Rig Calibration

Uploaded by

jonathanRig Calibration

Uploaded by

jonathanU

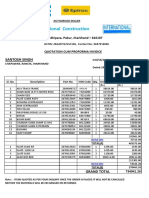

Rig Calibration Tool

Version 2.8

Epiroc Rock Drills AB

No. 9852 2596 01

Version: 2020-06-08

Content

Introduction 1

General ...................................................................................................................................... 1

The Rig Calibration Tool user ................................................................................................. 2

Questions and suggestions ....................................................................................................... 2

Installation 3

System Requirements ............................................................................................................... 3

Installation ................................................................................................................................. 4

License....................................................................................................................................... 5

Program overview 6

System overview ....................................................................................................................... 6

Starting Rig Calibration Tool ................................................................................................... 6

The main window ..................................................................................................................... 7

Menu bar ................................................................................................................................... 7

File .............................................................................................................................. 7

Total station................................................................................................................ 8

Settings ....................................................................................................................... 9

Deploying the Total station .................................................................................................... 12

Operation .................................................................................................................. 12

Rig Calibration Tool ............................................................................................................... 20

Rig Laser .................................................................................................................. 21

Boomer 2 Prisms Calibration .................................................................................. 24

Boomer 3 Prisms Calibration .................................................................................. 27

Boltec/Cabletec/Simba Prisms Calibration ............................................................ 31

Boltec Prisms Calibration ....................................................................................... 45

Scaletec Prisms Calibration .................................................................................... 49

Direction ................................................................................................................... 52

Demo Fixpoint Measure .......................................................................................... 56

Total station Validation ........................................................................................... 58

Total station Calibration .......................................................................................... 61

Deflection ................................................................................................................................ 65

Prerequisites ............................................................................................................. 66

Preparations .............................................................................................................. 66

Boom deflection for BUT32/35 .............................................................................. 69

Boom deflection for BUT45 ................................................................................... 76

Precision .................................................................................................................................. 82

Prerequisites ............................................................................................................. 82

Preparations .............................................................................................................. 82

Scooptram Articulation Angle Measurement ....................................................................... 90

Prerequisites ............................................................................................................. 90

Articulation Angle Measurement ........................................................................... 90

Scooptram Odometer Calibration .......................................................................................... 91

Prerequisites ............................................................................................................. 91

Odometer Calibration .............................................................................................. 91

Scooptram Laser Measurement ............................................................................................. 92

Prerequisites ............................................................................................................. 92

Laser Measurement.................................................................................................. 92

Rig Calibration Tool - User's Manual Content i

Firmware Upgrade .................................................................................................................. 93

Preparation Steps ..................................................................................................... 93

Preparing the CompactFlash (CF) memory card ................................................... 94

Performing the Upgrade .......................................................................................... 95

Index 99

Appendix 1 100

Conventions .......................................................................................................................... 100

General conventions .............................................................................................. 100

Mouse conventions ................................................................................................ 100

Keyboard conventions ........................................................................................... 100

Appendix 2 101

Drill plan file formats ........................................................................................................... 101

Other formats ........................................................................................................................ 101

Rig Calibration Tool - User's Manual Content ii

Introduction

General

Rig Calibration Tool from Epiroc is the support software and hardware

package for configuring, calibrating and controlling the precision of Epiroc drill

rigs.

Rig Calibration Tool consists of a total station, prisms, attachments and a PC

software package.

Figure 1 Rig Calibration Tool components

The Rig Calibration Tool package is intended for internal use and not to be

distributed to external users. For external use, Prism Calibration Tool is

available.

Rig Calibration Tool software package runs on a Windows PC and is

connected to a Leica total station. This Total station is a part of the service

package distributed from Aftermarket department in Örebro, Sweden.

Parts. No. 9106 2419 98.

Rig Calibration Tool - User's Manual Introduction 1

The Rig Calibration Tool user

The Rig Calibration Tool package is solely intended for internal Epiroc

Technical Service use.

This manual assumes that the user has:

- Good knowledge of the Epiroc underground drill rigs, such as Boomer C-

rigs with ABC Regular, ABC Total and/or total station Navigation option,

Boomer D-rigs with FAM3 and of Boltec, Scaletec and Simba C-rigs with

total station Navigation option.

- Basic knowledge of the Microsoft Windows environment.

- Basic knowledge of total stations and measurements.

Questions and suggestions

Questions and suggestions on Rig Calibration Tool are normally directed to

the nearest Epiroc representative.

Rig Calibration Tool - User's Manual Introduction 2

Installation

System Requirements

Rig Calibration Tool software package can only run on Epiroc

must be defined in, and connected to, the Epiroc internal network.

To use Rig Calibration Tool software package you will need:

An Epiroc PC connected to the internal Epiroc network.

A Leica total station, a radio modem, and/or Bluetooth connectability for

the PC.

Prisms and reflectors for the drill rig.

A Rig Calibration Tool license, either on a USB key, on a network

license server, or as an offline license.

A computer with a 1 GHz processor or higher.

A USB port.

512 MB RAM memory minimum, > 1 GB recommended.

Disc space of 50 MB required.

Microsoft Windows Vista, 7 or 10, in 32- or 64-bit mode.

Microsoft Word 2003 or later.

Mouse with two or more buttons.

A Color monitor with a minimum resolution of 1024 x 768.

Rig Calibration Tool - User's Manual Installation 3

Installation

N.B. The Rig Calibration Tool software package can only run on Epiroc

To install the Rig Calibration Tool software package, administration rights for

the computer is required.

Double-click on the setup-file and follow the instructions on screen.

Rig Calibration Tool - User's Manual Installation 4

License

When the Rig Calibration Tool program starts for the first time, it will search

for a license on a hardware key.

If a license cannot be found, a dialog will be displayed, see Figure 2

Figure 2 License missing dialog.

Retry button

Tries to find a valid license. If a hardware key is available, insert it and click this

button.

Server button

Shows the dialog in Figure 3. Check the checkbox, enter a hostname or an IP

address to a license server and click OK. The program will search for a license

on the server and start if a license is found. If no license is found the dialog in

Figure 2 is shown again.

Figure 3 License Server Settings Dialog with an example IP address.

Cancel button

Closes the dialog and shuts down the program.

Rig Calibration Tool - User's Manual Installation 5

Program overview

System overview

The Rig Calibration Tool package consists of:

Rig Calibration Tool software package

USB key with license

total station with battery, battery charger, and tripod

Cable between PC and total station

Radio modem

Reflective tapes and bracket

Round prisms with laser line attachments:

9106 2419 25 001, 9106 2419 26 001

360 Degrees Prism:

9106 2419 10 001

Prism brackets:

9106 2417 60 001,

9106 2257 82 003,

9106 2257 83 003,

9106 2257 84 02,

9106 2257 85 002

Starting Rig Calibration Tool

Rig Calibration Tool is started from the Program folder on the Start Menu or

from the shortcut on the computer desktop. Make sure you insert the USB

hardware key before starting the program.

Figure 4 Program start

Rig Calibration Tool - User's Manual Program overview 6

The main window

When Rig Calibration Tool is started the main window will appear:

Figure 5 Main window.

Menu bar

Figure 6 Menu bar.

File

From the File menu a new measure can be started, or the application can be

closed.

Figure 7 File menu

Rig Calibration Tool - User's Manual Program overview 7

Total station

In the total station menu you can interact directly with the total station, get the

status and known information of the total station, turn on or off the laserpointer

and select if the program should simulate a connected total station.

Figure 8 Total station menu

When the system is run with a simulated total station, an indicator is shown in

the lower left corner of the application.

Figure 9 Simulated total station indicator

Handle Communication

Figure 10 Handle Communication

Radio Communication Channel

If a radio handle is attached, the radio channel can be changed. There are 16

channels for radio communication between the total station and the drill rig or

the total station and Rig Calibration Tool on your PC.

Selecting an appropriate channel is essential, since there might be several total

stations on the work site and a big risk for interference. A good practice is to

document the channel on the total station by adding a label on the total station

telling which channel is selected.

Activate Handle Communication

Since the total station can communicate in several modes: cable, internal

Bluetooth or communication handle (radio or Bluetooth) mportant to set it

Rig Calibration Tool - User's Manual Program overview 8

back to using the communication handle before using it with the drill rig. There

are radio handles and Bluetooth handles available.

Total station Status...

Figure 11 Total station status

Check the status of the total station. A report can be generated as a text file for

documentation purposes.

The status of the battery on the total station is also checked.

You may use this feature to upgrade the firmware of the total station.

Please see Firmware Upgrade, page 93, for more information.

Settings

The settings menu gives access to system settings.

Figure 12 Settings menu

License Server Settings

To be able to use a server license the user have to enter a hostname or an IP

address to the server who hosts the license. The checkbox must be checked for

the license server to be used.

Rig Calibration Tool - User's Manual Program overview 9

Figure 13 License Server Settings Dialog with an example IP address.

Select Language

The user can change which language the system should display. Available

options are Swedish and English.

COM-port

When connecting the total station and the PC there might be several

communication ports on the PC. Decides which com-port the total station is

connected to.

Training Measure Mode

With this option the user can turn on or off Training Measure Mode. This makes

it possible to do measures with higher tolerance on the laser angle in an

educational or demonstrational setting. The only available measurements are

Boomer (3 booms and 1 or 2 booms) and Simba/Cabletec. If the produced

parameter file is loaded on the RCS system a warning is given.

When the Training Measure Mode is active, an indication is shown in the lower

left corner of the application.

Figure 14 Training Measure Mode indicator

Prism Settings...

Prism settings give the possibility to select what type of prisms that are used in

the different rig calibrations.

The default settings are for the prisms delivered together with the Rig

Calibration Tool package.

Rig Calibration Tool - User's Manual Program overview 10

Figure 15 Prism settings

Help

Figure 16 Help menu

In the Help menu the user can access information about the current license,

create offline-licenses, copy licenses information to paste in an email and send to

Epiroc if any questions arise regarding licenses.

The Rig Calibration Tool manual can be opened from this menu. The About

dialog can also be opened from this menu. It contains information about the

current Rig Calibration Tool version.

Figure 17 About Dialog

Rig Calibration Tool - User's Manual Program overview 11

Deploying the Total station

Operation

Operate the total station with great caution.

Note

Careless operation may lead to the total station being damaged.

Cleaning

Check regularly that the prisms and lenses are intact and clean. Replace or clean

as necessary.

Blow off dust from the lenses and prisms.

Never touch lenses or prisms with your fingers.

When wiping clean, use only a soft, clean cloth which does not cause

scratches. If necessary, moisten the cloth with water or pure alcohol. Do not

use any other liquids or cleaning agents.

Storage and transport

Always store the total station in the bag.

Always keep the bag closed, even when the total station is in use.

Always transport the total station in the bag.

If the equipment or the inside of the bag has become damp, let it dry before it

is packed.

For longer storage, remove the battery from the total station. Do not store the

battery in the battery charger either.

Bag contents

Figure 18 Bag contents

Table 1 Bag contents

Rig Calibration Tool - User's Manual Program overview 12

Pos. Description

A The instrument with adjustment plate mounted.

B Protection for the instrument and sunshield for the objective

C Battery

Total station components

Figure 19 Instrument components

Table 2 Instrument components

Pos Description

A Optical sight

B Vertical adjustment

C Focus ring

D Lateral adjustment

E Retaining screw for adjustment plate

F Adjustment instructions

G Battery compartment

H Box spirit level

I Adjusting screw

J Eyepiece with crosshair focus ring

K Control panel

Rig Calibration Tool - User's Manual Program overview 13

Control panel

Figure 20 Total station control panel

LED Color/Light Meaning

PWR off switched off

green switched on, battery OK

green flashing low battery

red very low battery - the battery should

be replaced.

Red also during shut off.

BT Bluetooth

red radio communication active. Used

when the total station communicates

with the rig.

blue-green bluetooth communication active

off cable communication active.

N.B. cable communication might not

be active even if the BT LED is out. If

the total station is resetted, the BT

LED is out but communication is

undefined. Turn it back into the

communication mode you want as

described here.

TRK

Note This is controlled from the drill rig, the

LED provides information on what is

happening.

off no prisms detected

red instruments are in start-up mode, not

ready

green flashing prism detected but not locked

green prism locked/searching

red flashing loading firmware

Rig Calibration Tool - User's Manual Program overview 14

Communication handle

On the communication handle are four LEDs that provide information about the

communication handle condition.

Figure 21 Communication handle LEDs

A Off/On

B Remote link

C Data transfer

D State

Table 3 Communication handle LEDs

LED Colour/Light Meaning

Off/On off switched off

green switched on

Remote

link

Note Should be illuminated in red when the

drill rig and total station are switched on.

off no contact with the rig

red contact with the rig

Data off no data transfer taking place

transfer

green or data transfer to/from the rig is taking

flashing green place

State

Note Should never be illuminated.

off data mode

red configuration mode

Rig Calibration Tool - User's Manual Program overview 15

Replacing the battery

Figure 22 Replacing the battery

1. Turn the knob on the battery compartment so that it is vertical.

2. Pull out the battery compartment.

3. Remove the battery from the battery compartment.

4. An illustration on the inside of the battery compartment shows how the

battery to should be fitted.

5. Fit the charged battery in the battery compartment with the connectors

outwards and click it into place.

6. Refit the battery compartment.

7. Turn the knob on the battery compartment to horizontal position.

Setting up

1. Mount the total station as described in the application case.

Note

The total station and two prisms or reflective tapes should never be positioned in

a straight line.

2. Level the total station. Check the levelling by turning the total station 180º;

the bubble shall still be in the centre of the levell.

Figure 23 Set it level

The bubble in the total station spirit level should be clearly within the

circular mark. When total station is level then this is also confirmed on the

Check Bubble view in the PC.

Rig Calibration Tool - User's Manual Program overview 16

3. Connect the cable between the PC and the total station.

4. Start the total station by pressing the ON/OFF button until the PWR goes

green.

Figure 24 Start the total station

5. Start the total station by pressing the ON/OFF button for two seconds.

a. Release the button when the PWR LED illuminates in green.

b. After a while (5 seconds) the TRK lights red and there is a faint sound

from the total station (open and closing its shutter).

c. The On/Off LED on the radio handle will go green.

d. The TRK goes out and the BT turns red (mostly).

e. Turn the total station into cable communication mode as described in

Changing communication mode, page 18.

f. The total station is ready for use with the Rig Calibration Tool package.

6. Activate radio communication

When the total station is switched on!

Normal operation of the total station together with the drill rig require radio

communication mode. See Changing communication mode, page 18.

NB.

Do not press the button (D) too long; release it immediately as the diode

goes out. If you press the button (D) in 20 seconds the total station will be

resetted and the on-off sequence must be repeated.

Rig Calibration Tool - User's Manual Program overview 17

Figure 25 The control panel of the total station

Changing communication mode

The total station has three communication modes. Change between modes can be

done when the total station is switched on.

1. Communication handle mode (Radio or Bluetooth)

Handle communication mode is the normal mode when using the total

station together with the drill rig.

a. Press PWR and keep pressed.

b. BT goes out if not already out.

c. PWR turns red keep pressing

d. PWR turns green and BT goes blue-green (flickering)

e. BT goes out keep pressing.

f. BT turns red.

g. Release PWR when BT has turned red.

h. The total station is in handle communication mode!

The PWR LED is green, the BT is red and the TRK is off.

The communication handle has at least the green ON/OFF LED light. If

there is communication with a drill rig: The remote link and data

transfer are active as described above.

2. Cable mode

a. Press PWR and keep pressed.

b. BT goes out if not already out.

c. PWR turns red keep pressing

d. PWR turns green and BT goes blue-green (flickering)

e. Release PWR when BT has gone out.

f. The total station is in cable mode!

The PWR LED is green. The other two are off.

The radio handle has just the green ON/OFF LED light.

3. Bluetooth

Not used.

4. Reset: (for example when the firmware has been updated)

a. Press ON/OFF and keep pressed (20-25 seconds) until

- TRK goes red

- BT goes blue-green (flickering)

- and PWR goes red

ALL THREE CONDITIONS

Rig Calibration Tool - User's Manual Program overview 18

b. The TRK and PWR stay red, BT goes out and the system restarts.

c. After a while (5 seconds) the TRK lights red and there is a faint sound

from the total station (open and closing its shutter).

d. Ready when the PWR goes green again.

e. The total station is now reset and the communication mode must be set

as described above.

Switching off the Total station

Press and hold the ON/OFF button (D), release the button when the LED PWR

(C) turns red after approx. 15 seconds.

Figure 26 Total station control panel

Note

Do not hold the button depressed for too long, but release it when the LED (C)

has turned red. If depressed for 20 seconds then a reset of the total station is

performed and the total station must be turned back into radio communication

mode.

Rig Calibration Tool - User's Manual Program overview 19

Rig Calibration Tool

Rig Calibration Tool is used for calibrating the positions of the rig prisms for

the total station Navigation option. The method is different for the different drill

rig types. Rig Calibration Tool is also used for adjusting rig laser, total station

validation and calibration, calculating boom bending and check the precision for

rigs.

Figure 27 Rig Calibration Tool Initial view

There are different methods for different rig types.

Rig Calibration Tool - User's Manual Program overview 20

Rig Laser

Prerequisites

To calibrate the position and direction of the Boomer rig laser you need the Rig

Calibration Tool package consisting of the total station, tripod, Rig

Calibration Tool software package installed on your PC, cable between the

total station and the PC and reflective tapes.

You need also to place the drill rig in front of a flat wall where you can compare

the hit points of the rig laser and the total station laser.

NB.

Two persons are needed for the calibration.

Figure 28 Test points for rig laser calibration

Figure 29 Reflective tape on console

Figure 30 Reflective tape in front of rig laser

1. Lower the booms down to the ground and swing them outwards that you

have good sight to the booms plates at the console.

Level the drill rig thoroughly. Use a high precision level to calibrate the rig

Rig Calibration Tool - User's Manual Program overview 21

inclination sensors!

If the rig is not correctly levelled the calibration of the rig prisms will not

succeed.

2. Mount the total station on the tripod beside the drill rig.

Both console positions, rig laser eye and the rig laser aiming point on the

wall must all be visible from the position of the total station.

The wall must be flat in an area of 1 square meter around the point where

the rig laser hits the wall.

3. Level and start the total station as described in Deploying the Total station,

page 12.

4. Light up the rig laser.

5. Start the Rig Calibration Tool on the PC.

6.

Figure 31

The following table will show the steps to calibrate the rig prisms.

7. Calibration steps.

Every accepted step is documented in the report window.

Step Action

1 Check bubble Check that the total station is correctly

levelled. If not adjust the levelling knobs

2 Console 1 Place a reflective tape on the left console,

as illustrated in (A) in Figure 29. Aim

with the total station at the centre of the

reflective tape

button to proceed.

3 Console 2 Move the reflective tape to the right

console. You must use a bolt head that

has the same distance to the boom plate

junction as you did when you measured

the left side. Aim with the total station at

the centre of the reflective tape. Press the

4 Laser eye Light the rig laser. Place and hold a

reflective tape with the centre mid over

the eye of the rig laser, as described in

Rig Calibration Tool - User's Manual Program overview 22

(B) in Figure 30. Aim with the total

station at the centre of the reflective tape.

proceed.

5 Find point Aim with the total station towards the

wall close to the point where the rig laser

button to proceed.

6 The total station now automatically

measures three points on the wall. Finally

it aims at the point where the rig laser

should hit the wall and lights up its own

laser.

7 Adjust laser Adjust the rig laser with the adjustment

bolts or plates; see the rig maintenance

manual for details, so that the two laser

points hit the same spot.

proceed.

8. If the total station shall be used for total station Navigation with the drill rig;

Activate handle communication. See Handle Communication on page 8.

9. Disconnect the cable between the PC and the total station.

Rig Calibration Tool - User's Manual Program overview 23

Boomer 2 Prisms Calibration

For Large Boomers as L3C, L4C, E3C, E4C equipped with total station

Navigation option. Detailed description for the rig maintenance can be found in

the maintenance manual.

Prerequisites

The rig laser must be checked and adjusted. The position and direction of the rig

laser is the base for all other calibrations!

The rig must be equipped with the total station Navigation option and the two (or

three) prisms must be mounted on the drill rig.

To calibrate the positions of the prisms on the Boomer C-large rigs you need the

Rig Calibration Tool package consisting of the total station, tripod, Rig

Calibration Tool software package installed on your PC, cable between the

total station and the PC and reflective tapes.

NB.

Two persons are needed for the calibration.

1. Level the drill rig thoroughly. Use a high precision level to calibrate the rig

inclination sensors! A rig laser calibration has to be done before doing this

measure.

If the rig is not correctly levelled the calibration of the rig prisms will not

succeed.

2. Mount the two calibration plates onto the feed of boom2. Light up the rig

laser and position

calibration plate and hits the next. The beam needs not to be centered.

3. Mount the total station on the tripod beside the drill rig.

Both rig prisms, both calibration plates and the junction at the boom plate

for boom 2 must all be visible from the position of the total station.

4. Level and start the total station as described in Deploying the Total station,

page 12.

5. Start the Rig Calibration Tool on the PC.

6. Select File New Measure Boomer 3 booms (2 prisms)

Figure 32 New measure Boomer 3 booms (2 prisms)

The following table will show the steps to calibrate the rig prisms.

Rig Calibration Tool - User's Manual Program overview 24

7. Calibration steps.

Every accepted step is documented in the report window.

Step Action

1 Check Bubble Check that the total station is correctly

levelled. If not adjust the levelling knobs

2 Rear Laser Place a reflective tape on the calibration

plate closest to the rig cabin, so that the

rig laser beam hits in the middle of the

reflective tape. Aim with the total station

Ste

3 Front Laser Remove the used calibration plate and

place a reflective tape on the calibration

plate furthest away from the rig cabin, so

that the rig laser beam hits in the middle

of the reflective tape. Aim with the total

station at the same point. Press the

4 Console Place and hold the reflective tape just at

the junction at the boom plate for boom

2. The reflective tape must be held in the

same plan as the boom plate junction.

Aim with the total station at the middle

of the reflective tape

5 Rear prism Aim with the total station at the rear

6 Front prism Aim with the total station at the front

7 Measure finished Create Parameter

File... Now you can select where to

place the parameter file. Save it to an

empty PC-card or USB stick depending

on what is used on the drill rig.

Figure 33 Measure finished

Rig Calibration Tool - User's Manual Program overview 25

8. Load the parameters from the PC-card or USB stick onto the Display

unit in the drill rig.

NB. This parameter file (DATABASE.TXT) is not a complete

parameter file. It just contains the rig prism positions.

9. Save a new parameter file and store it in a safe place.

10. If the total station shall be used for total station Navigation with the

drill rig; Activate handle communication. See Handle Communication

on page 8.

11. Disconnect the cable between the PC and the total station.

Rig Calibration Tool - User's Manual Program overview 26

Boomer 3 Prisms Calibration

For small Boomers as L1C, L2C, E1C, E2C equipped with total station

Navigation option. I.e. rigs with articulated middle. Detailed description for rig

maintenance can be found in the maintenance manual.

Prerequisites

The rig laser must be checked and adjusted. The position and direction of the rig

laser is the base for all other calibrations!

The rig must be equipped with the total station Navigation option and the three

prisms must be mounted on the drill rig.

To calibrate the positions of the prisms on the smaller Boomer C-rigs you need

the Rig Calibration Tool package consisting of the total station, tripod, Rig

Calibration Tool software package installed on your PC, cable between the

total station and the PC and reflective tapes.

NB.

Two persons are needed for the calibration.

1. Level the drill rig thoroughly. Use a high precision level to calibrate the rig

inclination sensors!

If the rig is not correctly levelled the calibration of the rig prisms will not

succeed.

2. Mount the calibration plates onto the feed of boom1. Light up the rig laser

and position

calibration plate and hits the next. The beam needs not to be centered.

3. Mount the total station on the tripod of the left side of the drill rig.

Two rig prisms, both calibration plates and the junction at the boom plate

must all be visible from the position of the total station.

4. Level and start the total station as described in Deploying the Total station,

page 12.

5. Start the Rig Calibration Tool on the PC.

6. Select File New Measure Boomer 1 or 2 booms (3 prisms)

Figure 34 New measure 1 or 2 booms (3 prisms)

The following table will show the steps to calibrate the rig prisms.

Rig Calibration Tool - User's Manual Program overview 27

7. Calibration steps.

Every accepted step is documented in the report window.

Step Action

1 Position the Position the total station to the left side of the

total station drill rig, as described above.

2 Check Check that the total station is correctly levelled.

Bubble If not adjust the levelling knobs on the total

proceed.

3 Rear Laser Place a reflective tape on the calibration plate

closest to the rig cabin, so that the rig laser beam

hits in the middle of the reflective tape. Aim

with the total station at the same point. Press the

4 Front Laser Remove the used calibration plate and place a

reflective tape on the calibration plate furthest

away from the rig cabin, so that the rig laser

beam hits in the middle of the reflective tape.

Aim with the total station at the same point.

5 Console Place and hold the reflective tape just at the

junction at the boom plate. The reflective tape

must be held in the same plan as the boom plate

junction. See illustration in Figure 35. Aim with

the total station at the middle of the reflective

tape oceed.

6 Rear prism Aim with the total station at the rear prism on the

drill rig, mostly placed high behind the cabin.

7 Front left Aim with the total station at the front left prism

prism on the drill rig. Pr

to proceed.

Now you have to continue to calibrate the prism

on the right side of the drill rig.

8 Position the Position the total station to the right side of the

total station drill rig, correspondingly as described above.

9 Check Check that the total station is correctly levelled.

Bubble If not adjust the levelling knobs on the total

proceed.

10 Rear Laser Place a reflective tape on the calibration plate

closest to the rig cabin, so that the rig laser beam

hits in the middle of the reflective tape. Aim

with the total station at the same point. Press the

Perform Step

11 Front Laser Remove the used calibration plate and place a

reflective tape on the calibration plate furthest

away from the rig cabin, so that the rig laser

beam hits in the middle of the reflective tape.

Aim with the total station at the same point.

Perform Step

12 Console Place and hold the reflective tape just at the

junction at the boom plate. Aim with the total

Rig Calibration Tool - User's Manual Program overview 28

station at the middle of the reflective tape. Press

Perform Step

13 Rear prism Aim with the total station at the rear prism on the

drill rig, mostly placed high behind the cabin.

Perform Step

Now the first and second measurements are

compared and if there is too much error, a

warning will be issued.

The error has probably occurred when measuring

the rig laser or the console with the reflective

tapes.

Repeat the measure series from the beginning,

i.e. left side. Another reason for the error might

be that the rig laser is not calibrated!

14 Front right Aim with the total station at the front right prism

prism Perform Step

to proceed.

15 Measure Create Parameter File...

finished you can select where to place the parameter file.

Save it to an empty PC-card or USB stick

dependent on what is used on the drill rig.

Figure 35 Reflective tape at boom plate junction

Rig Calibration Tool - User's Manual Program overview 29

Figure 36 Measure finished

8. Load the parameters from the PC-card or USB stick onto the Display unit in

the drill rig.

NB This parameter file (DATABASE.TXT) is not a complete parameter

file. It just contains the rig prism positions.

9. Save a new parameter file and store it in a safe place.

10. If the total station shall be used for total station Navigation with the drill rig;

Activate handle communication. See Handle Communication on page 8.

11. Disconnect the cable between the PC and the total station.

Rig Calibration Tool - User's Manual Program overview 30

Boltec/Cabletec/Simba Prisms Calibration

For Boltec, Cabletec and Simba equipped with Total station Navigation option.

Detailed description for the rig maintenance can be found in the maintenance

manuals.

Prerequisites

The rig must be equipped with the total station Navigation options and the

prisms must be mounted on the drill rig.

To calibrate the positions of the prisms you need the Rig Calibration Tool

package consisting of the total station, tripod, Rig Calibration Tool software

package installed on your PC, cable between the total station and the PC, special

prisms with attachment and reflective tapes.

Rig Calibration Tool supports two prism configurations:

One zero-prism, and two position prisms (left and right)

One zero-prism, and three position prisms (left, right and center)

When utilizing three position prisms, a calibration may be completed by using

two measurements, and merge the measurements. The first measurement uses the

left and center prism, and the second measurement uses the right and center

prism. Measurements may be performed from left to right, or right to left.

All possible modes of calibration includes measuring the direction of the rig. The

rig direction is measured by the use of reflection tapes. The tapes may either be

located on a line along the rig, or across the rig.

NB.

One person can carry out the calibration.

Measurements Utilizing Two Position Prisms

1. Level the drill rig thoroughly. Use a high precision level to calibrate the rig

inclination sensors!

If the rig is not correctly levelled the calibration of the rig prisms will not

succeed.

2. Mount the prism on the boom bracket. Two M8 bolts are mounted to insure

the right placement.

3. Fit the reflective tapes on top of the cabin roof for measuring the rig

direction along the rig, or on the slide table for measuring the rig direction

across the rig. Distance should if possible be greater than 1m.

4. Start the Rig Calibration Tool on the PC.

Rig Calibration Tool - User's Manual Program overview 31

5. or Boltec Prism

Figure 37 or Boltec Prism

6. Click New measurement

Figure 38 New measure Simba/Cabletec or Boltec Prism New

measurement

7. Make sure

if you intend to

measure the direction of the rig across the rig, check it, otherwise leave it

unchecked.

Enter the offset value of the zero prism.

8.

Rig Calibration Tool - User's Manual Program overview 32

Figure 39 New measure Simba/Cabletec or Boltec - Two prisms

The following table will show the steps to calibrate the rig prisms.

9. Calibration steps.

Every accepted step is documented in the report window.

Step Action

1 Check Make sure that the rig is correctly leveled. Press the

Rig Level

2 Check Check that the total station is correctly levelled. If not

Bubble adjust the levelling knobs on the total station. Press the

3 Rear Measurement direction: along the rig

Direction

Aim at the rear reflective tape, at the top of the roof,

to proceed.

OR

Measurement direction: across the rig

Left

Direction Aim at the left reflective tape on the slide table with

Perform Step

proceed.

4 Front Measurement direction: along the rig

Direction

Aim at the front reflective tape, at the top of the roof,

with the total sta

to proceed.

OR

Measurement direction: across the rig

Right

Direction Aim at the left reflective tape on the slide table with

Perform Step

proceed.

5 Zero Aim at the centre of the prism at the boom bracket with

Prism

proceed.

6 Left Aim with the total station at the left-hand prism on the

prism

Rig Calibration Tool - User's Manual Program overview 33

7 Right Aim with the total station at the right-hand prism on

prism

proceed.

8 Measure Create Parameter File..

finished can select where to place the parameter file. Save it to

an empty USB stick dependant on what is used on the

drill rig.

Figure 40 Measured finished - Simba/Scaletec or Boltec

10. Load the parameters from the USB stick onto the Display unit in the drill

rig.

NB This parameter file (DATABASE.TXT) is not a complete parameter

file. It just contains the rig prism positions.

11. Save a new parameter file and store it in a safe place.

12. If the total station shall be used for total station Navigation with the drill rig;

Activate handle communication. See Handle Communication on page 8.

13. Disconnect the cable between the PC and the total station.

Measurements Utilizing Three Position Prisms in One

Sequence

1. Level the drill rig thoroughly. Use a high precision level to calibrate the rig

inclination sensors!

If the rig is not correctly levelled the calibration of the rig prisms will not

succeed.

2. Mount the prism on the boom bracker. Two M8 bolts are mounted to insure

the right placement.

3. Fit the reflective tapes on top of the cabin roof for measuring the rig

direction along the rig, or on the slide table for measuring the rig direction

across the rig. Distance should if possible be greater than 1m.

4. Start the Rig Calibration Tool on the PC.

Rig Calibration Tool - User's Manual Program overview 34

5.

Prism

Figure 41 or Boltec Prism

6. Click New measurement

Figure 42 or Boltec Prism

measurement

Make sure

are c

measuring strategy if you intend to measure the direction of the rig across

the rig, check it, otherwise leave it unchecked.

Enter the offset value of the zero prism.

7.

Rig Calibration Tool - User's Manual Program overview 35

Figure 43 New measure Simba/Cabletec or Boltec - Three prisms in one

sequence

The following table will show the steps to calibrate the rig prisms.

8. Calibration steps.

Every accepted step is documented in the report window.

Step Action

1 Check Make sure that the rig is correctly leveled. Press the

Rig Level

2 Check Check that the total station is correctly levelled. If not

Bubble adjust the levelling knobs on the total station. Press the

3 Rear Measurement direction: along the rig

Direction

Aim at the rear reflective tape, at the top of the roof,

to proceed.

OR

Measurement direction: across the rig

Left

Direction Aim at the left reflective tape on the slide table with

r

proceed.

4 Front Measurement direction: along the rig

Direction

Aim at the front reflective tape, at the top of the roof,

to proceed.

OR

Measurement direction: across the rig

Right

Direction Aim at the left reflective tape on the slide table with

r

proceed.

5 Zero Aim at the center of the prism at the boom bracket with

Prism the t

proceed.

6 Left Aim with the total station at the left-hand prism on the

Rig Calibration Tool - User's Manual Program overview 36

prism

7 Right Aim with the total station at the right-hand prism on

prism

proceed.

8 Center Aim with the total station at the center prism on the

prism

9 Measure Press the

finished can select where to place the parameter file. Save it to

an empty USB stick dependent on what is used on the

drill rig.

Figure 44 Measured finished - Simba/Scaletec or Boltec Three prisms in

one sequence

9. Load the parameters from the USB stick onto the Display unit in the drill

rig.

NB This parameter file (DATABASE.TXT) is not a complete parameter

file. It just contains the rig prism positions.

10. Save a new parameter file and store it in a safe place.

11. If the total station shall be used for total station Navigation with the drill rig;

Activate handle communication. See Handle Communication on page 8.

12. Disconnect the cable between the PC and the total station.

Measurements Utilizing Three Position Prisms In Two

Sequences

1. Level the drill rig thoroughly. Use a high precision level to calibrate the rig

inclination sensors!

If the rig is not correctly levelled the calibration of the rig prisms will not

succeed.

2. Mount the prism on the boom bracker. Two M8 bolts are mounted to insure

the right placement.

3. Fit the reflective tapes on top of the cabin roof for measuring the rig

direction along the rig, or on the slide table for measuring the rig direction

across the rig. Distance should if possible be greater than 1m.

4. Start the Rig Calibration Tool on the PC.

Rig Calibration Tool - User's Manual Program overview 37

5. or Boltec Prism

Figure 45 or Boltec Prism

6. Click New measurement

Figure 46 or Boltec Prism New

measurement

Make sure

the intended measuring strategy if you intend to measure the direction of

the rig across the rig, check it, otherwise leave it unchecked. Similarly,

measure first on the left side, and complete the calibration with a second

measurement on the right side.

Enter a file name, o

from the measurement, that will be used in the second measuring sequence.

Enter the offset value of the zero prism.

7.

Rig Calibration Tool - User's Manual Program overview 38

Figure 47 New measure Simba/Cabletec or Boltec - Three prisms in two

sequences, first sequence

The following table will show the steps to calibrate the rig prisms.

8. Calibration steps.

Every accepted step is documented in the report window.

Step Action

1 Check Make sure that the rig is correctly leveled. Press the

Rig Level

2 Check Check that the total station is correctly levelled. If not

Bubble adjust the levelling knobs on the total station. Press the

3 Rear Measurement direction: along the rig

Direction

Aim at the rear reflective tape, at the top of the roof,

to proceed.

OR

Measurement direction: across the rig

Left

Direction Aim at the left reflective tape on the slide table with

Perform Step

proceed.

4 Front Measurement direction: along the rig

Direction

Aim at the front reflective tape, at the top of the roof,

to proceed.

OR

Measurement direction: across the rig

Right

Direction Aim at the left reflective tape on the slide table with

Perform Step

proceed.

5 Zero Aim at the centre of the prism at the boom bracket with

Prism the t

proceed.

Rig Calibration Tool - User's Manual Program overview 39

6 Left The first measurement is on the left side:

prism

Aim with the total station at the left-hand prism on the

drill rig. Press the

OR

The first measurement is on the right side:

Right Aim with the total station at the right-hand prism on

prism

proceed.

7 Right The first measurement is on the left side:

prism

Aim with the total station at the right-hand prism on

proceed.

OR

The first measurement is on the right side:

Left

prism Aim with the total station at the left-hand prism on the

8 Center Aim with the total station at the center prism on the

prism

9 Measure Store measurements You may now

finished turn off the Rig Calibration Tool and disconnect the

total station, or continue the calibration by measuring

the other side.

Figure 48 Measured finished - Simba/Scaletec or Boltec - Three prisms in

two sequences, first sequence

9. Start the Rig Calibration Tool on the PC.

10. or Boltec Prism

Figure 49 or Boltec Prism

Rig Calibration Tool - User's Manual Program overview 40

11. Click measurement

Figure 50 or Boltec Prism Continue

measurement

Enter the file name that was used in the first measurement sequence (see

step 6). By default, Rig Calibration Tool will enter the last known file name

automatically. When a file name has been entered, information about the

first measurement is shown below. Rig Calibration Tool will also change the

Y-offset by inverting the offset.

You may also enter a tolerance value for differences between the first and

ond

measure that does not fall within the tolerance value, will not allow the user

to proceed in the work flow.

Rig Calibration Tool - User's Manual Program overview 41

12.

Figure 51 or Boltec - Three prisms in two

sequences, second sequence

The following table will show the steps to calibrate the rig prisms.

13. Calibration steps.

Every accepted step is documented in the report window.

Step Action

1 Check Rig Make sure that the rig is correctly leveled. Press

Level

2 Check Bubble Check that the total station is correctly levelled. If

not adjust the levelling knobs on the total station.

to proceed.

3 Rear Measurement direction: along the rig

Direction

Aim at the rear reflective tape, at the top of the

OR

Measurement direction: across the rig

Left Direction

Aim at the left reflective tape on the slide table

Perform Step

button to proceed.

4 Front Measurement direction: along the rig

Direction

Aim at the front reflective tape, at the top of the

OR

Measurement direction: across the rig

Right

Direction Aim at the left reflective tape on the slide table

Perform Step

button to proceed.

5 Zero Prism Aim at the center of the prism at the boom bracket

with the t

Rig Calibration Tool - User's Manual Program overview 42

button to proceed.

6 Left prism If the first measurement was made on the left side:

This row will show the measurement made in that

sequence. No action is required.

If the first measurement was made on the right

side:

Aim with the total station at the left-hand prism on

proceed.

7 Right prism The first measurement was made on the right side:

This row will show the measurement made in that

sequence. No action is required.

If the first measurement was made on the left side:

Aim with the total station at the right-hand prism

proceed.

8 Center prism This row will show the measurement made in the

(first first sequence. No action is required.

measurement)

9 Center prism Aim with the total station at the center prism on the

proceed.

10 Difference This row will show the difference between the first

between measuring sequence and the second one. It will

measurements show the absolute distance in mm, as well as the

distance along all axes.

11 Measure

finished you can select where to place the parameter file.

Save it to an empty USB stick dependant on what

is used on the drill rig.

Figure 52 New measure Simba/Cabletec or Boltec - Three prisms in two

sequences

14. Load the parameters from the USB stick onto the Display unit in the drill

rig.

Rig Calibration Tool - User's Manual Program overview 43

NB This parameter file (DATABASE.TXT) is not a complete parameter

file. It just contains the rig prism positions.

15. Save a new parameter file and store it in a safe place.

16. If the total station shall be used for total station Navigation with the drill rig;

Activate handle communication. See Handle Communication on page 8.

17. Disconnect the cable between the PC and the total station.

Rig Calibration Tool - User's Manual Program overview 44

Boltec Prisms Calibration

For Boltec LC and MC equipped with total station Navigation option. Detailed

description for the rig maintenance can be found in the Boltec maintenance

manual.

Prerequisites

The rig must be equipped with the total station Navigation option and the prisms

must be mounted on the drill rig.

To calibrate the positions of the prisms on the Boltec C-rigs you need the Rig

Calibration Tool package consisting of the total station, tripod, Rig

Calibration Tool software package installed on your PC, cable between the

total station and the PC, special prisms with attachment and reflective tapes.

NB.

One person can carry out the calibration.

1. Level the drill rig thoroughly. Use a high precision level to calibrate the rig

inclination sensors!

If the rig is not correctly levelled the calibration of the rig prisms will not

succeed.

2. Mount both of the rig's reflective tapes on the frame at the steps to the rig. It

is important that the reflective tapes are parallel to the frame and that the

dimension (A) should be greater than 1 m.

Figure 53 Reflective tape

Figure 54 Reflective tapes on the rig step.

Mount the prism on the boom shaft; ensure that the bolts align into the recess in

the base. Measure the distance (B) of the lower edge of the prism base and the

plane on the boom shaft.

Rig Calibration Tool - User's Manual Program overview 45

Figure 55 Fitting the prism

3. Mount the total station on the tripod (A) beside the drill rig.

Both rig prisms (D), both reflective tapes on the step (B) and the prism at

the boom shaft (C) must all be visible from the position of the total station.

Figure 56 Boltec set-up

4. Level and start the total station as described in Deploying the Total station,

page 12.

5. Start the Rig Calibration Tool on the PC.

6. Prism (offset in one dimension)

Figure 57 Prism (offset in one

dimension)

The following table will show the steps to calibrate the rig prisms.

Rig Calibration Tool - User's Manual Program overview 46

7. Calibration steps.

Every accepted step is documented in the report window.

Step Action

1 Check Bubble Check that the total station is correctly

levelled. If not adjust the levelling knobs

2 Rear Direction Aim at the rear reflective tape, at the step,

3 Front Direction Aim at the front reflective tape, at the step,

4 Centre Prism Aim at the center of the prism at the boom

shaft with the total station. Press the

Enter the previously measured value (B in

0 above) for the prism.

5 Left prism Aim with the total station at the left-hand

6 Right prism Aim with the total station at the right-hand

7 Measure

finished Now you can select where to place the

parameter file. Save it to an empty USB

stick dependant on what is used on the drill

rig.

Figure 58 Measure finished - Boltec

Rig Calibration Tool - User's Manual Program overview 47

8. Load the parameters from the USB stick onto the Display unit in the drill

rig.

NB This parameter file (DATABASE.TXT) is not a complete parameter

file. It just contains the rig prism positions.

9. Save a new parameter file and store it in a safe place.

10. If the total station shall be used for total station Navigation with the drill rig;

Activate handle communication. See Handle Communication on page 8.

11. Disconnect the cable between the PC and the total station.

Rig Calibration Tool - User's Manual Program overview 48

Scaletec Prisms Calibration

For Scaletec equipped with total station Navigation option. Detailed description

for the rig maintenance can be found in the maintenance manual.

Prerequisites

The rig must be equipped with the total station Navigation and Tunnel Profiler

options and the prisms must be mounted on the drill rig.

A laser range finder.

To calibrate the positions of the prisms on the Scaletec C-rigs you need the Rig

Calibration Tool package consisting of the total station, tripod, Rig

Calibration Tool software package installed on your PC, cable between the

total station and the PC and reflective tapes.

NB.

It is easier to be two persons for the calibration.

1. Make sure the rig is positioned so that there are approximately 16 metres of

free space in front of the rig.

2. Start up the RCS system and the Tunnel Profiler.

3. Level the drill rig thoroughly. Use a high precision level to calibrate the rig

inclination sensors, as described in the maintenance manual!

If the rig is not correctly levelled the calibration of the rig prisms will not

succeed.

4. Since the calibration of the prism positions utilizes the Tunnel Profiler you

need to have calibrated the Tunnel Profile scanner thoroughly, as described

in the manual.

5. Mount a reflective label (1) in front of the Tunnel Profiler, so that its laser

hits it.

6. Mount the total station on the tripod beside the drill rig.

Both rig prisms (4 and 5) and all three reflective tapes (1, 2 and 3) must all

be visible from the position of the total station.

Figure 59 Scaletec set-up

Rig Calibration Tool - User's Manual Program overview 49

7. Level and start the total station as described in Deploying the Total station,

page 12.

8. Start the Rig Calibration Tool on the PC.

9. Select File New measure Scaletec

Figure 60 New measure - Scaletec

The following table will show the steps to calibrate the rig prisms.

10. Calibration steps.

Every accepted step is documented in the report window.

Step Action

1 Check Bubble Check that the total station is correctly

levelled. If not adjust the levelling knobs

2 Rear Laser Aim with the total station at the same

point as where the Tunnel Profiler's laser

hits the reflective tape (1). Press the

Perform Step

3 Front Laser Move the reflective plate about 16 metres

(2) from the Tunnel Profiler so that its

laser hits it. Aim at the same point with

Perform Step

button to proceed.

These two steps indicate the direction of

the rig for X-axis and the coordinates Z =

0 and Y = 0.

4 Side Laser On the display screen for the Tunnel

Profiler:

Go via the Services menu, on to Sys

and there select the Developer menu.

Enter the following values in order to

turn the profile scanner's laser direction:

Main axis = 90º

Scanner axis = the actual value

obtained in the preparation, step 6 (see

maintenance manual) + 90º/270º

(depending on which side of the rig total

Rig Calibration Tool - User's Manual Program overview 50

station is)

Move the reflective tape to position (3)

so that the profile scanner's laser hits it.

Aim at the same point with the total

station Perform Step

to proceed.

In this step the direction in which X = 0

is determined.

Aim at the rig's left-hand prism (4) with

5 Left prism

the total station. Press Perform Step

button to proceed.

Aim at the rig's right-hand prism (5) with

6 Right prism

the total station Perform Step

button to proceed.

7 Measure Create Parameter

finished File...

place the parameter file. Save it to an

empty USB stick dependant on what is

used on the drill rig.

Figure 61 Measure finished - Scaletec

11. Load the parameters from the USB stick onto the Display unit in the drill

rig.

NB This parameter file (DATABASE.TXT) is not a complete parameter

file. It just contains the rig prism positions.

12. Save a new parameter file and store it in a safe place.

13. If the total station shall be used for total station Navigation with the drill rig;

Activate handle communication. See Handle Communication on page 8.

14. Disconnect the cable between the PC and the total station.

Rig Calibration Tool - User's Manual Program overview 51

Direction

In order to increase the precision for total station navigation for Boltec and

Simba a more precise boom swing calibration should be carried out.

Prerequisites

A basic calibration of the boom must be carried out, see the Boltec and Simba

maintenance manuals

The rig must be equipped with the total station Navigation option and the prisms

must be mounted on the drill rig.

To calibrate the positions of the prisms you need the Rig Calibration Tool

package consisting of the total station, tripod, Rig Calibration Tool software

package installed on your PC, cable between the total station and the PC, special

prisms with attachment and reflective tapes.

NB.

One person can carry out the calibration.

1. The rig levelling must be previously calibrated, see the Boltec and the

Simba, maintenance manuals.

2. Level the drill rig thoroughly. Use the readings from the rig inclination

sensors.

If the rig is not correctly levelled the calibration of the rig prisms will not

succeed.

3. Mount both of the rig's reflective tapes on the frame at the steps to the rig. It

is important that the reflective tapes are parallel to the frame and that the

dimension (A) should be greater than 1 m.

Figure 62 Reflective tape

Figure 63 Reflective tapes on the rig step.

4. Level and start the total station as described in Deploying the Total station,

page 12.

5. Start the Rig Calibration Tool on the PC.

Rig Calibration Tool - User's Manual Program overview 52

6. Select File New measure Direction

Figure 64 New measure Direction

The following table will show the steps to calibrate the rig prisms.

7. Calibration steps.

Every accepted step is documented in the report window.

Step Action

1 Check Bubble Check that the total station is correctly

levelled. If not adjust the levelling knobs

on to proceed.

2 Direction 1 Aim at the rear reflective tape, at the

step, with the total station. Press the

3 Direction 2 Aim at the front reflective tape, at the

step, with the total station. Press the

8. Move the reflective tapes from the steps to the boom. It is important that the

reflective tapes are parallel to the bracket and that the dimension (B) should

be greater than 1 m.

Figure 65 Reflective tapes on Boltec

9. Continue with the calibration steps.

Rig Calibration Tool - User's Manual Program overview 53

Step Action

4 Direction 3 Aim at the rear reflective tape, on the

boom, with the total station. Press the

5 Direction 4 Aim at the front reflective tape, on the

boom, with the total station. Press the

6 Measure Record angles.

finished

10. Record the angle value shown, at H for Direction 4, when calibration is

complete. (-5.71º in the example below).

Figure 66 Measure finished Simba/Cabletec Direction

11. Access the Calibration menu (M3.1.1) on the RCS display screen and

enter the angle value from the previous point, (5 Direction 4 H: x.xxº), for

the parameter Boom swing . Then press the button Set.

Figure 67 Sensors - Boltec

12. Operate the boom to zero and check that the value on the screen goes to

zero.

12. Save a new parameter file and store it in a safe place.

Rig Calibration Tool - User's Manual Program overview 54

13. If the total station shall be used for total station Navigation with the drill rig;

Activate handle communication. See Handle Communication on page 8.

13. Disconnect the cable between the PC and the total station.

Rig Calibration Tool - User's Manual Program overview 55

Demo Fixpoint Measure

The Demo Fixpoint Measure is used for demonstrational purposes to create a

tunnel line with a number of fixpoints. The created files can then be imported

into Tunnel Manager.

Prerequisites

To perform a Demo Fixpoint Measure you need the Rig Calibration Tool

package consisting of the total station, tripod, Rig Calibration Tool software

package installed on your PC, cable between the total station and the PC and

reflective tapes or prisms.

1. Place the total station in the origo of the imaginary tunnel line to create.

2. Place a number of prisms and/or reflective tapes in the room to mark the

fixpoints to be created.

3. Level and start the total station as described in Deploying the Total

station, page 12.

4. Start the Rig Calibration Tool on the PC.

5. Demo Fixpoint Measure.

6. Select the number of prisms or reflective tapes to measure.

Figure 68 Select number of prisms.

Figure 69 Demo Fixpoint Measure

7. Measure steps.

Step Action

1 Check Bubble Check that the total station is correctly

levelled. If not, adjust the levelling knobs on

Rig Calibration Tool - User's Manual Program overview 56

button to proceed.

2 Aim in the Aim the total station in the direction of the

tunnel line imaginary tunnel line. The location of the total

direction station will be the origo of the tunnel line.

3- Prism number Aim with the total station at the prism. Press

X X Select

the prism type in the dialog.

Repeat this step until all prisms have been

measured.

Measure

finished tunnel line file and the fix point file.

8. Note the location where the files were exported to.

9. If the total station shall be used for total station Navigation with the drill

rig; Activate handle communication. See Handle Communication on

page 8.

10. Disconnect the cable between the PC and the total station.

Rig Calibration Tool - User's Manual Program overview 57

Total station Validation

The total station validation is a check that should be performed regularly.

Described here is the basic validation to detect coarse errors.

Prerequisites

To validate the total station you need the Rig Calibration Tool package

consisting of the total station, tripod, Rig Calibration Tool software package

installed on your PC, cable between the total station and the PC and a standard

round prism.

1. Mount a Standard round prism (9106 2419 25 001) on a distant place. The

minimal distance between the total station and the prism should be 100 m.

2. Mount the total station on the tripod.

3. Level and start the total station as described in Deploying the Total station,

page 12.

4. Start the Rig Calibration Tool on the PC.

5. Select File New measure total station Validation.

Figure 70 New measure total station Validation

6. The following table will show the steps to validate the total station.

7. Validation steps.

Every accepted step is documented in the report window.

Step Action

1 Check Bubble Check that the total station is correctly

levelled. If not adjust the levelling knobs

2 Choose Prism Select, from the table in Figure 71, the

type of prism you are using to aim at.

3 Measure Prism Aim with the total station at the prism.

Perform Step

proceed.

The total station automatically turns 180º

horizontally and then around.

Rig Calibration Tool - User's Manual Program overview 58

The total station measures the same

prism again.

4 Measure The Validation result is displayed.

finished

Figure 71 Choose prism

Figure 72 Measure finished Total station Validation

Figure 73 Validation result

Rig Calibration Tool - User's Manual Program overview 59

Figure 74 Validation detailed result

RESULT

As a general rule: the values shall be very small. If the horizontal or vertical

deviation exceeds 30 arcsec a calibration is needed, if a calibration just has

been performed a service is needed. If the deviation exceeds 300 arcsec a

service is needed regardless.

MEASURE INFO

Difference from horizontal plane must not be more than ±10º, preferably

much smaller.

Distance to prism must be more than 100 meters.

8. If the total station shall be used for total station Navigation with the drill rig;

Activate handle communication. See Handle Communication on page 8.

9. Disconnect the cable between the PC and the total station.

Rig Calibration Tool - User's Manual Program overview 60

Total station Calibration

The total station calibration should be performed if the horizontal or vertical

deviation is more than 30 arcsec when doing a total station Validation. The

calibration has three parts: Combined calibration, ATR (Automatic Target

Recognition) calibration and tilt calibration.

The combined calibration will calibrate compensator longitudinal and transversal

index errors, vertical index error and horizontal collimation error. The

compensator index errors compensate for inclination errors for the horizontal

plane. Vertical index error compensates for inclination errors for the vertical

axis. Horizontal collimation error compensates for angle errors between the

vertical axis and the measuring device that should be perpendicular.

The ATR calibration calibrates the ATR zero point error for horizontal angle and

the ATR zero point error for vertical angle.

The tilt calibration calibrates the tilting axis that compensates for inclination

errors for the axis.

When the total station has changed face and a new aim at the target should be

performed, turn the aim away a bit from the target before aiming again. This

should be done because each aim should be independent of the previous aim.

It is important to avoid parallax errors when aiming at the target. Avoid parallax

errors by ensuring that the crosshair still is aimed at the target when moving the

eye slightly to the sides.

Prerequisites

To calibrate the total station you need the Rig Calibration Tool package

consisting of the total station, tripod, Rig Calibration Tool software package

installed on your PC, cable between the total station and the PC and a prism.

1. Mount the total station on the tripod.

2. Level and start the total station as described in Deploying the Total station,

page 12.

3. Mount a Standard round prism (9106 2419 25 001) on a distant place. The

minimal distance between the total station and the prism should be 100 m.

The prism should be positioned within ±9 degrees/±10 gon of the horizontal

plane of the total station. This prism will be used during the combined

calibration and the ATR calibration. A prism is only required for the ATR

calibration, but recommended for the combined calibration too.

4. Find a target positioned at least 27 degrees/30 gon above or beneath the

horizontal plane, as far away as possible. This target will be used during the

tilt calibration.

5. Start the Rig Calibration Tool on the PC.

Rig Calibration Tool - User's Manual Program overview 61

6. Total station Calibration.

Figure 75 Calibration

7. The following table will show the steps to calibrate the total station.

8. Calibration steps.

Every accepted step is documented in the report window.

Step Action

1 Information Shows important information about the

calibration. Read the information

carefully and press the button to proceed.

Enter operator name and location in the

dialog that appears. See Figure 76.

2 Initialize Initializes the total station for calibration

and turns on the laser plummet.

3 Adjust Check that the total station is correctly

Inclination levelled. If not, adjust the levelling knobs

b

4 Combined Shows information about the combined

Calibration calibration part of the calibration.

Read the information and press

5 Check Face Coarse aim at the prism and press

total station

has the wrong face towards the prism it

will turn around. Otherwise nothing

happens.

6 Combined Aim at the prism manually and with high

Measure Face 1 accuracy. Measure

button to proceed.

The total station automatically changes

face after the measure.

7 Combined Aim at the prism manually and with high

Measure Face 2 accuracy. Measure

button to proceed.

Rig Calibration Tool - User's Manual Program overview 62

The total station automatically changes

face after the measure.

8 Combined Aim at the prism manually and with high

Measure Face 1 accuracy again.

Measure

The total station automatically changes

face after the measure.

9 Combined Aim at the prism manually and with high

Measure Face 2 accuracy again.

Measure

The total station automatically changes

face after the measure.

A result dialog will be displayed,

showing the old and new values for the

different calibrated errors.

10 ATR Shows information about the ATR

Calibration calibration part of the calibration.

Read the information and press

11 ATR Measure Aim at the prism manually and with high

Face 1 accuracy. Measure

button to proceed.

The total station automatically changes

face after the measure.

12 ATR Measure Aim at the prism manually and with high

Face 2 accuracy. Measure

button to proceed.

The total station automatically changes

face after the measure.

13 ATR Shows a confirmation saying that the

Calibration ATR calibration has been updated.

Result

14 Tilt Calibration Shows information about the Tilt

calibration part of the calibration.

Find a target positioned at least 27

degrees/30 gon above or beneath the

horizontal plane, as far away as possible.

Read the information and press

15 Tilt Measure Aim at the target manually and with high

Face 1 accuracy. Measure

button to proceed.