0% found this document useful (0 votes)

225 views33 pagesWeek 5 Processing 3

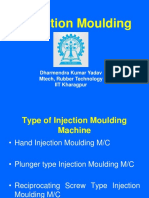

Plastic injection molding involves injecting molten plastic into a mold cavity under high pressure. It has 3 main functional units: injection, mold, and clamping. The molten plastic is injected into a metal mold cavity, which then cools and hardens to the shape of the cavity. Common materials used are polystyrene, ABS, nylon, polypropylene, and PVC. Key factors for success include the proper machine, material, mold design, and operating parameters.

Uploaded by

ashiq_a99Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

225 views33 pagesWeek 5 Processing 3

Plastic injection molding involves injecting molten plastic into a mold cavity under high pressure. It has 3 main functional units: injection, mold, and clamping. The molten plastic is injected into a metal mold cavity, which then cools and hardens to the shape of the cavity. Common materials used are polystyrene, ABS, nylon, polypropylene, and PVC. Key factors for success include the proper machine, material, mold design, and operating parameters.

Uploaded by

ashiq_a99Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

/ 33