0% found this document useful (0 votes)

91 views32 pagesControllers

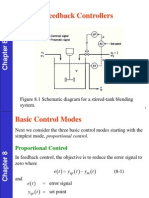

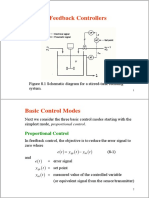

This document discusses different types of controllers, including on-off controllers, proportional controllers, proportional-integral (PI) controllers, and proportional-integral-derivative (PID) controllers. On-off controllers have two output states and are simple and cheap but cause excessive wear. Proportional controllers reduce error but can cause offset. PI controllers eliminate offset but can experience integral windup. PID controllers combine proportional, integral, and derivative control to stabilize processes, though ideal derivative control is physically unrealizable.

Uploaded by

Eric KamauCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

91 views32 pagesControllers

This document discusses different types of controllers, including on-off controllers, proportional controllers, proportional-integral (PI) controllers, and proportional-integral-derivative (PID) controllers. On-off controllers have two output states and are simple and cheap but cause excessive wear. Proportional controllers reduce error but can cause offset. PI controllers eliminate offset but can experience integral windup. PID controllers combine proportional, integral, and derivative control to stabilize processes, though ideal derivative control is physically unrealizable.

Uploaded by

Eric KamauCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

/ 32