0% found this document useful (0 votes)

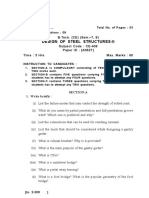

5 views11 pagesFEA Assignment

The document provides a comprehensive overview of the Finite Element Method (FEM) and its application in Finite Element Analysis (FEA) within engineering. It covers definitions, importance, advantages, disadvantages, types of elements, and basic steps involved in FEA, as well as specific methods for applying boundary conditions. Additionally, it discusses the global stiffness matrix and the concept of mesh refinement to enhance analysis accuracy.

Uploaded by

ANSH RANKACopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

5 views11 pagesFEA Assignment

The document provides a comprehensive overview of the Finite Element Method (FEM) and its application in Finite Element Analysis (FEA) within engineering. It covers definitions, importance, advantages, disadvantages, types of elements, and basic steps involved in FEA, as well as specific methods for applying boundary conditions. Additionally, it discusses the global stiffness matrix and the concept of mesh refinement to enhance analysis accuracy.

Uploaded by

ANSH RANKACopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 11