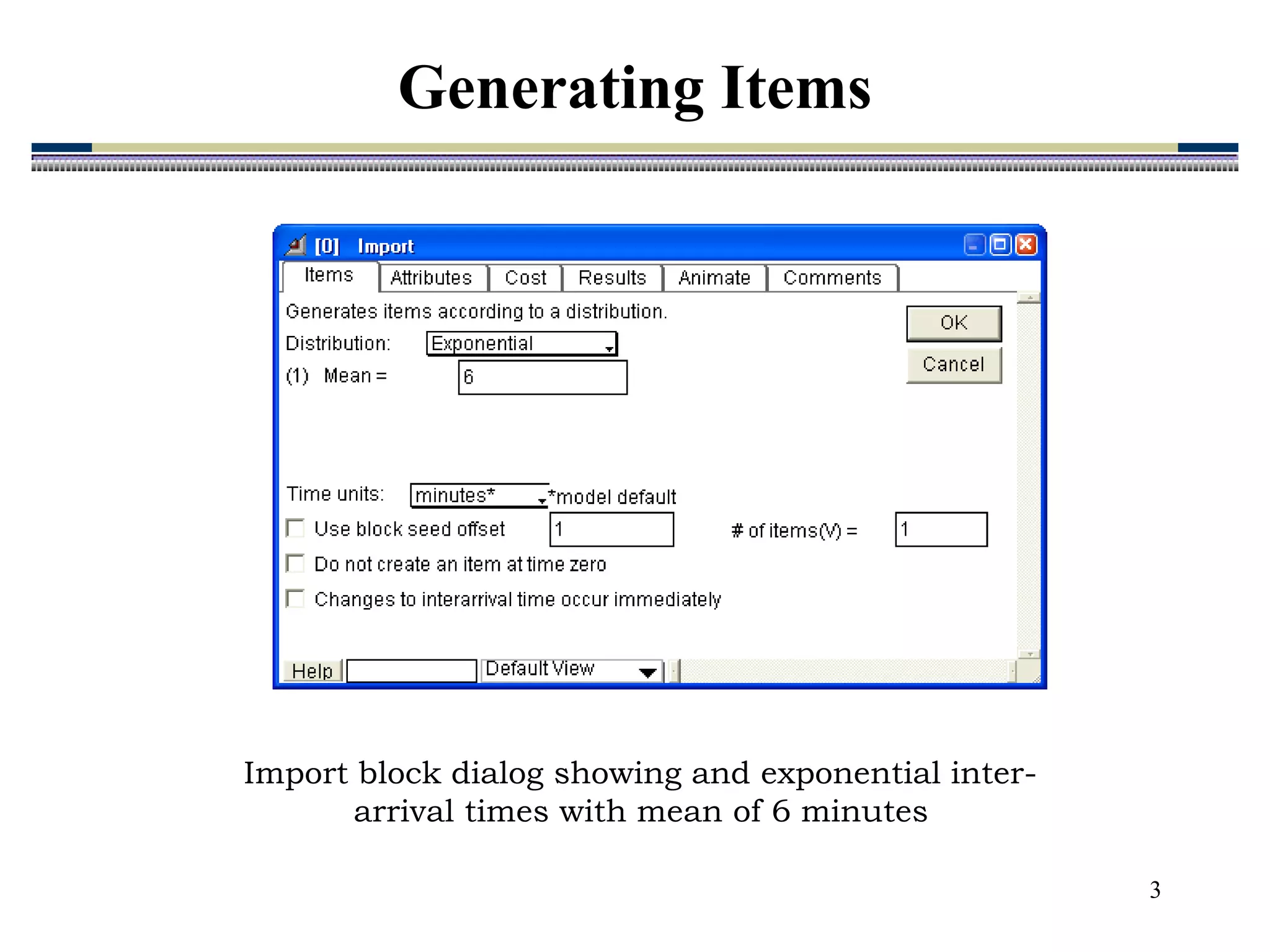

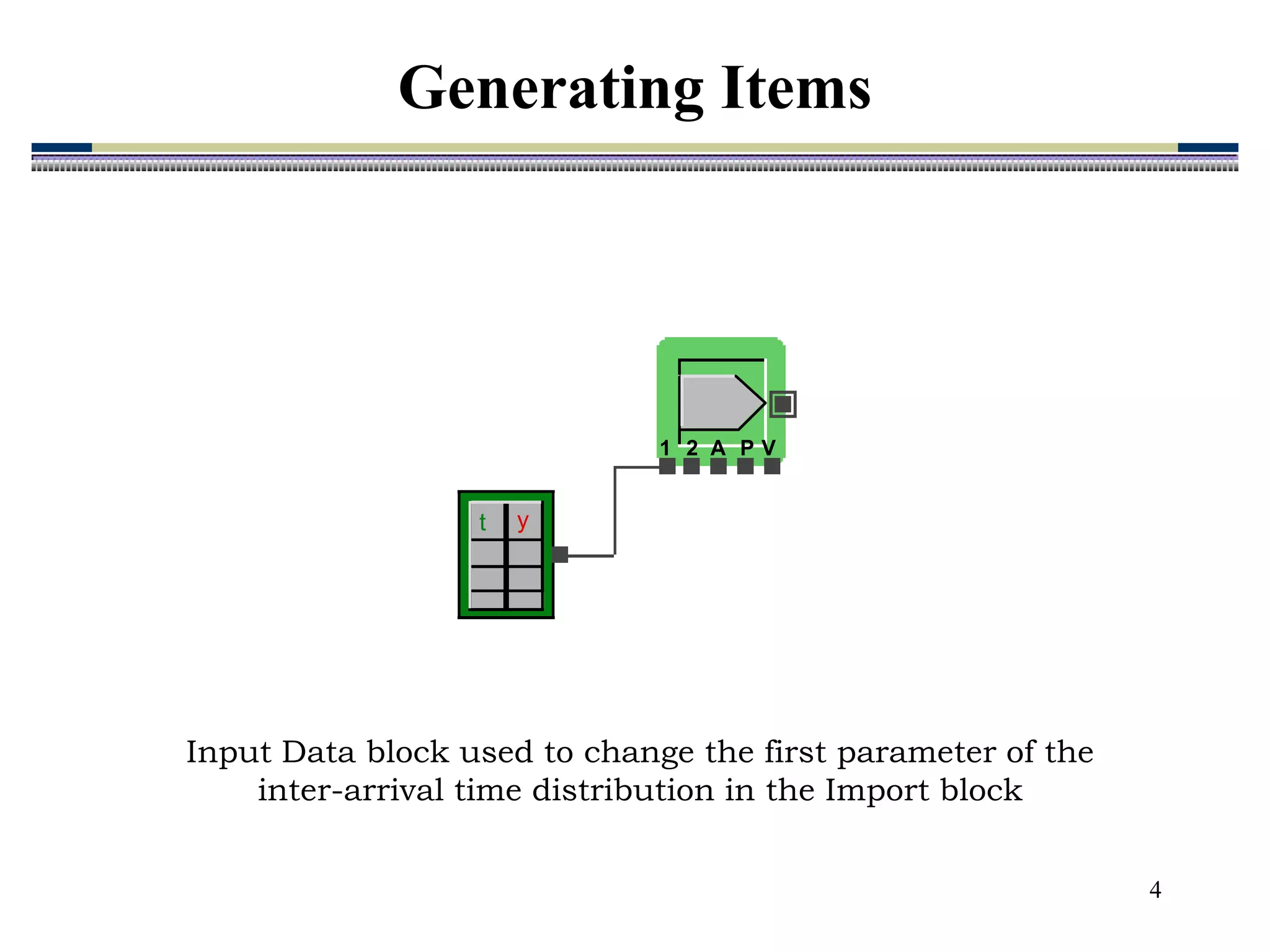

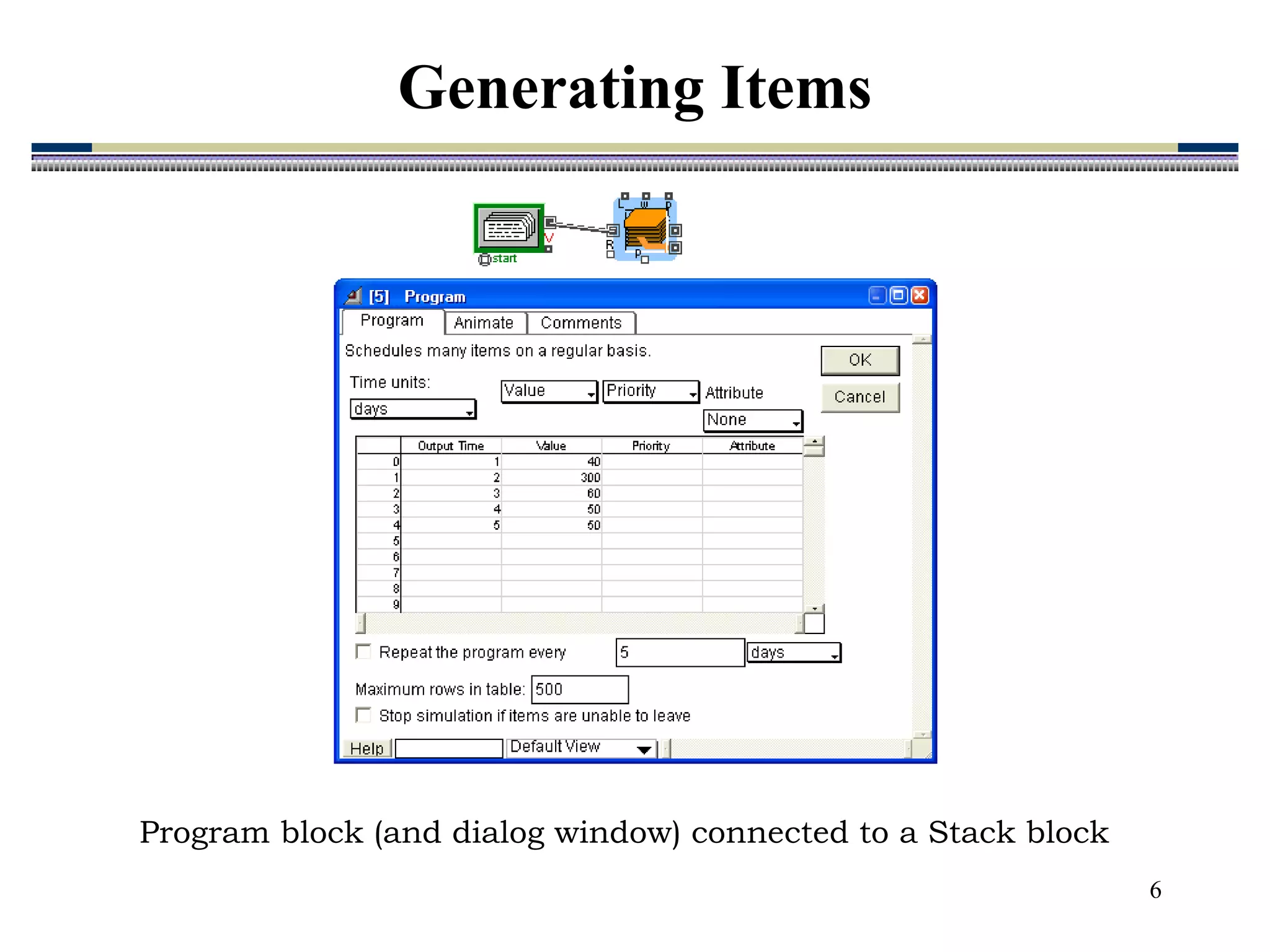

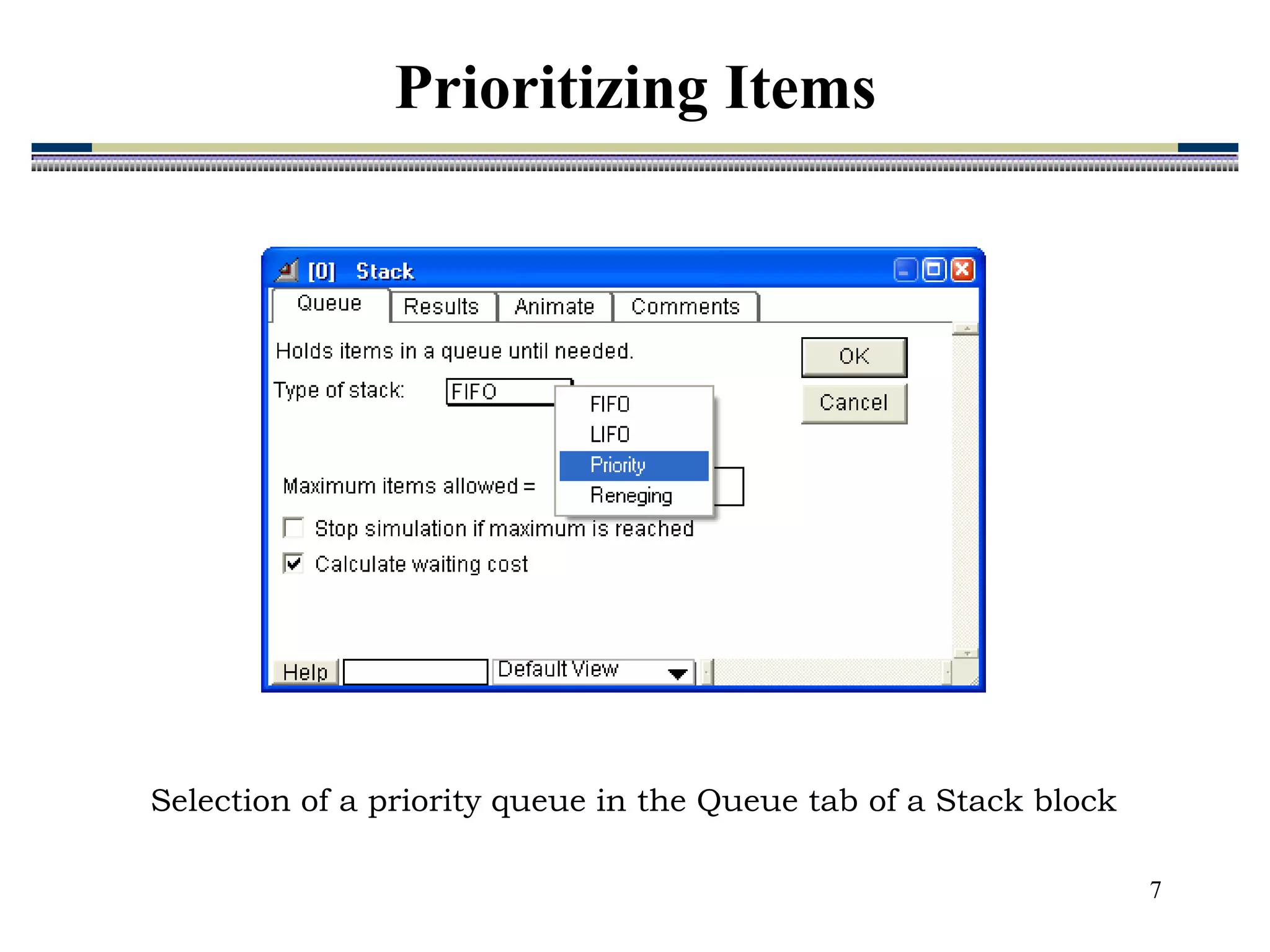

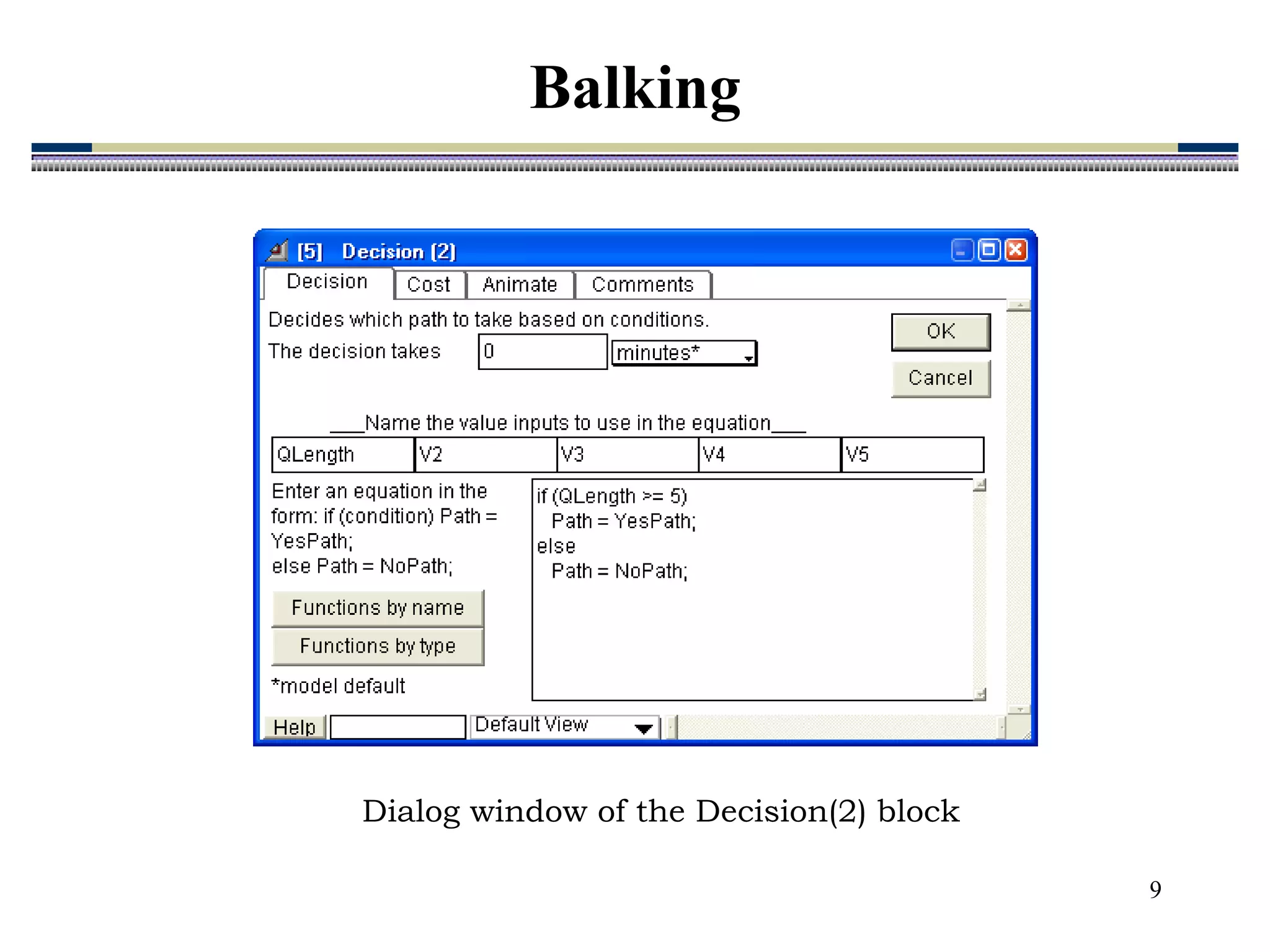

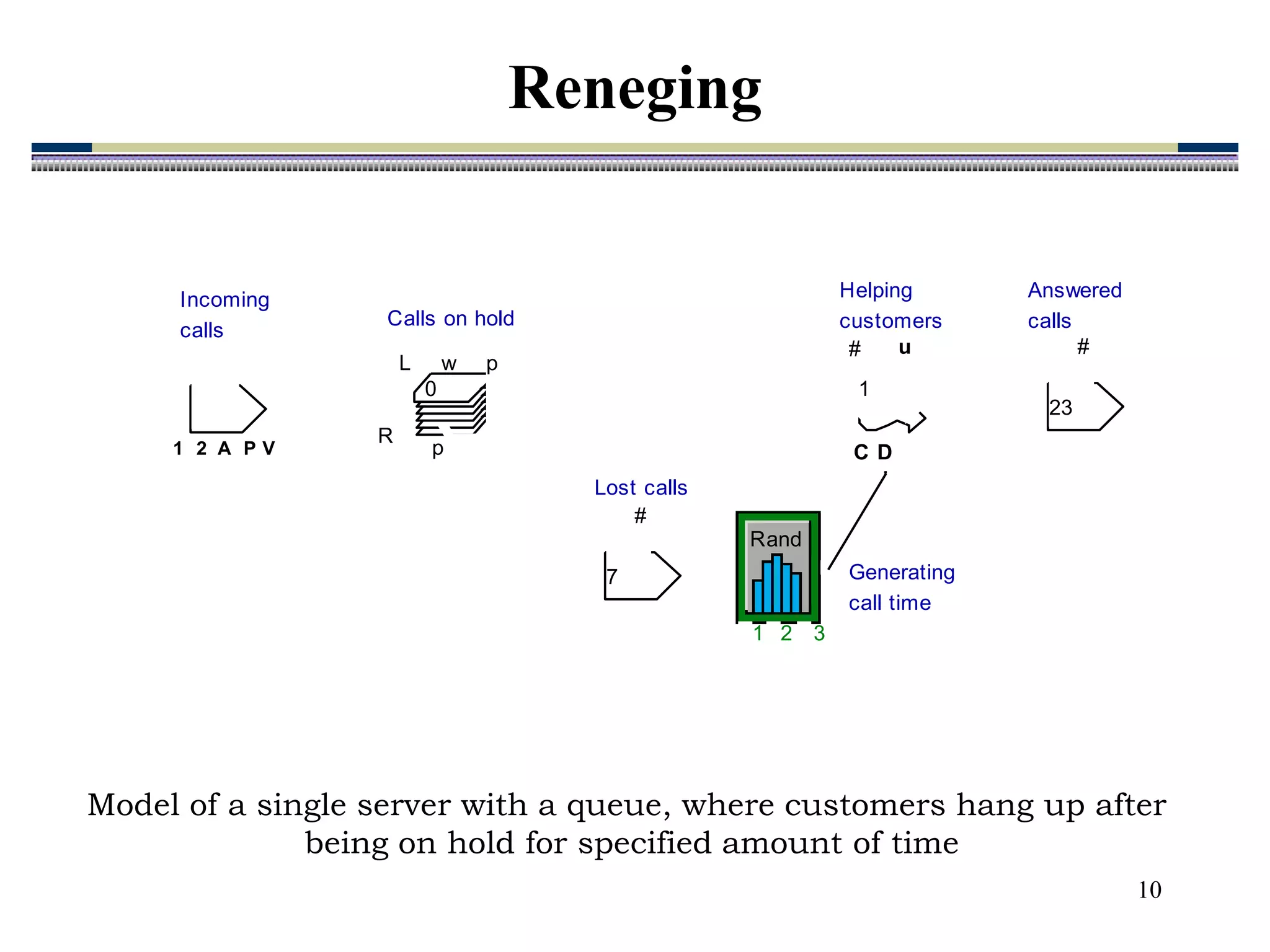

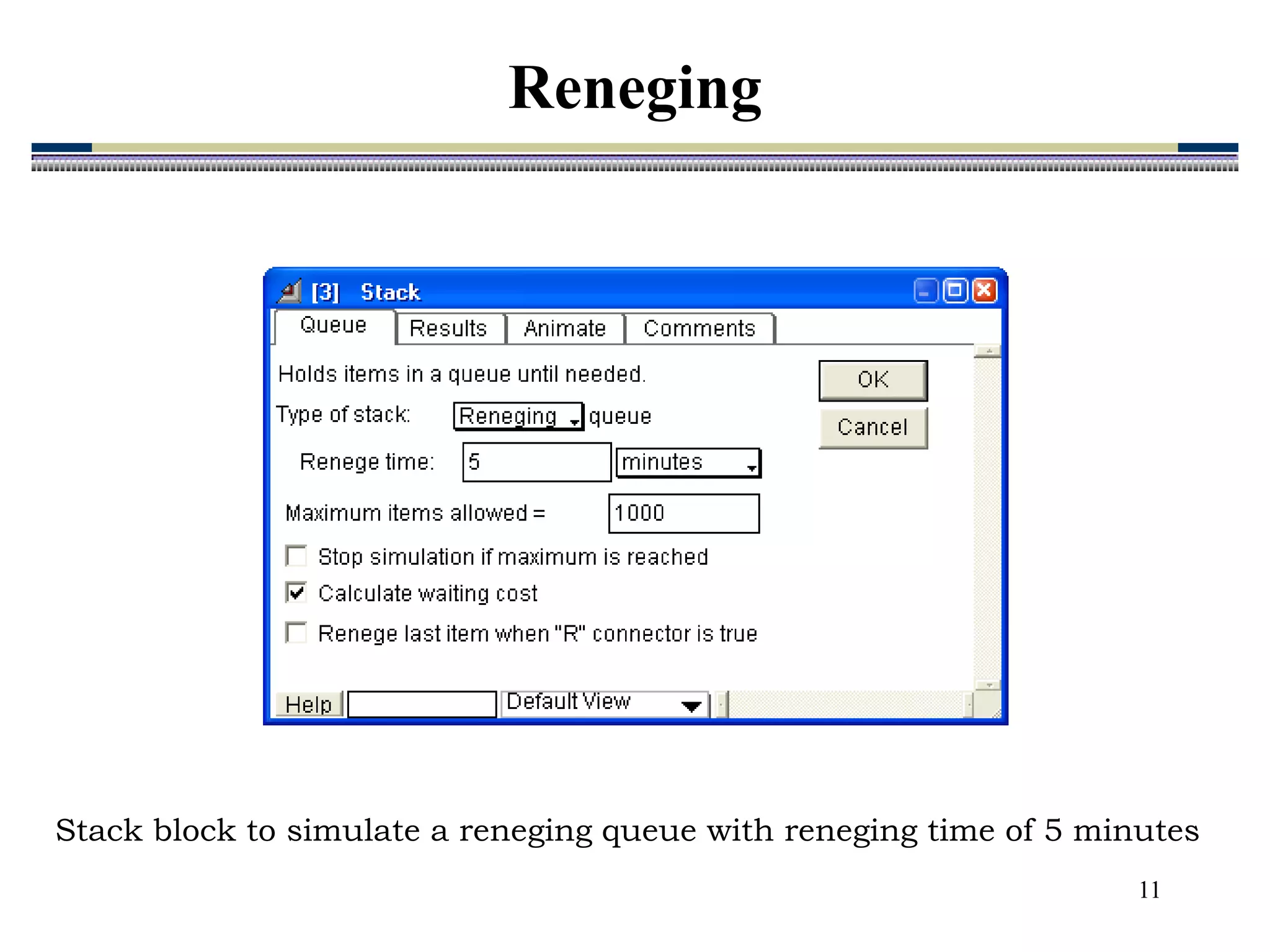

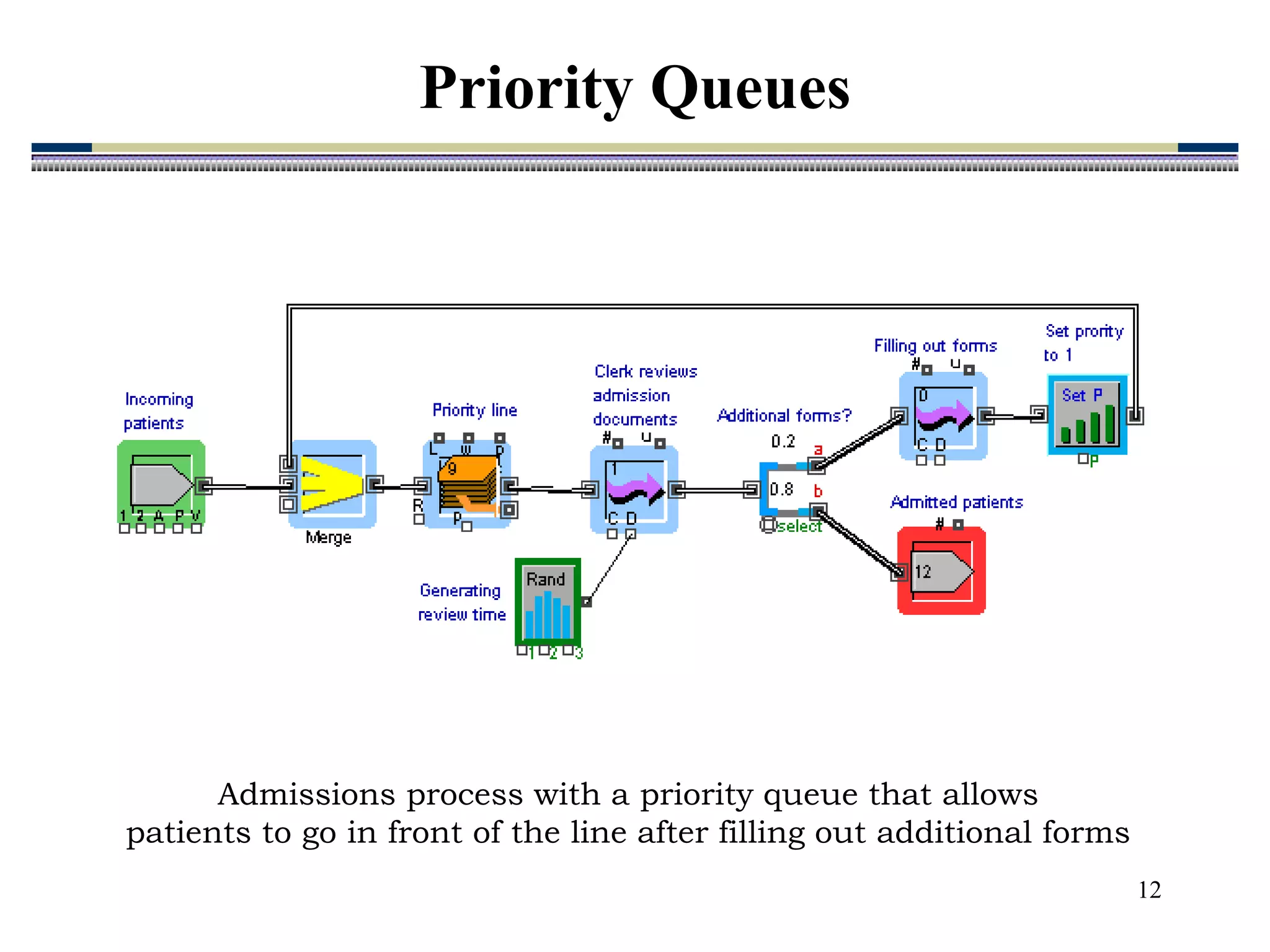

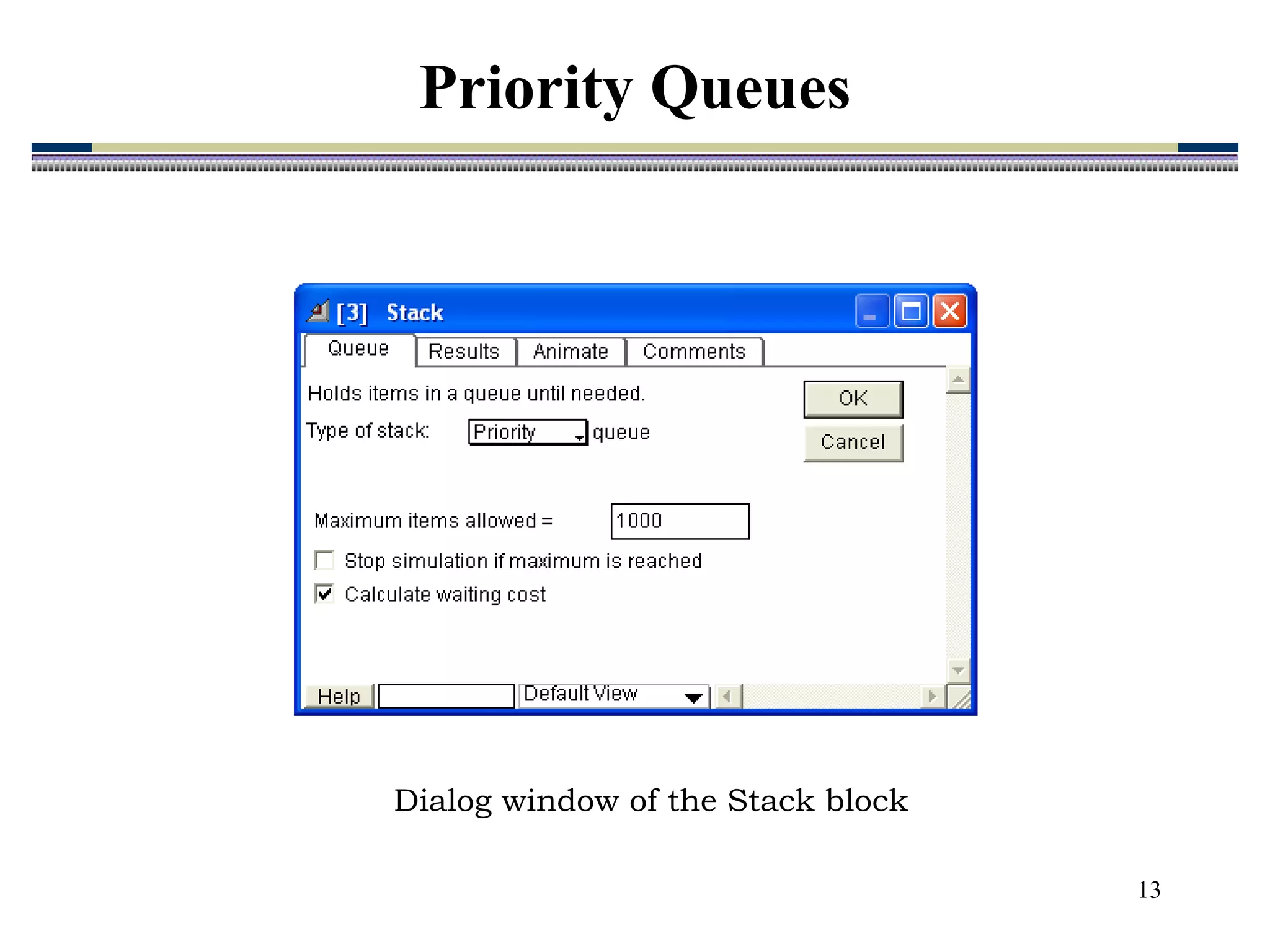

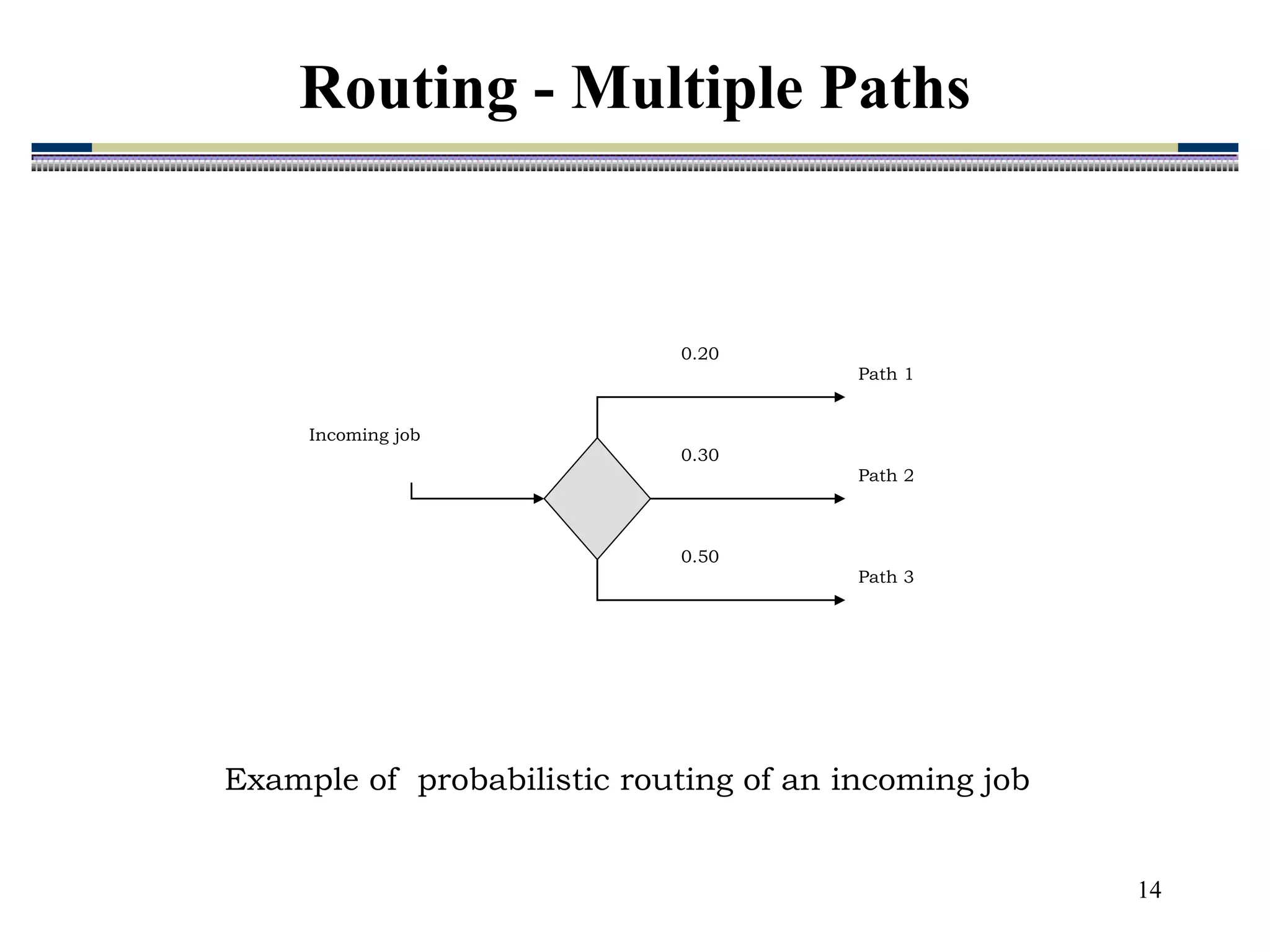

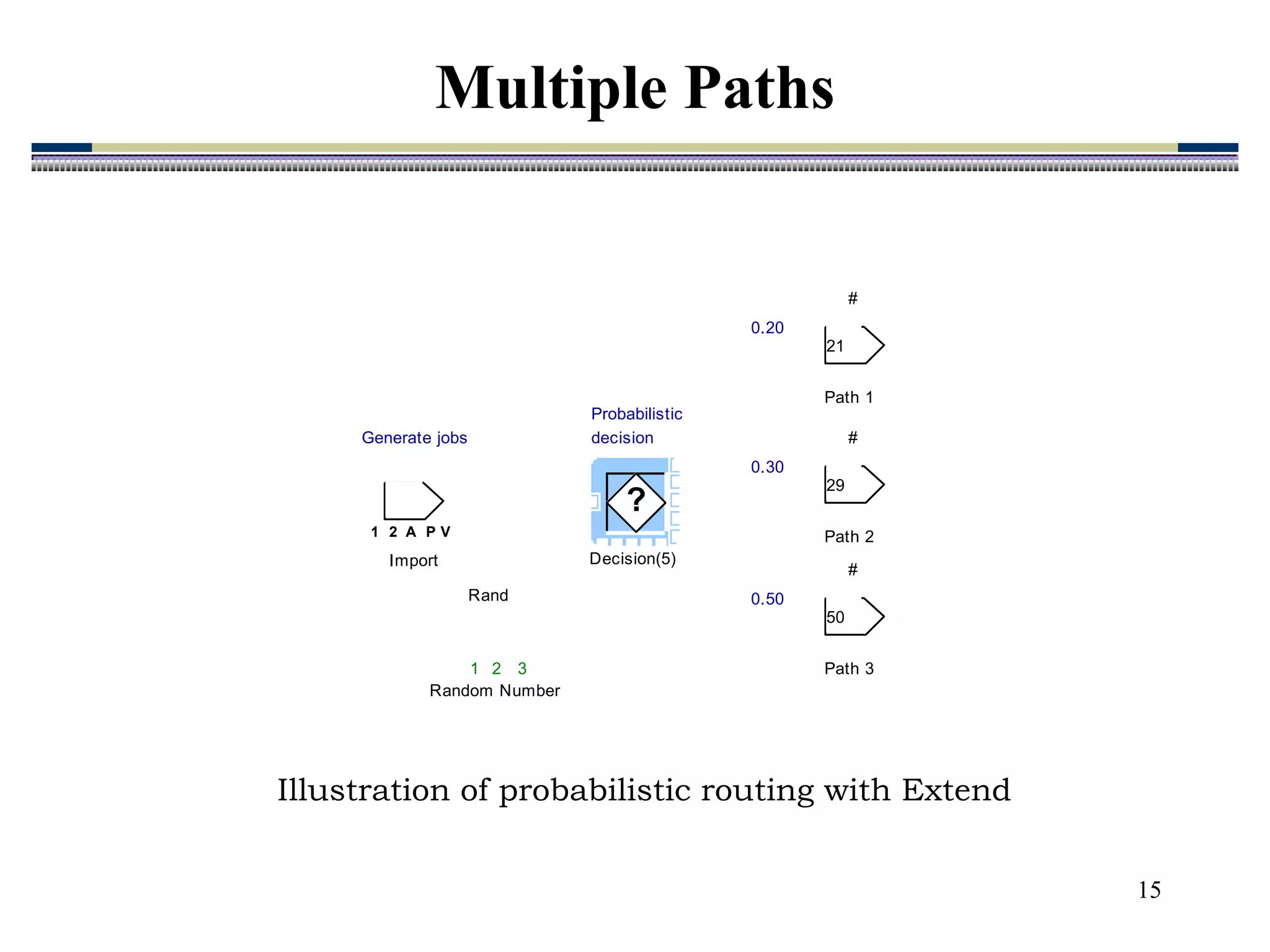

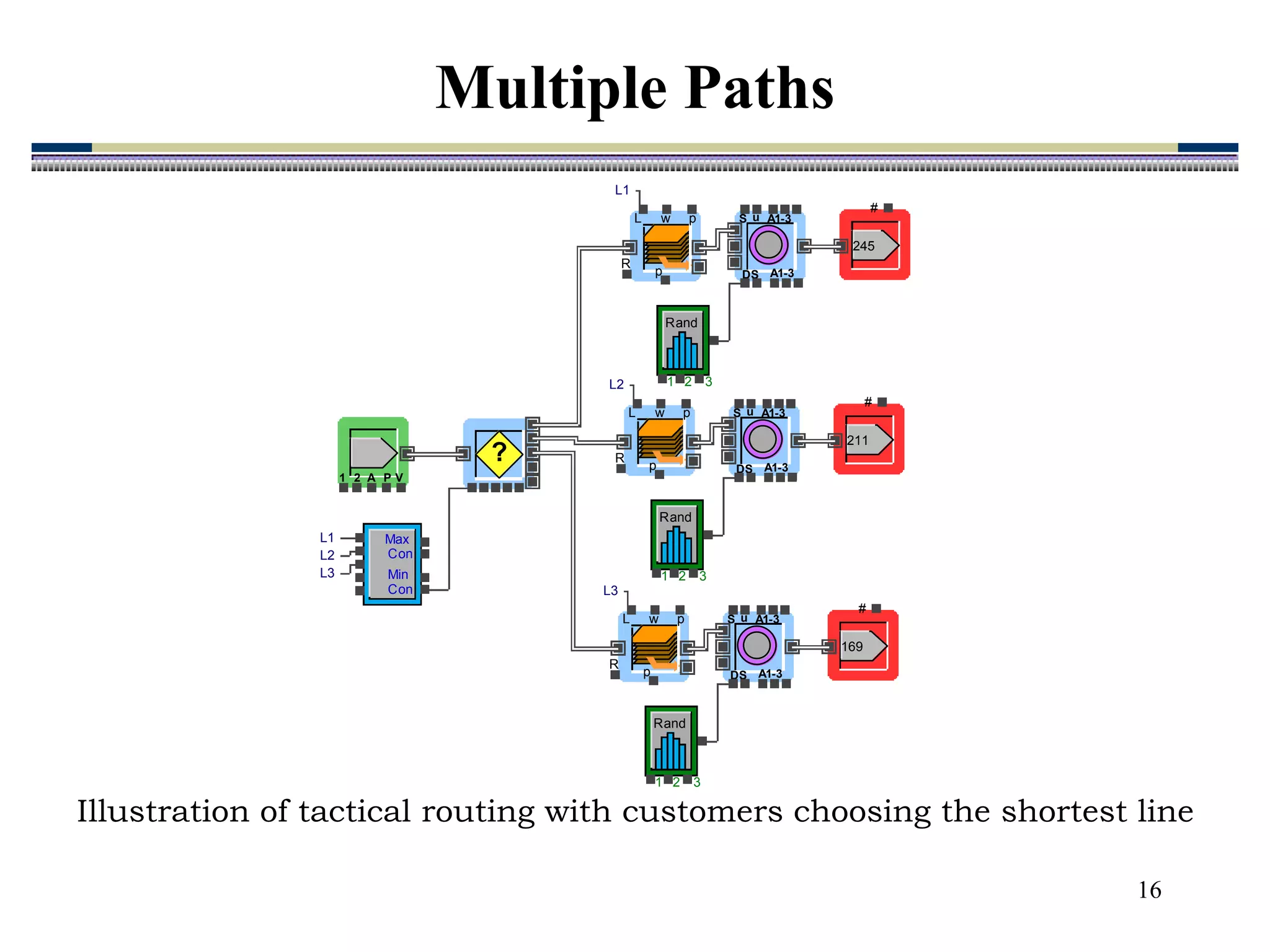

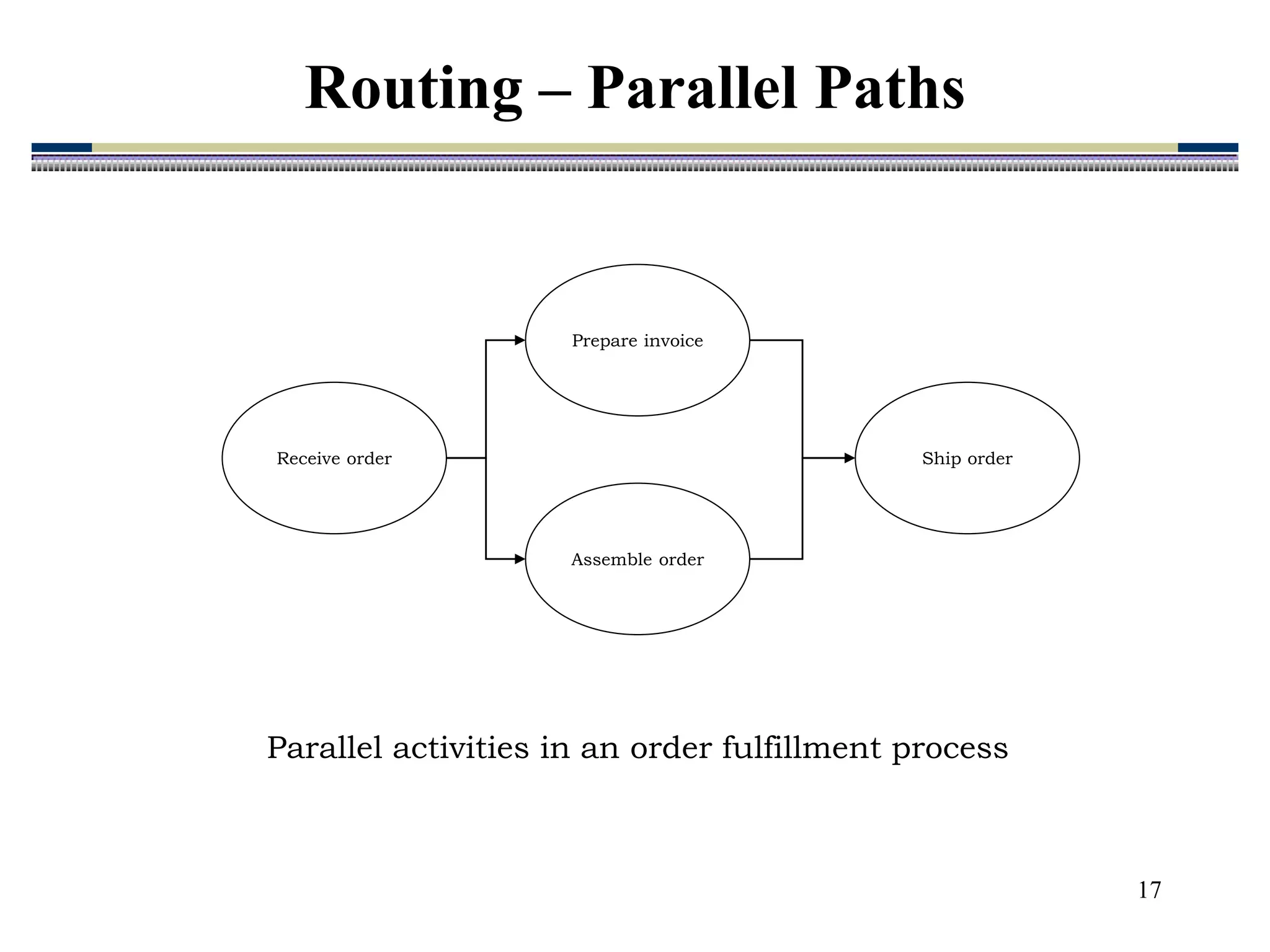

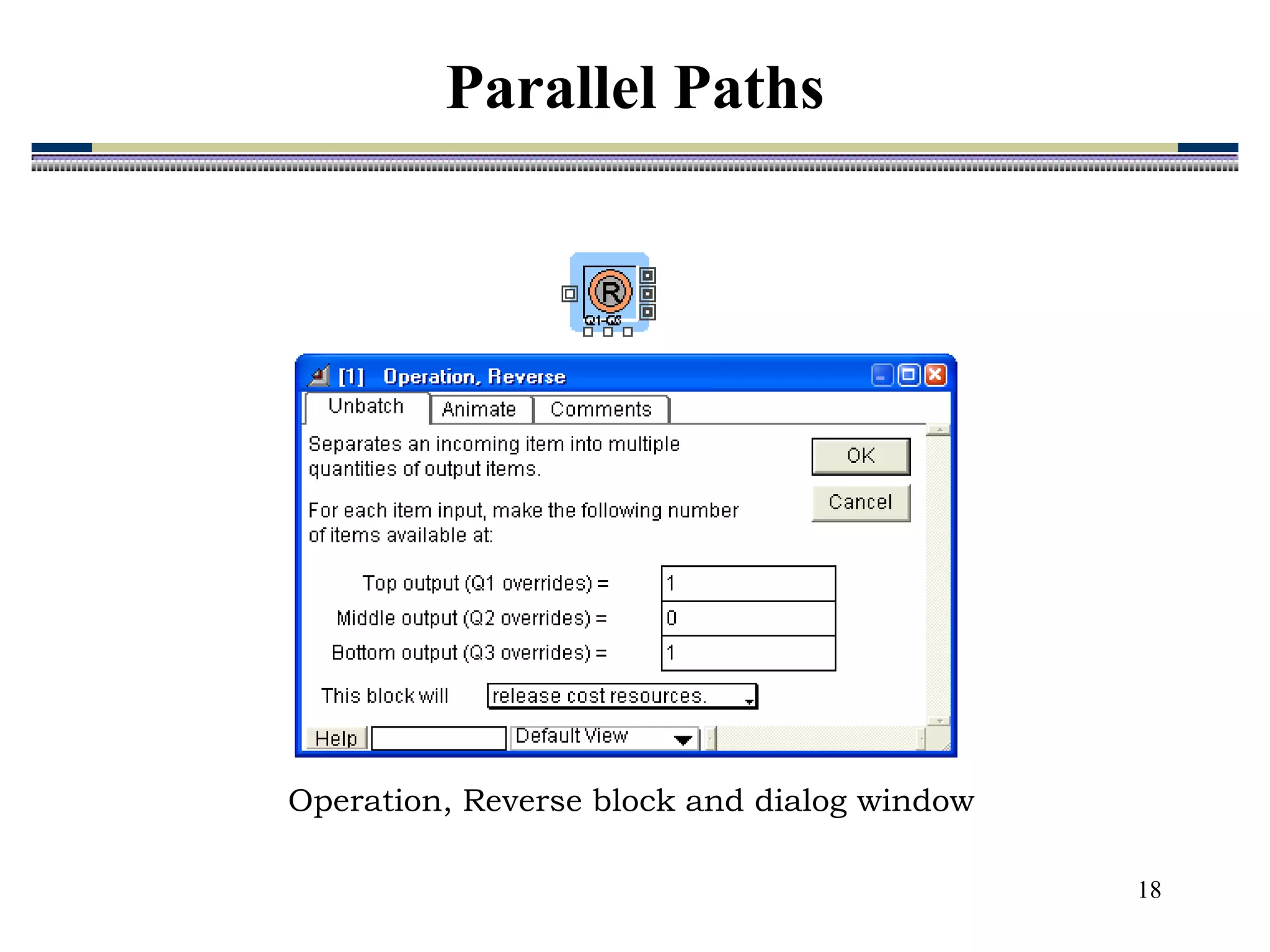

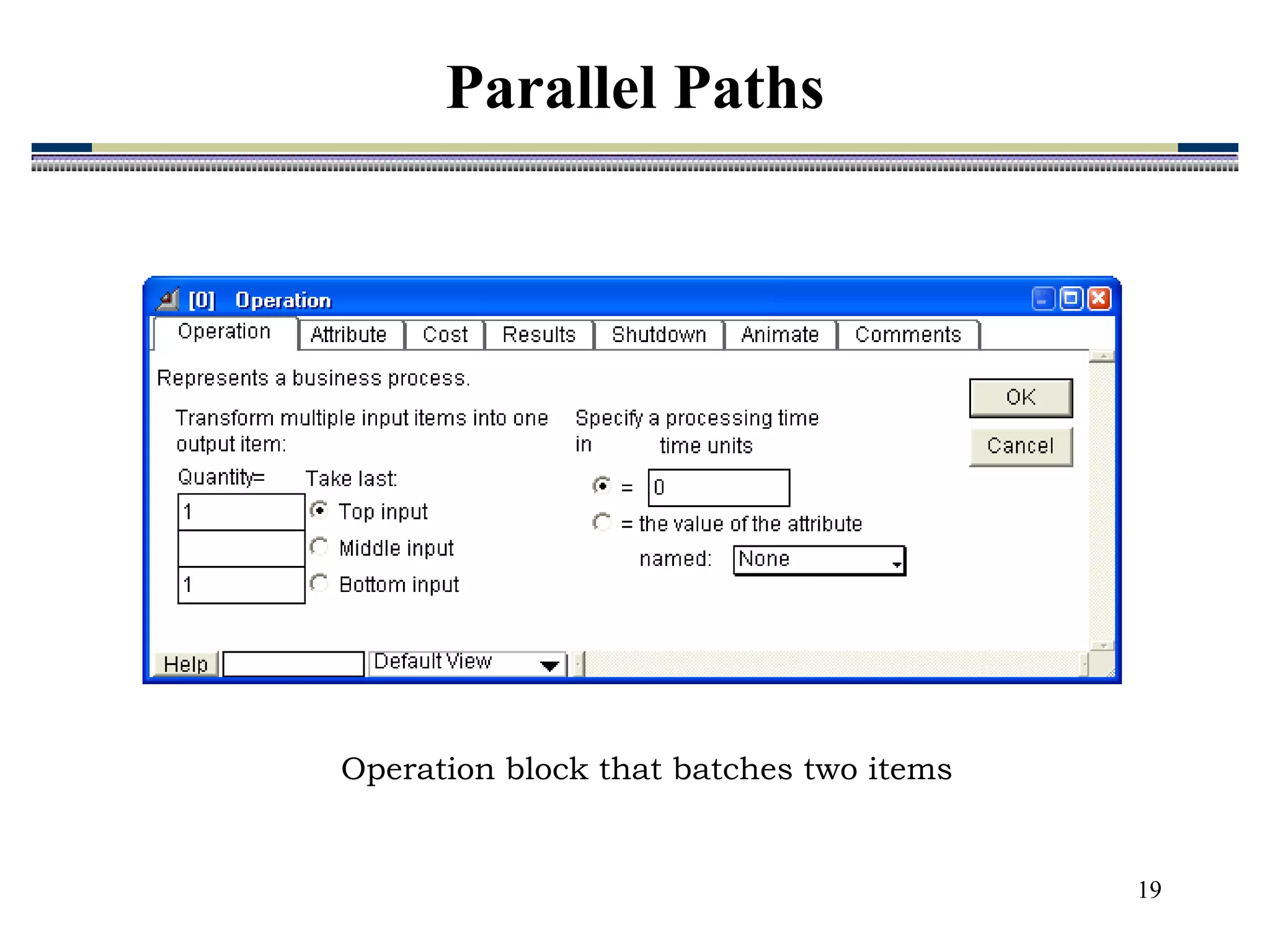

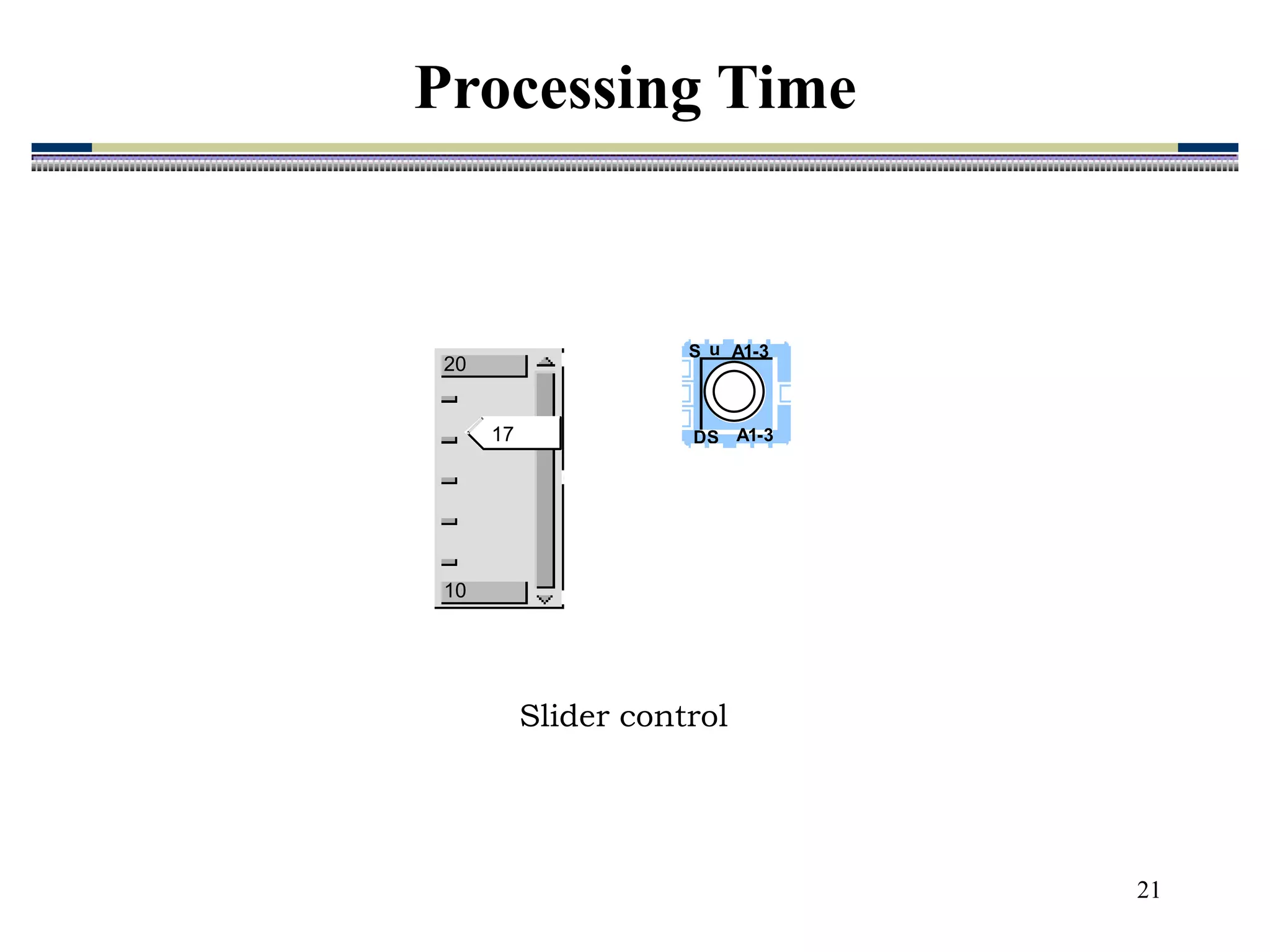

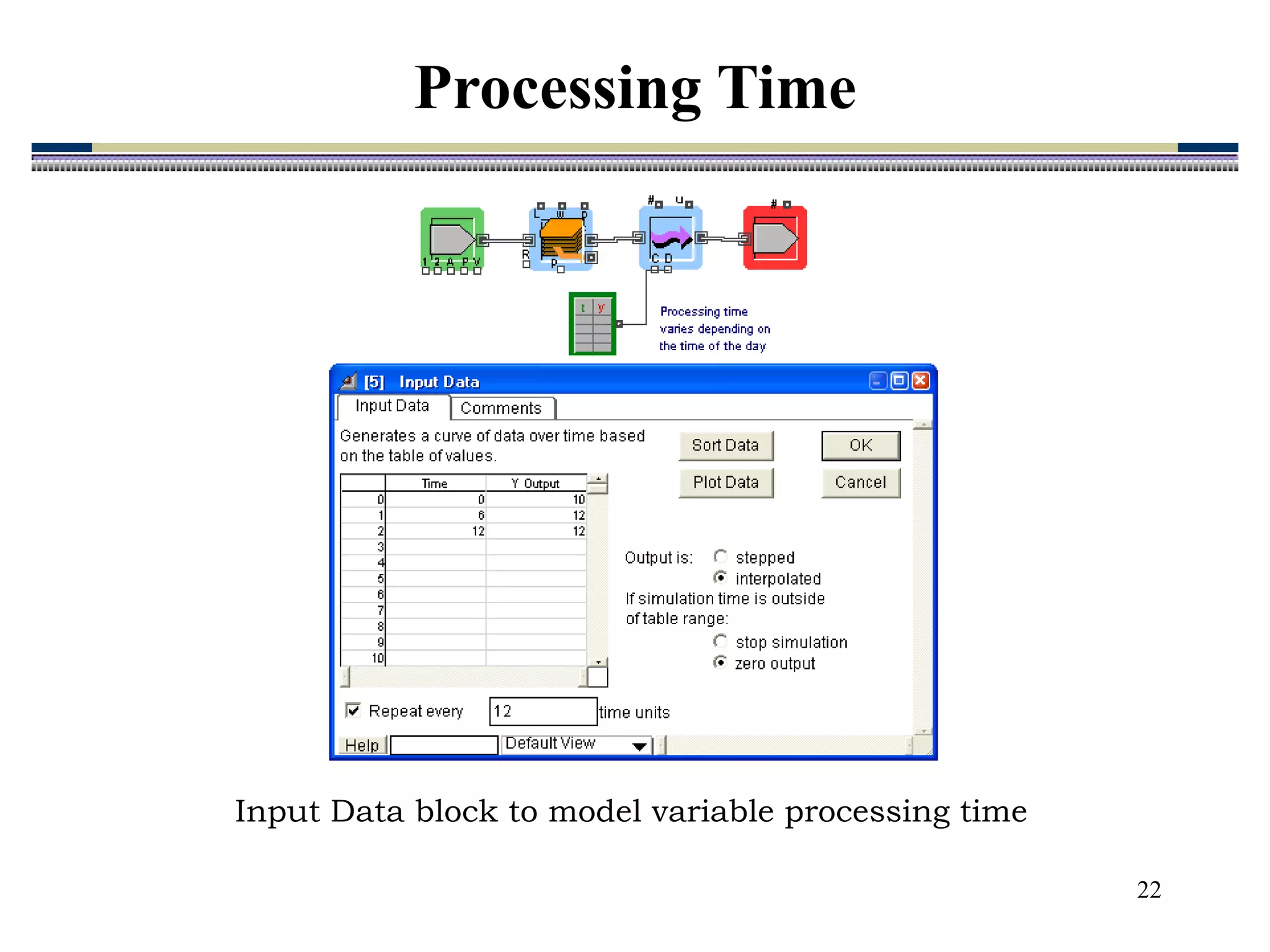

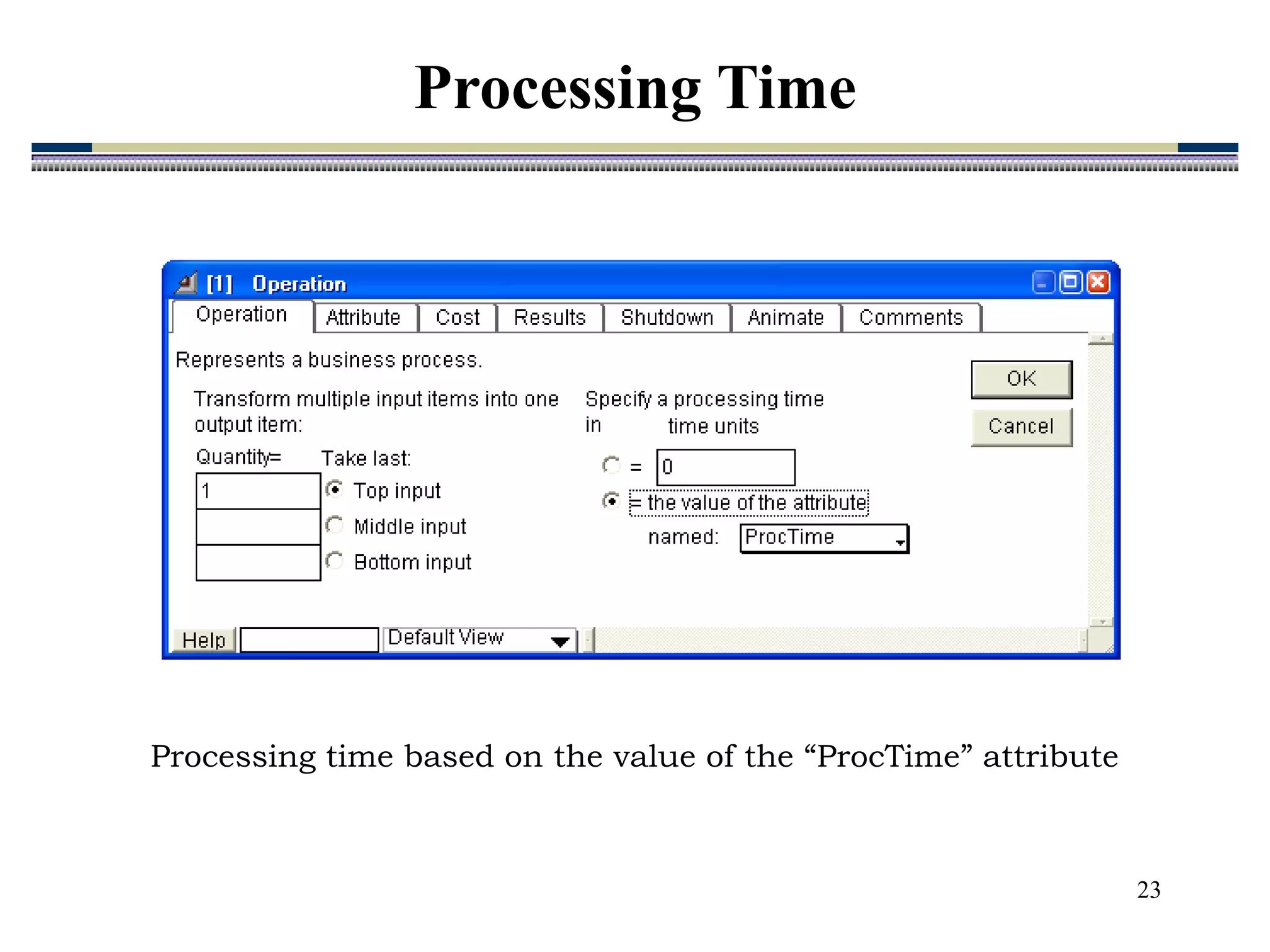

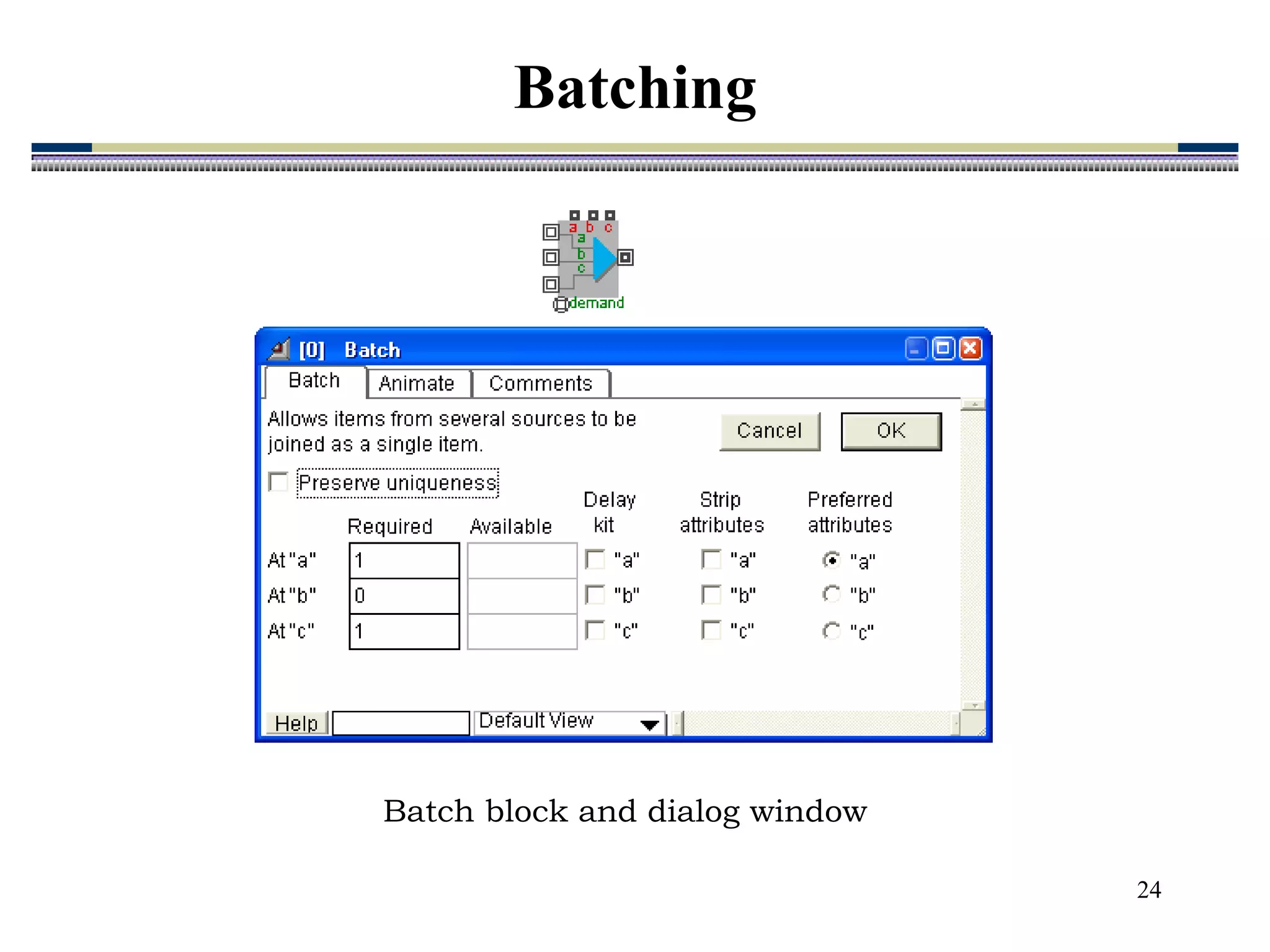

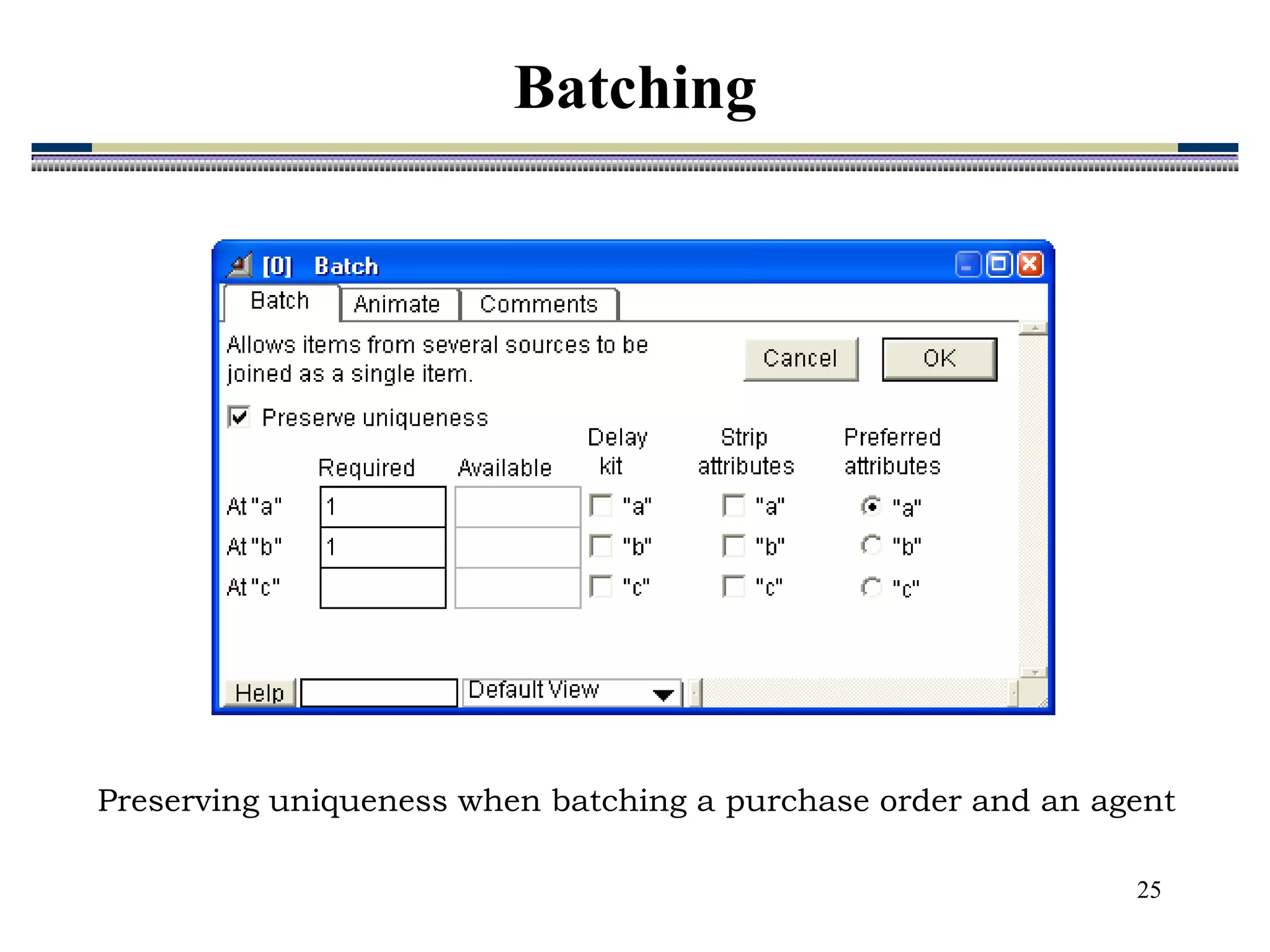

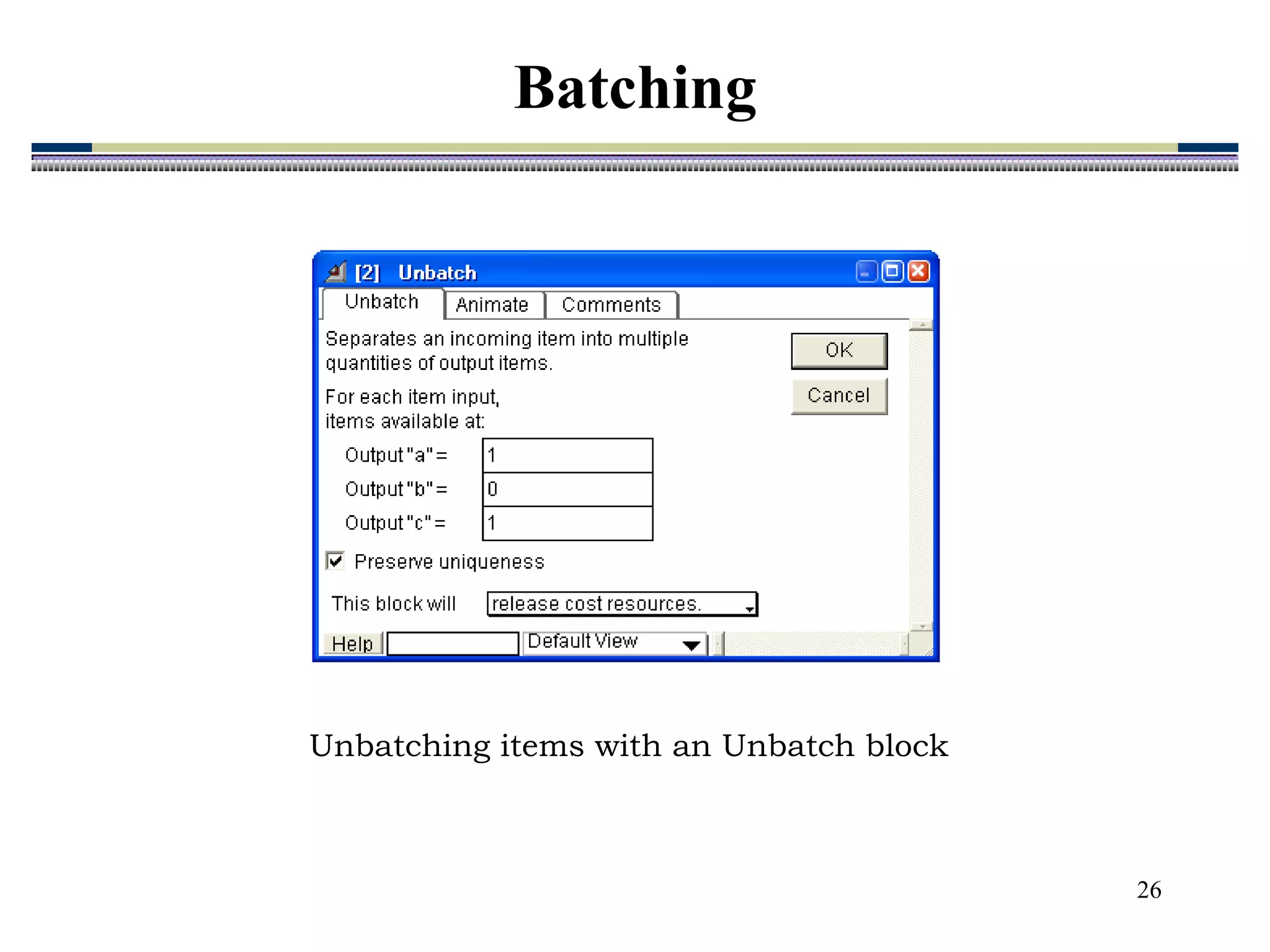

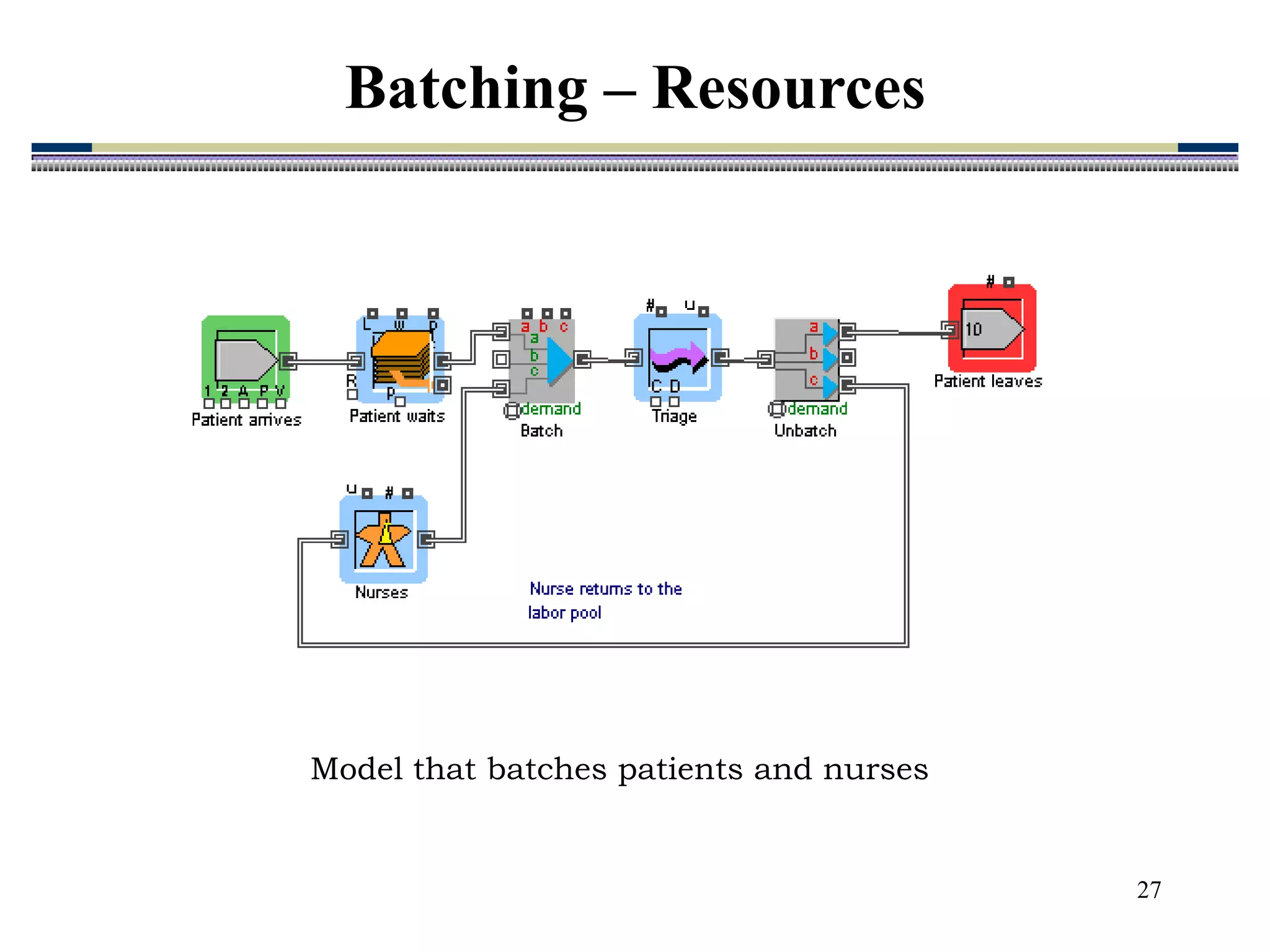

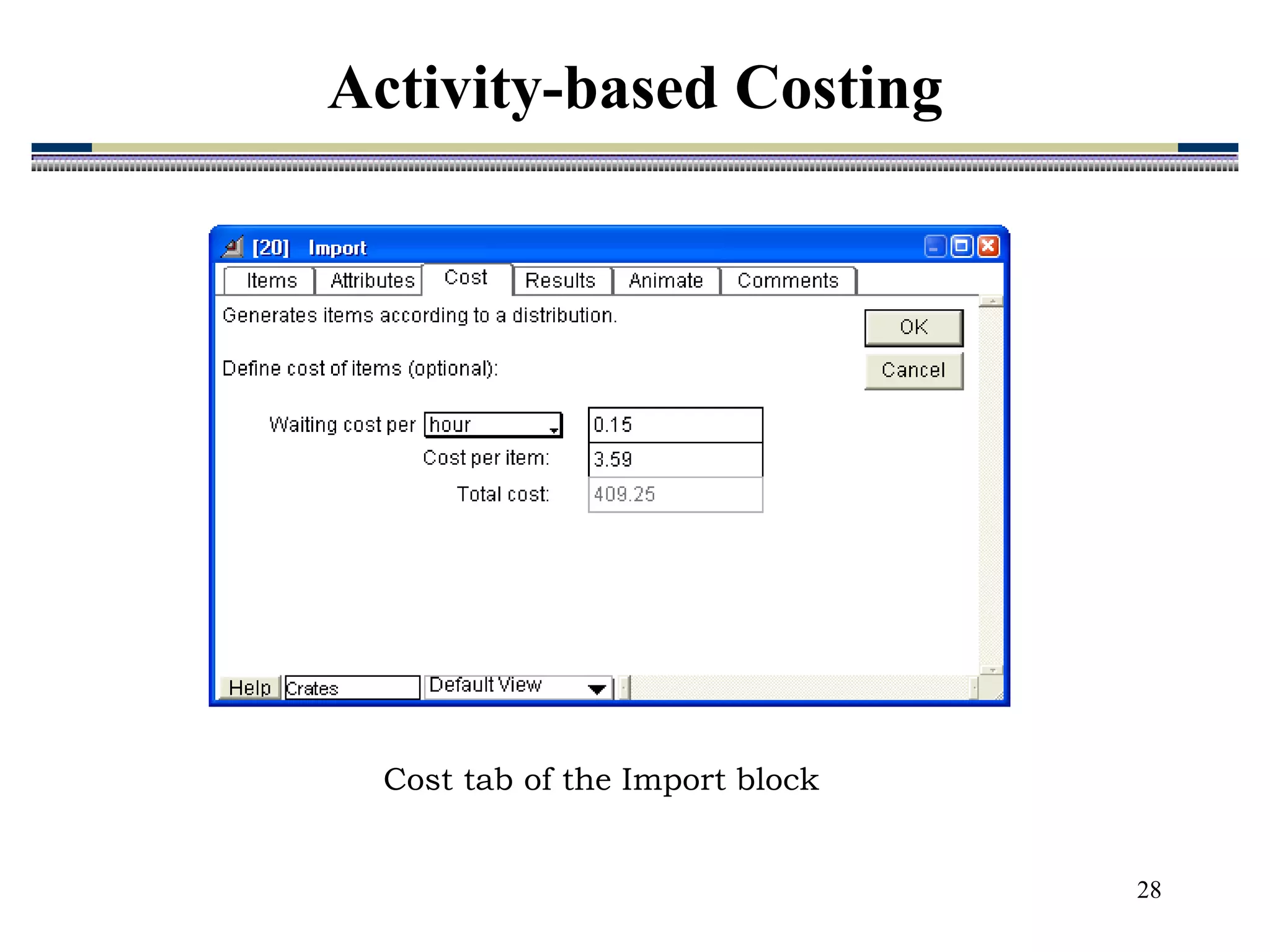

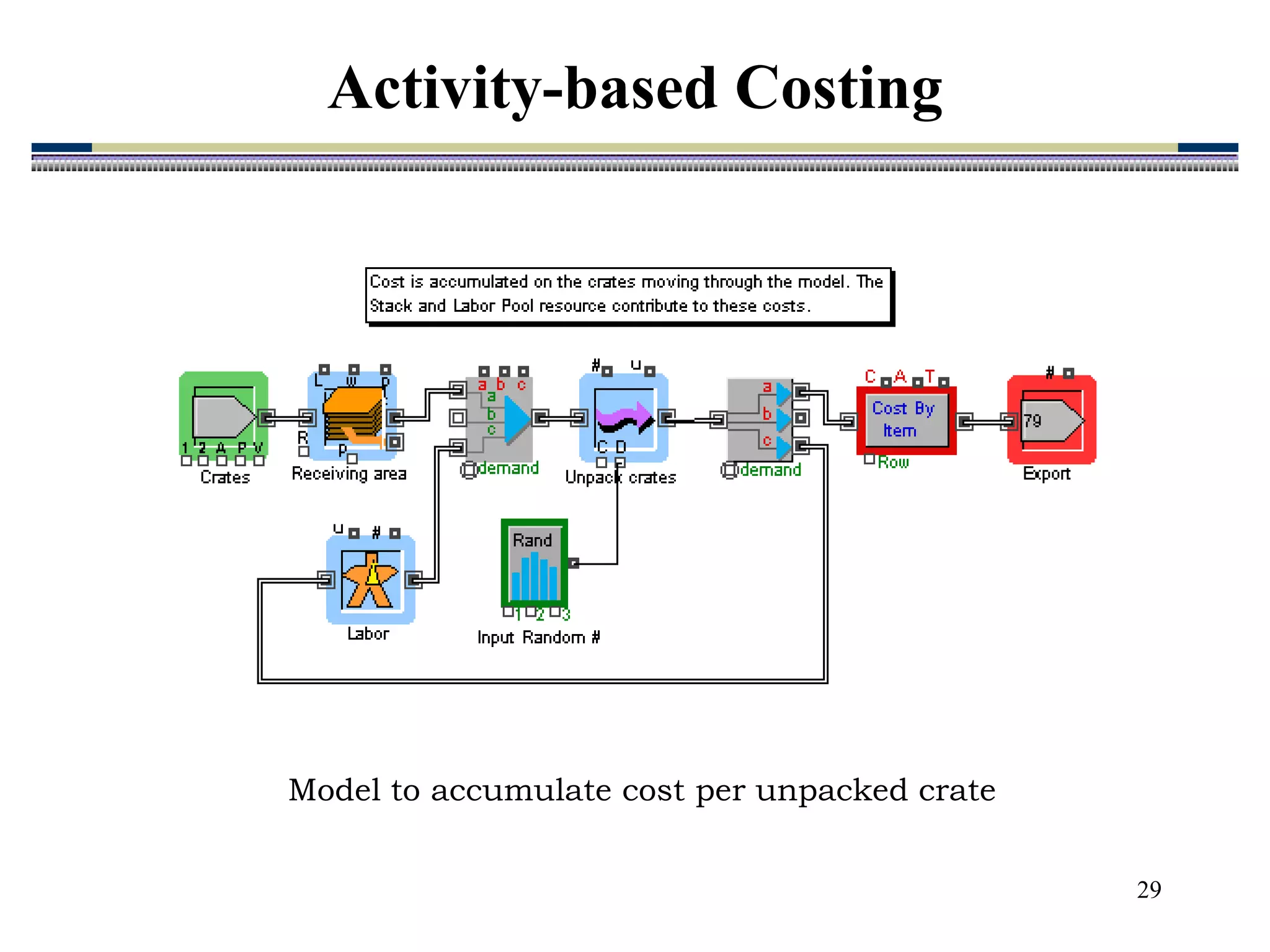

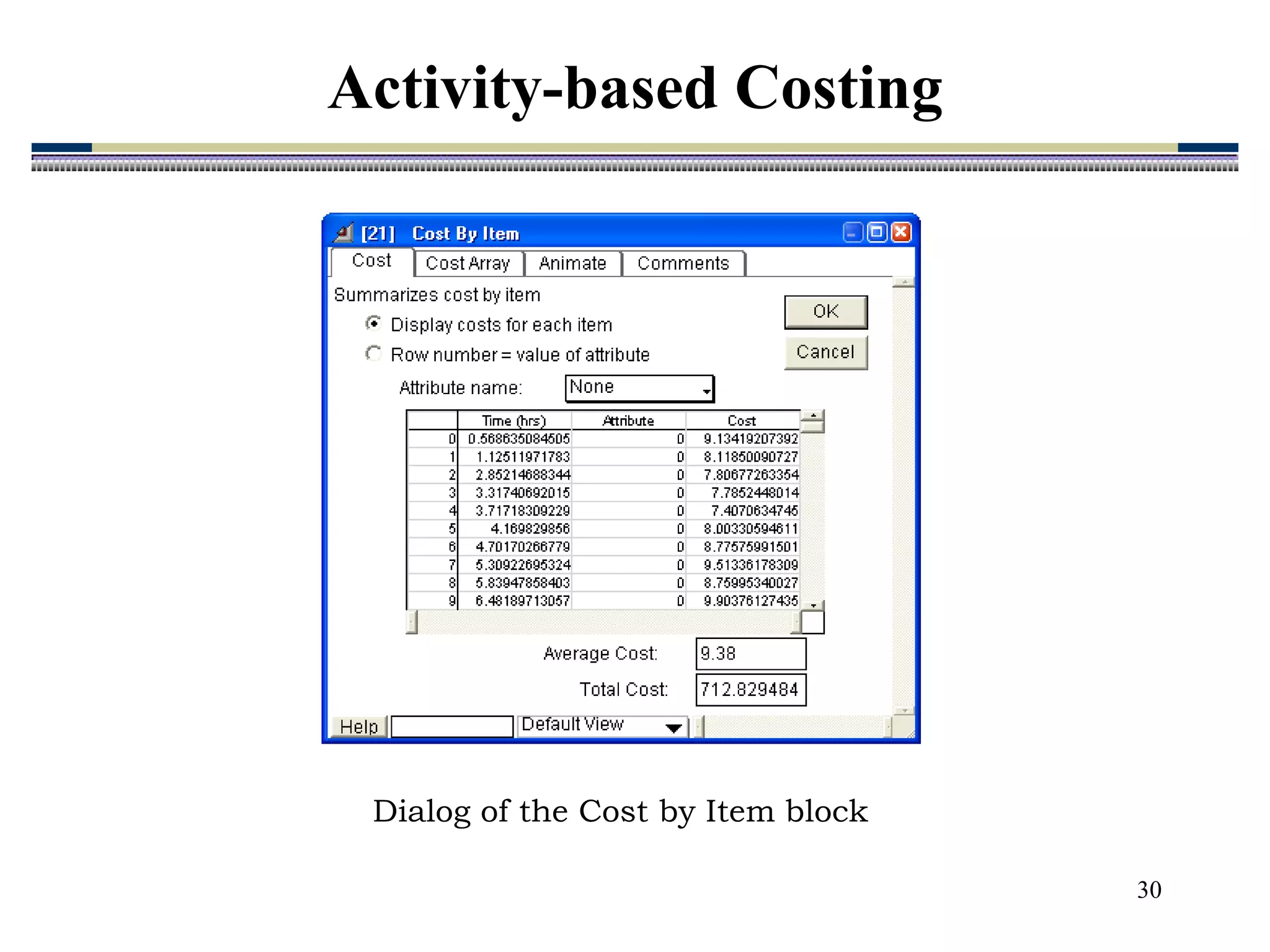

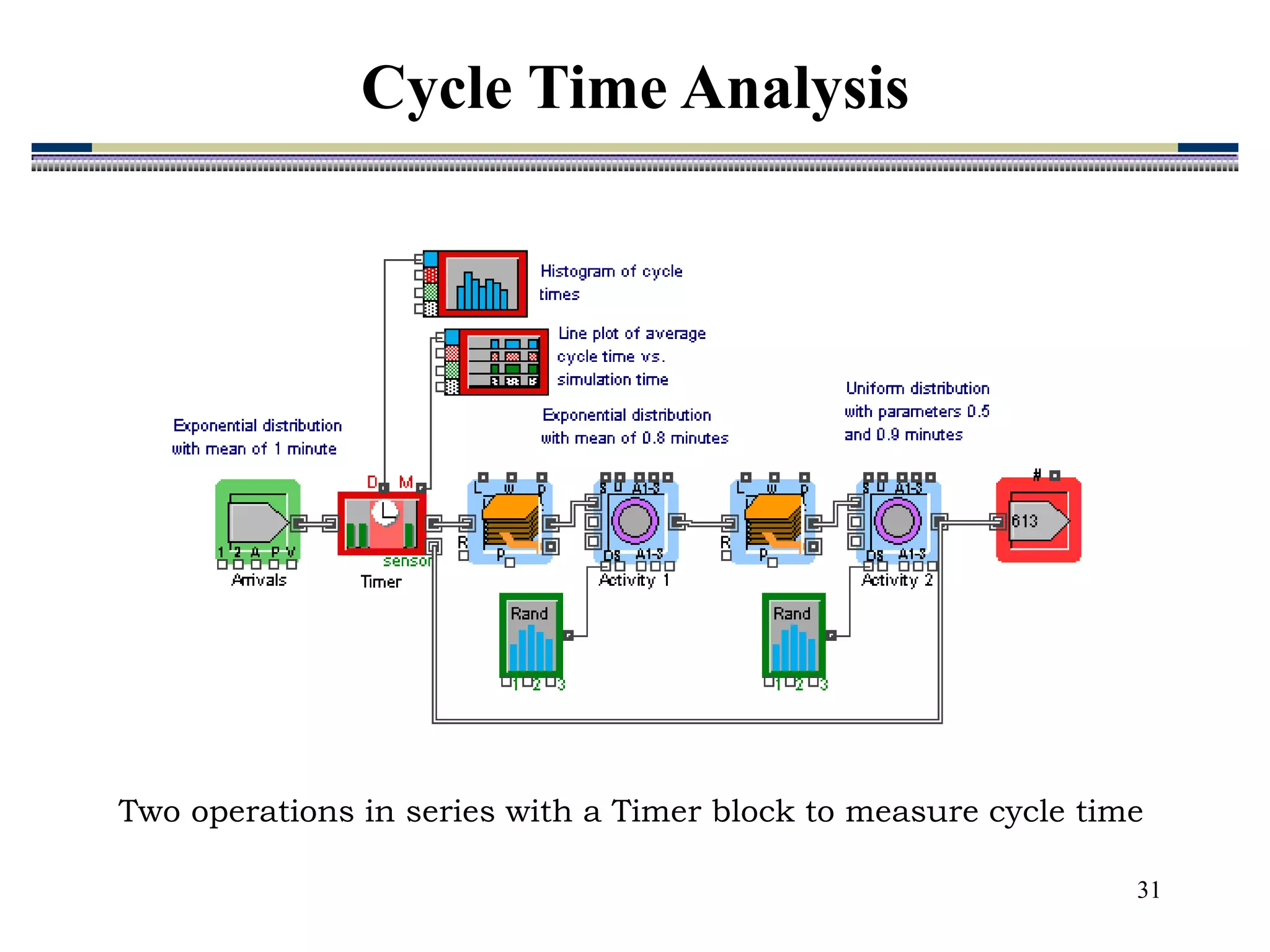

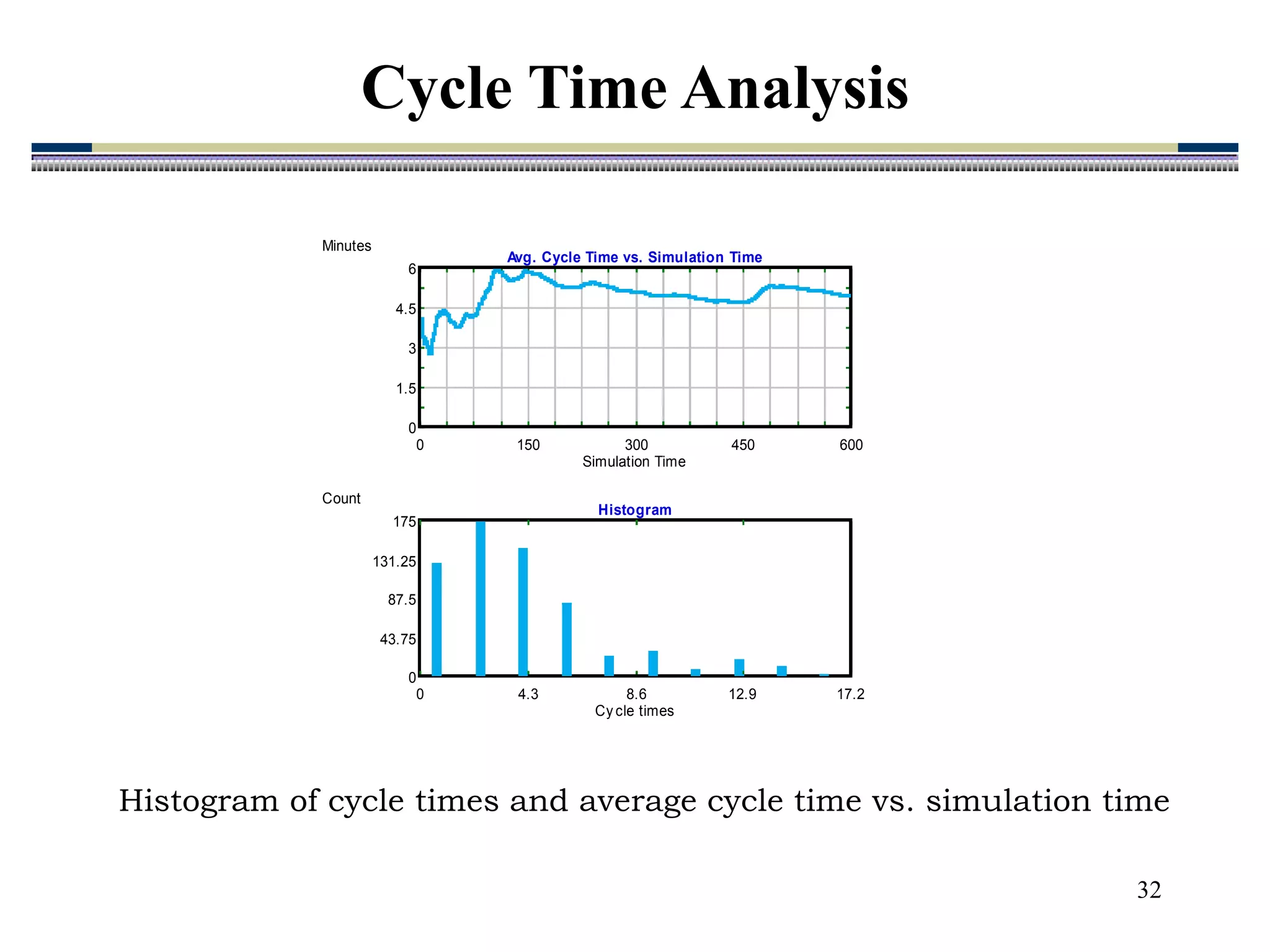

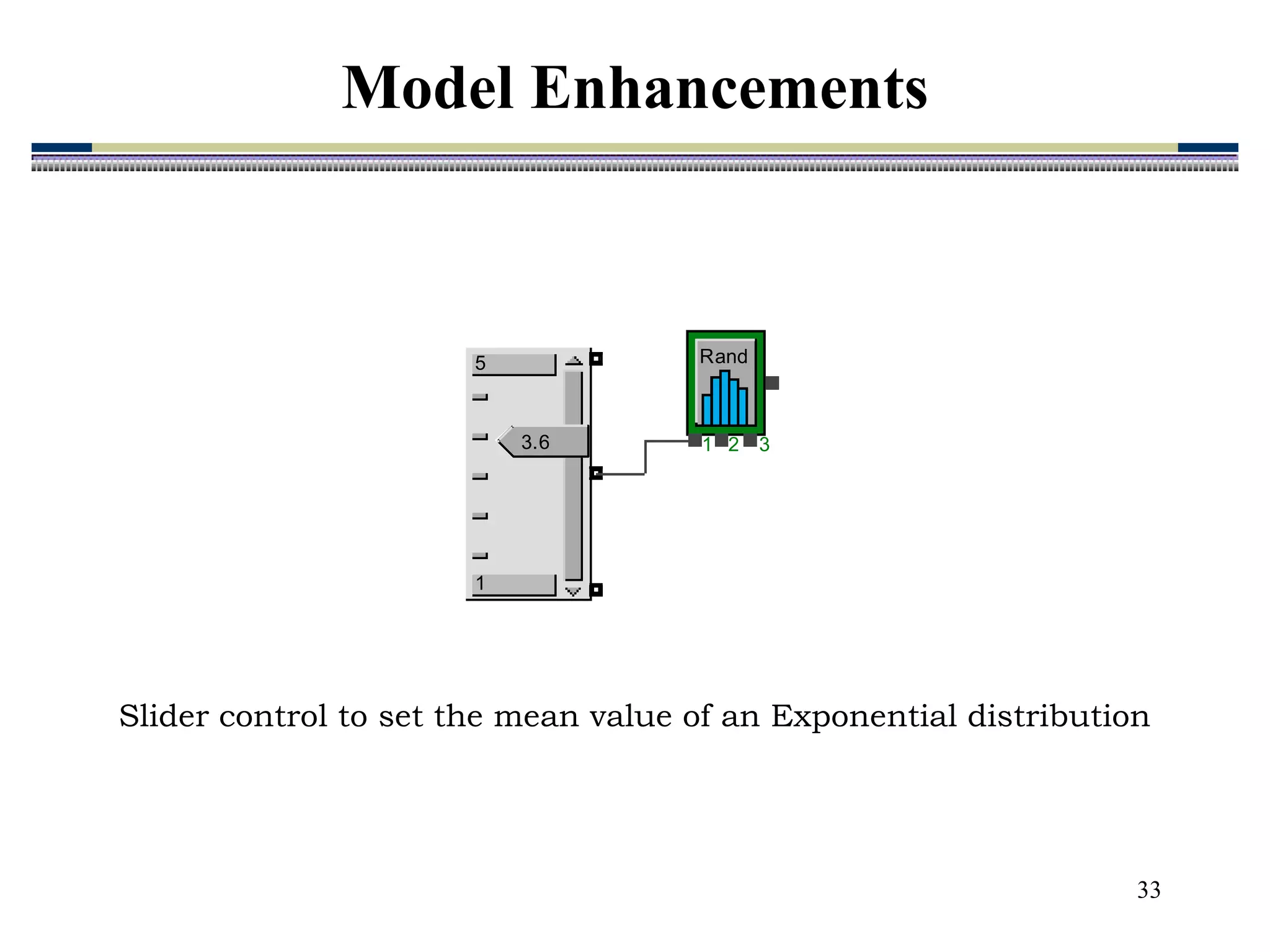

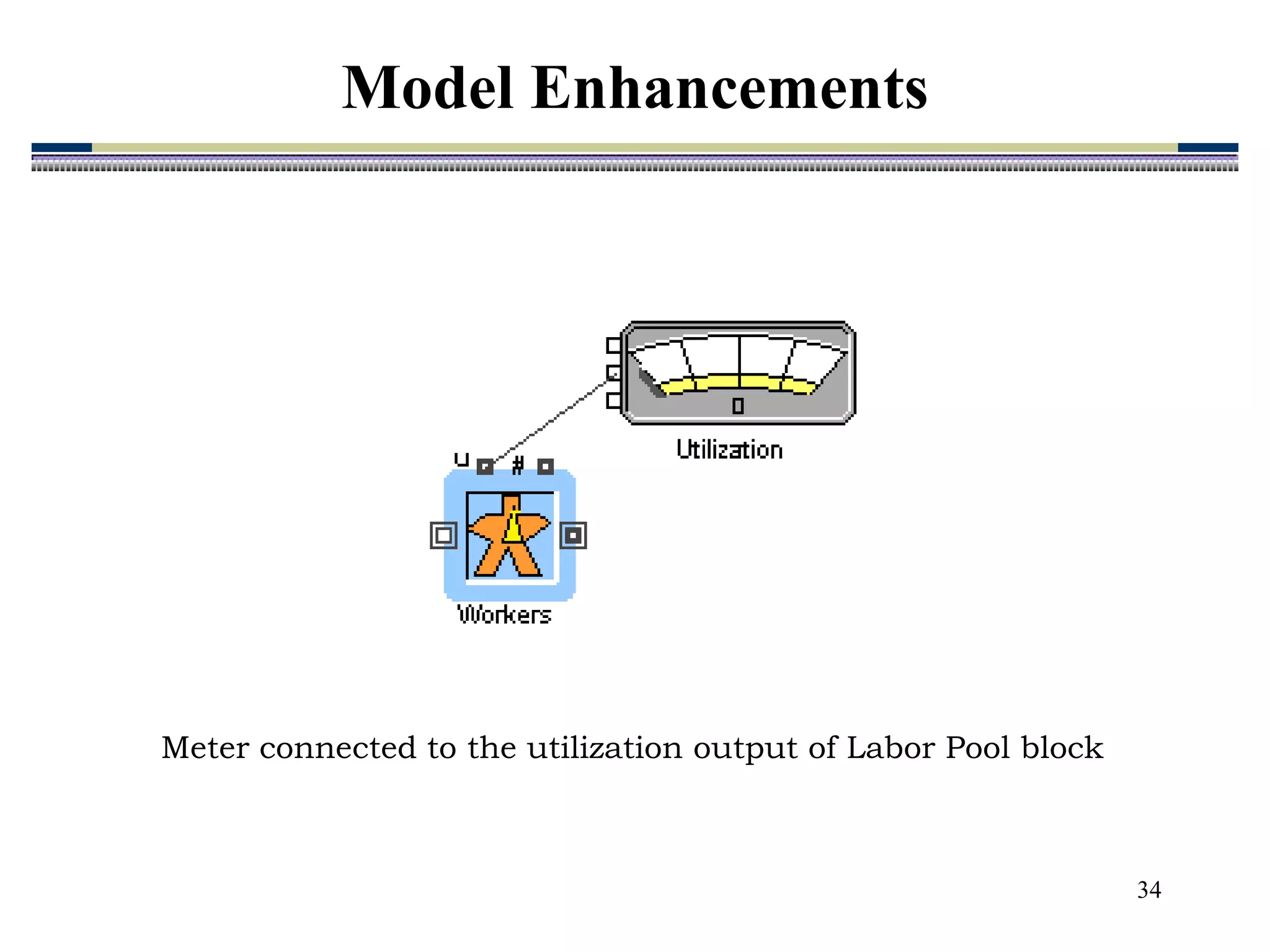

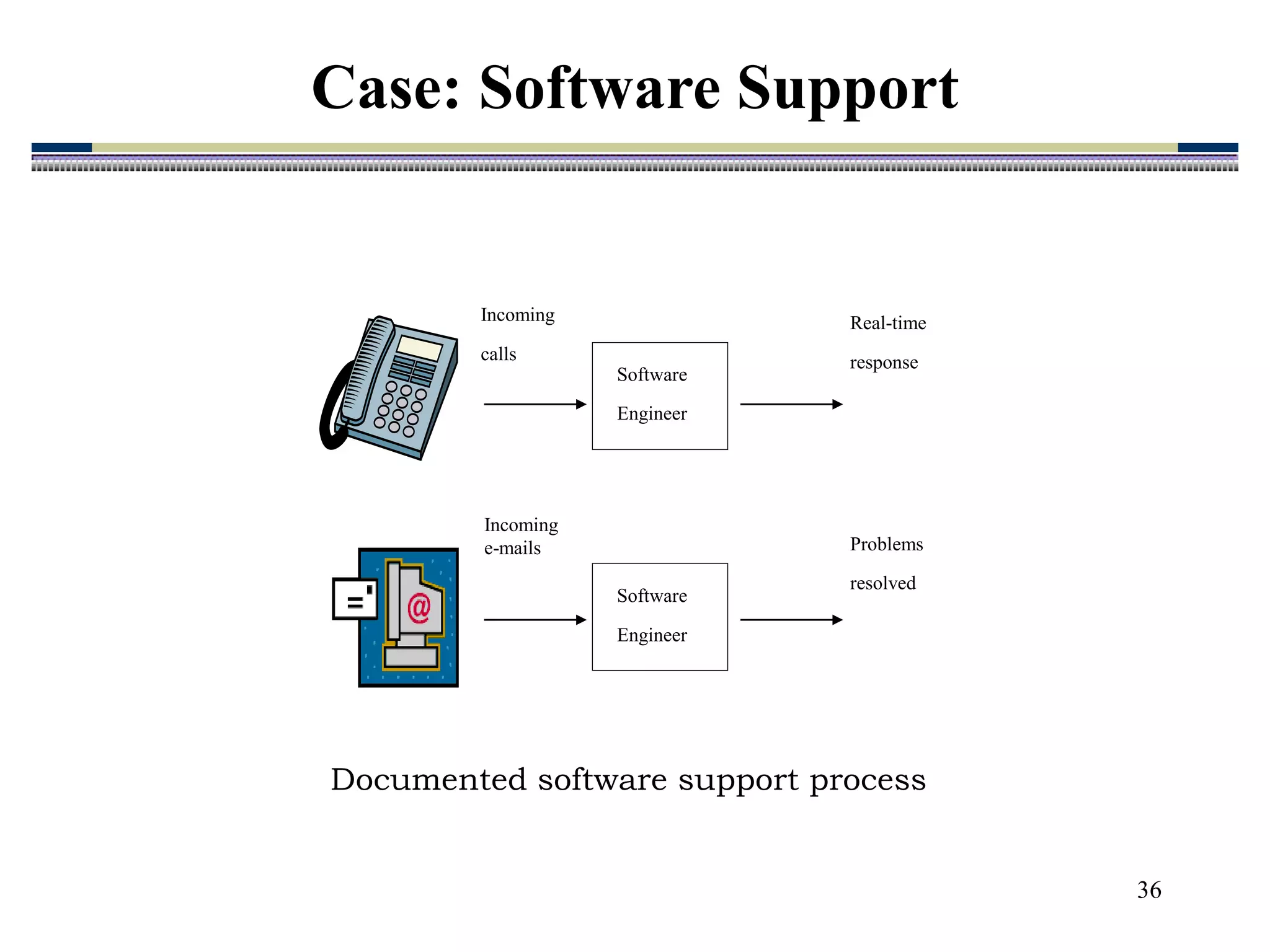

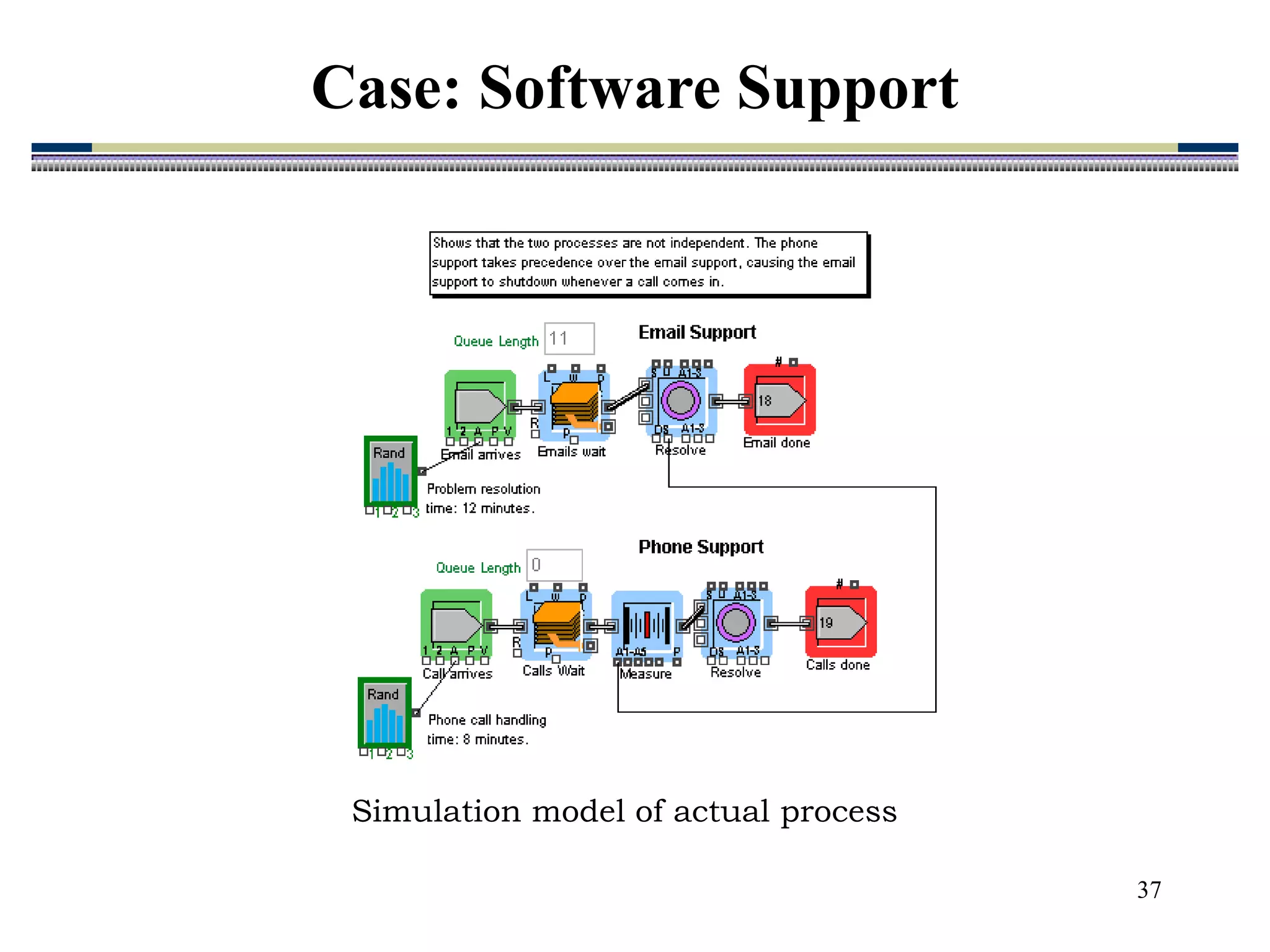

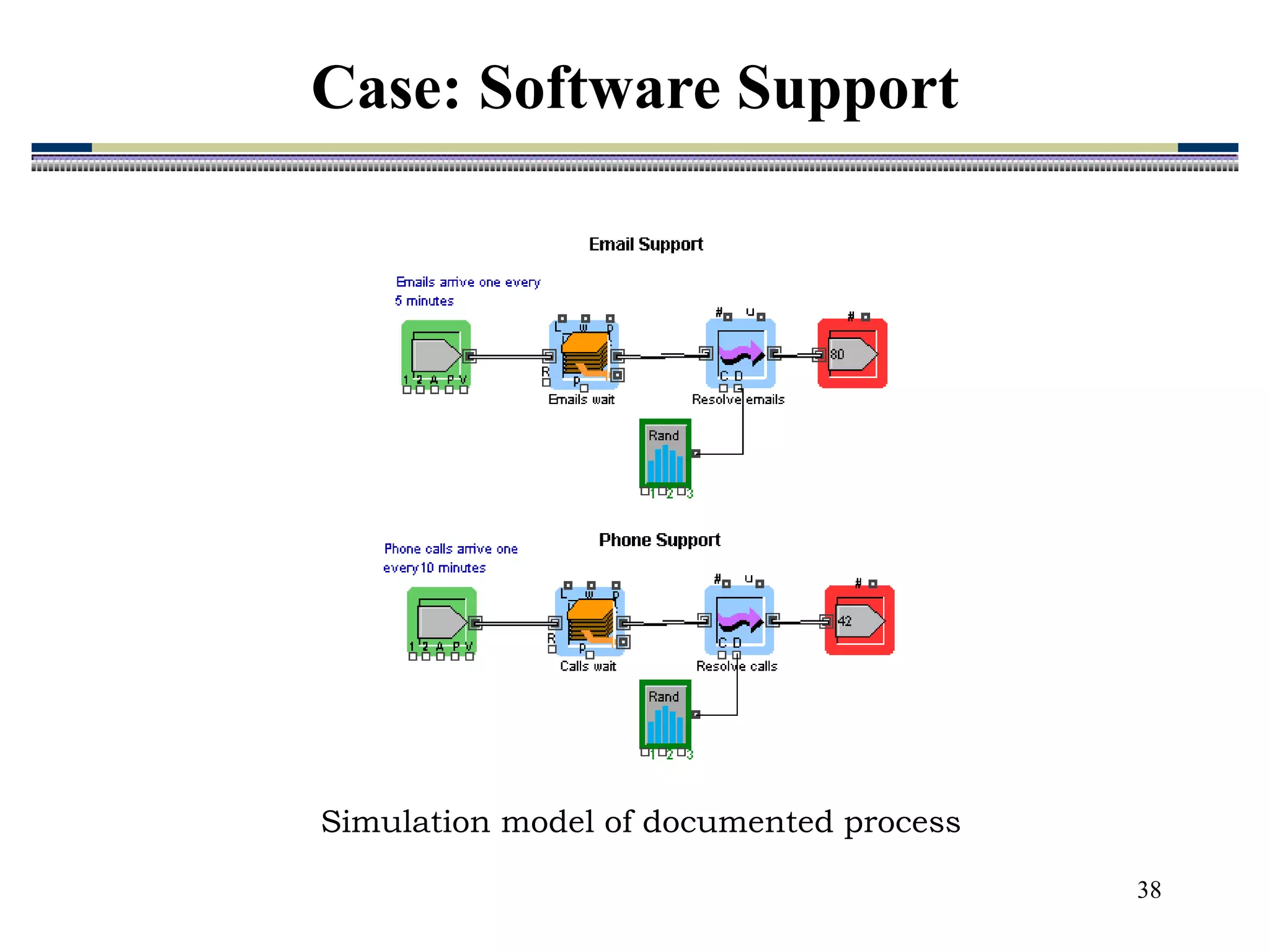

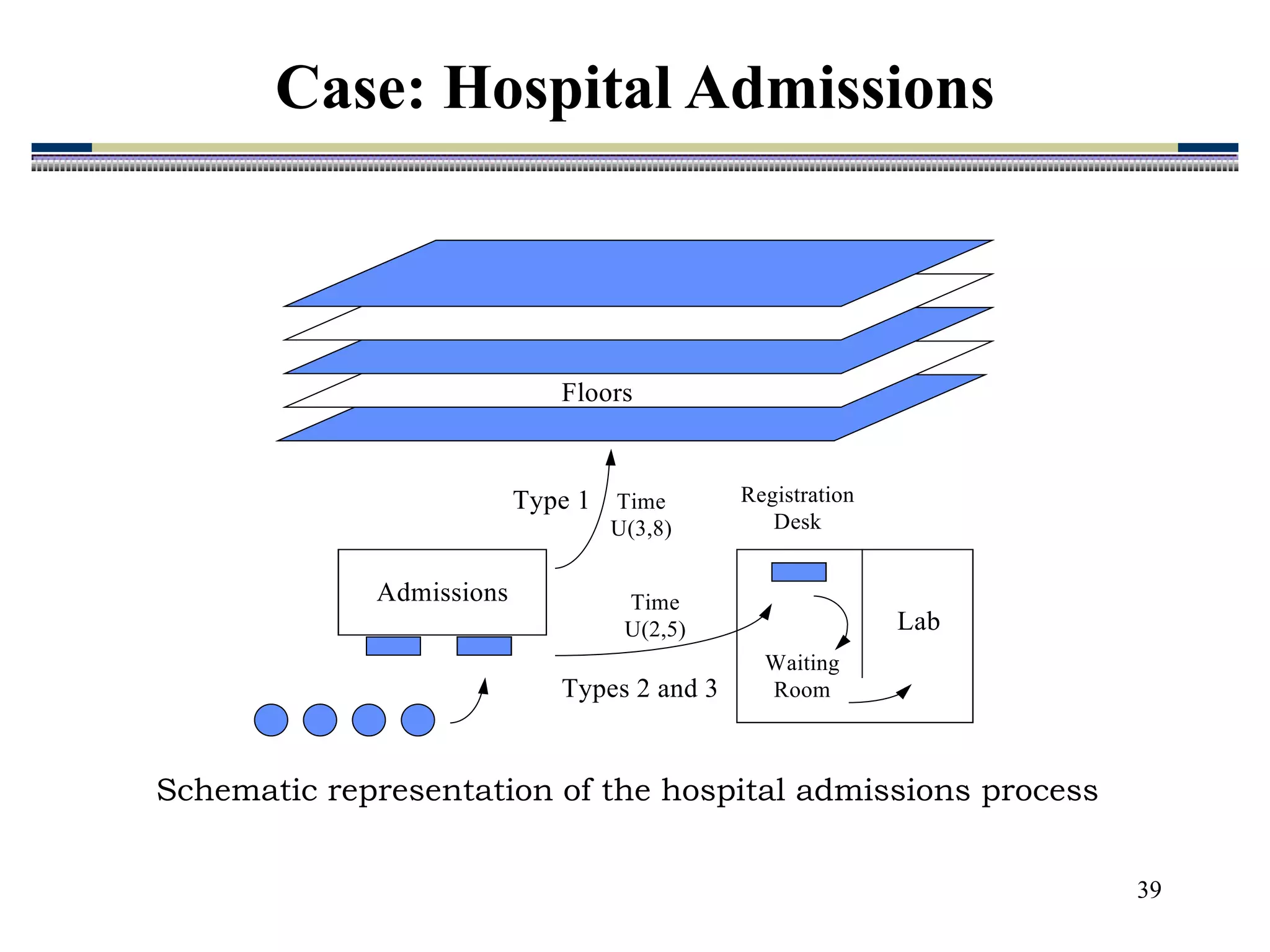

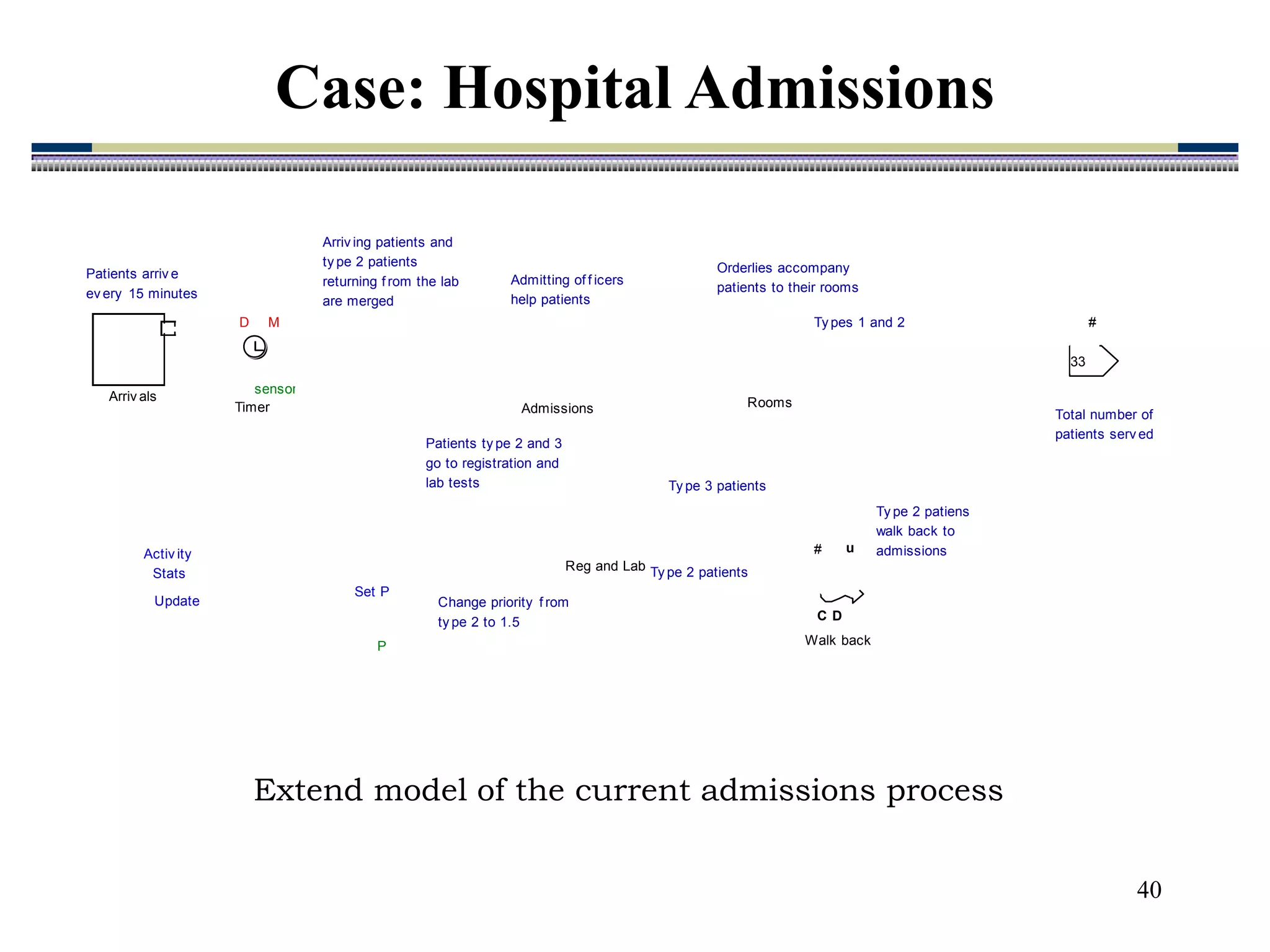

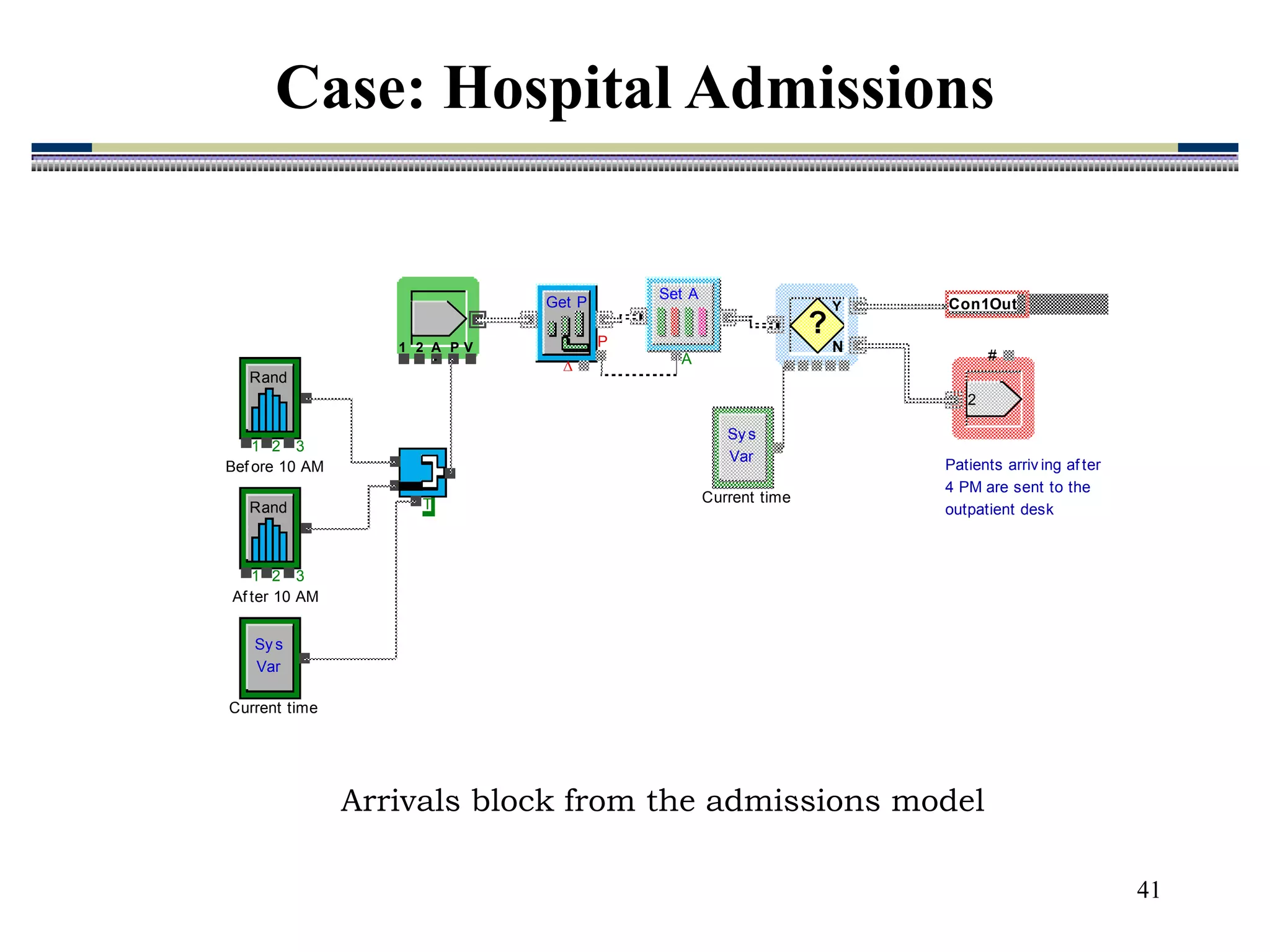

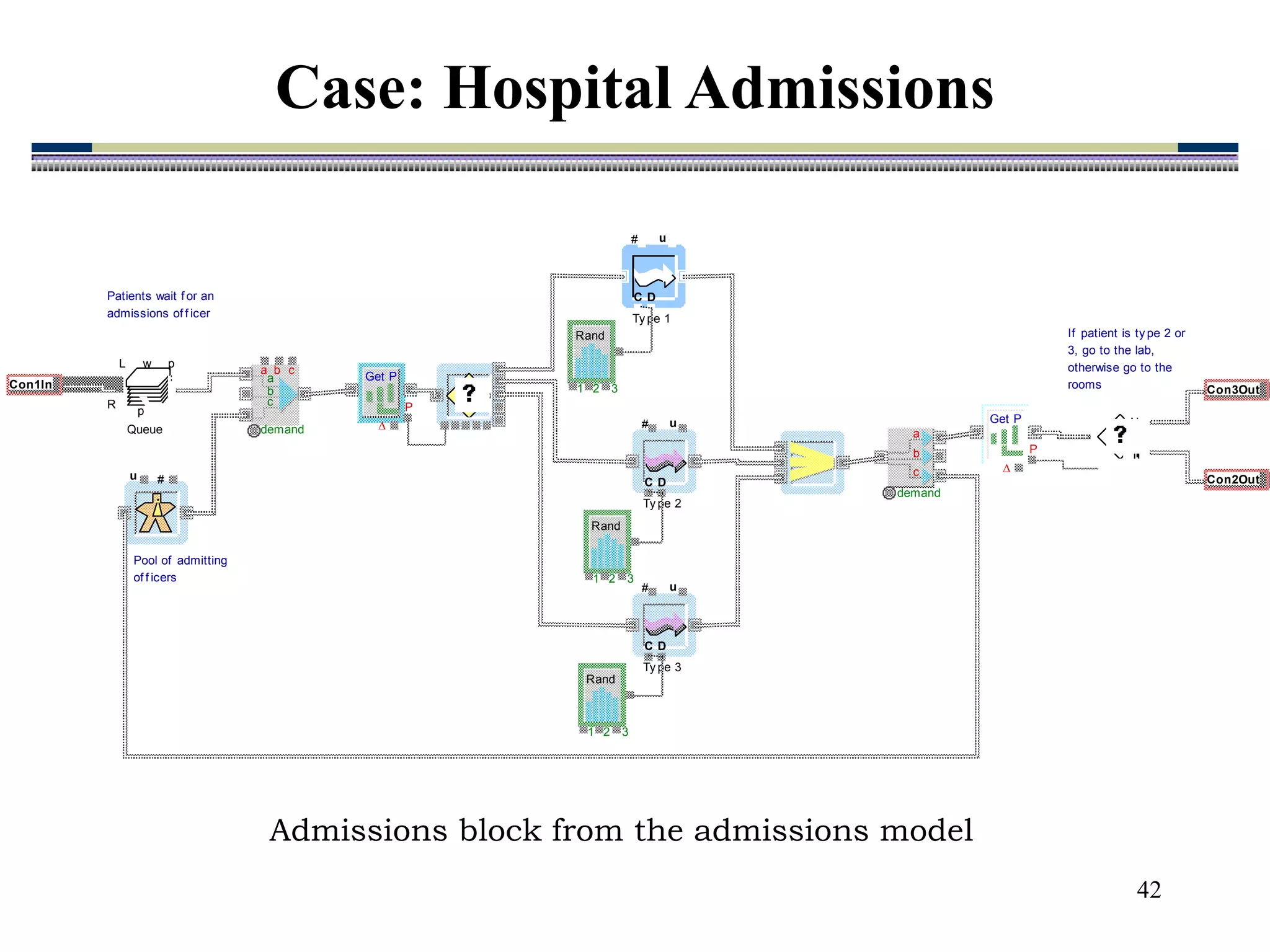

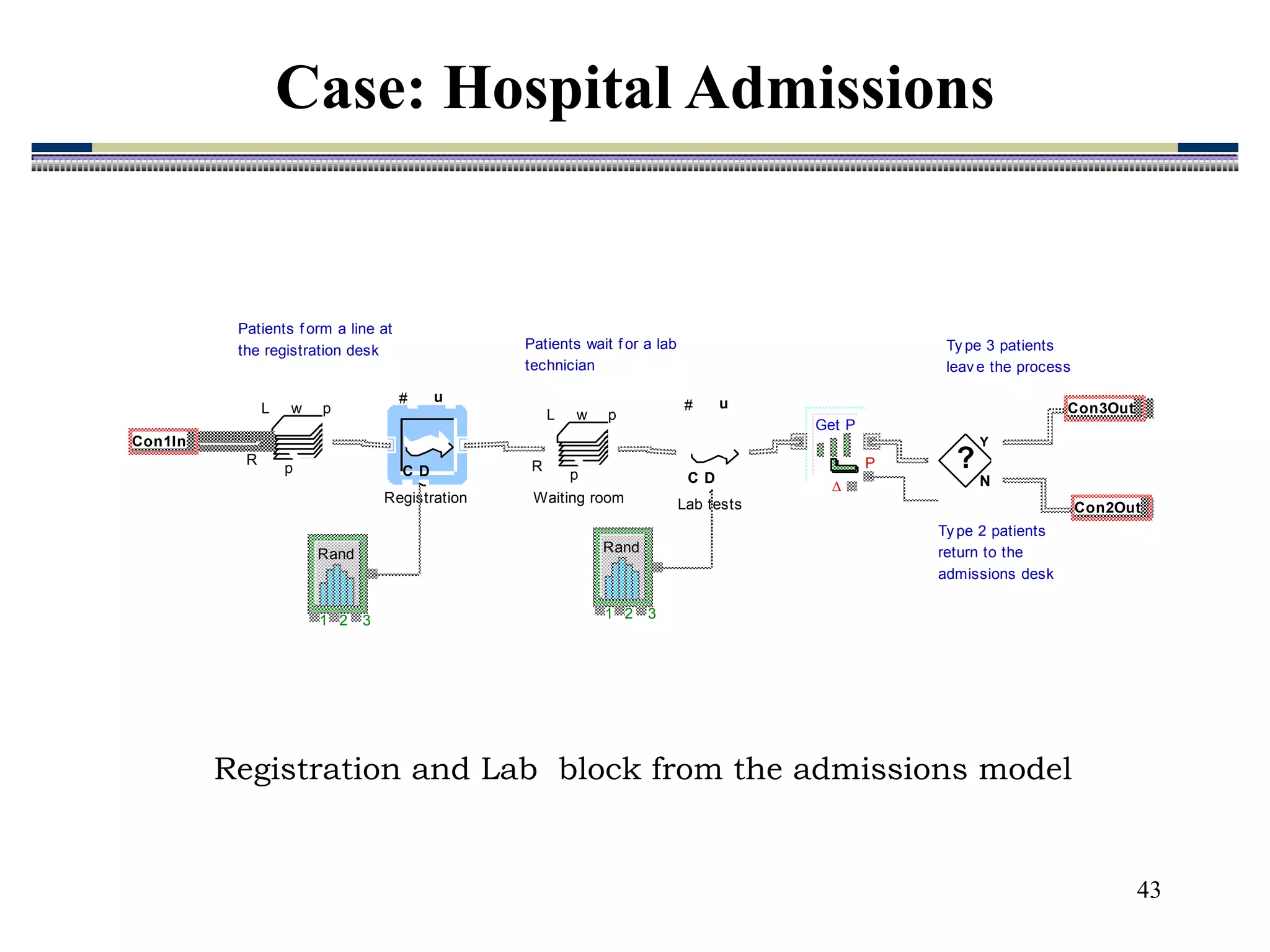

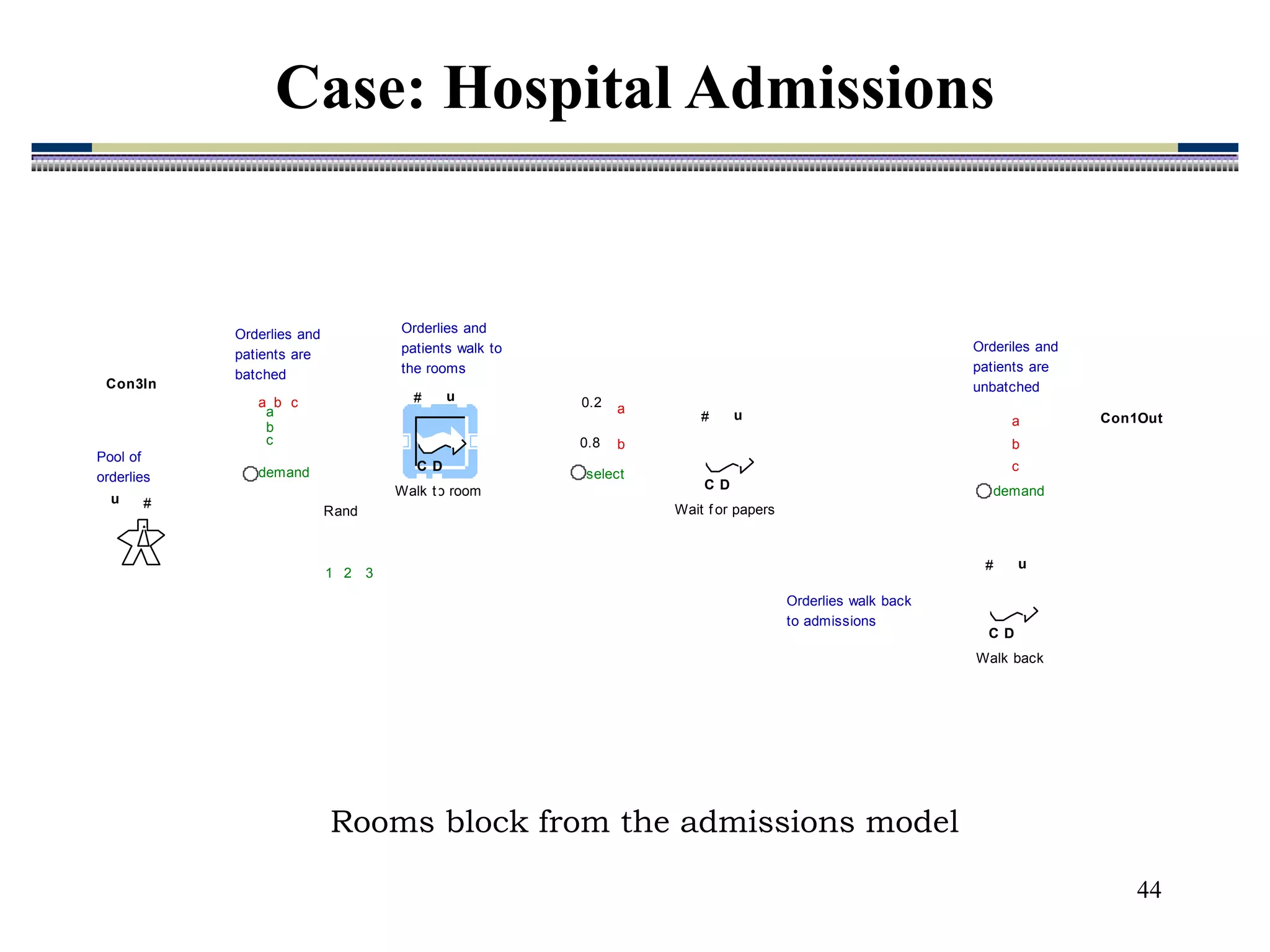

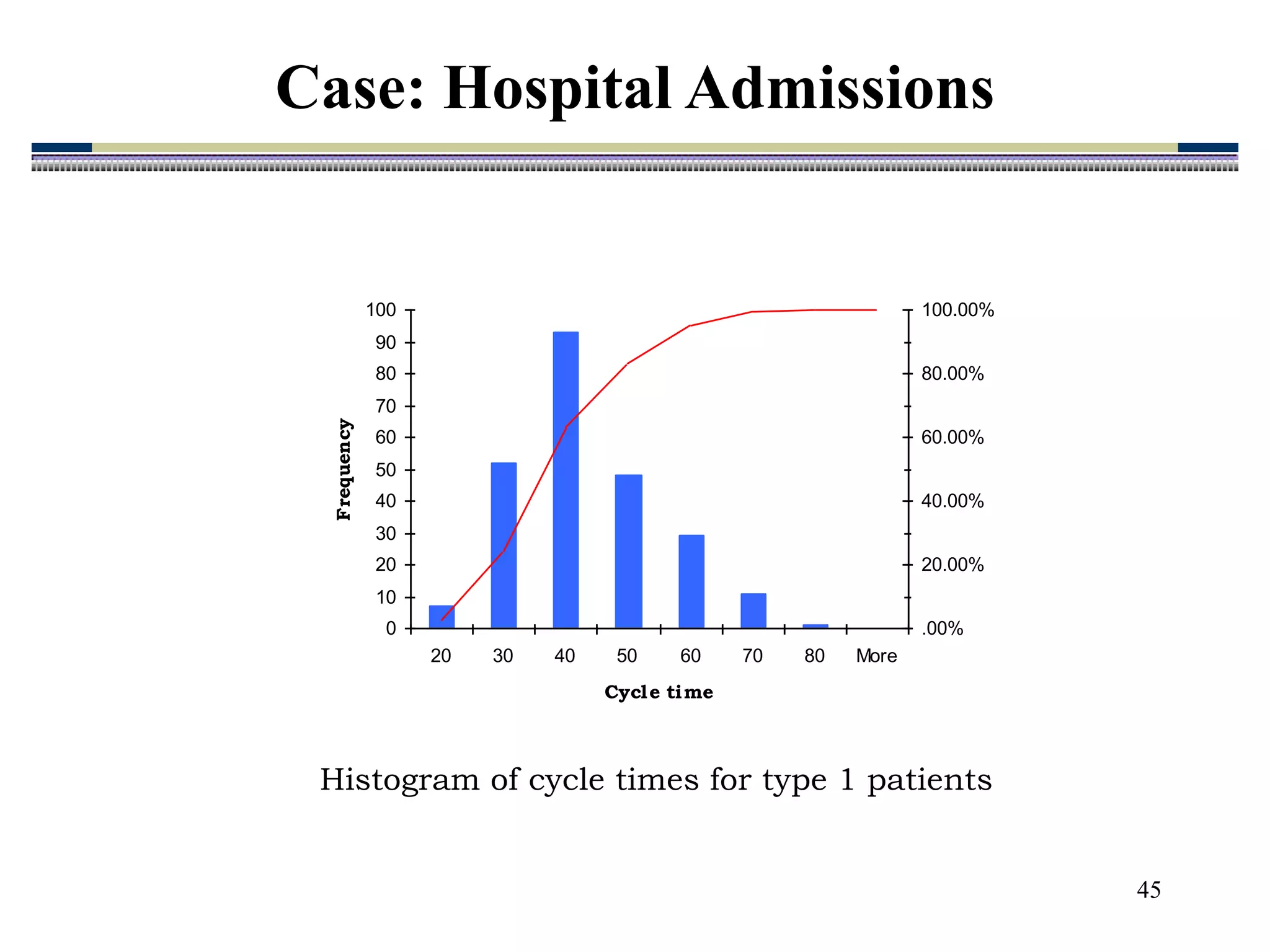

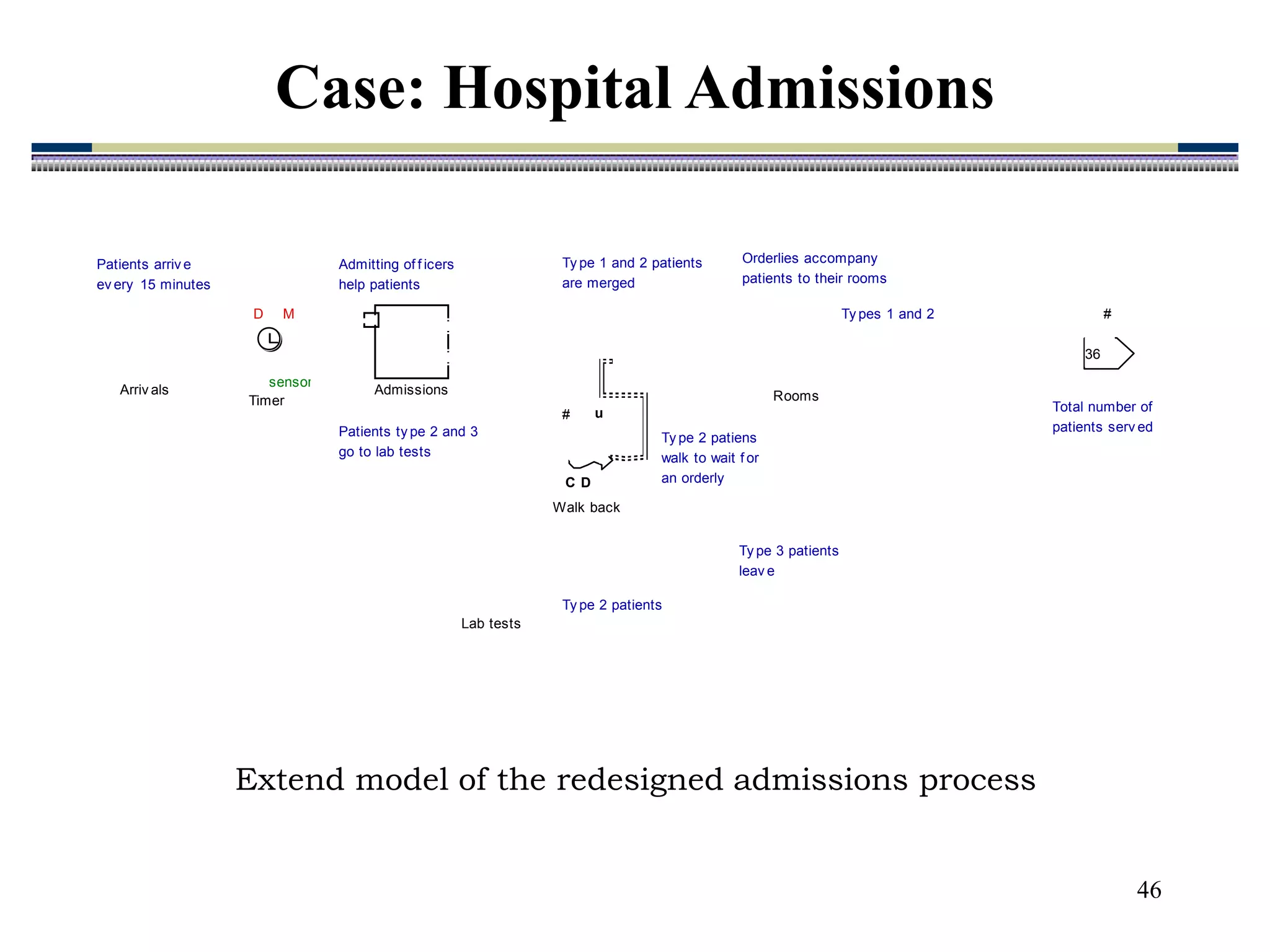

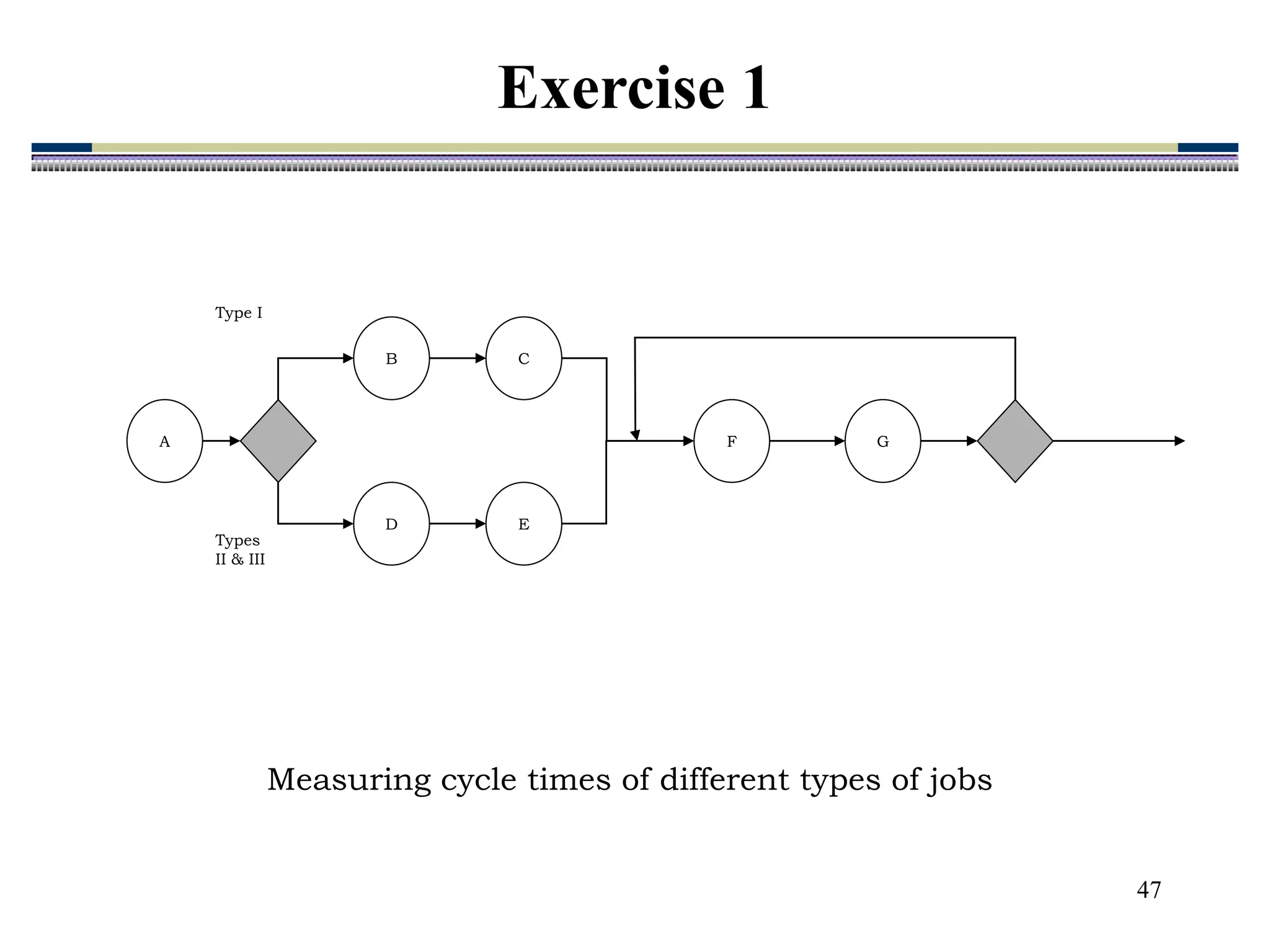

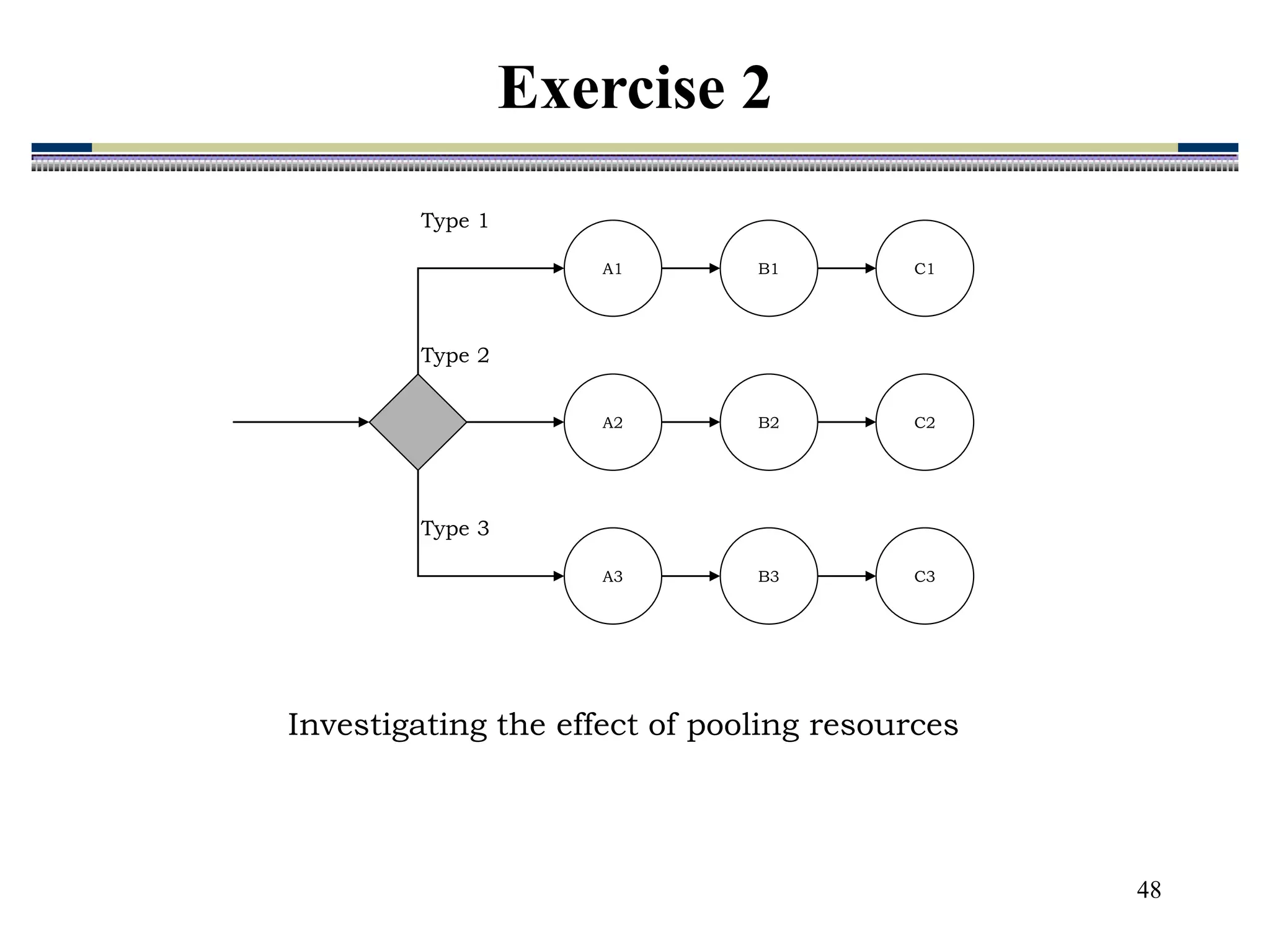

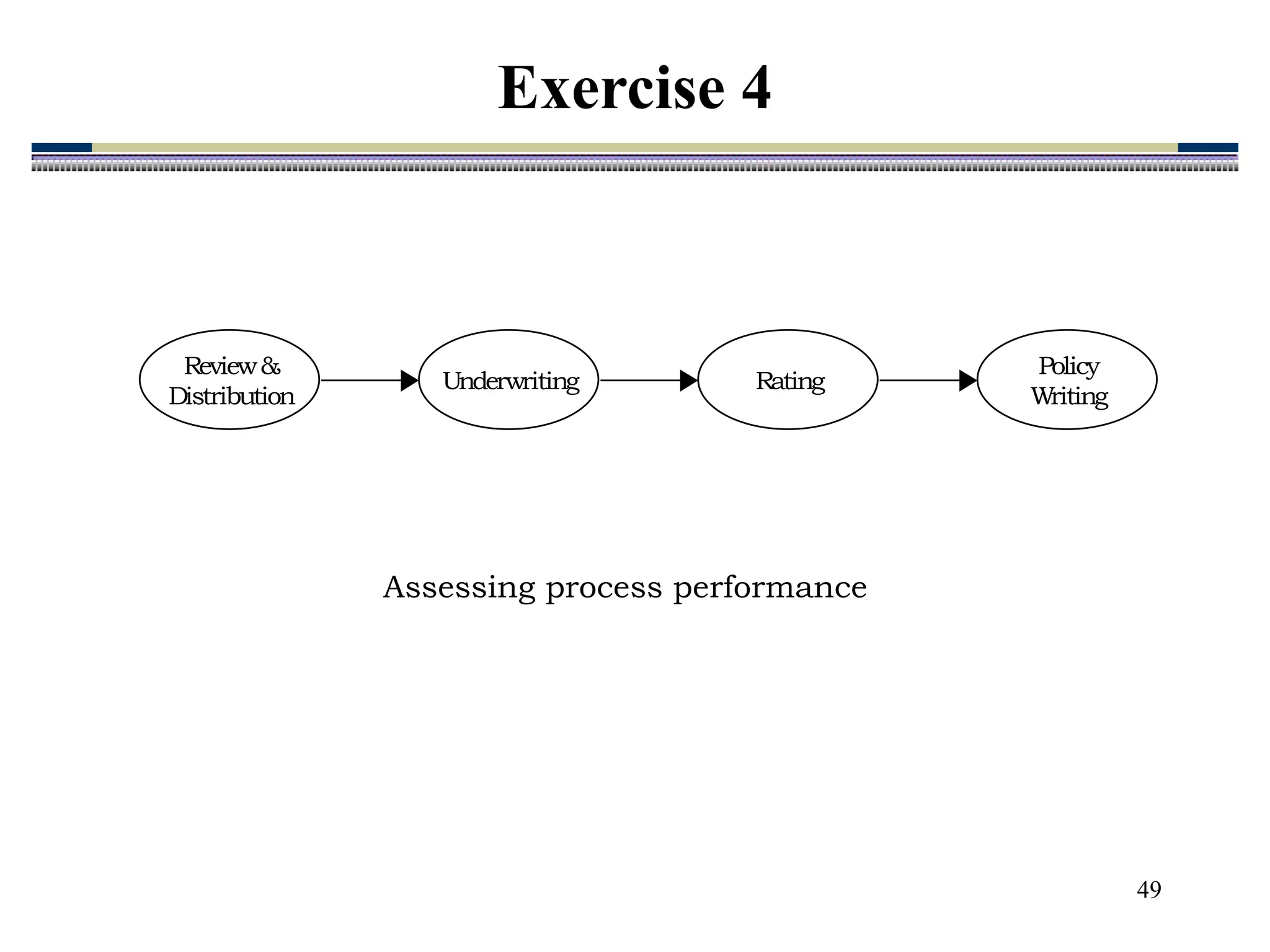

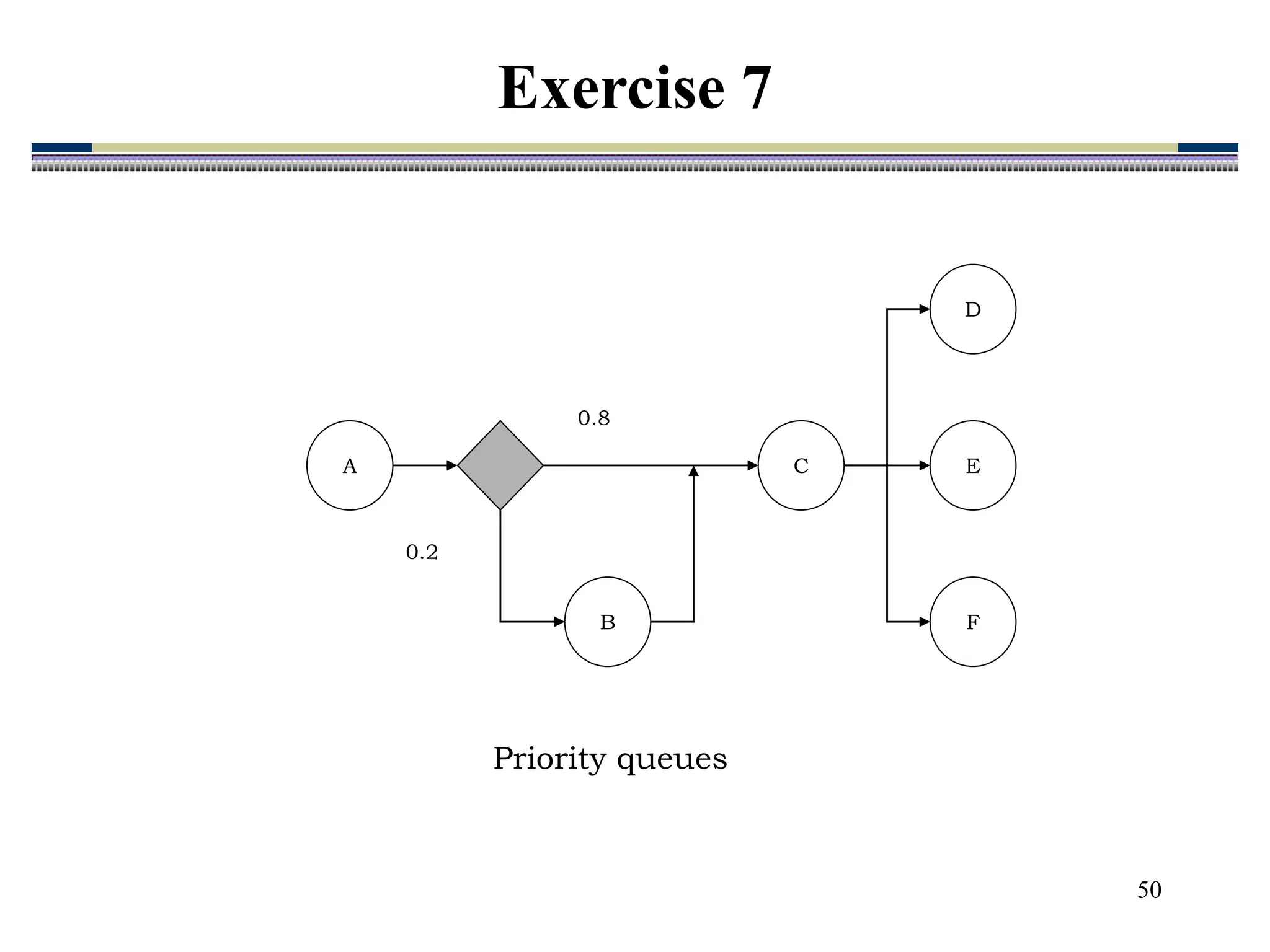

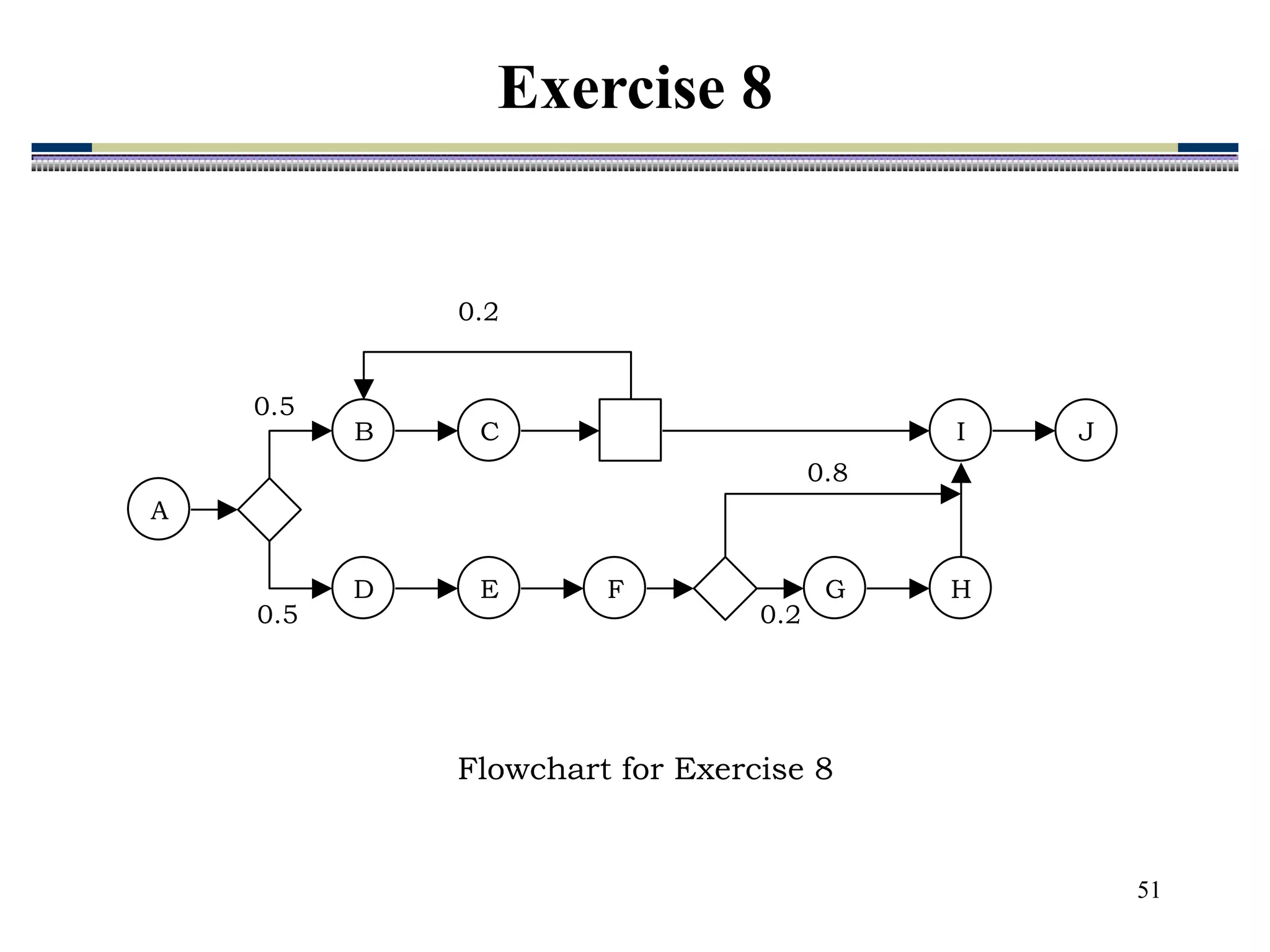

This document provides screenshots and descriptions from a book about modeling and simulating business processes using Extend simulation software. It includes examples of importing data, probabilistic routing, parallel paths, batching, activity-based costing, cycle time analysis, and case studies on a software support process and hospital admissions process. Models demonstrate different queues, priorities, resource pooling, and using Extend blocks to simulate various business scenarios.