400 non-addressable CO gas alarm

Installation Instructions

Optional

Cautions Remote Indicator

ELECTRICAL HAZARD: Disconnect power from equipment prior to +

making any internal adjustments. Service should only be performed by

2 3 2 3

qualified personnel.

End-of-line

FRAGILE: Inspect the equipment prior to installation. Do not install the Alarm Zone device

equipment if damage is apparent. Do not attempt to disassemble this Circuit

equipment. If damaged, return to the supplier.

ELECTROSTATIC HAZARD: This is sensitive electronic equipment. Apply 6 5 6 5

safe ant-static practices when handling this equipment. _

CIRCUIT LIMITATIONS: The maximum number of detectors connected to

a single detection zone is limited by the control and indicating equipment,

and may be limited by local regulations.

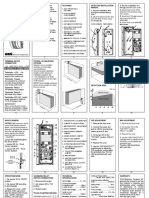

Fig. 1: 2-wire base wiring connections

Introduction

Note 1: 5-terminal base required if a remote indicator is installed.

400-series non-addressable carbon monoxide (CO) gas alarms Note 2: If a remote indicator is not installed, the polarity of the zone circuit

are suitable for connection to 2-wire and 4-wire non-addressable wiring may be reversed.

fire detection control and indicating equipment. 400 detectors can WARNING: Do not short-circuit terminals 2 and 5.

also connect to 2-wire and 4-wire addressable fire detection +

control and indicating equipment that can accept non- Power

addressable detectors1. _

Optional

Power

These instructions provide trained installation personnel with 5 6 5 6 Supervision

Relay

details to install and commission 400 CO gas alarms for optimum

performance.

Preparation Alarm Zone

3 2 3 2

Circuit

Before commencing installation, ensure all equipment (base and

detector) and tools to mount and connect the equipment are

available, such as drills, mounting screws, cables and ladders.

Fig. 2: 4-wire base wiring connections

400 CO gas alarms can be installed with the following bases and

accessories.

WARNING: Do not short-circuit terminals 2 and 5.

Description Part number Datasheet

3. Check the wiring for continuity, short circuits and earth

3-terminal 99 mm low profile faults.

487-003 31-0117

continuity base a

Output Relay (where fitted)

5-terminal 99 mm low profile

487-007 31-0117 The output relay is factory-adjusted with normally-open contacts

continuity base

b that close on alarm. The relay can be configured for normally-

Remote indicator 681-001 31-0034

closed operation as follows.

Detector monitor module 620-001 31-0027

1. Unscrew the two screws on the underside of the body of

a Onlycompatible with 400-001 only. the detector and carefully lift the cover from the body.

b Requires 5-terminal base.

2. Remove the jumper header located adjacent to the relay,

and reinsert it in the N/C position (see Fig. 3).

3. Replace the front cover and screws.

Installation Relay

Base

The base can be mounted directly onto an electrical junction box

such as an octagonal (75 mm, 90 mm or 100 mm), a round

(75 mm), or a square (100 mm) box without using any type of

mechanical adapter.

1. Feed the conductors through the middle of the base for

termination to the base contacts. N/O N/C

2. Mount the base on the junction box or directly onto a flat

surface.

3. Mount the base to the surface using fixing screws that are

suitable to securely fix the base to the surface.

Wiring

Base terminals will accept (0.4 ~ 2.5) mm2 conductors.

1. Strip the conductor insulation to expose 5 mm of the

conductor.

2. Connect the conductors to the base terminals.

a. See Fig. 1 for detectors using 2-wire bases.

Reed Switch LED

b. See Fig. 2 for detectors using 4-wire bases.

WARNING: Take care to ensure the insulation does not get Fig. 3: Adjusting the output relay

clamped by the terminal contact.

1 May be used with the 620-001 detector monitor module.

www.numens.com 1 32-0005-r05_2019-12

�Detector

WARNING: Do not install the detector head until the area is

thoroughly cleaned of construction debris, dust, etc.

1. Align the detector alignment mark with the short alignment

mark in the base, as shown in Fig. 4.

2. Mate the detector head onto the base and rotate it clockwise

to secure it. The long alignment marks should be aligned.

Fig. 4: Fitting the detector to the base

Commissioning

Gas Detector

1. Ensure all the alarm signal services, releasing devices and

extinguisher systems are disabled during the commissioning

period.

2. Connect power to the detector for approximately 10 min.

3. At the end of the start-up time, check that the red LED

flashes every 5 s. If the LED fails to flash, it indicates the

detector is not operating. Check the wiring for the correct

voltage and earth leakage. Replace the detector if

necessary.

4. Initiate a simulated alarm condition by placing a magnet on

the cover of the detector, between the LED and the sounder

grill.

5. Remove the magnet when the alarm condition is released.

6. Observe that the LED is on steady and the sounder is

operating.

7. Reset the alarm at the control and indicating equipment.

8. Listen for the sounder to silence and the LED returns to

flashing.

Output Relay (where fitted)

1. Follow Gas Detector procedure steps 4 ~ 5.

2. Monitor the output relay for activation.

3. Reset the detector at the control and indicating equipment.

4. Monitor the output relay resets to its quiescent setting.

Final Conditions

Ensure all the alarm signal services, releasing devices and

extinguisher systems disabled for the commissioning are returned

to their previous condition.

References

Document Description

31-0012 400 non-addressable CO gas alarm datasheet

View the complete range of products at

www.numens.com

2 32-0005-r05_2019-12

Numens

55 Yunhui Road, Yunlong Town, Yinzhou District, Ningbo, Zhejiang 315137 China

© 2015 ~ 2019 Ambest Electronics (Ningbo) Co Ltd. All rights reserved. All specifications and other information shown were current at the date of

publication and subject to change without notice.