THERMO 2B (Thermodynamics 2)

BS in Mechanical Engineering 2A

Second Semester SY: 2024-2025

Topic 1

SIMPLE RANKINE CYCLE ANALYSIS

SAMPLE PROBLEM

1. Steam is generated at 4.10 MPa and 440°C and condensation occurs at 0.105 MPa. For a

Rankine Engine operating between these limits, Compute:

a.) Heat Added (QA), Heat Rejected (QR), Net Work (Wnet), Thermal Efficiency (eth)

b.) What mass flow rate is required for a net output of 30,000 kW?

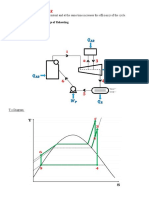

Illustrations:

Pressure of steam at point 1;

P1 = 4.10 MPa & 440°C

Pressure of the

condensed substance

(water) at point 3;

P3 = 0.105 MPa

T-S Diagram:

Processes:

1-2: Isentropic Expansion

2-3: Isobaric Heat Rejection

P1 =4.10 MPa

3- & 440°C

4: Isentropic Compression

4-1: Isobaric Heat Addition

P3 =0.105 MPa

SOLUTION:

From Steam Table:

At P1 = 4.10 MPa & 440°C, we obtained the following values of its thermodynamic properties as

follows:

(1) enthalpy h1 = 3305.7 kJ/kg

(2) entropy s1 = 6.8911 kJ/kg-°K

Pssssssssst... Hello!

This is how we get values

from the Steam Table…

At Table 3. Vapor

� Remember that at point 1 during

isentropic expansion, the steaming

pressure is P1 = 4.10 MPa with a

saturation temperature of tsat. =

251.87°C. But since the actual

temperature of steam produced by

the boiler is 440°C, the quality of

steam is already a “Superheated

Steam” because of its temperature

that is higher than saturated vapor.

This is how we classify the quality

of steam:

Highly Superheated

Superheated

Saturated

Wet

Actual temperature of

steam produced by the

boiler; t1 = 440°C thus,

SUPERHEATED STEAM

Solving for h2:

Since the quality of steam at point 2 is already a mixture of dry & wet steam, we will use the

following formula:

h2 = hf2 + (x2) (hfg2)

where:

h2 = enthalpy of a mixture at point 2

hf2 = enthalpy of fluid at point 2

x2 = quality of the mixture at point 2

� hfg2 = enthalpy of the mixture at point 2

Also;

where:

x2 = (s2 – sf2) / sfg2

But Since;

S1 =(3) s2 = 6.8911 kJ/kg-°K (from T-S diagram)

From: Table 2. Saturation: Pressure @ 0.105 MPa

hf2 = 423.24 kJ/kg

hfg2 = 2254.4 kJ/kg

sf2 = 1.3181 kJ/kg-°K

sfg2 = 6.0249 kJ/kg-°K

0.105 MPa

Thus;

� x2 = (6.8911 – 1.3181) / 6.0249

= 0.925 or 92.5% Dry Steam

Solving for h2:

h2 = 423.24 + (0.925) (2254.4)

h2 = 2508.6 kJ/kg

Solving for h3:

h3 = hf @ 0.105 MPa

h3 = 423.24 kJ/kg

Solving for h4:

h 4 = h3 + W p

where:

Wp = Pump Work

= vf3 (P4 – P3)

also, where:

vf3 = from Steam Table; vf at 0.105 MPa = 1.0443 x 10³ m³/kg or 0.0010443 m³/kg

P4 = P1 (in KPa) = 4100 kPa

P3 = P3 (in KPa) = 105 kPa

thus:

Wp = (0.0010443) (4100 – 105)

= 4.17 kJ/kg

h4 = 423.24 + 4.17

h4 = 427.4 kJ/kg

A. Heat Added;

QA = (h1 – h4)

= (3305.7 – 427.4)

QA = 2878.3 kJ/kg

Heat Rejected;

QR = (h2 – h3)

= (2508.6 – 423.24)

QR = 2085.4 kJ/kg

Net Work;

� Wnet = QA – QR

= (2878.3 – 2085.4)

Wnet = 792.9 kJ/kg

or;

Wnet = (h1 – h2 – Wp)

= (3305.7– 2508.6 – 4.17)

Wnet = 792.9 kJ/kg

Thermal Efficiency;

eth = Wnet / QA

= 792.9 / 2878.3

eth = 0.2755 or 27.55%

B. Steam Flow

= 30,000 kW / Wnet

= 30,000 kW / 792.9 kJ/kg

= 37.84 kg/s

**END**