0% found this document useful (0 votes)

35 views20 pagesInternship Report 1

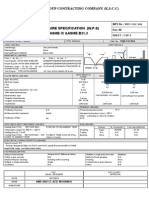

The internship report by Vaishnavi Revansidha Bandichode focuses on the study of industrial CNC milling machines during her internship at SONA Industries. It outlines the objectives, processes, and equipment involved in CNC milling, emphasizing the importance of practical experience in engineering education. The report includes sections on manufacturing processes, quality inspection, and various welding techniques, concluding with insights gained from the internship experience.

Uploaded by

vaishnavibandichode261Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

35 views20 pagesInternship Report 1

The internship report by Vaishnavi Revansidha Bandichode focuses on the study of industrial CNC milling machines during her internship at SONA Industries. It outlines the objectives, processes, and equipment involved in CNC milling, emphasizing the importance of practical experience in engineering education. The report includes sections on manufacturing processes, quality inspection, and various welding techniques, concluding with insights gained from the internship experience.

Uploaded by

vaishnavibandichode261Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 20