0% found this document useful (0 votes)

8 views18 pagesPCM Decoder 9445

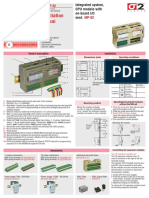

The PCM Decoder, Model 9445, is designed for studying pulse code modulation (PCM) and can process both serial and parallel PCM signals. It features a digital-to-analog converter and allows for fault simulation for troubleshooting purposes. The manual includes specifications, operating features, and warranty information, emphasizing its use in supervised industrial and educational settings.

Uploaded by

sutrakarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

8 views18 pagesPCM Decoder 9445

The PCM Decoder, Model 9445, is designed for studying pulse code modulation (PCM) and can process both serial and parallel PCM signals. It features a digital-to-analog converter and allows for fault simulation for troubleshooting purposes. The manual includes specifications, operating features, and warranty information, emphasizing its use in supervised industrial and educational settings.

Uploaded by

sutrakarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 18