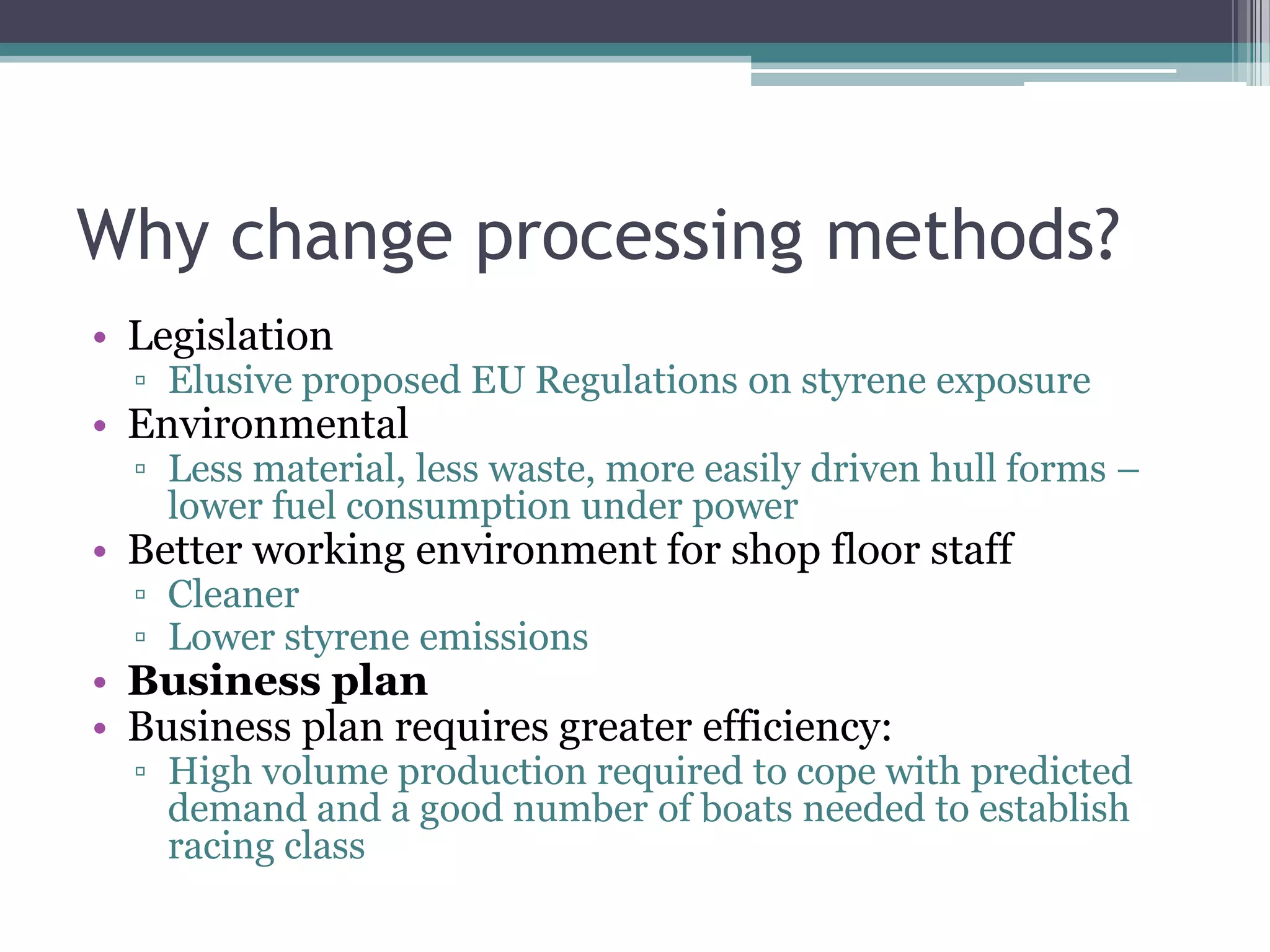

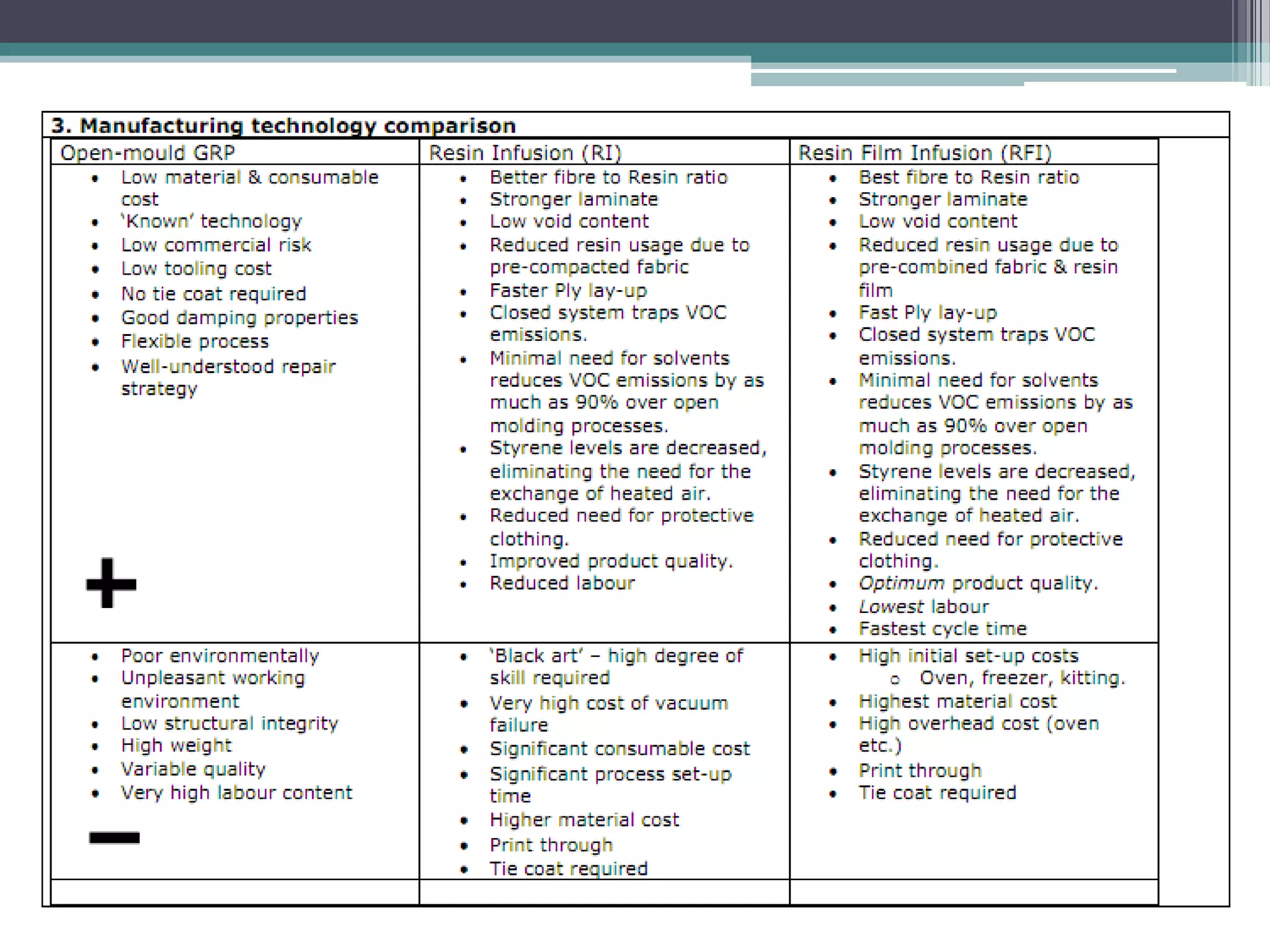

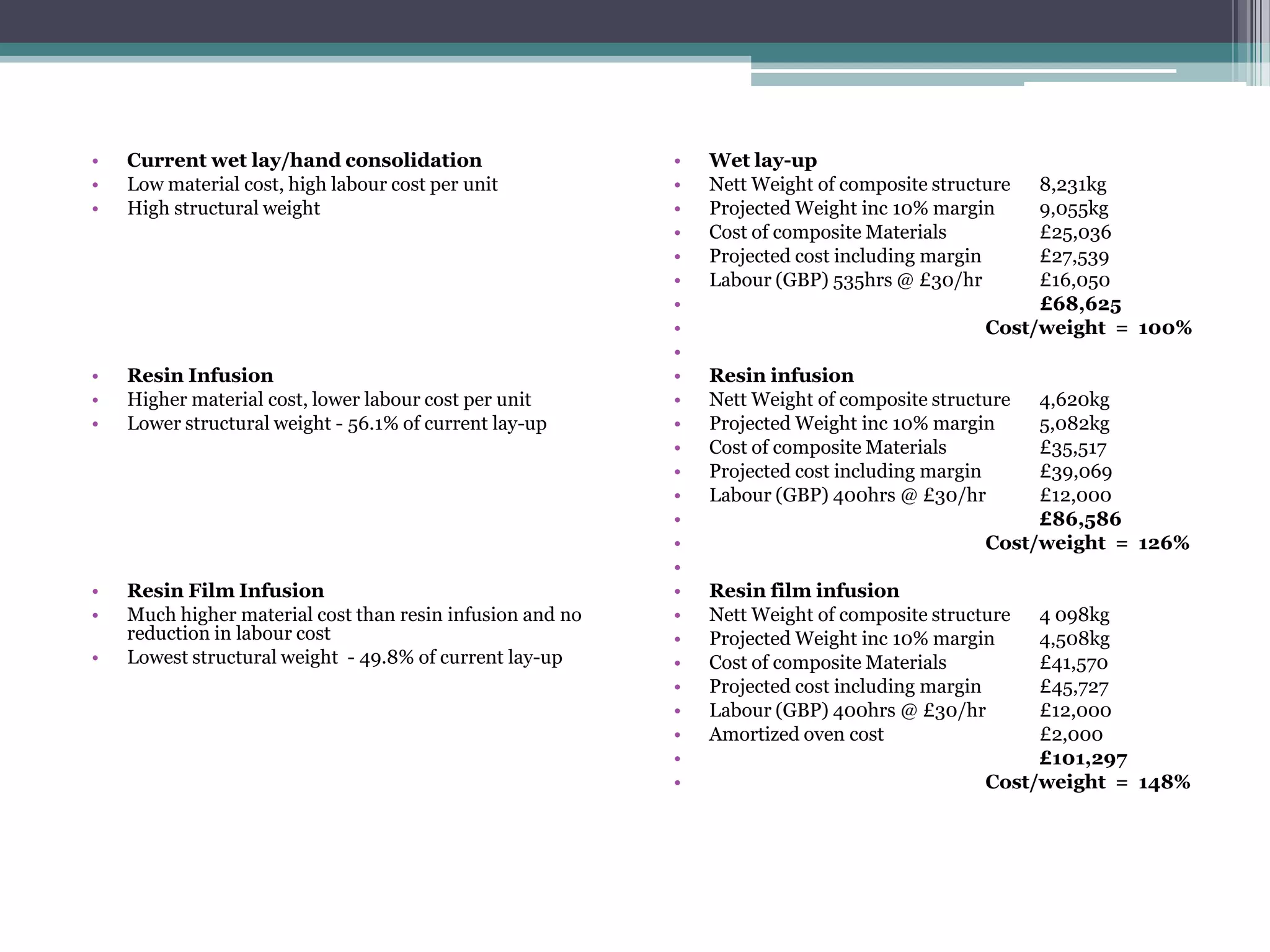

The document discusses alternative composite materials processing methods for boat building, including hand layup, resin infusion, and resin film infusion. Resin infusion offers the lowest structural weight at 56.1% of current methods and lower labor costs, but higher material costs. Resin film infusion has the lowest structural weight at 49.8% but much higher material and total costs. While pre-pregs have high costs, developments may make them more affordable. The learning curve is steep, so seeking help from experts and practicing small sections is recommended before full implementation.