100% found this document useful (1 vote)

724 views136 pages002-CNC Machine Tools+Programming

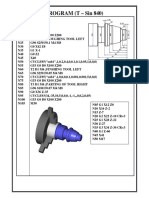

The document discusses computer numerical control (CNC) technology and CNC programming. It covers the history and definition of CNC, various CNC applications in industries like automotive and aerospace manufacturing. Examples of CNC machines for turning, milling, laser cutting, plasma cutting, pressing and rapid prototyping are provided. Advantages of CNC like increased productivity and quality are highlighted. Key elements of a CNC system like the part program, program input device, machine control unit, drive system, machine tool and feedback system are described.

Uploaded by

Malik MuchamadCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

724 views136 pages002-CNC Machine Tools+Programming

The document discusses computer numerical control (CNC) technology and CNC programming. It covers the history and definition of CNC, various CNC applications in industries like automotive and aerospace manufacturing. Examples of CNC machines for turning, milling, laser cutting, plasma cutting, pressing and rapid prototyping are provided. Advantages of CNC like increased productivity and quality are highlighted. Key elements of a CNC system like the part program, program input device, machine control unit, drive system, machine tool and feedback system are described.

Uploaded by

Malik MuchamadCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

/ 136