0% found this document useful (0 votes)

42 views9 pagesDesign Strap

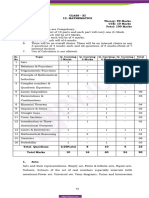

The document contains detailed calculations for flexural capacity and reinforcement based on ACI 318 - 2005 standards, including maximum concrete and steel strains, neutral axis depth, and moment capacity. It also includes shear calculations, torsion calculations, and the required reinforcement for various conditions. The calculations are presented in both metric and imperial units, with final results for shear force capacity and torsion capacity provided.

Uploaded by

nalalyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

42 views9 pagesDesign Strap

The document contains detailed calculations for flexural capacity and reinforcement based on ACI 318 - 2005 standards, including maximum concrete and steel strains, neutral axis depth, and moment capacity. It also includes shear calculations, torsion calculations, and the required reinforcement for various conditions. The calculations are presented in both metric and imperial units, with final results for shear force capacity and torsion capacity provided.

Uploaded by

nalalyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 9