0% found this document useful (0 votes)

81 views9 pagesAssembly Instructions

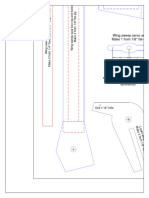

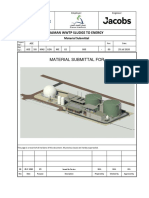

The document details the design and assembly instructions for a 3D model of the Razor Crest from the Mandalorian series, highlighting the extensive time and effort invested in its creation. It emphasizes the importance of crediting the designer when sharing printed models and prohibits the sale or alteration of the provided files. Additionally, it outlines specific changes made to the original model and provides comprehensive assembly and printing instructions, including tips for adding lights.

Uploaded by

jean pierre truszkowskiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

81 views9 pagesAssembly Instructions

The document details the design and assembly instructions for a 3D model of the Razor Crest from the Mandalorian series, highlighting the extensive time and effort invested in its creation. It emphasizes the importance of crediting the designer when sharing printed models and prohibits the sale or alteration of the provided files. Additionally, it outlines specific changes made to the original model and provides comprehensive assembly and printing instructions, including tips for adding lights.

Uploaded by

jean pierre truszkowskiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 9