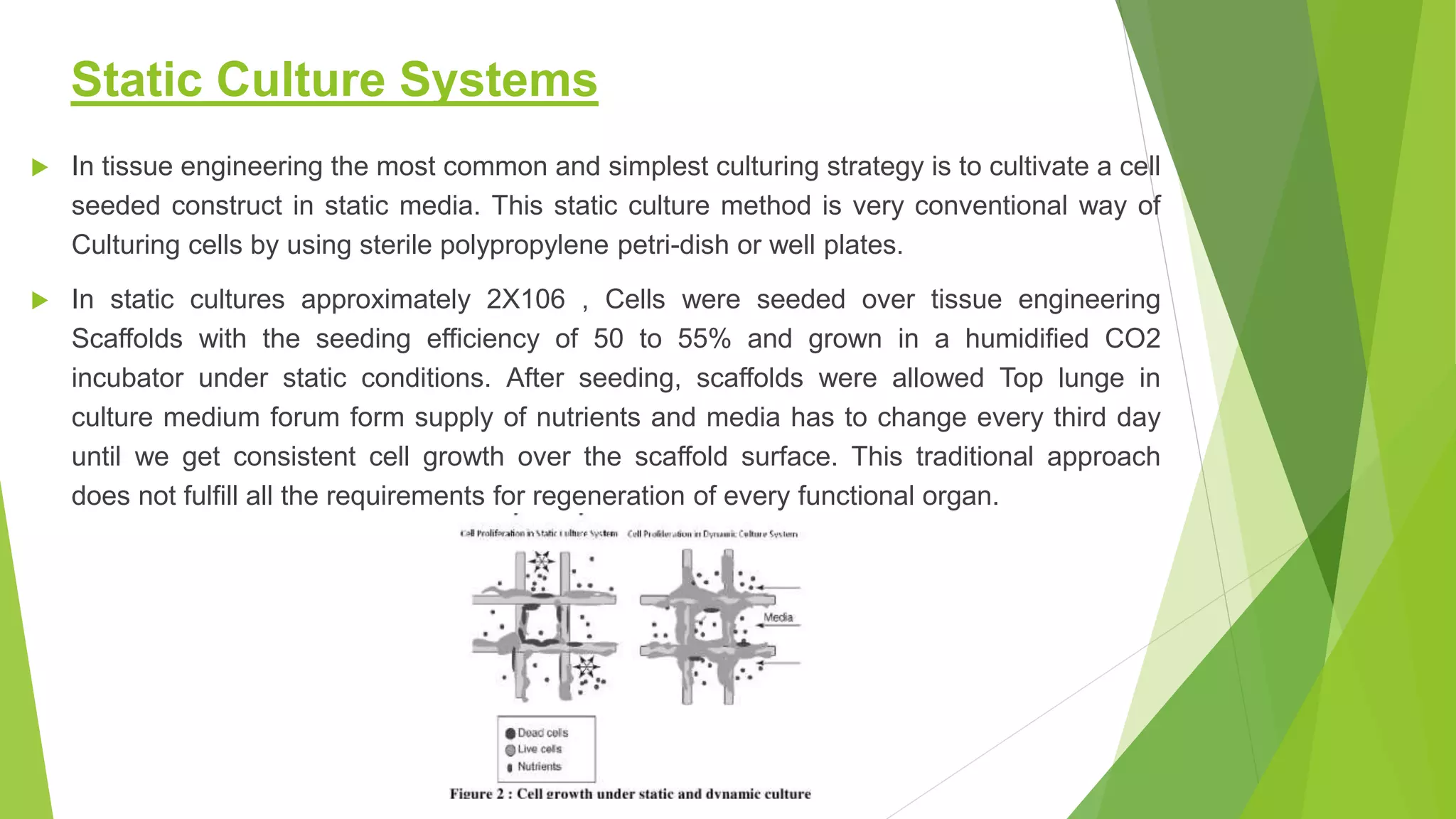

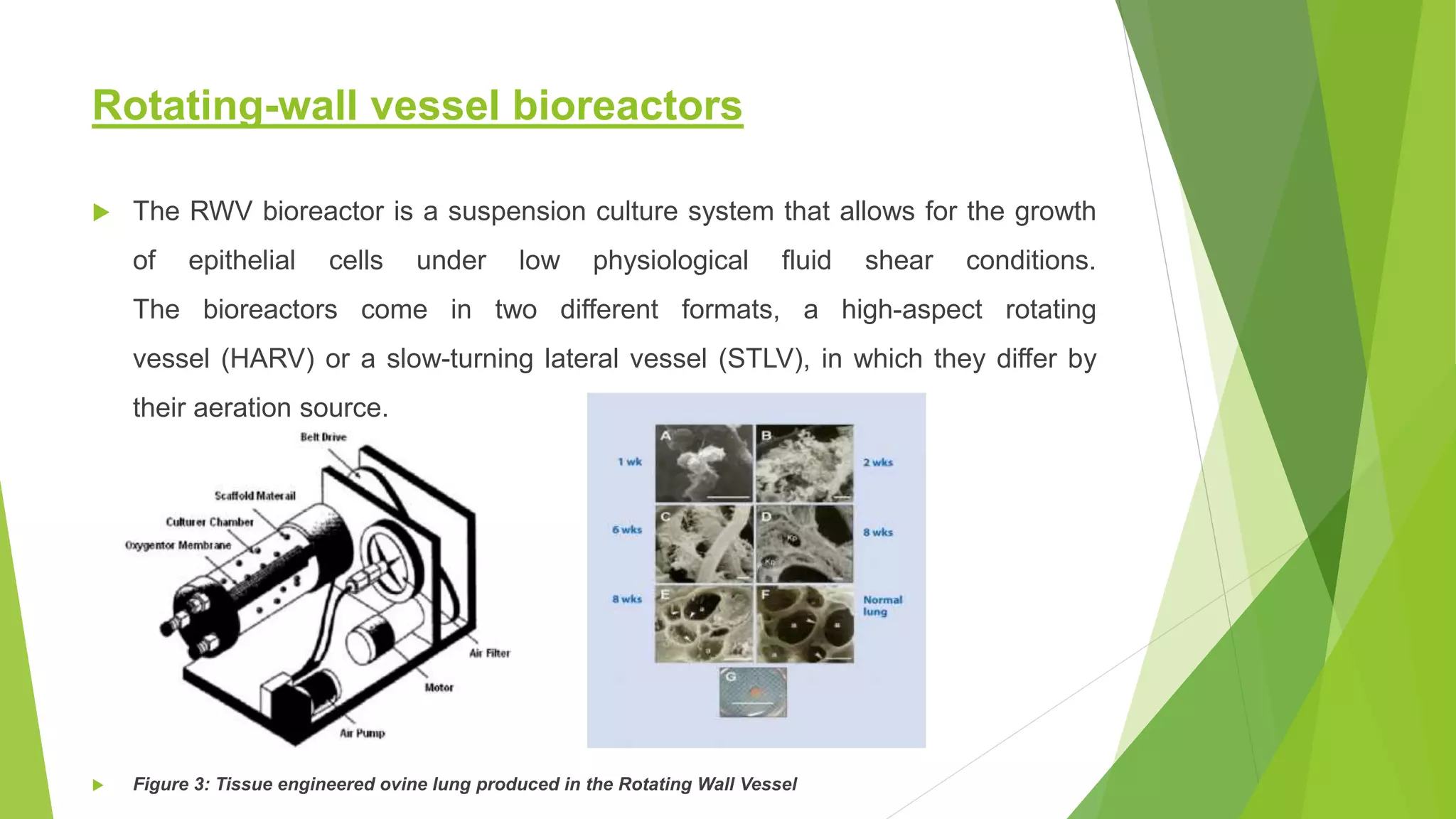

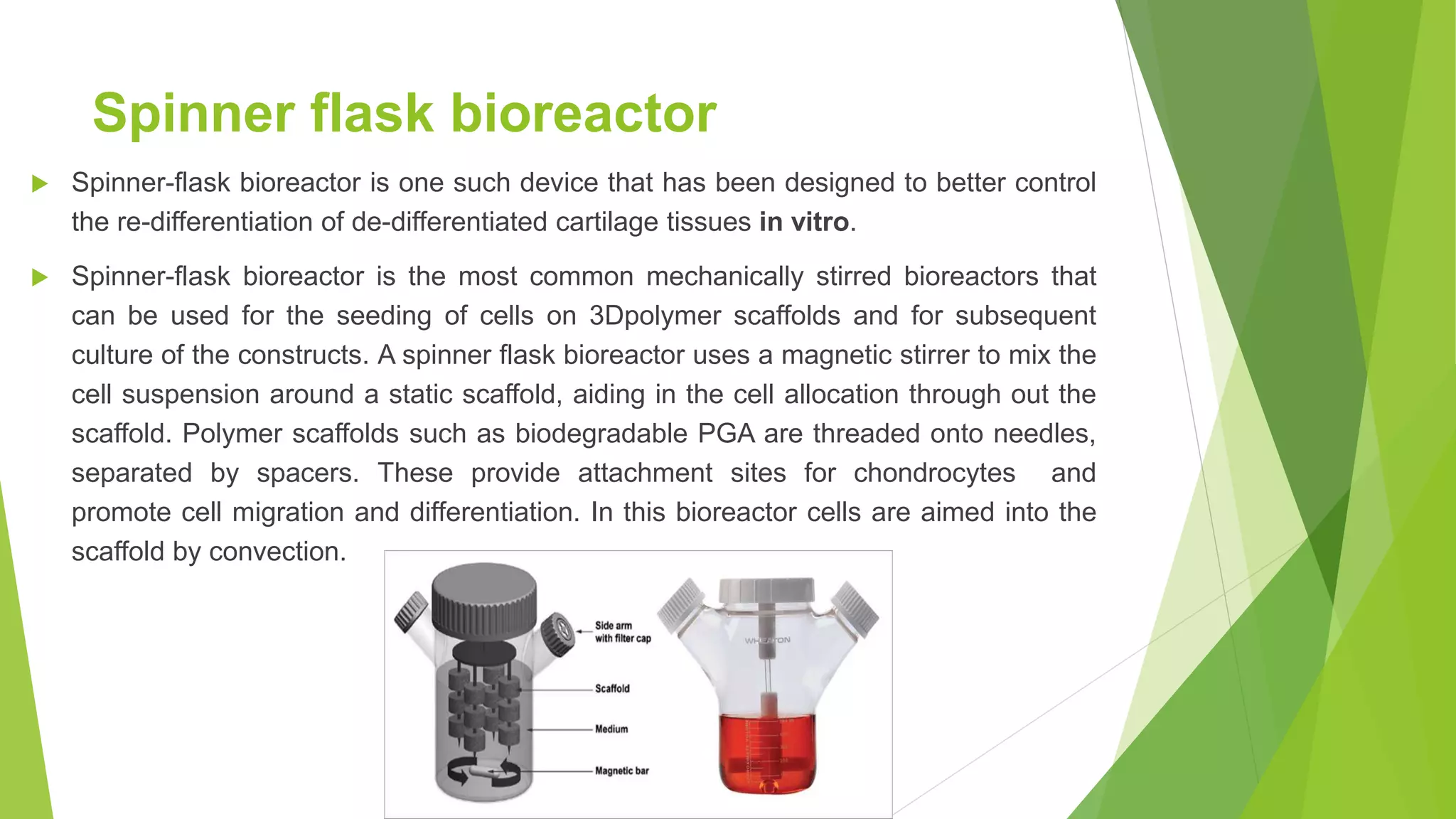

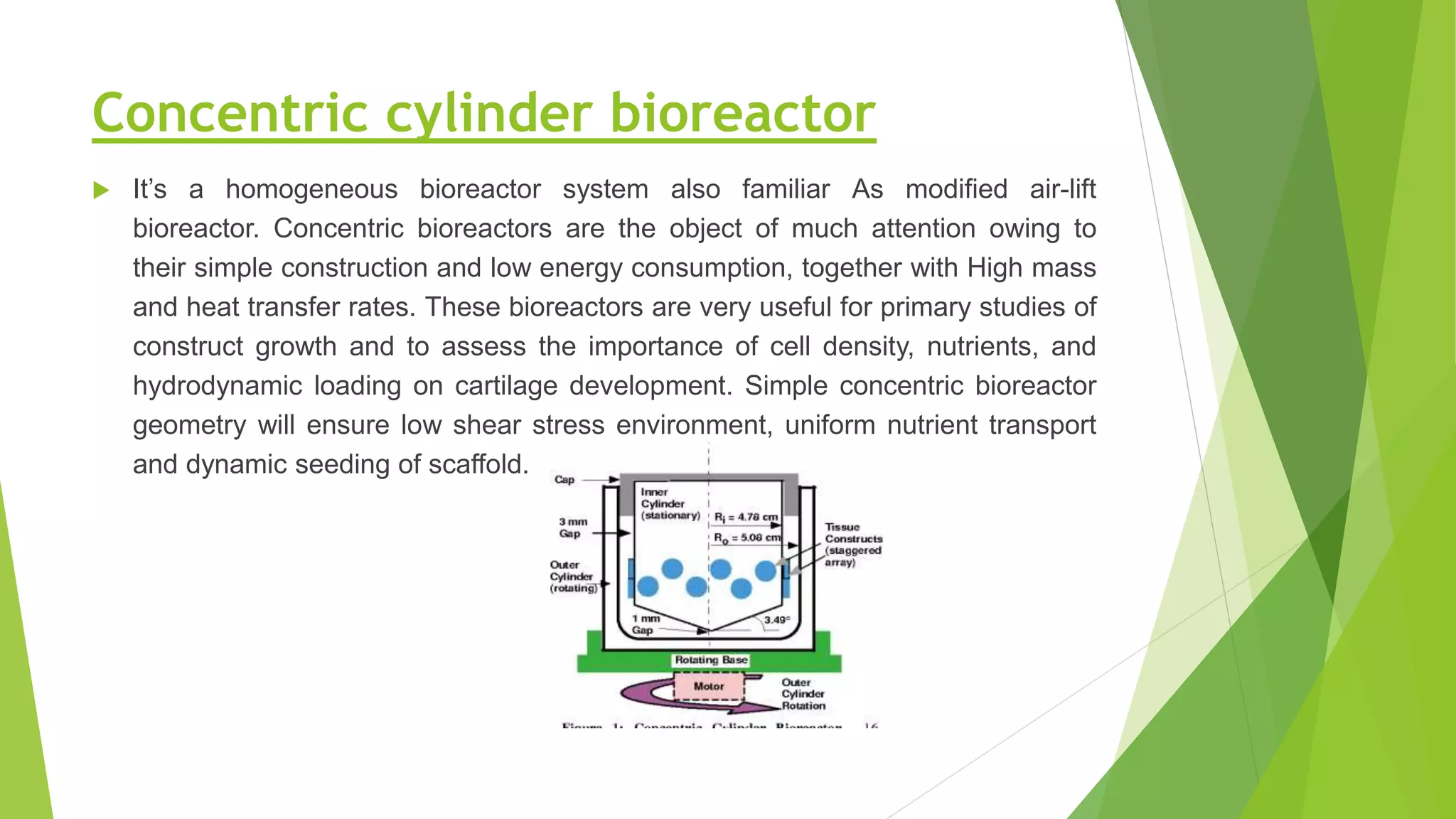

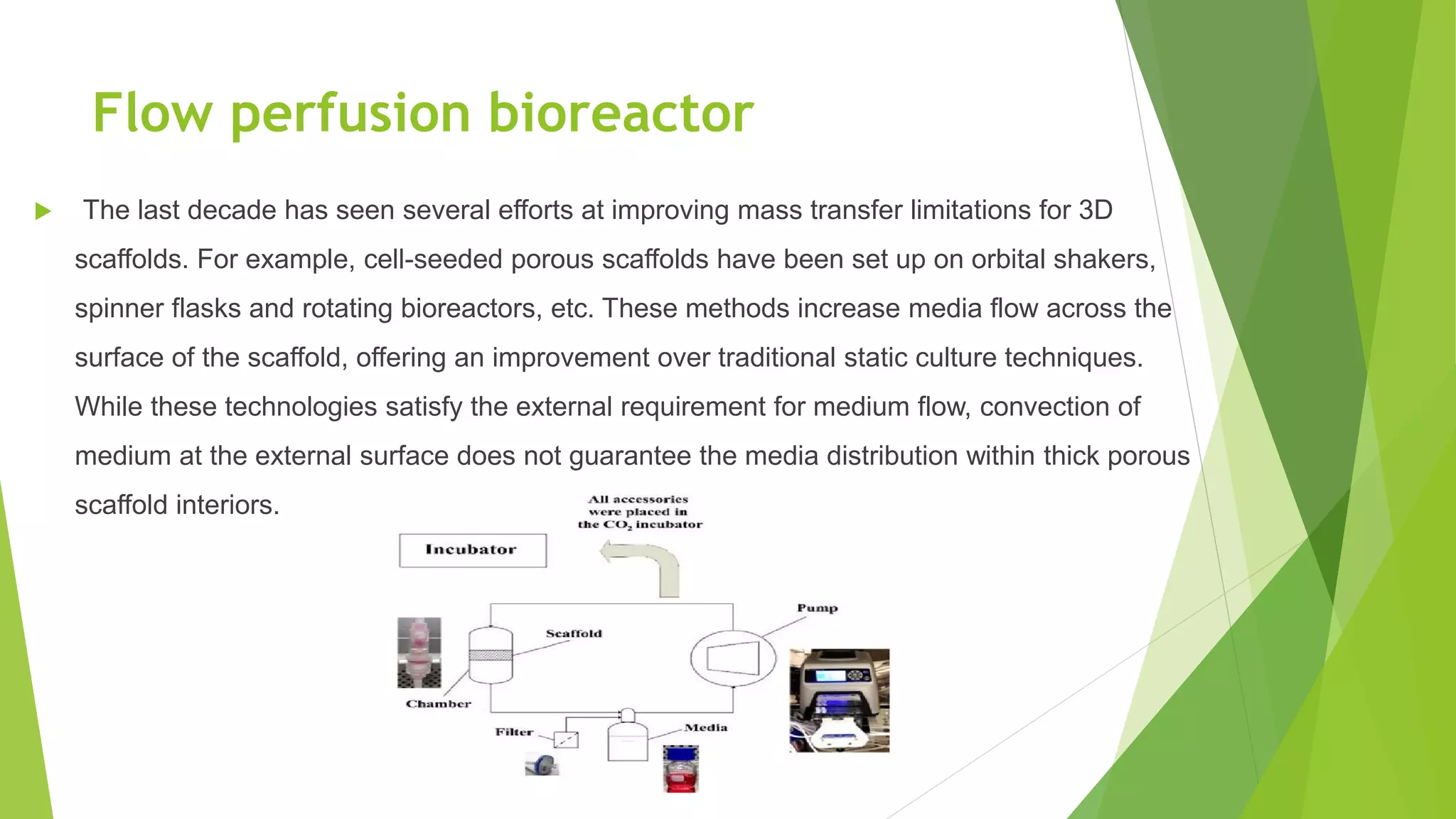

The document discusses bioreactors used in tissue engineering. It defines bioreactors as devices that closely control conditions for cells and tissues. There are two main types of bioreactor culture systems - static and dynamic. Static systems simply culture cells in dishes while dynamic systems like rotating wall vessel bioreactors, spinner flask bioreactors, and perfusion bioreactors enhance mass transfer and mimic physiological fluid flow using stirred media. The document concludes that bioreactor design must consider the specific tissue needs and that applying mechanical forces in novel bioreactor systems can better develop functional engineered tissues.