0% found this document useful (0 votes)

11 views18 pagesSection14B - Design Examples

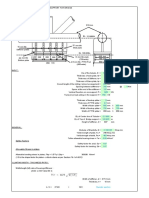

The document provides design examples for fixed and expansion elastomeric bearings in bridge design, detailing the procedures for custom designing these components based on specific loads and geometric constraints. It includes calculations for bearing pad dimensions, shape factors, and stresses, as well as considerations for curved plates and anchor rods. The examples are based on standard specifications and include necessary checks to ensure compliance with design requirements.

Uploaded by

Kamlesh RaikwarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

11 views18 pagesSection14B - Design Examples

The document provides design examples for fixed and expansion elastomeric bearings in bridge design, detailing the procedures for custom designing these components based on specific loads and geometric constraints. It includes calculations for bearing pad dimensions, shape factors, and stresses, as well as considerations for curved plates and anchor rods. The examples are based on standard specifications and include necessary checks to ensure compliance with design requirements.

Uploaded by

Kamlesh RaikwarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 18