Power Factor & APFC

�What is power factor?

Power Factor = Active Power (kW)/Apparent Power (kVA)

PF1.0

Usually P.F is always Lag (Inductive)

Some time P.F can be Lead (Capacitive).

�Origin of Low Power Factor

Electrical Equipment need Reactive Power

Inductive loads draw Reactive Power

Phase difference between current & Voltage

reduces Displacement PF.

Reactive Power to maintain magnetic fields

in Motors.

Non-Linear loads reduces Distortion PF.

True PF, being product of displacement and

distortion PF is lower than both.

Capacitors can only improve displacement PF.

3

�Disadvantages of low power factor

Inefficient use of Electrical Energy:

Overloading of Transformer/Generator;

Overloading of Cable, Switchgear, Busbar

Higher temperature due to increased losses

Imposes larger kVA demand

Limits No. of loads that can be connected

Reduced revenue to Electrical Utilities

Poor Voltage regulation

�Power Factor

Correction

Reactive Current

(capacitive) IR(C)

I=Active Current

1

Reactive Current

(inductive) IR(L)

V= Line Voltage

2

I2

I1

�Advantages of P.F

Correction

Reduction in

Switchgear

Rating

Reduction in KVAR

Demand

Reduction in

Cable / Bus-bar

size

Reduction in KVA

Demand

Reduction in KVA

Demand

Reduction in Line

Current

Avoid power factor

penalties

Reduction in

Transformer Rating

Reduction in Line

loss

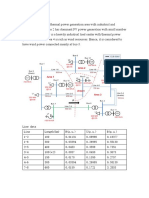

�ESTIMATION OF kVAr REQUIRED

for New Electrical Installations

500kVA, 11kV/415V,

%Impedance = 4.25%

75 HP, Other loads,

30 HP,

(415V, (total of 25

(415V,

3ph,

Kw)

3ph, I M pf

compressor

0.7)

pf. 0.7)

20 HP,

50 kVA,

75 HP,

(415V,

(440V,

(415V,

3ph,

3ph,

3ph,

UPS)

compressor) Pump,

PF =0.70

Lag)

M

Lighting

(Load

10kW)

Let us assume that the target Power Factor as desired by the Customer is

0.95.

�Kvar For The Supply TransformerFor 500 kVA transformer, kVAr = 30 kVAr

Kvar For Induction Motorrating of motor = 200 HP x 0.746

= 150 kW

Kvar for motor = 150*[tan(cos-1(0.95)- tan(cos-1(0.99)]

= 104 Kvar

Kvar For UPSrating of UPS = 50 KVA* 0.7

= 35 Kw

Kvar for UPS = 35 [tan(cos-1(0.70)- tan(cos-1(0.99)]

= 25 Kvar

Kvar For Others & lighting loadKvar for UPS = 24 [tan(cos-1(0.70)- tan(cos-1(0.99)]

= 17 Kvar

Total kvar requirement = (30+104+35+25+17)kvar =211 Kvar

Assuming 15% design assumption and contigency = 221*0.15=31.65 Kvar

Total kvar = 242.65 kvar

Kavr recommended= 250 kvar

Capacitor req. (c) = Qc/V2(2f)

Hence Capacitor req. for UPF=106*250/(2302*100)

8

= 150.51F.

�Type of compensation

1. Individual compensation

2. Group compensation

3. Central compensation

Fixed compensation

- Steady Loads

No load compensation of Induction Motors

No load compensation of Transformers

Variable compensation(for varying loads)- APFC

Svc

�Disadvantages of fixed capacitor

Manual operation(on/off)

Not meet the require kvar under varying

loads.

Can result leading power factor

Cause over voltage

Mal-operation of relays, diesel generators

Saturation of transformer

Penalty by electricity authority

10

�NEED FOR AUTOMATIC POWER FACTOR

CORRECTION

varying power demand on the supply system.

power factor also varies as a function of the load requirements.

difficult to maintain a consistent power factor by use of Fixed

Compensation i.e. fixed capacitors.

leading power

compensation)

factor

under

light

load

conditions(fixed

This result in over voltages, saturation of transformers, maloperation of diesel generating sets, penalties by electric supply

authorities.

automatically variation, without manual intervention, the compensation to

suit the load requirements.

Automatic Power Factor Correction(APFC) system provide this facility.

leading power factor will be also prevented.

11

�Benefits of APFC

Consistently high power factor under fluctuating loads

Prevention of leading power factor

Eliminate power factor penalty

Lower energy consumption by reducing losses.

Continuously sense and monitor load

Automatically switch on/off relevant capacitors steps for

consistent power factor.

Ensures easy user interface

Protect under any internal fault

Advance - relay with communication facility

Used MPP-H/MD-XL/FF(APP) type capacitors

User friendly, aesthetecally designed enclosure, dust and vermin

proof.

12

�Automatic Power Factor Correction

(APFC):

Capacitors grouped into several steps.

Suitable switching devices with coupled with

inrush current limiting devices are provided for

each step

Power Factor sensed by CT in line side

kVAr required to achieve target PF is computed

by the Microprocessor based APFC relay

APFC relay switches appropriate capacitor steps

CT senses improved PF and gives feedback

Thus target PF is achieved

13

�How to Improve Power Factor Without

Causing Harmonic Problem ?

Conventional capacitors should not be used.

Capacitors should be replaced by harmonic suppression filters

(series combination of suitable series reactor & capacitors) so

that,

It offers capacitive reactance at fundamental frequency for

necessary power factor correction.

It offers inductive reactance at all higher order dominant

harmonic frequencies to avoid resonance.

Its self series resonance frequency fR do not coincide with

predominant harmonics.

14

�Network With Harmonic

Filters

GRID

ZN

No resonance at harmonic frequencies

as filter is inductive at such

frequencies

ZT

Harmonic currents flow towards Grid ,

as it offers least impedance compared

to filter

BUS

L

Non Linear

Load

M

Equivalent Load

Impedance ZL

Predominantly fundamental current

flows through Capacitors

Moderate THD(V) in the Bus

No harmonic overloading of

Capacitors

Improvement in Power Factor

without Harmonic overload

15

�Qkvar

Degree Of Protection IP20

Ambient temperature

Voltage rise should be 3.0% [% Vc = (Q kvar

*%X)/(kva)]

Voltage rise due to series reactor and harmonics

Size of individual capacitor banks (step requirement)

Directly connected Discharge Device(Resistor, VT)

to discharge the capacitor to reduce voltage to 50

Specification of capacitors in APFC

volts within one minute

16

�Selection of switching equipment

FOR LT

Switch- fuse units/CBs/ Thyristers

Switch should be quick make and break type

Rating of CB, contactors, fuse and cable should be130% of

capacitor rated current.

For automatic switching, each step capacitor should be provided

with fuse and contactor.

FOR HT

Ht capacitor is connected to bus by CB

Cb rating should be maximum operating voltage of circuit

Continuous current rating of CB should be 135% of rated

capacitor bank current

17

H=Kp 1 (converter) where k= 1,2,3,4,.

p= pulsating index

High Harmonics current produces high harmonics

voltages.

When harminics current frequency and parrellel

resonance become equal than corrosponding

harmonics voltage produces over current in

capacitor.

Harmonics and parallel resonance

18

�XT= Xc/h2

Supress high inrush current to safe value at

time of capacitor switching.

Improve voltage waveform

Reactor should be able to carry 135%of rated

contineous current.

Discharge VT

To discharge voltage of capacitor

Series reactor

19

�TYPES OF CAPACITOR TECHNOLOGIES

MPP - METALLISED POLYPROPYLENE

MD - MIXED DIELECTRIC

FF/ALL PP - FILM - FOIL OR ALL POLY

PROPELENE

MD -XL - MIXED DIELECTRIC LOW LOSS

20

�METALISED POLYPROPELENE CAPACITOR

MPP - METALLISED

POLYPROPELENE

METALLISED LAYER

METALISATION HAS BEEN DONE ON

ONE SIDE OF POLY PROPELENE

FILM AND USED FOR CAPACITOR

WINDING

ECNOMICAL AND COMPETITIVE

DESIGN

MPP-S - NORMAL DUTY

MPP-H - MEDIUM DUTY

PP FILM

21

�MIXED DIELECTRIC TYPE

MD - MIXED DIELECTRIC

PP FILM, FOIL AND PAPER ARE USED TO

PAPER

FORM CAPACITOR WINDING

PP FILM

FOIL

22

�FILM FOIL OR APP

FILM FOIL OR APP - ALL POLY

PROPELENE

METAL LAYER IS PLACED IN -

PP FILM

BETWEEN PP FILM TO FORM

CAPACITOR WINDING

PP FILM

FOIL

23

�FILM FOIL OR APP

FILM FOIL OR APP - ALL POLY

PROPELENE

PP FILM

METAL LAYER IS PLACED IN -

BETWEEN PP FILM TO FORM

CAPACITOR WINDING

PP FILM

FOIL

24

�MIXED DIELECTRIC - LOW

LOSS

MD-XL - MIXED DIELECTRIC LOW LOSS

DOUBLE SIDE METALLISED

PAPER

PP FILM AND DOUBLE SIDED

METALISED FILM ARE USED TO FORM

CAPACITOR WINDING

PP FILM

25

�Film foil/APP verses Mixed

dielectric comparison

Film foil/APP

Mixed dielectric

low dielectric watt loss

High dielectric watt loss

Film not impregnable

Paper impregnable

More prone to Self healing

less prone to Self healing

Inferior long term stability

Superior long term stability

Moderate harmonic overload

Good harmonic overload

capability

capability

26

�Mixed dielectric verses MDXL

Comparison

Mixed dielectric

MDXL

High dielectric watt loss

Lowest dielectric watt loss

Paper impregnable

Combines plus points of MD

less prone to Self healing

and APP types

Superior long term stability

Excellent long term stability

Good harmonic overload

Superior harmonic overload

capability

capability

27

�APFC

28

�29

�30

percentage of Non linear loads in an

installation becomes greater than 20% of

connected load.

N/w Harmonics

Overloading cap

Conventional

capacitor

Current amp

Cap failure

Power factor correction in

Voltage distortion

harmonics enrich environment

Parallel resonance

31

�solution

Use detuned filter circuit

Avoid parallel resonance by offering inductive impedance to specific

harmonics frequency.

The tuning frequency is generally lower than 90 % of the lowest

harmonic frequency whose amplitude is significant.

Protect capacitors from harmonics over loading

Reduces over loading of transformer and other rotating equipments.

Prevent current amplification

Achieve consistently high power factor.

Can be used as fixed or APFC

32

�COMPONENTS

33

�CONTROLLER

34

�DRY TYPE RESIGN EMBADED

REACTOR

35

�Circuit Diagram

36

�THYRISTER CONTROLLED

VAR

STATCOM

37