0% found this document useful (0 votes)

14 views17 pagesChapter 3 Notes

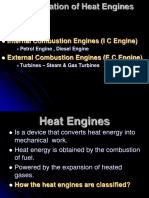

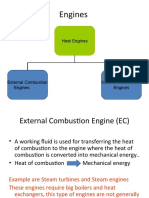

Chapter 3 discusses various types of engines, including multi-cylinder configurations, firing orders, two-stroke and diesel cycles, Wankel engines, and radial/rotary types. It highlights the importance of engine layout and firing order for performance and smooth operation. Additionally, it covers the size variations and applications of different engine types, emphasizing the creativity in engine design.

Uploaded by

teddykaanga60Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

14 views17 pagesChapter 3 Notes

Chapter 3 discusses various types of engines, including multi-cylinder configurations, firing orders, two-stroke and diesel cycles, Wankel engines, and radial/rotary types. It highlights the importance of engine layout and firing order for performance and smooth operation. Additionally, it covers the size variations and applications of different engine types, emphasizing the creativity in engine design.

Uploaded by

teddykaanga60Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 17