0% found this document useful (0 votes)

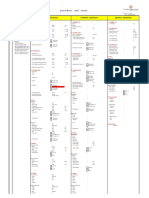

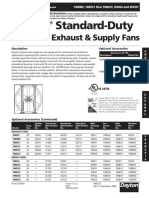

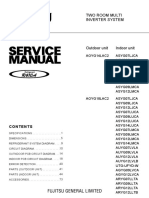

29 views7 pagesTechnical Data Sheet Format

Technical data sheet

Uploaded by

Manshi KhareCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

29 views7 pagesTechnical Data Sheet Format

Technical data sheet

Uploaded by

Manshi KhareCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

/ 7