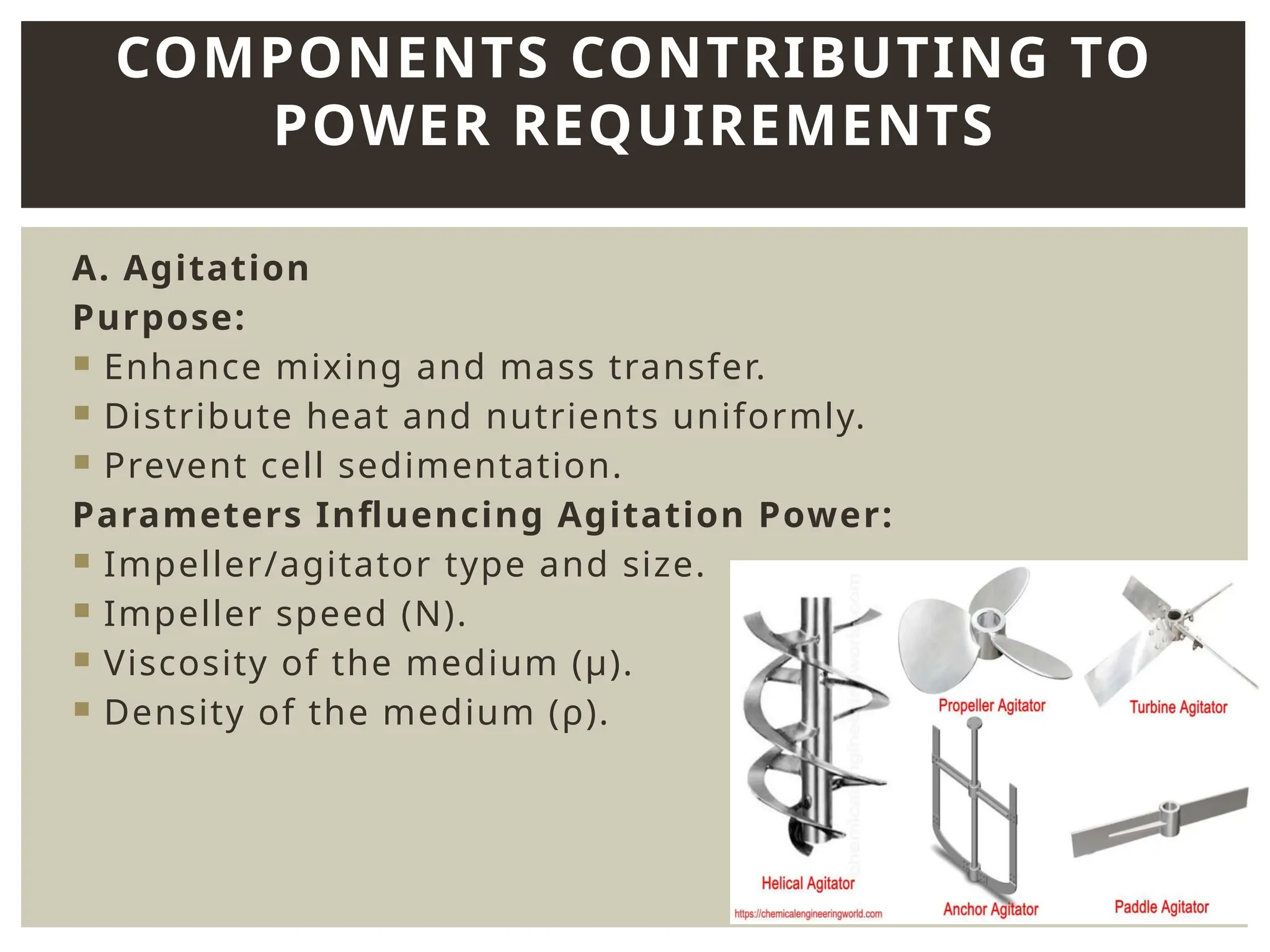

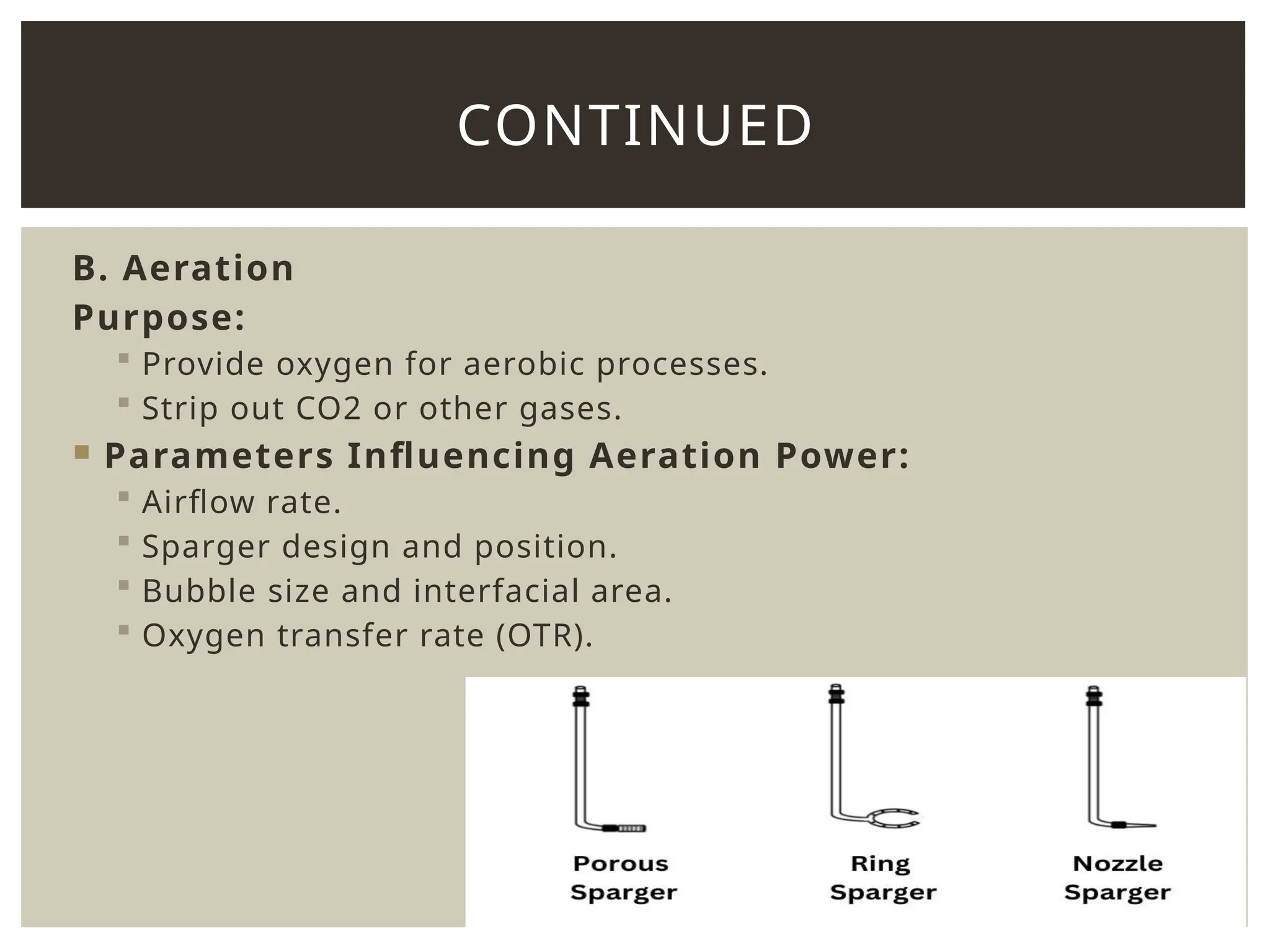

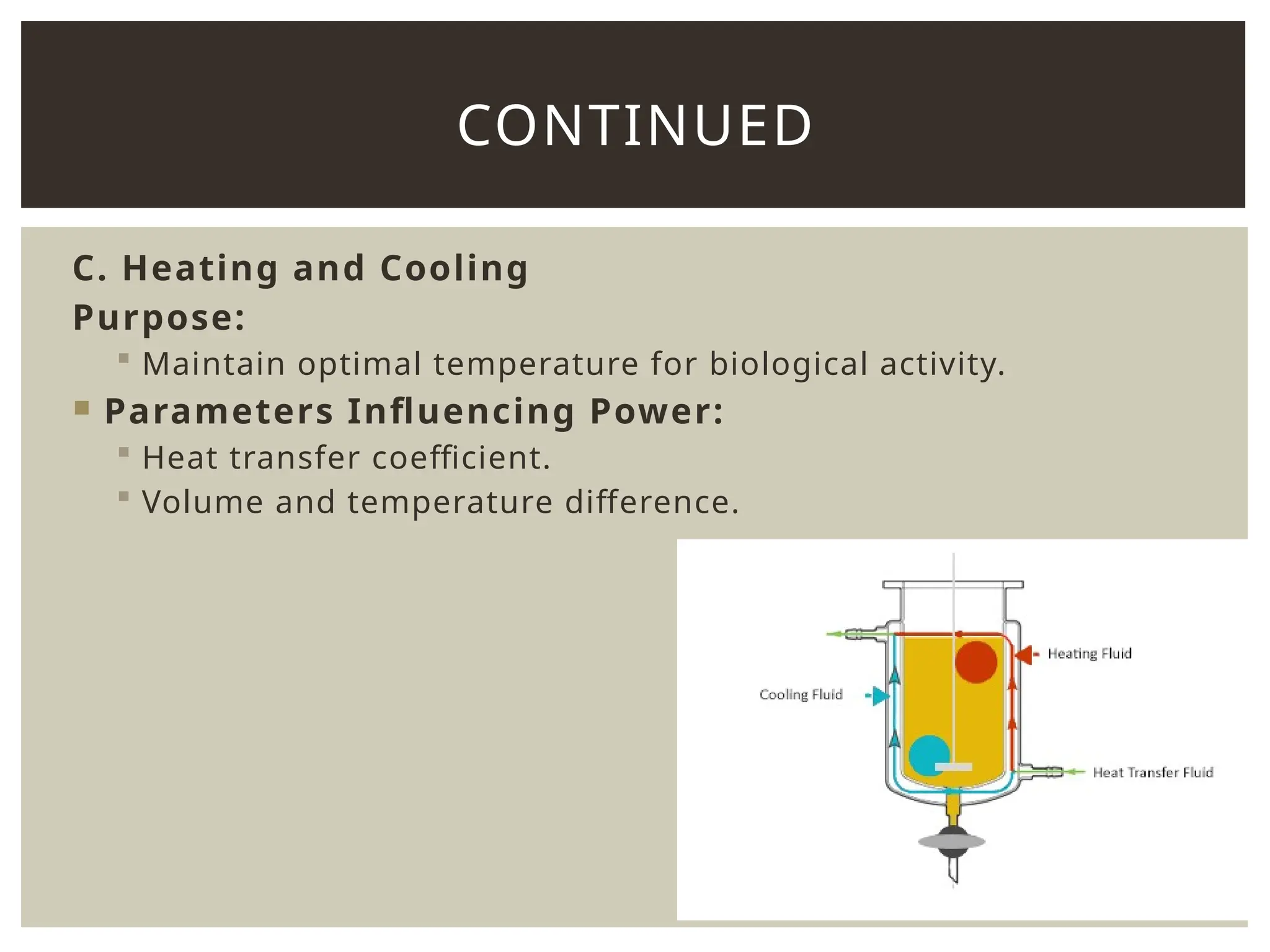

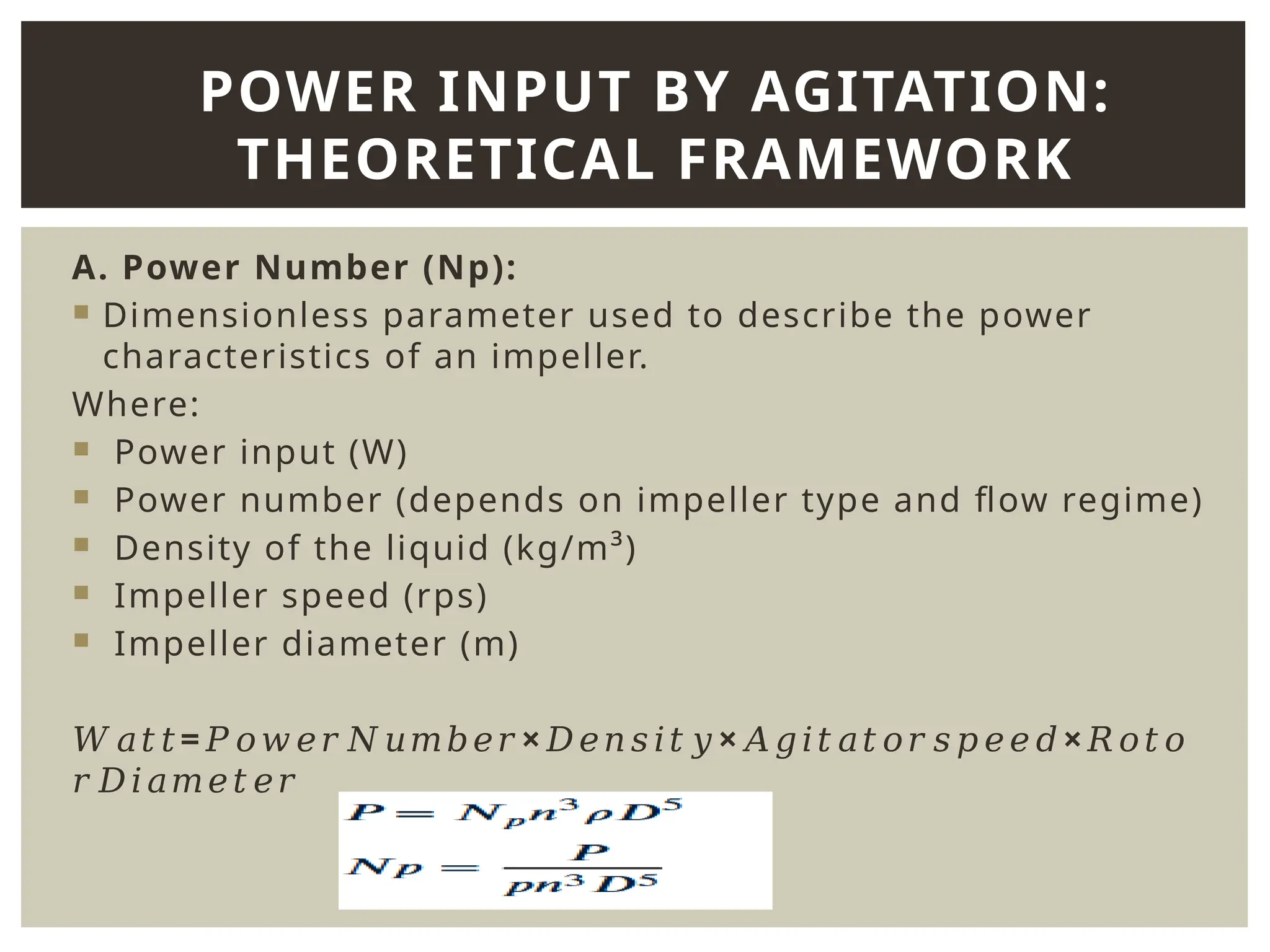

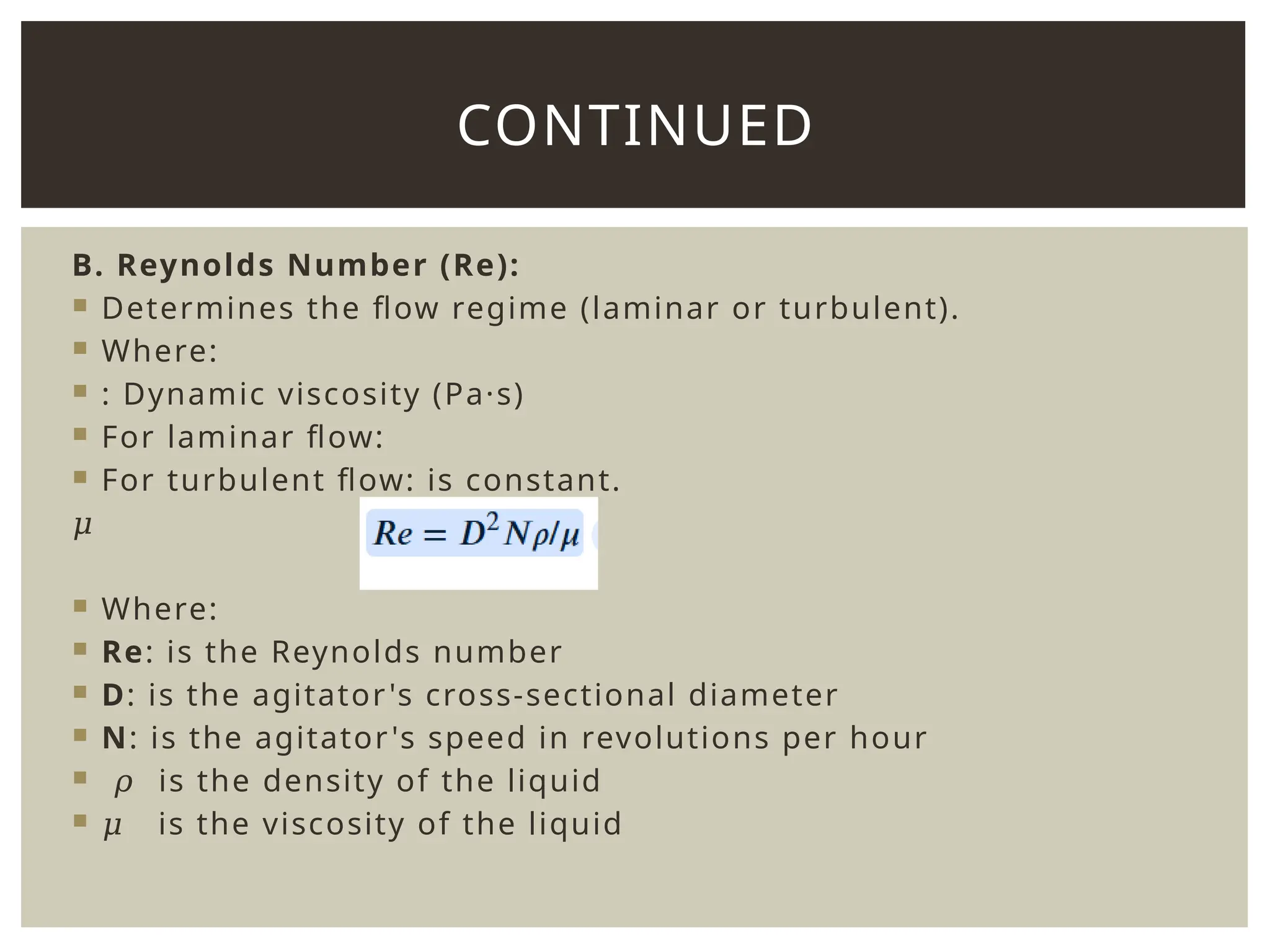

The document discusses the power requirements for bioreactors, which are vital for biological reactions in various industries. It outlines the main components influencing power, including agitation, aeration, and heating/cooling, as well as parameters such as impeller type, airflow rate, and oxygen transfer rates. Additionally, it emphasizes the importance of energy efficiency and optimization in bioreactor operations.