request note

modification request

(hard copy) note

Preparation of Timing Plan for change introduction (if Discussion with

Head Engg Engineering Change

5 Approved Engineering change note req.) all CFT CFT

After ECN approval

Note

members

Validation activities, Validation&

Customer requirements, Head Engg

6 Verify and Validate the process and keep records Conducting Trial As per TimePlan Verification records/

ECN Get Part approval from customer/Internal CFT

run Trail Reports

Review and Update affecting Documents as per

Engineering Change Document check sheet. Discussion with Within 10 working days after

Note- All the process sequence should be verified and Head Engg

7 ECN all CFT CFT

receipt of any change Updated process doc

updated for any process change carried out requiremennt as per checksheet

immediately in all process documents. members

Submitting to

Preparation of PPAP file/internal ECN document & Customer/ Internal Head Engg

8 ECN, Updated process Docs submission to customer(if applicable)/ internal for Customer CFT

As per Time Plan PSW (if req.)

PSW.

Document Ref : Record Ref.

IATF Clause No.: 8.5.6 , 8.5.6.1

Engineering Change note OAL/ECN/01/00

Format Number

MR/F/08

Prepared by Approved By

THIS DOCUMENT CONTAINS CONFIDENTIAL INFORMATION. Its use is restricted to employees with a need to know and third parties with a need to know and who have signed a non-disclosure agreement.