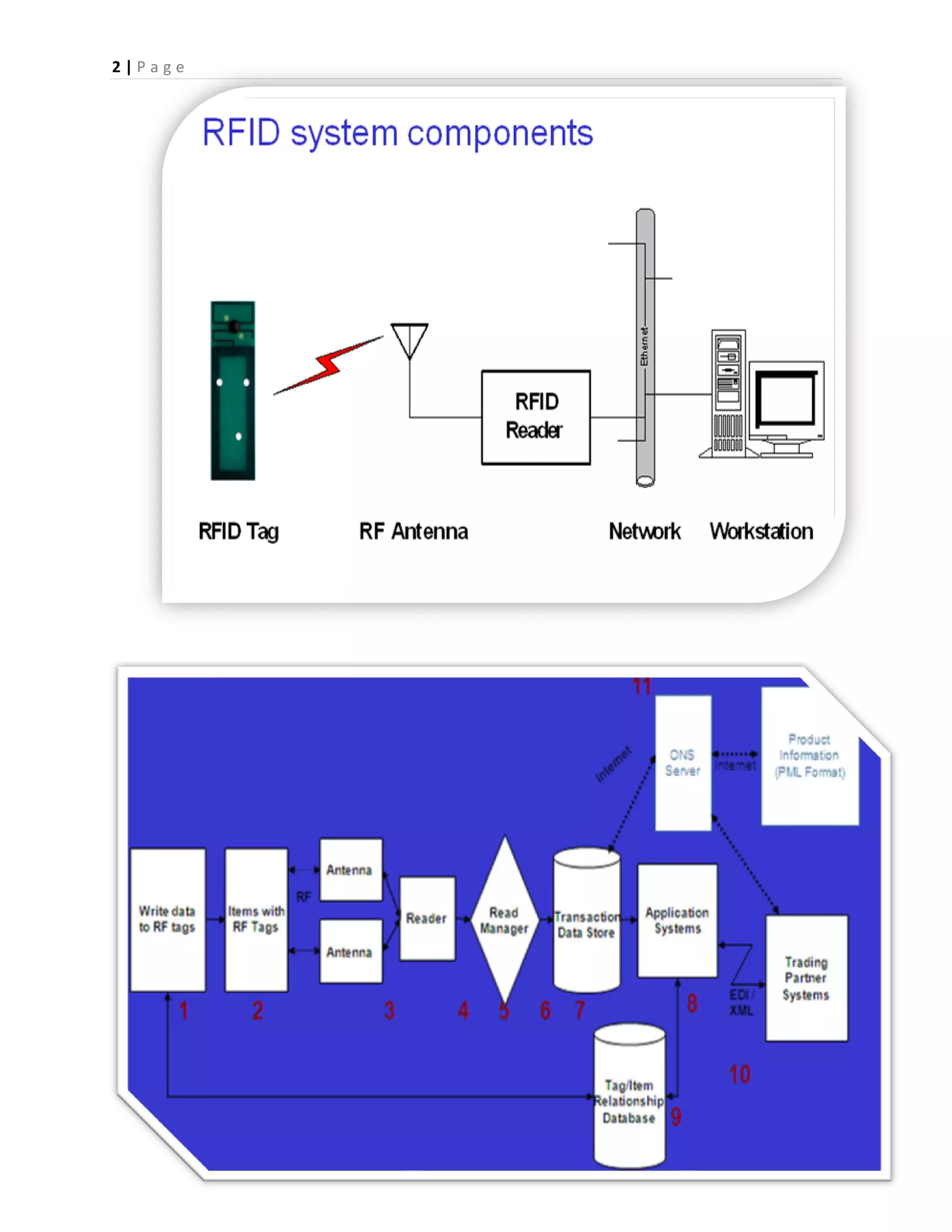

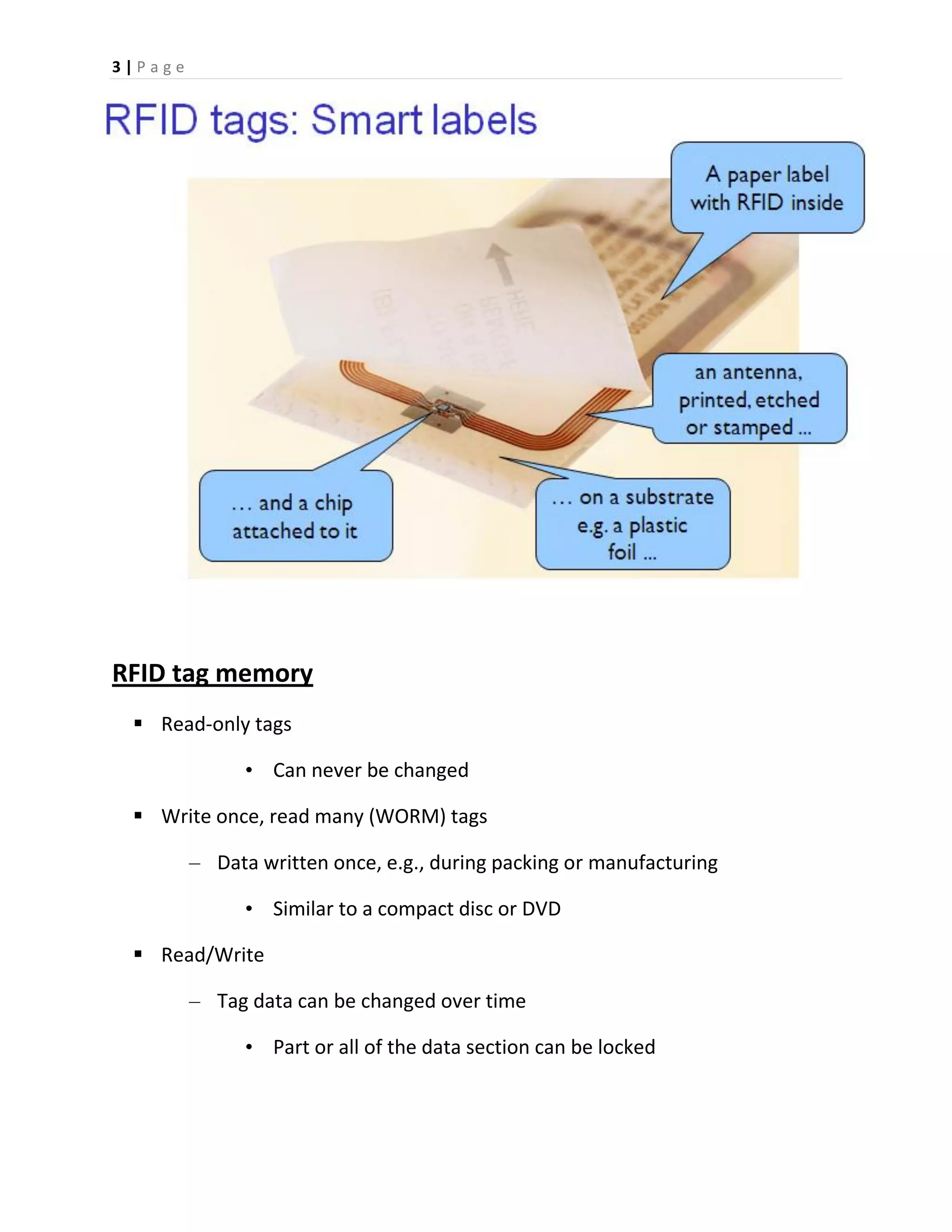

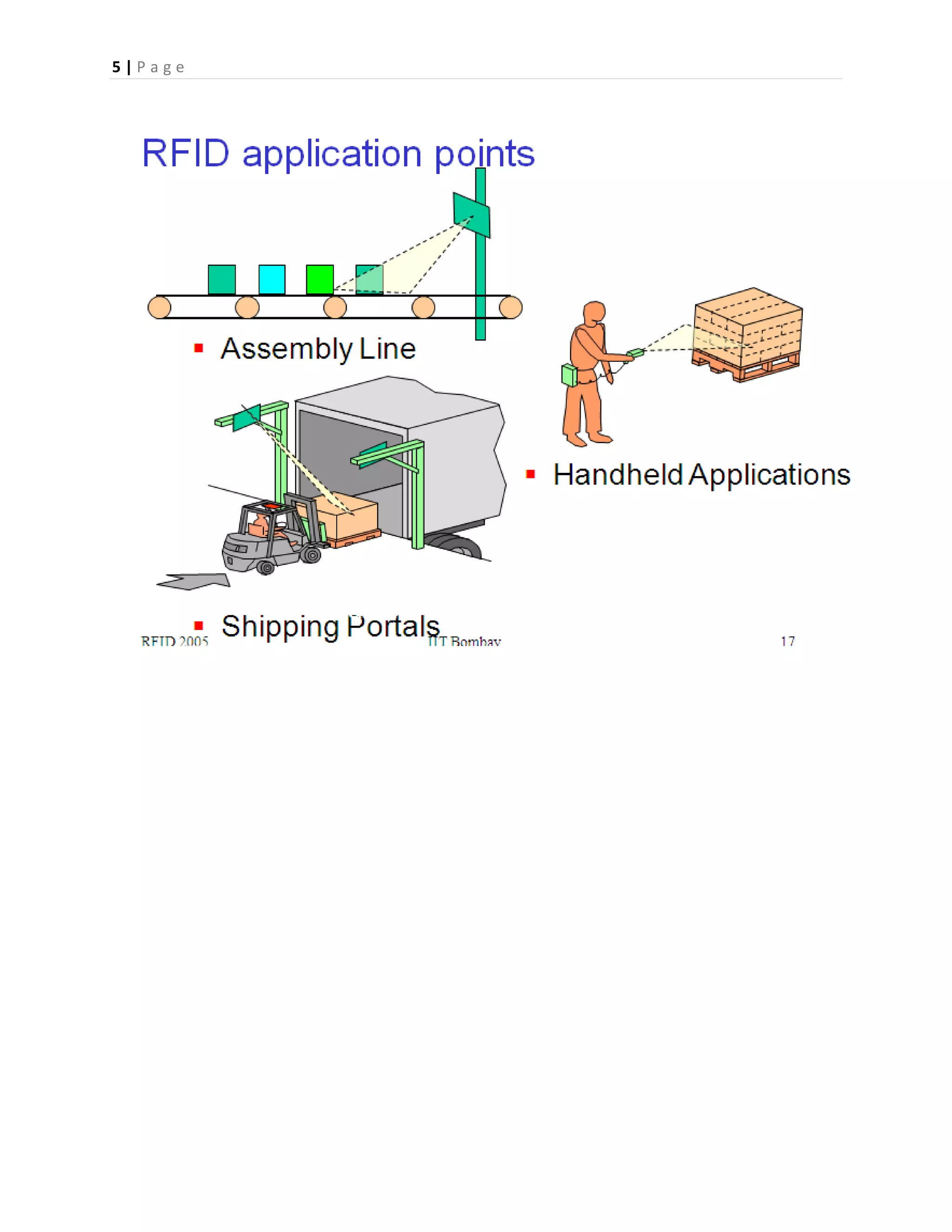

This document discusses radio-frequency identification (RFID) technology and its applications. RFID uses radio waves to transfer data between a reader and a tagged item to identify and track objects without requiring physical contact or line-of-sight. RFID tags can be read-only, write-once read-many, or read/write. RFID readers remotely power tags, establish data links, and can read 100-300 tags per second. The document outlines how RFID can help with inventory management, assembly process control, supply chain integration, and other applications in manufacturing, logistics, retail, security, and location tracking.