0% found this document useful (0 votes)

36 views29 pagesAPI 653 Lecture Note

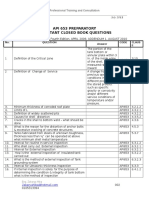

API 653 outlines the standards for inspecting, repairing, and altering aboveground storage tanks, emphasizing the importance of maintaining safe operating conditions. It details inspection frequencies, material requirements, and methods for evaluating tank integrity, including thickness measurements and radiographic inspections. The document also specifies procedures for tank relocation, dismantling, and hydrostatic testing, ensuring compliance with safety regulations and standards.

Uploaded by

Venkateswaran Ananthu KrishnamoorthyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

36 views29 pagesAPI 653 Lecture Note

API 653 outlines the standards for inspecting, repairing, and altering aboveground storage tanks, emphasizing the importance of maintaining safe operating conditions. It details inspection frequencies, material requirements, and methods for evaluating tank integrity, including thickness measurements and radiographic inspections. The document also specifies procedures for tank relocation, dismantling, and hydrostatic testing, ensuring compliance with safety regulations and standards.

Uploaded by

Venkateswaran Ananthu KrishnamoorthyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 29