HO CHI MINH CITY UNIVERSITY OF TECHNOLOGY

VIETNAM NATIONAL UNIVERSITY HO CHI MINH CITY

FACULTY OF MECHANICAL ENGINEERING

MACHINE ELEMENT

INDIVIDUAL ASSIGNMENT REPORT

Lecturer: Dr. Phạm Minh Tuấn

Full Name: Nguyễn Phúc Khang

Student ID: 2352485

1

�Contents

1. Project requirements ................................................................................................... 3

2. Electric motor selection and transmission ratio distribution ...................................... 3

2.1. Selecting efficiency of transmission systems: ....................................................... 3

2.2. Selecting transmission ratio: ................................................................................. 3

2.3. Power, speed and torque calculations .................................................................. 4

3. Design of bevel gear drive in speed reducer ................................................................ 5

3.1. Working life and allowable stress ......................................................................... 5

3.2. Geometric calculations ......................................................................................... 6

3.3. Kinematics and dynamics ..................................................................................... 7

3.4. Verification for contact stress ............................................................................... 7

4. Design of roller chain drive .......................................................................................... 8

4.1. Choosing number of sprocket teeth Z .................................................................. 8

4.2. Calculating pitch pc ............................................................................................... 8

4.3. Preliminary geometric calculations ...................................................................... 9

4.4. Kinematics and dynamics ................................................................................... 10

4.5. Verification .......................................................................................................... 10

4.6. Dimensions of sprockets: .................................................................................... 11

5. Design of shafts in speed reducer .............................................................................. 12

5.1. Shaft 1 ................................................................................................................. 12

5.2. Shaft 2 ................................................................................................................. 14

6. Selecting bearings for shafts ...................................................................................... 17

6.1. Pair 1 (shaft 1) ..................................................................................................... 17

6.2. Pair 2 (shaft 2) ..................................................................................................... 18

2

� 1. Project requirements

• Power of blender' shaft, P = 5 kw

• Rotation speed of blender' shaft, n = 130 rpm

• Working life: L = 3 years

• Allowable transmission error: ± 5%

• Operating conditions: one-direction working, light-impact loading, 2-shift operation

(8 hours/shift) and 300 days/year

2. Electric motor selection and transmission ratio distribution

2.1. Selecting efficiency of transmission systems:

gear = 0.97

chain = 0.95 bearing = 0.99 coupling = 1

System efficiency: sys = gear chain 2bearing coupling

= 0.97 0.95 0.992 1 = 0.9

2.2. Selecting transmission ratio:

u gear = 3.6

, uchain = 2.04

3

� 2.3. Power, speed and torque calculations

PIII 5

Required power of motor: Prequired = = = 5.55

• 0.9 0.9 Kw

→ Selected motor:

Motor Power kW n (rpm)

DK 62-6 7 960

• Speed distribution for each shaft:

n1 = 960 rpm

n1 960

n2 = = = 266.67 rpm

u gear 3.6

n2 266.67

n3 = = = 130.72 rpm

uchain 2.04

n3 − nrequired 130.72 − 130

Rotational speed error: % = 100% = 100% = 0.55%

nrequired 130

• Calculating power for each shaft:

PI = 5 kW

PIII 5

PII = = = 5.32 kW

chain bearing 0.95 0.99

PII 5.32

PI = = = 5.54 kW

gear bearing 0.97 0.99

• Calculating torque:

PIII 9.55 106 5 9.55 106

TIII = = = 365284.58 Nmm

nIII 130.72

TIII 365284.58

TII = = = 179061.07 Nmm

uchain 2.04

TII 179061.07

TI = = = 49739.19 Nmm

ugear 3.6

4

� Motor I II III

P 5.54 5.54 5.32 5.00

u 3.60 2.04

n 960.00 266.67 130.72

T 49739.19 179061.07 365284.58

3. Design of bevel gear drive in speed reducer

3.1. Working life and allowable stress

Selecting material hardness for drive and driven gear: HB1 = 250 , HB2 = 228

NHO1 = 30HB12.4 = 30 3302.4 = 33.23 106 Cycles

NHO2 = 30HB22.4 = 30 3202.4 = 30.87 106 Cycles

Assuming the gears would be changed twice in their lifetime, required gear life:

3

Lh = 2 8 300 = 7200 hours

2

Equivalent operating cycles (static loading):

NHE 1 = 60cnLh

= 60 1 960 7200 = 414.72 106 (Cycles)

NHE 2 = 60cnLh

= 60 1 266.67 7200 = 115.2 106 (Cycles)

OH lim1 = 2HB1 + 70 = 2 330 + 70 = 730 MPa

OH lim = 2HB2 + 70 = 2 320 + 70 = 710 MPa

2

Life factor:

33.23 106 30.87 106

KHL1 = 6 = 0.79 K = 6 = 0.8

141.72 106 115.2 106

HL2

0.9KHL1 0.9 0.79

[ H1 ] = OH lim1 = 730 = 471.85 MPa

SH 1.1

5

� 0.9KHL2 0.9 0.8

[ H2 ] = OH lim2 = 710 = 464.72 MPa

SH 1.1

For bevel gears, [ H ] = 1.15 min([ H1 ],[ H 2 ]) = 534.43 MPa

3.2. Geometric calculations

Select gear width factor be = 0.285

beu 0.285 3.6

Assuming angular contact bearing: = = 0.6

2 − be 2 − 0.285

→ KH = 1.23

Preliminary calculations of outer diameter:

T1 xK H

de1 = 95 3

0.85(1 − 0.5 be )2 beux[ H ]2

49739.19 1.23

= 95 3

0.85(1 − 0.5 0.285)2 0.285 3.6 242.512

= 111.62 mm

Select de1 = 100,u = 3.6 → Z1 p = 17

→ Z1 = 1.6 Z1 p = 1.6 17 27 , select Z1 = 25 → Z2 = Z1 u = 25 3.6 = 90

de1 100

Outer module: me = = = 4 mm

Z1 25

Actual outer diameter: de1 = me Z1 = 4 25 = 100

de2 = me Z2 = 4 90 = 360

Pitch diameters: dm1 = de1 (1 − 0.5 be ) = 100(1 − 0.5 0.285) = 85.75 mm

6

�dm2 = de2 (1 − 0.5 be ) = 360(1 − 0.5 0.285) = 308.7 mm

Outer cone distance: Re = 0.5me Z12 + Z22 = 0.5 4 252 + 902 = 186.82 mm

Face width: b = Re be = 186.82 0.285 = 53.24 mm

Pitch angles:

1 1

1 = arctan = arctan = 15.52

o

u 3.6

→ 2 = 90 − 15.52 = 74.48

o o o

3.3. Kinematics and dynamics

dm1n1 85.75 960

Tangential velocity: v1 = 4

= = 4.31 m/s

6 x10 6 x104

→ Accuracy class 8 → KHv = 1.1

Force calculations:

2T1 2 49739.19

Ft 1 = Ft 2 = = = 1160 N

d m1 85.75

Fr 1 = Fa2 = Ft 1 tan cos 1 = 1160 tan20o cos15.52o = 406.81 N

Fr 2 = Fa1 = Ft 1 tan sin1 = 1160 tan20o sin15.52o = 112.97 N

3.4. Verification for contact stress

Select ZM = 275 (MPa1/2 ) for steel gears

Selecting ZH = 1.76 based on helical angle and ratio between (x1 + x2 ) / (Z1 + Z2 )

Axial contact ratio: = 0 (No helical angle)

7

� 4 − 4 − [1.88 − 3.2(1 / Z1 + 1 / Z2 )] 4 − [1.88 − 3.2(1 / 25 + 1 / 90)]

→ Z = = = = 0.87

3 3 3

Loading factor for contact stress: KH = KH KHv KH = 1 1.1 1.23 = 1.35

2T1K H (u2 + 1)

H = Z M Z H Z

0.85dm2 1bu

2 49739.19 1.35 (3.62 + 1)

= 275 1.76 0.87

0.85 85.752 53.24 3.6

= 526.77 MPa < [ H ] = 534.43 MPa

➔ Satisfactory

4. Design of roller chain drive

4.1. Choosing number of sprocket teeth Z

Z1 = 29 − 2u = 29 − 2 2.04 = 25

→ Z2 = Z1 u = 25 2.04 = 51

4.2. Calculating pitch pc

Selecting Z1 = 25 , → Z2 = Z1 u = 25 2.04 = 51

Dynamic load correction factor: Kr = 1.2

Center distance correction factor: Ka = 1

Orientation correction factor: K o = 1

Tension correction factor: Kdc = 1

Lubrication correction factor: Kb = 1.5

Operation shift correction factor: Klv = 1.12

→ Operation correction factor: K = 2.02

Z 01 25

Sprocket teeth coefficient factor: K z = = =1

Z1 25

8

� n01 200

Rotation speed coefficient factor: K n = = = 0.75

n1 266.67

KK Z K nP1 2.02 0.75 5.32

Pt = = = 8.06 kW

Kx 1

From calculated values, select pitch pc = 25.4 mm

4.3. Preliminary geometric calculations

Selecting center distance: a = 40 pc = 40 25.4 = 1016 mm

Calculating number of linkages based on center distance:

2

2a Z + Z Z − Z p

X = + 1 2 + 2 1 c

pc 2 2 a

2

2 1016 25 + 51 51 − 25 25.4

= + +

25.4 2 2 1016

= 118.43 → Select X = 118

Recalculating center distance with X = 118:

Z1 + Z 2 Z1 + Z 2

2

Z 2 − Z1

2

a = 0.25pc X − + X− − 8

2 2 2

25 + 51 25 + 51

2

51 − 25

2

= 0.25 25.4 118 − + 118 − − 8

2 2 2

= 1010.53 mm

Selecting a = 1008 mm , a = 2.02 4.04 mm

9

� 4.4. Kinematics and dynamics

n1 Z1 pc 266.67 25 25.4

Average velovity: v = = = 2.82 m/s

6 104 6 104

Tension due to centrifugal force: Fv = qmv12 = 2.6 2.822 = 20.67 N

1000P1 1000 5.32

Tangential force: Ft = = = 1886.52 N

v1 2.82

Shaft load: Fr = KmFt = 1.15 1886.52 = 2169.5 N (Km = 1.15 because incline is < 40o)

Initial tension: Fo = K f aqmg = 6 1008 2.6 9.8 = 154.1 N

4.5. Verification

P1K 5.32 2.02

Verify pitch: pc = 25.4 mm 600 3 = 600 3 = 22.64 , where

Z1n1 [ p0 ]K x 25 266.67 30 1

[p0] = 30 MPa based on the table below

Safety factor:

Q

s= [ s]

F1 + Fv + Fo

50000

= 8.9

1886.52 + 20.67 + 154.1

= 24.26 8.9

10

�[s] is selected based on rotational speed and pitch:

Impacts per second:

Z 1n1

i= [i ]

15 X

25 266.67

= [i ]

15 118

= 3.77 20

[i] is selected from the table below based on chain type and pc

4.6. Dimensions of sprockets:

Pitch diameters:

pc 25.4

d1 = = = 202.66 mm

sin sin

Z1 25

pc 25.4

d2 = = = 412.6 mm

sin sin

Z1 51

11

�Outer diameters:

da1 d1 + 0.7pc =202.66+0.7 25.4=220.44 mm

da2 d2 + 0.7pc =412.6+0.7 25.4=430.38 mm

5. Design of shafts in speed reducer

5.1. Shaft 1

Select C45 steel for shaft material → [ ] = 70 MPa

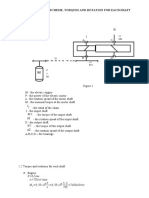

Free body diagram for shaft is as follow:

Point A connects to the motor, the bevel gear is mounted at point D.

Ft 1 = 1160 N , Fr 1 = 406.81 N

Ma1 = 0.5dm1 Fa1 =0.5 85.75 112.97=4847.59 N.mm

In Oyz plane:

{

M = −50R

/B y

C

− Ma1 + 80Fr 1 = 0

{

−50RyC − 4847.59 + 80 406.81 = 0 RyB = 147.13 N

{ C

F = −R

y

B

y + RyC − Fr 1 = 0 −RyB + RyC − 406.81 = 0 Ry = 553.94 N

In Oxz plane:

{

M /B = −50RxC + 80Ft 1 = 0

{

−50RxC + 80 1160 = 0

{

RxB = 696 N

F x = RxB − RxC + Ft 1 = 0 RxB − RxC + 1160 = 0 RxC = 1856 N

From the reaction forces above, the bending moment diagram can be drawn

12

�As well as the torque diagram:

13

�From the diagrams, critical section is at C, the equivalent moment is:

Mtd = Mx2 + My2 + 0.75T 2 = 348002 + 7356.52y + 0.75 49739.192 = 55862.76 N.mm

Mtd 55862.76

Therefore the diamter at section C: d 3 =3 = 19.98 mm

0.1[ ] 0.1 70

➔ Select dC = 20mm

Draft of shaft structure:

Base on diameter d = 15mm, select feather key size of 6mmx6mmx18mm

5.2. Shaft 2

Select C45 steel for shaft material → [ ] = 70 MPa

Free body diagram for shaft is as follow:

14

�Point A is where the sprocket will be mounted, the bevel gear at point D.

Ft 2 = 1160 N , Fr 2 = 112.97 N

Fr 3 = 2169.5 N (radial force by chain sprocket)

Ma2 = 0.5dm2 Fa2 =0.5 308 406.81=62791.12 N.mm

In Oyz plane:

{

M = −50R

/B y

C

+ Ma2 − 80Fr 2 = 0

{

−50RyC + 62791.12 + 80 112.97 = 0 RyB = 1188.04 N

{ C

F = −R

y

B

y + RyC + Fr 2 = 0 −RyB + RyC + 112.97 = 0 Ry = 1075.07 N

In Oxz plane:

{

M = −50F + 50R

/B r3

C

x + 80Ft 2 = 0

{

−50 2169.5 + 50RxC + 80 1160 = 0

{

RxB = 3643 N

F = −R + R + F

x

B

x

C

x t 2 + Fr 3 = 0 RxB − RxC + 1160 + 2169.5 = 0 RxC = 313.5 N

From the reaction forces above, the bending moment diagram can be drawn

15

�Mtd /B = Mx2 + My2 + 0.75T 2 = 1080922y + 0.75 179061.072 = 189026.5 N.mm

Mtd /C = Mx2 + My2 + 0.75T 2 = 348002 + 594022 + 0.75 179061.072 = 169666.7 N.mm

From the calculations, critical section is at B.

Mtd 189026.5

Therefore the diamter at section B: d 3 =3 = 30 mm

0.1[ ] 0.1 70

➔ Select dB = 30mm

16

�Draft of shaft 2 structure:

Base on diamter d = 25mm, select feather key size of 10mmx8mmx22mm

6. Selecting bearings for shafts

6.1. Pair 1 (shaft 1)

Since there is no axial load, selecting single-row deep groove ball bearing with bore

diameter of 20mm for the shaft.

Radial force at section B:

FrB = RBx 2 + RBy 2 = 6962 + 147.132 = 711.38 N

Radial force at section C:

FrC = RCx 2 + RCy 2 = 18562 + 553.942 = 1937 N

➔ Calculating with FrC

Select K = Kt = V = 1

17

�No axial load → X = 1,Y = 0

Dynamic equivalent load:

Q = (XVFrC + YFa )K Kt = FrC = 1937 N

Work life in million revolutions (3 years):

60nLh 60 960 14400

L= = = 829.44

106 106

Calculated dynamic load factor:

Ctt = Qm L = 1937 3 829.44 = 18199 N

Given the calculated variables, select the 6304 ETN9 bearing from SKF:

6.2. Pair 2 (shaft 2)

Since there is no axial load, selecting single-row deep groove ball bearing with bore

diameter of 30mm for the shaft.

Radial force at section B:

FrB = RBx 2 + RBy 2 = 36432 + 1188.042 = 3831.83 N

Radial force at section C:

FrC = RCx 2 + RCy 2 = 313.52 + 1075.072 = 1119.84 N

Moving on using FrB

Select K = Kt = V = 1

No axial load → X = 1,Y = 0

Dynamic equivalent load:

18

�Q = (XVFrB + YFa )K Kt = FrB = 3831.83 N

Work life in million revolutions, assume the bearings are changed twice in their life time:

60nLh 60 960 7200

L= = = 414.72

106 106

Calculated dynamic load factor:

Ctt = Qm L = 3831.83 3 414.724 = 28757 N

Given the calculated variables, select the 6306-Z bearing:

19