Field Survey & Asbuilt Submittal Guidelines - v3.0

Uploaded by

Sooraj Gopi PanikkasseryField Survey & Asbuilt Submittal Guidelines - v3.0

Uploaded by

Sooraj Gopi PanikkasseryField Survey & As-built

Drawings Submittal

Guidelines

Issue : 3 07/09/2020 Unclassified Page 1 of 119

Field Survey & As-built Submittal Guidelines

Document Control

Department Document Type Document Title

Field Survey & As-built

EP Guideline Drawings Submittal

Guidelines

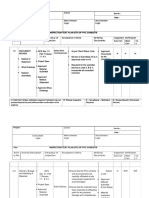

Issue Approval

Prepared By Reviewed By Approved By

Farhia Ibrahim Abdallah Hashim Mohammed

Sr. Specialist

Mohd Thani Al Maadead

Abdullathif Alsada Manager, Water Network Planning

Technology Development Head, GIS Section

Signature: Signature: Signature:

signed original filed separately signed original filed separately signed original filed separately

Issue Record

Issue No. Date Reason for issuing the Procedure

0.0 12/04/2015 First issue of the procedure

1.0 06/04/2017 Modify the job titles as per new WP structure &

Change the document format

2.0 11/07/2019 Reviewed and change the document ID

3.0 27/07/2020 Updated following the ArcFM Implementation

4.0

5.0

Review Frequency: Annual

Issue : 3 07/09/2020 Unclassified Page 1 of 119

Field Survey & As-built Submittal Guidelines

Table of Contents

Content Page

1 Purpose 4

2 Scope 4

3 Responsibilities & Authorities 5

4 Abbreviations, Definitions of Terms & Key References 5

4.1 Abbreviations 5

4.2 Terms 6

4.3 Disclaimer 6

5 Spatial Information Submittals Policy 6

6 Field Survey 8

6.1 Assets Survey Accuracy 8

6.2 Data Collection Method 8

6.3 Data Requirements 9

7 Asbuilt Standard Specifications 13

7.1 Organize Data by ESRI Format 13

7.2 Organize Data by CAD Objects 24

Appendix A - Data Requirements 34

A.1 Electric Network Features Attributes 34

A.2 Water Network Features Attributes 47

A.3 Electric Attribute Details for Domains 60

A.4 Water Attribute Details for Domains 75

Appendix B - Connectivity Rules 86

B.1 Electric Network Split Policy 86

B.2 Water Network Split Policy 89

Appendix C - Layers Matrix (GIS to CAD) 91

C.1 Electric CAD to GIS Mapping Matrix: 91

C.2 Water CAD to GIS Mapping Matrix: 95

Appendix D - Online As-built Submissions 97

D.1 Access the Online Asbuilt Submission 97

D.2 Pre-conditions: 98

D.3 Preliminary Checks 99

Issue : 3 07/09/2020 Unclassified Page 2 of 119

Field Survey & As-built Submittal Guidelines

D.4 View Submissions 99

D.5 Submissions Status 102

D.6 Submission Type 102

D.7 New Asbuilt Submission 102

D.8 New Engineering Drawing 105

D.9 New Request for Inspection 108

D.10 Access Rejection Report 109

D.11 Revise Rejected Submission 110

D.12 Request for Information 112

Appendix E - Forms 114

E.1 Survey Report (KM/WGIS/SUR/STD1) 114

E.2 Water Project Information Template 117

Issue : 3 07/09/2020 Unclassified Page 3 of 119

Field Survey & As-built Submittal Guidelines

1 Purpose

To set forth a “General Specifications of field survey & As-Built Drawing ” guideline for

Electric & Water As-Built drawings to ensure that all submissions are inline with

Kahramaa enterprise Geodatabase for seamless review, approval & data loading into the

enterprise repository.

2 Scope

This document provides an overview of the standard developed by KAHRAMAA for the

exchange of Spatial Information (GIS) with external third parties. This standard provides

drawing specifications to streamline the process of capturing network schemes and

assets information, thereby, easing the conversion of as-built submission into Kahramaa

enterprise database including the verification and acceptance procedures. This will

maximize the usability of the information between KAHRAMAA and other external parties

(such as consultants and contractors).

As such, KAHRAMAA requires that all spatial information submitted to the company

be structured according to the guidelines specified herein. The contractor, for example,

is required to adhere to the structure of the required data in ESRI Data Format

(Geodatabase) in order to help improve the structure of the data, create GIS-ready

data and reduce the time required for the conversion into GIS. The contractor is

emphasized to submit all network schemes and projects' Shop drawings and As-built

drawings in accordance with the requirements in this document.

However, Kahramaa is providing the option to submit the projects’ Shop drawings and

As-built drawings in AutoCAD (.dwg) format following specific template and using

defined tools that are presented in this document as well. Noting that Kahramaa based

on her decision, may refuse to receive the AutoCAD templates and request to maintain

the Geodatabase template following the section requirements prior the execution of

any project.

The document will focus on the guidelines for building data that can easily be collected

as assets information and used as GIS content. These General specifications describe

the following:-

Issue : 3 07/09/2020 Unclassified Page 4 of 119

Field Survey & As-built Submittal Guidelines

Field Survey details of data collection method and requisite data for all

features, electric & water network in addition to electric & water facilities and

non-network assets

As-Built Drawings details of all dimensions , layers & features type

3 Responsibilities & Authorities

Responsibilities and authority for ensuring that the steps in this guideline shall be

carried out are specified at relevant steps in the guideline and include:

Electricity Planning Manager (EP)

Water Planning Manager (WP)

Head of GIS Section (EPN)

GIS Sr. Specialist

GIS Specialist

GIS Surveyor

GIS Support

KM Contractors

4 Abbreviations, Definitions of Terms & Key References

Abbreviations

Abbreviation Description

CAD Computer Aided Design

DWG Drawing, used for AutoCAD format

ESRI Environmental Systems Research Institute

FC Feature Class, GDB Object Layer

GDB Geographic Database

GIS Geographical Information System

PDF Portable Document Format

QC Quality Check

QND Qatar National Datum

URL Uniform Resource Locator

Table 1: Abbreviations List

Issue : 3 07/09/2020 Unclassified Page 5 of 119

Field Survey & As-built Submittal Guidelines

Terms

Term Description

Set of drawings submitted by a contractor upon completion of a project or a

particular job. They reflect all changes made in the specifications and

As Built

working drawings during the construction process, and show the exact

Drawings

dimensions, geometry, and location of all elements of the work completed

under the contract.

Engineering Classified as Electrical, Mechanical, Civil and Structural drawings pertaining

Drawings to Reservoirs, Water towers, Elevated tanks, Well fields, Kahramaa

buildings and tanker filling stations

Geodatabase Geographic database used to store spatial information for assets with their

/ GeoDB attributes.

Table 2: Terms definitions

Disclaimer

Technical details related to this document can be verified for any clarifications

with the GIS Section.

The information contained in this document is the exclusive property of

KAHRAMAA.

This document should not be reproduced or transmitted in any form or by any

Means, electronic or mechanical, including photocopying and recording, or by

any information storage or retrieval system, except as expressly permitted in

writing by the GIS Section.

The information contained in this document is subject to change without

notice.

All contractors should commit to the importance of the submission of projects’

field survey & as-built as per the requirements in this document - and in both

stages of submission: Shop drawings and As-built drawings – including the

CAD Specifications shall also be used by Consultants/Developers for

submittals of Approved Design drawings as well.

5 Spatial Information Submittals Policy

The contractor is required to adhere to the following when submitting deliverables to

KAHRAMAA related to the as-built submissions:

1. The contractor should consult with Kahramaa prior the execution and data collection

of each project on the data structure that should be delivered:

The contractor shall obtain the latest Geodatabase schema for the layers and

attributes structure to be maintained

Alternatively and if approved by Kahramaa, the contractor may obtain the latest

AutoCAD templates to be used following the submission type.

Issue : 3 07/09/2020 Unclassified Page 6 of 119

Field Survey & As-built Submittal Guidelines

2. The contractor shall accompany the deliverables with spatial and attribute information

in digital format according to the standards described herein and as available in the

received templates.

3. The contractor shall make use of the received templates (GDB or DWG) to populate

the collected data.

4. The contractor shall ensure that any submitted network drawings contain a Key Map

and properly measured dimensions from the road center line or edge of a parcel.

5. The contractor shall use the following Spatial Reference as the projection system for

all spatial information QND_1995_Qatar_National_Grid.

6. The contractor shall submit all data structured according to Kahramaa Data Models

described hereafter in this document that are in accordance with the industry

standard data models.

7. The contractor shall ensure that physical connectivity of the water assets is upheld

and shall model all edge-junction related rules, described later in this document, in

the submissions.

8. When applicable, the contractor shall adhere to the following general AutoCAD

Standard Guidelines, which are elaborated further in this document:

Create Objects with Consistent Geometry

Do Not Create Symbols using Cross Lines, Cross Lines and Circle combinations

Snap Lines at their Intersection

Create Polygons using Closed Polylines only

Create and Save Attributes in the CAD Drawing File Using the Corresponding

“XRecords” tools

9. KAHRAMAA shall verify the compliance, completeness, and accuracy of the

submitted information. The contractor shall make all necessary modifications to

achieve compliance with KAHRAMAA Standard.

10. Any violation to below rules will result to automated rejection of the submission for

revision and will not be considered a successful submission:

Proper projection system (QND_1995_Qatar_National_Grid)

Proper geo-referencing of the data

Compliance with the data model and data structure (GDB or DWG)

Completeness of the mandatory data identified in this document

11. The acceptance of the work executed by the contractor shall not be considered

complete until all information is submitted and approved by KAHRAMAA during the

following QC phase after the successful submission.

Issue : 3 07/09/2020 Unclassified Page 7 of 119

Field Survey & As-built Submittal Guidelines

12. The contractor shall obtain the latest (most updated) Base Map used at KAHRAMAA,

to be used as the Key Map of all network layout drawings.

13. All contractors are advised to officially request/receive the new upgraded Landbase

from KAHRAMAA for all their new projects. And, use only this map for creating /

aligning their as built network drawings.

6 Field Survey

KAHRAMAA implemented these Survey & Asbuilt standards to improve the quality of the

asbuilt data submission for loading to GIS enterprise database and its usefulness as a

source of asset information and GIS content. The most important aspect is the use and

enforcement of the Asbuilt standard. The output will be GIS file Geodatabase or CAD files

compatible with Kahramaa enterprise Geodatabase and containing valuable asset

information. The following are the standard specifications that KAHRAMAA has set for

contractors to follow while capturing data.

Assets Survey Accuracy

Qatar National Grid Coordinate system – QND_1995_Qatar_National_Grid –

shall be followed for all coordinates measurements.

Survey accuracy of all assets should be maintained at the middle of the

corresponding asset with accuracy of 0.2 meters.

Survey Report should be generated describing survey procedure, methodology,

control points and other details as per survey report Standard – Ref No.

KM/WGIS/SUR/STD1. (Refer to Appendix E - Forms)

Surveying methodology should be according to CGIS “Qatar Survey Manual” and

CGIS new referencing system “QCORS”). For further queries please contact The

Centre for GIS , MMUP or www,gisqatar.org.qa

Data Collection Method

Cables shall be measured at every interval of 10 meters as well as every asset

point along the cables routes.

Pipeline shall be measured at every interval of 25 meters for straight as well as

every asset point for all curved or straight pipe-routes

Route of Service Connection (Service Pipe or LV Cable) shall be measured at

every 5 meters, if service connection length is above 20 meters.

Coordinates for all apparatus and assets shall be measured accurately at the

center of the object.

Issue : 3 07/09/2020 Unclassified Page 8 of 119

Field Survey & As-built Submittal Guidelines

Elevations or Buried Depth (in meters) shall be measured with respect to Qatar

National Datum and at the TOP of the pipe or cable, assets and apparatus.

Diameters or size of the pipes, cables, assets & apparatus shall be confirmed from

field survey and recorded in the corresponding attribute field. e.g. (Diameter =

200mm or Size = 185mm2)

Data Requirements

Please refer to Appendix A – Data Requirements for the required attributes.

6.3.1 Electric Data Requirements References

# Feature Class / Layer Name Attribute Requirement

1 BPL Appendix A.1.1

2 Busbar Appendix A.1.2

3 CableDepth Appendix A.1.3

4 Communication Cable Appendix A.1.4

5 Communication Joint Appendix A.1.5

6 DuctEdge Appendix A.1.6

7 Dynamic ProtectiveDevice Appendix A.1.7

8 Fuse Appendix A.1.8

9 Generator Appendix A.1.9

10 Instrument Transformer Appendix A.1.10

11 LVJoint Appendix A.1.11

12 LVOverheadLine Appendix A.1.12

13 LVUnderGround Cable Appendix A.1.13

14 Motor Appendix A.1.14

15 MVJoint Appendix A.1.15

16 MVOverheadLine Appendix A.1.16

17 MVUnderGroundCable Appendix A.1.17

18 Pole Appendix A.1.18

19 ReactivePower Compensator Appendix A.1.19

20 ServicePoint Appendix A.1.20

21 SSCable Appendix A.1.21

22 Substation Appendix A.1.22

Issue : 3 07/09/2020 Unclassified Page 9 of 119

Field Survey & As-built Submittal Guidelines

# Feature Class / Layer Name Attribute Requirement

23 Switch Appendix A.1.23

24 Terminator Appendix A.1.24

25 Transformer Appendix A.1.25

26 Issue Appendix A.1.26

27 T_Busbar Appendix A.1.27

28 T_CircuitBreaker Appendix A.1.28

29 T_Communication Cable Appendix A.1.29

30 T_Communication Joint Appendix A.1.30

31 T_DuctEdge Appendix A.1.31

32 T_Generator Appendix A.1.32

33 T_Joint Appendix A.1.33

34 T_OverheadLine Appendix A.1.34

35 T_Reactor Appendix A.1.35

36 T_SSCable Appendix A.1.36

37 T_Substation Appendix A.1.37

38 T_Switch Appendix A.1.38

39 T_Tower Appendix A.1.39

40 T_Transformer Appendix A.1.40

41 T_UGCable Appendix A.1.41

Table 3: Electric Data Requirements References

Issue : 3 07/09/2020 Unclassified Page 10 of 119

Field Survey & As-built Submittal Guidelines

6.3.2 Water Data Requirements References

# Feature Class / Layer Name Attribute Requirement

1 AirValve Appendix A.2.1

2 CasingProtection Appendix A.2.2

3 ChlorinationPoint Appendix A.2.3

4 ControlValve Appendix A.2.4

5 Distiller Appendix A.2.5

6 Enclosure Appendix A.2.6

7 Facility Appendix A.2.7

8 FieldPressure CheckingPoint Appendix A.2.8

9 Fitting Appendix A.2.9

10 GravityChannel Appendix A.2.10

11 GravityPipe Appendix A.2.11

12 Hydrant Appendix A.2.12

13 IWPP_Out Appendix A.2.13

14 Manhole Appendix A.2.14

15 MarkerPlate Appendix A.2.15

16 Meter Appendix A.2.16

17 Miscellaneous Line Appendix A.2.17

18 Miscellaneuos Point Appendix A.2.18

19 Miscellaneuos Polygon Appendix A.2.19

20 PipeElevation Appendix A.2.20

21 Pump Appendix A.2.21

22 RM_Source Appendix A.2.22

23 RPS Appendix A.2.23

24 RPS_Inlet Appendix A.2.24

25 RoPlant Appendix A.2.25

26 ScadaEquipment Appendix A.2.26

27 ServicePipe Appendix A.2.27

28 ServiceValve Appendix A.2.28

29 StoragePoint Appendix A.2.29

30 SurgeTank Appendix A.2.30

31 SystemValve Appendix A.2.31

32 TankerFillingPoint Appendix A.2.32

Issue : 3 07/09/2020 Unclassified Page 11 of 119

Field Survey & As-built Submittal Guidelines

# Feature Class / Layer Name Attribute Requirement

33 ThrustBlock Appendix A.2.33

34 VirtualLines Appendix A.2.34

35 WServiceConnection Appendix A.2.35

36 WaterFaciltiy Appendix A.2.36

37 WaterMain Appendix A.2.37

38 Well Appendix A.2.38

Table 4: Water Data Requirements References

Issue : 3 07/09/2020 Unclassified Page 12 of 119

Field Survey & As-built Submittal Guidelines

7 As-built Standard Specifications

Organize Data by ESRI Format

Kahramaa and following the directions of the related authorities in the state of Qatar,

relies on ESRI GIS data format to maintain the GIS enterprise databases.

Accordingly, Kahramaa encourages all contractor to maintain their submissions in ESRI

Geodatabase format (File Geodatabase).

Contactors will populate the provided schema following their actual work type and can

leave the unrelated feature classes – representing layers in GIS – empty. Noting that the

submission will be rejected if any related feature class features are required in the

submission if not populated.

7.1.1 Electric GDB Schema

Below is the electric GDB structure that should be adopted for data population following

the collection from site:

Issue : 3 07/09/2020 Unclassified Page 13 of 119

Field Survey & As-built Submittal Guidelines

Figure 1: Electric Distribution Dataset Figure 2: Electric Transmission Dataset

Issue : 3 07/09/2020 Unclassified Page 14 of 119

Field Survey & As-built Submittal Guidelines

7.1.2 Water GDB Schema

Below is the water GDB structure that should be adopted for data population following

the collection from site:

Figure 3: Water Distribution Dataset

Issue : 3 07/09/2020 Unclassified Page 15 of 119

Field Survey & As-built Submittal Guidelines

7.1.3 Electric Feature Classes / Layers

# Feature Class / Layer Description Feature Attribute

Layer Name Type Requirement

1 BPL Broadband over power lines (BPL) is a method of Point Appendix

power line communication (PLC) that allows A.1.1

relatively high-speed digital data transmission over

the public electric power distribution wiring.

BPL feature will be added to the end of the circuit

busbar within the substation

2 Busbar Distribution Busbars are classified based on the Line Appendix

voltage levels. Besides, a Busbar Category field is A.1.2

available to classify it based on station types

3 CableDepth A point feature storing the depth of the underground Point Appendix

cable A.1.3

4 Communication Communication cables are classified as Telemetry, Line Appendix

Cable Pilot Cable and Earthing cables A.1.4

5 Communication Communication joints are classified as Straight Joint, Point Appendix

Joint Tee Joint, Cable End, Pot End, SUBS, Issue, LV A.1.5

compartments, Marshalling Box, Hood Enclosure

and FC Joint

6 DuctEdge Electrical conduit may be made of metal, concrete, Line Appendix

plastic, fiber, or fired clay A.1.6

7 Dynamic In addition to opening when a fault is detected, Point Appendix

ProtectiveDevice dynamic protective devices also reclose to attempt to A.1.7

reestablish service. If the fault remains after a

prescribed number of reclosings, the device may lock

open the circuit. Reclosing is designed to reduce or

eliminate the effects of temporary faults.

8 Fuse An essential component in fuse is a metal wire or strip Point Appendix

that melts when too much current flows through it, A.1.8

interrupting the circuit that it connects. Short circuits,

overloading, mismatched loads, or device failure are

the prime reasons for excessive current

9 Generator Mostly Kahramaa generator is an alternative power Point Appendix

source feeding into the electrical network or in some A.1.9

cases customer generator is an alternative source

Issue : 3 07/09/2020 Unclassified Page 16 of 119

Field Survey & As-built Submittal Guidelines

# Feature Class / Layer Description Feature Attribute

Layer Name Type Requirement

10 Instrument Current transformer is used to measure the current Point Appendix

Transformer drawn/ supplied by the transformer. The measured A.1.10

current helps to know the load of transformer and it is

also used to protect the transformer from various

faults like overloading, ground fault, for operating

differential protection relay etc. It also provides

isolation between power and control circuit.

Potential transformer is used to reduce the voltage of

primary/ secondary side of transformer. This reduced

voltage is used for both measurement and protection

purposes. PT also provides isolation between power

circuit

11 LVJoint Low voltage joints are installed for continuity, routing, Point Appendix

transforming and terminating underground cables or A.1.11

overhead lines

12 LVOverheadLine Low voltage overhead lines and connected with Line Appendix

Fuse, Joints and Switches along the network path A.1.12

and on pole location, connected to fuse and Busbar

13 LVUnderGround Low voltage underground cables connected to LV Line Appendix

Cable side of the substation and to end connections A.1.13

14 Motor Motor asset Point Appendix

A.1.14

15 MVJoint Medium voltage joints are installed for establishing Point Appendix

continuity, routing, transforming and terminating A.1.15

medium voltage underground cables or medium

voltage overhead lines

16 MVOverheadLine Each Medium voltage overhead lines connected with Line Appendix

Fuse, Joints and Switches along the network path A.1.16

and on pole location fuses, transformers, switches

and busbar enclosed on pole and is named as PMT

station

17 MVUnderGround Medium voltage underground cables are connected Line Appendix

Cable with joints along the network path and at substation A.1.17

location, connected to dynamic protective devices

and switches

18 Pole Overhead structures, such as poles, H-frames, and Point Appendix

towers, vary in material, height, and guying and/or A.1.18

bracing requirements based on the combination of

anticipated vertical and horizontal loads.

Issue : 3 07/09/2020 Unclassified Page 17 of 119

Field Survey & As-built Submittal Guidelines

# Feature Class / Layer Description Feature Attribute

Layer Name Type Requirement

19 ReactivePower Reactive Power Compensators are classified as Point Appendix

Compensator Capacitor Bank and Shunt reactor. A.1.19

A Capacitor Bank is a group of several capacitors of

the same rating that are connected in series or

parallel with each other to store electrical energy .

The resulting bank is then used to counteract or

correct a power factor lag or phase shift in an

alternating current (AC) power supply.

A shunt reactor is an absorber of reactive power, thus

increasing the energy efficiency of the system

20 ServicePoint A service point can have one or many meters Point Appendix

A.1.20

21 SSCable SS cables connect to transformers, switches and Line Appendix

generators, they are usualy within a substation A.1.21

22 Substation Distribution stations include primary feeders (medium Polygon Appendix

voltage cables), transformers and Low voltage A.1.22

feeders (overhead or underground) that serve a

specified area. Distribution substations operate at 11

to 33 kV and usually have a number of three-phase

feeders off which branch lines, or low voltage cables

are tapped to deliver power to residences, stores,

garages, and other loads

23 Switch Switches may act as tie devices, which are set in an Point Appendix

open state and energized from two directions at A.1.23

once. Switches can be manually or power operated

and can be operated individually or as a group

24 Terminator Terminators are Junction boxes are used in Point Appendix

substation switchyards provided with Terminal A.1.24

Blocks to which control cables are connected

25 Transformer Distribution transformers convert electrical energy Point Appendix

from primary voltages to utilization voltages i.e. from A.1.25

33/11 kv to 415/240 Volts

26 Issue Issues are marked in data for future reference and Point Appendix

resolving them. like connectivity mismatch, cables A.1.26

missing, inspection reports not found and so on. It

can be used when assets are not included in the

submission too like being available in the existing

network.

Table 5: Electric Distribution Feature Classes / Layers

Issue : 3 07/09/2020 Unclassified Page 18 of 119

Field Survey & As-built Submittal Guidelines

# Feature Class / Layer Description Feature Attribute

Layer Name Type Requirement

1 T_Busbar Transmission Busbars are classified based on the Line Appendix

voltage levels. Besides, a Busbar Category field is A.1.27

available to classify it based on station types

2 T_CircuitBreaker Transmission circuit breaker Point Appendix

A.1.28

3 T_Communication Communication cables are classified as Telemetry, Line Appendix

Cable Pilot Cable and Earthing cables A.1.29

4 T_Communication Communication joints are classified as Straight Point Appendix

Joint Joint, Tee Joint, Cable End, Pot End, SUBS, Issue, A.1.30

LV compartments, Marshalling Box, Hood

Enclosure and FC Joint

5 T_DuctEdge Electrical conduit may be made of metal, concrete, Line Appendix

plastic, fiber, or fired clay A.1.31

6 T_Generator Mostly Kahramaa generator is an alternative power Point Appendix

source feeding into the electrical network or in some A.1.32

cases customer generator is an alternative source

7 T_Joint Transmission voltage joints are installed for Point Appendix

continuity, routing, transforming and terminating A.1.33

underground cables or overhead lines

8 T_OverheadLine Transmission overhead lines and connected with Line Appendix

circuit breakers, Joints and Switches along the A.1.34

network path and on tower location

9 T_Reactor Reactor device asset Point Appendix

A.1.35

10 T_SSCable Transmission Substations internal cables connect to Line Appendix

transformers, switches and reactors, they are A.1.36

usually within the substation

11 T_Substation Transmission stations include transmission feeders, Polygon Appendix

transformers, switches & circuit breakers A.1.37

12 T_Switch Switches may act as tie devices, which are set in an Point Appendix

open state and energized from two directions at A.1.38

once.

13 T_Tower Overhead structures, vary in material, height, and Point Appendix

guying and/or bracing requirements based on the A.1.39

combination of anticipated vertical and horizontal

loads.

14 T_Transformer Transmission transformers convert electrical energy Point Appendix

from tranmission voltages to primary voltages A.1.40

15 T_UGCable transmission underground cables Line Appendix

A.1.41

Table 6: Electric Transmission Feature Classes / Layers

Issue : 3 07/09/2020 Unclassified Page 19 of 119

Field Survey & As-built Submittal Guidelines

7.1.4 Water Feature Classes / Layers

# Feature Class / Layer Description Feature Attribute

Layer Name Type Requirement

1 AirValve Air Valve allows the release of air in the system, Point Appendix

through a closed throttle plate, permitting the A.2.1

system to idle

2 CasingProtection Casing Protection is a type of the Protection Line Appendix

Structures that that surrounds or encloses a A.2.2

water line in order to protect it from physical

damage or contamination

3 ChlorinationPoint Chlorination Point is the point within a Point Appendix

Chlorination Station where the sterilization A.2.3

process (Chlorination of water) takes place

4 ControlValve Control Valve is a valve whose flow opening is Point Appendix

controlled by the rate of flow of the fluid through A.2.4

it. It is usually controlled by differential pressure

across an orifice at the valve

5 Distiller Distiller is a water facility in which saline or Point Appendix

brackish water is treated by a process that A.2.5

removes the saline content to produce potable

water for consumption

6 Enclosure An enclosed compartment, built to provide an Polygon Appendix

access to the underground water features or to A.2.6

serve a specific water network function

7 Facility Facilities represent various types of stations for Point Appendix

monitoring network flow A.2.7

8 FieldPressure Field Pressure Check Point is selected point on Point Appendix

CheckingPoint a water line to check its pressure A.2.8

9 Fitting Fittings are points that represent the location and Point Appendix

the mechanism that two or more pipes are A.2.9

connected together

10 GravityChannel Gravity Channel is a conduit or water course Line Appendix

carrying water flowing under gravity A.2.10

11 GravityPipe Gravity Pipes are mainly related with the Line Appendix

transportation of water from tanks to other A.2.11

destinations through the use of gravity

12 Hydrant Hydrant is a water facility installed on the Point Appendix

distribution system as a fire fighting mechanism. A.2.12

In addition, hydrants are also being used to

sample, drain, and flush the distribution network

as per requirement

Issue : 3 07/09/2020 Unclassified Page 20 of 119

Field Survey & As-built Submittal Guidelines

13 IWPP_Out Represents the outflow point from the Integrated Point Appendix

Water and Power Plant used for desalination and A.2.13

electricity generation

14 Manhole Cover plates for holes made for accessing, Polygon Appendix

inspecting, and maintaining the network utilities A.2.14

15 MarkerPlate Marker plate is plaque mounted onto a Point Appendix

permanent structure adjacent to the route of a A.2.15

water pipe. It identifies the location of a buried

water feature

16 Meter Meter is a water facility installed on the pipeline Point Appendix

network that measures the amount of water A.2.16

flowing

17 Miscellaneous Line Miscellaneous line FC contains any feature that Line Appendix

is considered essential to the daily work A.2.17

procedures and must be presented

geographically on the map. I.E: Fiber Optic

Network for communication

18 Miscellaneuos Point This feature class contains point features Point Appendix

necessary for daily work procedures that should A.2.18

be represented on the map geographically

19 Miscellaneuos The Miscellaneous Polygon FC contains any Polygon Appendix

Polygon feature that is considered essential to the daily A.2.19

work procedures and must be presented

geographically on the map

20 PipeElevation The Pipe Elevation point represents the asset Point Appendix

elevation from the sea level A.2.20

21 Pump Pump is a water facility device that inputs energy Point Appendix

to a fluid, thereby raising its hydraulic head A.2.21

22 RM_Source Point feature separating the discharge header in Point Appendix

an RPS from the Rising Main exiting the RPS A.2.22

23 RPS The reservoir and pumping station "RPS" is an Polygon Appendix

enclosed facility where the water structures are A.2.23

maintained

24 RPS_Inlet A virtual point feature representing the limit Point Appendix

between the watermain entering the RPs and the A.2.24

TankIn

25 RoPlant RO (Reverse Osmosis) Plant is a complex or Point Appendix

facility in which saline or brackish water is treated A.2.25

by a process that removes the saline content to

produce potable water for consumption

26 ScadaEquipment A SCADA (Supervisory Control And Data Point Appendix

Acquisition) Sensor is a device installed on the A.2.26

water network components to measure pressure,

Issue : 3 07/09/2020 Unclassified Page 21 of 119

Field Survey & As-built Submittal Guidelines

flow, water level, temperature, water quality

(residual chlorine)

27 ServicePipe Service Pipe is a type of a water conduit that Line Appendix

supplies any customer with water by connecting A.2.27

the customer’s premises with the main network

28 ServiceValve Service Valve is a water facility that is installed Point Appendix

on the service line to control and regulate the flow A.2.28

of water in the distribution system

29 StoragePoint Storage Point is water facility for storing large Point Appendix

amounts of potable water A.2.29

30 SurgeTank Surge Tank is a device used to absorb sudden Point Appendix

pressure increases and to furnish water quickly A.2.30

during a drop in pressures in the water

distribution system. To avoid sudden rises of

pressure within the system, the water is let into

the tank through a pressure valve

31 SystemValve System Valve is water facility that is installed on Point Appendix

the distribution line to control and regulate the A.2.31

flow of water in the distribution system. A System

Valve can be used to manipulate flows and

pressures throughout the distribution system by

partially opening and closing its mechanism

32 TankerFillingPoint Tanker Filling Point is an outlet situated above Point Appendix

ground and connected to the water network A.2.32

whose purpose is to replenish tanker trucks with

water

33 ThrustBlock Thrust Block is a type of Point Protection that is Point Appendix

used to prevent pipe movement. Thrust blocks A.2.33

are usually made of concrete that are placed at

bends and around valve structures

34 VirtualLines Virtual Lines features used to connect the TankIn Line Appendix

line to the TankOut line through storage points in A.2.34

the reservoir

35 WServiceConnection A Water Service Connection is at the end of a Point Appendix

service line representing the water supply A.2.35

location from the distribution network to the

consumer.

The WServiceConnection is linked to the Meter

Information for the retrieval of the end-customer

meter information

36 WaterFaciltiy Water Facility is a type of Water Feature that Polygon Appendix

consists of large features that are used to house A.2.36

Issue : 3 07/09/2020 Unclassified Page 22 of 119

Field Survey & As-built Submittal Guidelines

or logically group other equipment in the water

system

37 WaterMain Water Main is a type of distribution pipe that Line Appendix

transports the water from the source to the sector A.2.37

mains and primarily runs along major roads and

supplies water to several sectors

38 Well A well is a man-made structure that facilitates the Point Appendix

extraction and pumping of water from natural A.2.38

aquifers

Table 7: Water Feature Classes / Layers

Issue : 3 07/09/2020 Unclassified Page 23 of 119

Field Survey & As-built Submittal Guidelines

7.1.5 Connectivity and integrity

The GIS system provides proper tools to control the features creation and population

(drawings) and provide the editor with strong tools to maintain the surveyed/collected

data.

Firstly, the two schema are powered with geometric network that contains predefined

connectivity rules to facilitate the data population while maintaining feature connectivity

integrity.

The connectivity rules are listed in Appendix B – Connectivity Rules to this document.

In the other hand, user will be selecting the fields attribute values from predefined data

when applicable to the type of the target field to eliminate the human spelling errors.

The predefined domain lists are listed in Appendix A – Data Requirements to this

document.

The templates for Water or Electrical submissions will be delivered by Kahramaa to the

contractors or can be found and downloaded from Kahramaa contractor portal.

The contractor will also receive basic QC tools to be installed on top of ESRI ArcGIS

software to validate the deliverable prior submission.

Organize Data by CAD Objects

When drafting any object for any given area, for example, one can decide to draw all

these objects in a single CAD layer. However, these objects may represent the different

type of objects (Joints, Switches, Transformers, Cables, Valves, Fittings, Pipes…)

representing Kahramaa Networks (Electricity & Water).

Thus, the need to distinguish between all of these different types of objects will

necessitate placing each type in its own layer which is defined to capture the spatial

information (location) and attribute information of each feature asset.

KAHRAMAA requires the use of different layers for each of these objects in order to have

a structured and organized CAD drawing. During the automated conversion, a migration

tool will load each layer to its corresponding feature in the related Geodatabase schema

structure along with the attributes of each object/feature.

The required layers are defined in the following matrix tables. It is crucial to note that the

AutoCAD Layer Names supplied in these tables must be followed and as such must not

Issue : 3 07/09/2020 Unclassified Page 24 of 119

Field Survey & As-built Submittal Guidelines

be changed. The contractor can use the templates as the basis of his network drawings

and may choose to add any other layers he/she feels are needed; however, only the

layers listed in the following tables will be converted into KAHRAMAA GIS Networks, any

additional layers will be disregarded and advised to be removed prior submission.

Please refer to Appendix A – Data Requirements for the required data in the submissions

and for their definitions.

7.2.1 AutoCAD Tools

A tool is developed to enable using the XRecords technology to integrate the CAD and

GIS data in simple and easily tools. XRecords tools provide a user-friendly interface to

set and store values every CAD object that the user drafts to have it integrated and loaded

into Kahramaa Enterprise GIS database.. Thus, the drawing and the related attributes of

each object in the drawing will be stored in a single CAD File. The tool named “CAD Tool”

provides a simple interface to the XRecord CAD including the needed attributes of each

object, as well as its subtype and domains for pickup predefined values.

For any Drawings submission, strictly the AutoCAD tools should be used to

populate the drawings, the submission will fail and rejected automatically through

the system if otherwise.

7.2.2 Terms of Use

The CAD Tool may be used for the ad hoc reasons provided by KAHRAMAA. However,

copying, distributing, recompiling, or reproducing the tool, or any portion thereof, in any

form or medium whatsoever, may be done only with specific written permission from

KAHRAMAA.

A custom layer named ‘Config’ is created with a single feature to hold the information of

the exported layers from ArcMap.

Note: “Config” layer and its feature shall not be edited/deleted as this may corrupt the

drawing file and the submission subsequently.

Issue : 3 07/09/2020 Unclassified Page 25 of 119

Field Survey & As-built Submittal Guidelines

7.2.3 Installing the CAD Tools (CAD GIS Integration)

The XRecords Tools (CAD Tools) Setup file will be provided with the CAD Drawings

Submittal Guidelines Document; it is also accessible for contractors to download from the

contractor’s portal.

Contractors are asked to follow the outlined procedure to setup the tools on their systems:

1. Install the tools by following the simple setup wizard steps

Figure 4: Installing the CAD Tools (CAD GIS Integration)

Open the AutoCAD template file obtained from the GIS section or from the

contractor portal.

If necessary, click ‘Load’ button if the below window opens up while opening

the CAD file.

2. Once loaded, the tools will be accessible from any AutoCAD drawing file, however,

are only compatible with the AutoCAD Layer naming convention specified in the

associated Electrical Distribution.

It is very important to keep the layer names as specified in order for the tools

to function otherwise submission will be rejected.

Additional layers can be created, but will not be accessible by the tools and

as such will not be converted into KAHRAMAA GIS.

3. Editing tools are available in ‘As-Built GIS as indicated below:

Issue : 3 07/09/2020 Unclassified Page 26 of 119

Field Survey & As-built Submittal Guidelines

Figure 5: XRecords CAD Tools - AutoCAD

7.2.4 Working with the CAD Tools

Load Colors

This tool is used to load the corresponding symbology from the symbology set for the

layer in ArcMap GIS. Custom symbology is not supported. This tool can be triggered by

the user after the startup of the AutoCAD Template file; it reads from the Config layer

mentioned in the section above. Do not alter this layer file.

Enter LC command or click ‘Load Colors’ for loading the color property and setting the

default symbol for point.

Figure 6: CAD Tools - Load Colors (Symbology) tool

Create Feature

This tool helps the CAD user to create new features in a selected layer following the below

steps:

1. Select the layer in which the feature has to be created.

Issue : 3 07/09/2020 Unclassified Page 27 of 119

Field Survey & As-built Submittal Guidelines

Figure 7: CAD Tools - Select Layer

2.

Issue : 3 07/09/2020 Unclassified Page 28 of 119

Field Survey & As-built Submittal Guidelines

Figure 8: CAD Tools - Create Feature tool

Attribute Editor

This tool is used to edit the attributes of a selected feature objects in the drawing as

follows:

1.

2.

Figure 9: CAD Tools - Attribute Editor tool

Issue : 3 07/09/2020 Unclassified Page 29 of 119

Field Survey & As-built Submittal Guidelines

3.

4.

Copy Attributes

This tool is used to copy attributes from the source feature to a destination feature to

share the same attributes that are repetitive with the other feature objects. This tool is

applicable between feature objects of the same layer.

1.

2.

3.

4.

5.

6.

7.2.5 AutoCAD Drafting Rules

While drafting features in CAD drawings, contractors are asked to follow the specifications

and drafting rules hereafter. The examples given are meant to be indicative of the desired

drawing methods and drafting rules to be followed and, as such, do not cover all the

drawing cases.

Split the Line feature (pipe, cable…) at the connection to a Point feature (joint, switch,

valve, fitting except Ferrule/Tap/Saddle). This is shown in Figure below.

Figure 10: Split Edge Overview

For the complete connectivity rules and split procedures, please refer to Appendix B –

Connectivity Rules in this document.

7.2.6 Consistent Geometry

Contractors are expected to create all objects with a single data system using a consistent

geometric type. For example, when drawing linear overhead lines, only use linear features

Issue : 3 07/09/2020 Unclassified Page 30 of 119

Field Survey & As-built Submittal Guidelines

and avoid using objects that will be interpreted by ArcGIS as points or areas. The previous

tables outline the geometric type for each layer in the column "Feature Type".

7.2.7 Symbology

An essential factor in the CAD Specifications is the type of the objects to be drawn in the

specified layers. Thus, contractors should not create a point symbol using crossed lines,

or combinations of crossed lines and circles because the symbol will be interpreted as

two lines or two lines and a polygon, instead of a simple point. As an example, drawing a

polyline in a layer with “point” feature type is restricted. Since popular point objects are

drawn in CAD as shapes that represent those objects, the CAD Specifications accept

shapes in case they are of type point. The figure below shows the different types of the

same shape, where the first shape (on the left) is of type polyline (and as such has more

than one point, 4 points) while the second shape (on the right), which is the one to be

followed, is of type point.

Figure 11: Sample of Acceptable Point Symbology

In addition, the use of built-in symbols from AutoCAD’s list of point styles for point symbols

is acceptable. The point style library in AutoCAD 2010 or later is displayed, as an

example, Figure below:

Issue : 3 07/09/2020 Unclassified Page 31 of 119

Field Survey & As-built Submittal Guidelines

Figure 12: Point Style Library in AutoCAD

Moreover, a line object (cable or pipe) should be represented in CAD as a single line in

the centerline of the feature asset. This means that it is not allowed to draw two parallel

lines to show the width.

Contractors are also free to place any symbology they need the CAD file, as long as the

point representing the feature to be imported into GIS is in its associated Point Layer.

7.2.8 Snapping

Contractors are expected to connect lines at their intersections using Snapping Tools and

in accordance with the AutoCAD Drafting Rules listed in the following section of this

document. For example, when drawing a pipe, all pipes should be snapped together at

their edges with the point feature (valve, fitting …) to ensure that they are going to be

snapped in ArcGIS, otherwise the flow of water will stop at any unsnapped location.

Refer to the connectivity rules supplied in Appendix B – Connectivity Rule

7.2.9 Polygon Representation

To represent a Polygon, create closed polygons using AutoCAD snapping and closed

polylines, since this need to be interpreted as areas by GIS.

Issue : 3 07/09/2020 Unclassified Page 32 of 119

Field Survey & As-built Submittal Guidelines

7.2.10 Dimensions

Dimension text size should be 2.5.

All arrow heads should be OPEN 30.

All text size should be of size 2.5, 3.5, 5.0 or 7.0mm of paper space in the

drawing area.

Issue : 3 07/09/2020 Unclassified Page 33 of 119

Field Survey & As-built Submittal Guidelines

Appendix A - Data Requirements

A.1 Electric Network Features Attributes

The following list shows which attributes should be available for a specific electric layer –

the list remains the same if using the Geodatabase schema or the AutoCAD templates:

A.1.1 BPL Attributes

Field Name Field Description Type Domain

OPERATINGVOLTAGE Operating Voltage Integer

MANUFACTURER Manufacturer String

MANUFACTURINGYEAR Manufacturing Year Integer Manufacturing Year

INSTALLATIONDATE Installation Date Date

Table 8: BPL Attributes

A.1.2 CableDepth Attributes

Field Name Field Description Type Domain

BOOKREFERENCE Book Reference String

DEPTH Material Integer

CONTRACTNO Contract Number String

CONTRACTOR Contractor String

Table 9: CableDepth Attributes

A.1.3 Busbar Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

MATERIAL Material String UG Material

MANUFACTURER Manufacturer String

INSULATIONTYPE Insulation Type String

BUSBARCATEGORY Busbar Category Integer Busbar Category

Type Type String Busbar CatType

Table 10: Busbar Attributes

A.1.4 CommunicationCable Attributes

Field Name Field Description Type Domain

SubtypeCD Subtype Integer

CABLETYPE Cable Type String Cable Type

CONTRACTNO Contract Number String

CONTRACTOR Contractor String

NUMOFFIBERCOURSES Number Of Fiber Courses Integer T_CommunicationCapacity

Issue : 3 07/09/2020 Unclassified Page 34 of 119

Field Survey & As-built Submittal Guidelines

CORESFREE Number Of Free Cores String

CORESUSED Number Of Used Cores String

LINKDESTINATION Link Destination String

LINKNUMBER Link Number String

LINKSOURCE Link Source String

Table 11: CommunicationCable Attributes

A.1.5 CommunicationJoint Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

CONTRACTNO Contract Number String

CONTRACTOR Contractor String

JOINTERNAME Jointer Name String

JOINTSIZE Joint Size Integer Conductor Size

Table 12: CommunicationJoint Attributes

A.1.6 DuctEdge Attributes

Field Name Field Description Type Domain

AVAILABLEINDICATOR Available Indicator String Yes/No Indicator

DUCTTYPE Duct Type String Duct Type

MATERIAL Material String UG Structure Material

DUCTNUMBER Duct Number Integer

PROJECTNAME Project Name String

CONTRACTNO Contract Number String

CONTRACTOR Contractor String

DIAMETER Diameter Integer UG Pipe Size

DEPTH Depth Double

Table 13: DuctEdge Attributes

A.1.7 DynamicProtectiveDevice Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

MANUFACTURER Manufacturer String

CURRENTSTATUS Current Status Integer Present Status

MANUFACTURINGYEAR Manufacturing Year Integer Manufacturing Year

SERIALNUMBER Serial Number String

SCADACONTROLID Scada Control ID String

SCADAMONITORID Scada Monitor ID String

Table 14: DynamicProtectiveDevice Attributes

Issue : 3 07/09/2020 Unclassified Page 35 of 119

Field Survey & As-built Submittal Guidelines

A.1.8 Fuse Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

CURRENTSTATUS Current Status Integer Present Status

NUMBEROFCUTOUTS Number Of Cutouts Integer

SERIALNUMBER Serial Number String

Table 15: Fuse Attributes

A.1.9 Generator Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

KW kW Integer

MANUFACTURER Manufacturer String

Manufacturing

MANUFACTURINGYEAR Manufacturing Year Integer

Year

SERIALNUMBER Serial Number String

MAXREACTIVEGENERATION Max Reactive Generation Integer

POSITIVESEQUENCEREACTANC

Positive Sequence Reactance double

E

POSITIVESEQUENCERESISTAN

Positive Sequence Resistance double

CE

Table 16: Generator Attributes

A.1.10 Instrument Transformer Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

MANUFACTURER Manufacturer String

MANUFACTURINGYEAR Manufacturing Year Integer Manufacturing Year

CTRATIO CT Ratio String CTRatio

METERNUMBER Meter Number String

VTRATIO VT Ratio String

Table 17: Instrument Transformer Attributes

A.1.11 LVJoint Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

MANUFACTURER Manufacturer String

MANUFACTURINGYEAR Manufacturing Year Integer Manufacturing Year

CONTRACTNO Contract Number String

CONTRACTOR Contractor String

JOINTERNAME Jointer Name String

Issue : 3 07/09/2020 Unclassified Page 36 of 119

Field Survey & As-built Submittal Guidelines

JOINTTYPE Joint Type String Joint Type

JOINTINGMETHOD Jointing Method String JointingType

Table 18: LVJoint Attributes

A.1.12 LVOverheadLine Attributes

Field Name Field Description Type Domain

SubtypeCD Subtype Integer

MATERIAL Material String LV OH Material

CONDUCTORSIZE Conductor Size Integer Conductor Size

MANUFACTURER Manufacturer String Conductor Manufacturer

CONTRACTNO Contract Number String

CONTRACTOR Contractor String

CONDUCTORCONFIGURATION Conductor Configuration String Conductor Configuration

Table 19: LVOverheadLine Attributes

A.1.13 LVUnderGroundCable Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

MATERIAL Material String UG Material

CONDUCTORSIZE Conductor Size Integer Conductor Size

Manufacturer Manufacturer String Conductor Manufacturer

INSULATIONMATERIAL Insulation Material String ElectricInsulationType

BURIEDDEPTH BURIED Depth Double

INCONDUITINDICATOR IN Conduit Indicator String Yes/No Indicator

BACKFILLMATERIAL Backfill Material String Backfill Material

CONTRACTNO Contract Number String

CONTRACTOR Contractor String

Table 20: LVUnderGroundCable Attributes

A.1.14 Motor Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

MANUFACTURER Manufacturer String

MANUFACTURINGYEAR Manufacturing Year Integer Manufacturing Year

RATEDSPEED Rated Speed Integer

RATEDPOWER Rated Power Integer

RATEDEFFICIENCY Rated Efficiency double

RATEDPOWERFACTOR Rated Power Factor double

STARTINGMODE Starting Mode String MotorStartingMode

STARTINGCURRENTRATIO Starting Current Ratio Integer

Table 21: Motor Attributes

Issue : 3 07/09/2020 Unclassified Page 37 of 119

Field Survey & As-built Submittal Guidelines

A.1.15 MVJoint Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

MANUFACTURER Manufacturer String

MANUFACTURINGYEAR Manufacturing Year Integer Manufacturing Year

CONTRACTNO Contract Number String

CONTRACTOR Contractor String

JOINTERNAME Jointer Name String

JOINTTYPE Joint Type String Joint Type

JOINTINGMETHOD Jointing Method String JointingType

Table 22: MVJoint Attributes

A.1.16 MVOverheadLine Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

Material Material String MV OH Material

CONDUCTORSIZE Conductor Size Integer Conductor Size

Conductor

MANUFACTURER Manufacturer String

Manufacturer

MANUFACTURINGYEAR Manufacturing Year Integer Manufacturing Year

CONTRACTNO Contract Number String

CONTRACTOR Contractor String

Conductor

CONDUCTORCONFIGURATION Conductor Configuration String

Configuration

Table 23: MVOverheadLine Attributes

A.1.17 MVUnderGroundCable Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

MATERIAL Material String UG Material

CONDUCTORSIZE Conductor Size Integer Conductor Size

Manufacturer Manufacturer String Conductor Manufacturer

INSULATIONMATERIAL Insulation Material String ElectricInsulationType

BURIEDDEPTH Buried Depth Double

INCONDUITINDICATOR In Conduit Indicator String Yes/No Indicator

BACKFILLMATERIAL Backfill Material String Backfill Material

CONTRACTNO Contract Number String

CONTRACTOR Contractor String

Table 24: MVUnderGroundCable Attributes

Issue : 3 07/09/2020 Unclassified Page 38 of 119

Field Survey & As-built Submittal Guidelines

A.1.18 Pole Attributes

Field Name Field Description Type Domain

SubtypeCD Subtype Integer

Material Material String Pole Material

ANCHORGUYCOUNT Anchor Guy Count Integer

MANUFACTURER Manufacturer String

CONTRACTNO Contract Number String

CONTRACTOR Contractor String

EARTHINGSWITCHIND Earthing Switch Indicator String Yes/No Indicator

Table 25: Pole Attributes

A.1.19 ReactivePowerCompensator Attributes

Field Name Field Description Type Domain

Subtype SUBTYPECD Integer

MANUFACTURER Manufacturer String

MANUFACTURINGYEAR Manufacturing Year Integer Manufacturing Year

GROUNDREACTANCE Ground Reactance double

GROUNDRESISTANCE Ground Resistance double

TOTALKVAR Total kVAR Integer

INSTALLATION Installation String InstallationLocation

CONNECTIONMETHOD Connection Method String ConnectionMethod

VOLTAGERANGE Voltage Range Integer

TECHNOLOGY Technology String ReactiveCompensatorProtection

RatedVoltage Rated Voltage Double

Type Type String ReactivePowerCompensatorType

NUMBEROFSTAGES Number Of Stages Integer

Table 26: ReactivePowerCompensator Attributes

A.1.20 ServicePoint Attributes

Field Name Field Description Type Domain

SubtypeCD Subtype Integer

MANUFACTURER Manufacturer String

NUMBEROFCUSTOMERS Number Of Customers Integer

Owner Owner String Ownership

CUTOUTSIZE Cut Out Size Integer CutOutSize

CONTRACTNO Contract Number String

CONTRACTOR Contractor String

MOCNBR MOC Number String

CUSTOMERNO Customer Number String

Table 27: ServicePoint Attributes

Issue : 3 07/09/2020 Unclassified Page 39 of 119

Field Survey & As-built Submittal Guidelines

A.1.21 SSCable Attributes

Field Name Field Description Type Domain

SubtypeCD Subtype Integer

MATERIAL Material String UG Material

CableSize Cable Size Integer SS Conductor Size

INSULATIONMATERIAL Insulation Material String ElectricInsulationType

CONTRACTNO Contract Number String

Table 28: SSCable Attributes

A.1.22 Substation Attributes

Field Name Field Description Type Domain

STATIONNUMBER Station Number String

STATIONNAME Station Name String

VOLTAGERATIO Voltage Ratio Integer Voltage Ratio

VIPINDICATOR VIP Indicator String Yes/No Indicator

LOCATIONTYPE Location Type String Structure Location Type

CONTRACTNO Contract Number String

CONTRACTOR Contractor String

Owner Owner String Ownership

CONSUMERTYPE Consumer Type String Consumertype

SUBSTATIONTYPE Substation Type String SubstationType

Table 29: Substation Attributes

A.1.23 Switch Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

MANUFACTURER Manufacturer String

MANUFACTURINGYEAR Manufacturing Year Integer Manufacturing Year

INSTALLATIONDATE Installation Date Date

JOINTDATE Jointing Date Date

JOINTERNAME Jointer Name String

CONTRACTNO Contract Number String

CONTRACTOR Contractor String

OPERATINGVOLTAGE Operating Voltage Integer Operating Voltage

STATIONNUMBER Station Number String

Table 30: Switch Attributes

A.1.24 Terminator Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

BOOKREFERENCE Book Reference String

Issue : 3 07/09/2020 Unclassified Page 40 of 119

Field Survey & As-built Submittal Guidelines

CONTRACTNO Contract Number String

CONTRACTOR Contractor String

JOINTERNAME Jointer Name String

INSTALLATIONDATE Installation Date Date

Table 31: Terminator Attributes

A.1.25 Transformer Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

TAGNUMBER Tag Number Integer TX Tag No

RATEDKVA Rated KVA Integer Transformer Rated KVA

METERNO Meter Number String

MANUFACTURER Manufacturer String

MANUFACTURINGYEAR Manufacturing Year Integer Manufacturing Year

SERIALNUMBER Serial Number String

LOWSIDEVOLTAGE Low Side Voltage Integer Low Side Voltage

COOLINGTYPE Cooling Type String TransformerCoolingType

CONTRACTNO Contract Number String

HIGHSIDEVOLTAGE High Side Voltage Integer High Side Voltage

Table 32: Transformer Attributes

A.1.26 Issue Attributes

Field Name Field Description Type Domain

Related Feature class

FEATURECLASSNAME String

name

Remarks Issue Remarks String

Table 33: Issue Attributes

A.1.27 T_Busbar Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

MATERIAL Material String UG Material

MANUFACTURER Manufacturer String

INSTALLATIONDATE Installation Date Date

MANUFACTURINGYEAR Manufacturing Year Integer Manufacturing Year

VOLTAGE Voltage Integer Transmission Voltage

STATIONNUMBER SS Number String

SERIALNUMBER Asset Serial Number String

Table 34: T_Busbar Attributes

Issue : 3 07/09/2020 Unclassified Page 41 of 119

Field Survey & As-built Submittal Guidelines

A.1.28 T_CircuitBreaker Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

MANUFACTURER Manufacturer String

INSTALLATIONDATE Installation Date Date

MANUFACTURINGYEAR Manufacturing Year Integer Manufacturing Year

VOLTAGE Voltage Integer Transmission Voltage

STATIONNUMBER SS Number String

SERIALNUMBER Asset Serial Number String

Table 35: T_CircuitBreaker Attributes

A.1.29 T_CommunicationCable Attributes

Field Name Field Description Type Domain

SubtypeCD Subtype Integer

CABLETYPE Cable Type String T_Cable Type

CONTRACTNO Contract Number String

CONTRACTOR Contractor String

NUMOFFIBERCOURSES Number Of Fiber Courses Integer T_CommunicationCapacity

CORESFREE Number Of Free Cores String

CORESUSED Number Of Used Cores String

LINKDESTINATION Link Destination String

LINKNUMBER Link Number String

LINKSOURCE Link Source String

INSTALLATIONDATE

Table 36: T_CommunicationCable Attributes

A.1.30 T_CommunicationJoint Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

CONTRACTNO Contract Number String

CONTRACTOR Contractor String

JOINTERNAME Jointer Name String

Table 37: T_CommunicationJoint Attributes

A.1.31 T_DuctEdge Attributes

Field Name Field Description Type Domain

AVAILABLEINDICATOR Available Indicator String Yes/No Indicator

DUCTTYPE Duct Type String Duct Type

MATERIAL Material String UG Structure Material

DUCTNUMBER Duct Number Integer

CONTRACTNO Contract Number String

Issue : 3 07/09/2020 Unclassified Page 42 of 119

Field Survey & As-built Submittal Guidelines

CONTRACTOR Contractor String

DIAMETER Diameter Integer UG Pipe Size

DEPTH Depth Double

Table 38: T_DuctEdge Attributes

A.1.32 T_Generator Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

KW kW Integer

MANUFACTURER Manufacturer String

Manufacturing

MANUFACTURINGYEAR Manufacturing Year Integer

Year

SERIALNUMBER Serial Number String

MAXREACTIVEGENERATION Max Reactive Generation Integer

POSITIVESEQUENCEREACTANC

Positive Sequence Reactance double

E

POSITIVESEQUENCERESISTAN

Positive Sequence Resistance double

CE

Table 39: T_Generator Attributes

A.1.33 T_Joint Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

MANUFACTURER Manufacturer String

MANUFACTURINGYEAR Manufacturing Year Integer Manufacturing Year

PROJECTNUMBER Project Number String

VOLTAGE Voltage String Transmission Voltage

INSTALLATIONDATE Installation Date Date

JOINTINGMETHOD Jointing Method String JointingType

SERIALNUMBER Asset Serial Number String

Table 40: T_Joint Attributes

A.1.34 T_OverheadLine Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

MATERIAL Material String T_ConductorMaterial

VOLTAGE Voltage Integer Transmission Voltage

CONDUCTORSIZE Conductor Size Integer T_OH_Size

T_CableConductorMa

MANUFACTURER Manufacturer String

nufacturer

MANUFACTURINGYEAR Manufacturing Year Integer Manufacturing Year

CONNECTIONSOURCE Connection Source String

Issue : 3 07/09/2020 Unclassified Page 43 of 119

Field Survey & As-built Submittal Guidelines

CONNECTIONDESTINATION Connection Destination String

SERIALNUMBER Conductor Configuration String

Table 41: T_OverheadLine Attributes

A.1.35 T_Reactor Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

VOLTAGE Voltage Integer Transmission Voltage

INSTALLATIONDATE Installation Date Date

T_CableConductorMa

MANUFACTURER Manufacturer String

nufacturer

MANUFACTURINGYEAR Manufacturing Year Integer Manufacturing Year

STATIONNUMBER Station Number String

Table 42: T_Reactor Attributes

A.1.36 T_SSCable Attributes

Field Name Field Description Type Domain

SubtypeCD Subtype Integer

MATERIAL Material String UG Material

CableSize Cable Size Integer T_CrossSection

VOLTAGE Nominal Voltage Transmission Voltage

NUMBEROFCABLES Number of Cables Integer

STATIONNUMBER Station Number String

Table 43: T_SSCable Attributes

A.1.37 T_Substation Attributes

Field Name Field Description Type Domain

STATIONNUMBER Station Number String

STATIONNAME Station Name String

VOLTAGERATIO Voltage Ratio Integer T_Voltage Ratio

TOTALCAPACITYMVA Total Capacity MVA Integer

INSTALLATIONDATE Installation Date Date

PROJECTNAME Project Name String

PROJECTNUMBER Project Number String

Table 44: T_Substation Attributes

A.1.38 T_Switch Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

MANUFACTURER Manufacturer String

MANUFACTURINGYEAR Manufacturing Year Integer Manufacturing Year

Issue : 3 07/09/2020 Unclassified Page 44 of 119

Field Survey & As-built Submittal Guidelines

INSTALLATIONDATE Installation Date Date

VOLTAGE Operating Voltage Integer Transmission Voltage

STATIONNUMBER Station Number String

Table 45: T_Switch Attributes

A.1.39 T_Tower Attributes

Field Name Field Description Type Domain

SubtypeCD Subtype Integer

TOWERTYPE Tower Type Date T_OHSType

INSTALLATIONDATE Installation Date Integer

MANUFACTURER Manufacturer String

MANUFACTURINGYEAR Manufacturing Year Integer Manufacturing Year

CONNECTIONSOURCE Connection Source String

CONNECTIONDESTINATION Connection Destination String

MAXCIRCUITSCAPACITY Max.Circuits Capacity Integer T_CircuitsPerLine

SUPPORTSTRUCTURETYPE Support Structure Type String T_OHSupportStructureType

TOWERNO Tower No String

Table 46: T_Tower Attributes

A.1.40 T_Transformer Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

INSTALLATIONDATE Installation Date Date

RATEDKVA Rated KVA Integer T_Transformer Rated KVA

MANUFACTURER Manufacturer String T_CableConductorManufacturer

MANUFACTURINGYEAR Manufacturing Year Integer Manufacturing Year

SERIALNUMBER Serial Number String

LOWSIDEVOLTAGE Low Side Voltage Integer T_Low Side Voltage

Table 47: T_Transformer Attributes

A.1.41 T_UGCable Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

MATERIAL Material String T_ConductorMaterial

VOLTAGE Voltage Integer Transmission Voltage

MANUFACTURER Manufacturer String T_CableConductorManufacturer

MANUFACTURINGYEAR Manufacturing Year Integer Manufacturing Year

SERIALNUMBER Serial Number String

CONDUCTORSIZE Conductor Size Integer T_CrossSection

INSULATIONMATERIAL Insulation Material String T_CableType

BACKFILLMATERIAL Back Fill Material String Backfill Material

CONNECTIONSOURCE Connection Source String

Issue : 3 07/09/2020 Unclassified Page 45 of 119

Field Survey & As-built Submittal Guidelines

CONNECTIONDESTINATION Connection Destination String

Table 48: T_UGCable Attributes

Issue : 3 07/09/2020 Unclassified Page 46 of 119

Field Survey & As-built Submittal Guidelines

A.2 Water Network Features Attributes

The following list shows which attributes should be populated in GIS or CAD applications:

A.2.1 AirValve Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

DIAMETER_MM Diameter (MM) Integer DiameterDomain

MATERIAL Valve Material String ValveMaterialDomain

MANUFACTURER Manufacturer String

ELEVATION Elevation Double

INSTALLATIONDATE Installation Date Date

CWRNUM Contact Work String

Request Number

WONUM Work Order String

Number

CONNECTIONTYPE Connection Type Integer ConnectionTypeDomain

EXTERNALCOATING External Coating Integer ExternalCoatingDomain

INTERNALLINING Internal Lining Integer InternalCoatingDomain

ORIENTATION Orient String OrientationDomain

SURVEYDATE Survey Date Date

Table 49: AirValve Attributes

A.2.2 CasingProtection Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

DIAMETER_MM Diameter (MM) Integer DiameterDomain

MATERIAL Material String WaterMainMaterial

INSTALLATIONDATE Installation Date Date

CWRNUM Work Request String

Number

WONUM Contact Work String

Request Number

PLACEMENT Placement String PlacementDomain

SURVEYDATE Survey Date Date

WIDTH Width (M) Double

Table 50: CasingProtection Attributes

A.2.3 ChlorinationPoint Attributes

Field Name Field Description Type Domain

Issue : 3 07/09/2020 Unclassified Page 47 of 119

Field Survey & As-built Submittal Guidelines

CWRNUM Contact Work String

Request Number

WONUM Work Order Number String

ELEVATION Elevation Double

SURVEYDATE Survey Date Date

INSTALLATIONDATE Installation Date Date

SUBTYPECD Subtype Integer

Table 51: ChlorinationPoint Attributes

A.2.4 Control Valve Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

DIAMETER_MM Diameter (MM) Integer DiameterDomain

MATERIAL Valve Material String ValveMaterialDomain

MANUFACTURER Manufacturer String

ELEVATION Elevation Double

INSTALLATIONDATE Installation Date Date

CWRNUM Contact Work String

Request Number

WONUM Work Order String

Number

CONNECTIONTYPE Connection Type Integer ConnectionTypeDomain

EXTERNALCOATING External Coating Integer ExternalCoatingDomain

INTERNALLINING Internal Lining Integer InternalCoatingDomain

ORIENTATION Orient String OrientationDomain

SURVEYDATE Survey Date Date

MAXIMUMFLOWRATE Maximum Flow Double

Rate

Table 52: Control Valve Attributes

A.2.5 Distiller Attributes

Field Name Field Description Type Domain

CWRNUM Contact Work String

Request Number

WONUM Work Order Number String

ELEVATION Elevation Double

SURVEYDATE Survey Date Date

INSTALLATIONDATE Installation Date Date

DISTILLERNUMBER Distiller Number String

Table 53: Distiller Attributes

Issue : 3 07/09/2020 Unclassified Page 48 of 119

Field Survey & As-built Submittal Guidelines

A.2.6 Enclosure Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

MATERIAL Material String EnclosureMaterialDomain

SHAPE_Length SHAPE_Length Double

INSTALLATIONDATE Installation Date Date

CWRNUM Contract Work String

Request Number

WONUM Work Order String

Number

COVERELEV Cover Elevation Double

COVERMANUFACTURER Cover String

Manufacturer

COVERMATERIAL Cover Material Integer FrameCoverMaterialDomain

COVERSHAPE Cover Shape Integer ChamberCoverShapesDomain

COVERTYPE Cover Type String

SURVEYDATE Survey Date Date

Table 54: Enclosure Attributes

A.2.7 Facility Attributes

Field Name Field Description Type Domain

CWRNUM Contact Work String

Request Number

WONUM Work Order Number String

ELEVATION Elevation Double

SURVEYDATE Survey Date Date

INSTALLATIONDATE Installation Date Date

SUBTYPECD Subtype Integer

Table 55: Facility Attributes

A.2.8 FieldPressureCheckingPoint Attributes

Field Name Field Description Type Domain

SURVEYDATE Survey Date Date

INSTALLATIONDATE Installation Date Date

ACCESSTYPE Access Type String AccessTypeDomain

SIZE_MM Size (MM) Double

DEPTH Depth Double

ELEVATION Elevation Double

Table 56: FieldPressureCheckingPoint Attributes

A.2.9 Fittings Attributes

Field Name Field Description Type Domain

Issue : 3 07/09/2020 Unclassified Page 49 of 119

Field Survey & As-built Submittal Guidelines

SUBTYPECD Subtype Integer

MANUFACTURER Manufacturer String

MATERIAL Material String FittingsMaterial

ANGLE Angle Double

DIAMETER_MM1 Diameter 1 (MM) Integer DiameterDomain

DIAMETER_MM2 Diameter 2 (MM) Integer DiameterDomain

DIAMETER_MM3 Diameter 3 (MM) Integer DiameterDomain

ORIENTATION Orient String OrientationDomain

INSTALLATIONDATE Installation Date Date

CWRNUM Contact Work Request String

Number

ELEVATION Elevation Double

JOINTTYPE Joint Type String JointTypeDomain

SURVEYDATE Survey Date Date

WONUM Work Order Number String

STRAINTYPE Strainer Type String StrainerTypeDomain

Table 57: Fittings Attributes

A.2.10 GravityChannel Attributes

Field Name Field Description Type Domain

CWRNUM Contact Work String

Request Number

WONUM Work Order Number String

SURVEYDATE Survey Date Date

INSTALLATIONDATE Installation Date Date

DIAMETER_MM Diameter (MM) Integer DiameterDomain

Table 58: GravityChannel Attributes

A.2.11 GravityPipe Attributes

Field Name Field Description Type Domain

CWRNUM Contact Work String

Request Number

WONUM Work Order Number String

SURVEYDATE Survey Date Date

INSTALLATIONDATE Installation Date Date

DIAMETER_MM Diameter (MM) Integer DiameterDomain

MATERIAL Material String WaterMainMaterial

Table 59: GravityPipe Attributes

A.2.12 Hydrant Attributes

Field Name Field Description Type Domain

SUBTYPECD Subtype Integer

Issue : 3 07/09/2020 Unclassified Page 50 of 119

Field Survey & As-built Submittal Guidelines

DIAMETER_MM Diameter (MM) Integer DiameterDomain

MATERIAL Material String HydrantMaterial

MANUFACTURER Manufacturer String

ELEVATION Elevation Double

INSTALLATIONDATE Installation Date Date

CWRNUM Contact Work String

Request Number

WONUM Work Order String

Number

EXTERNALCOATING External Coating Integer ExternalCoatingDomain

INTERNALCOATING Internal Coating Integer InternalCoatingDomain

SURVEYDATE Survey Date Date

HOSENOZD Hose Nozzle Integer DiameterDomain

Diameter

PUMPERNOZD Pump Nozzle Integer DiameterDomain

Diameter

SEATVALVED Seat Valve Integer DiameterDomain

Diameter

Table 60: Hydrant Attributes

A.2.13 IWPP_Out Attributes

Field Name Field Description Type Domain

DESALINATIONPLANTNAME Desalination Plant String

Name

Table 61: IWPP_Out Attributes

A.2.14 Manhole Attributes

Field Name Field Description Type Domain

WALLMATERIAL Wall Material Integer WallMaterialDomain

INSTALLATIONDATE Installation Date Date

COVERMATERIAL Cover Material Integer FrameCoverMaterialDomain

COVERSHAPE Cover Shape Integer ChamberCoverShapesDomain

GRADEELEVATION Grade Elevation Double

GRSURFACETYPE Ground Surafce Type String GroundSurfacetypeDomain

WIDTH Width Double

ACCESSDIAMETER_M Access Diameter (M) Double

INVERTLEVEL Invert Level Double

LENGTH Length Double

Table 62: Manhole Attributes

A.2.15 MarkerPlate Attributes

Field Name Field Description Type Domain

Issue : 3 07/09/2020 Unclassified Page 51 of 119