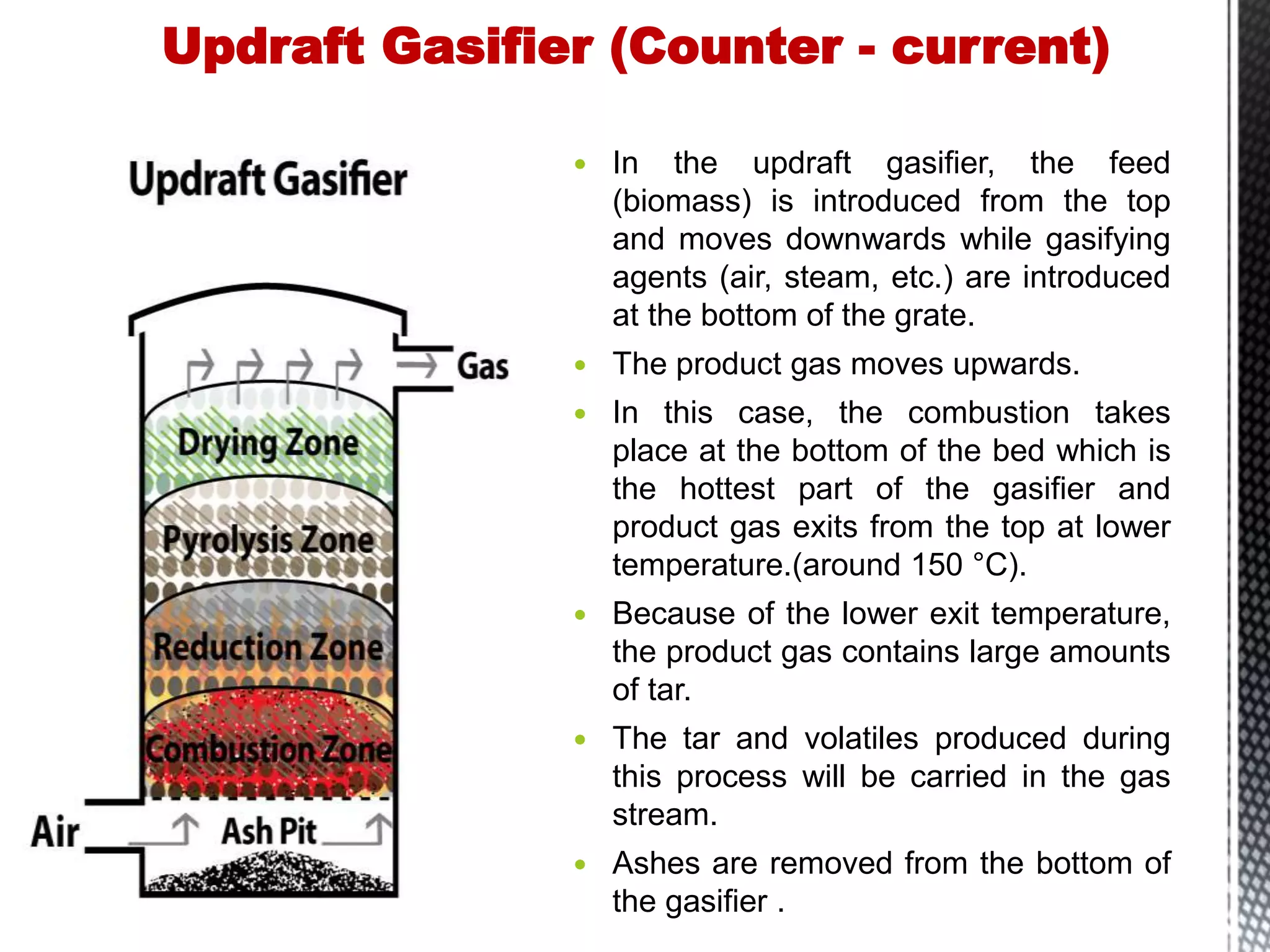

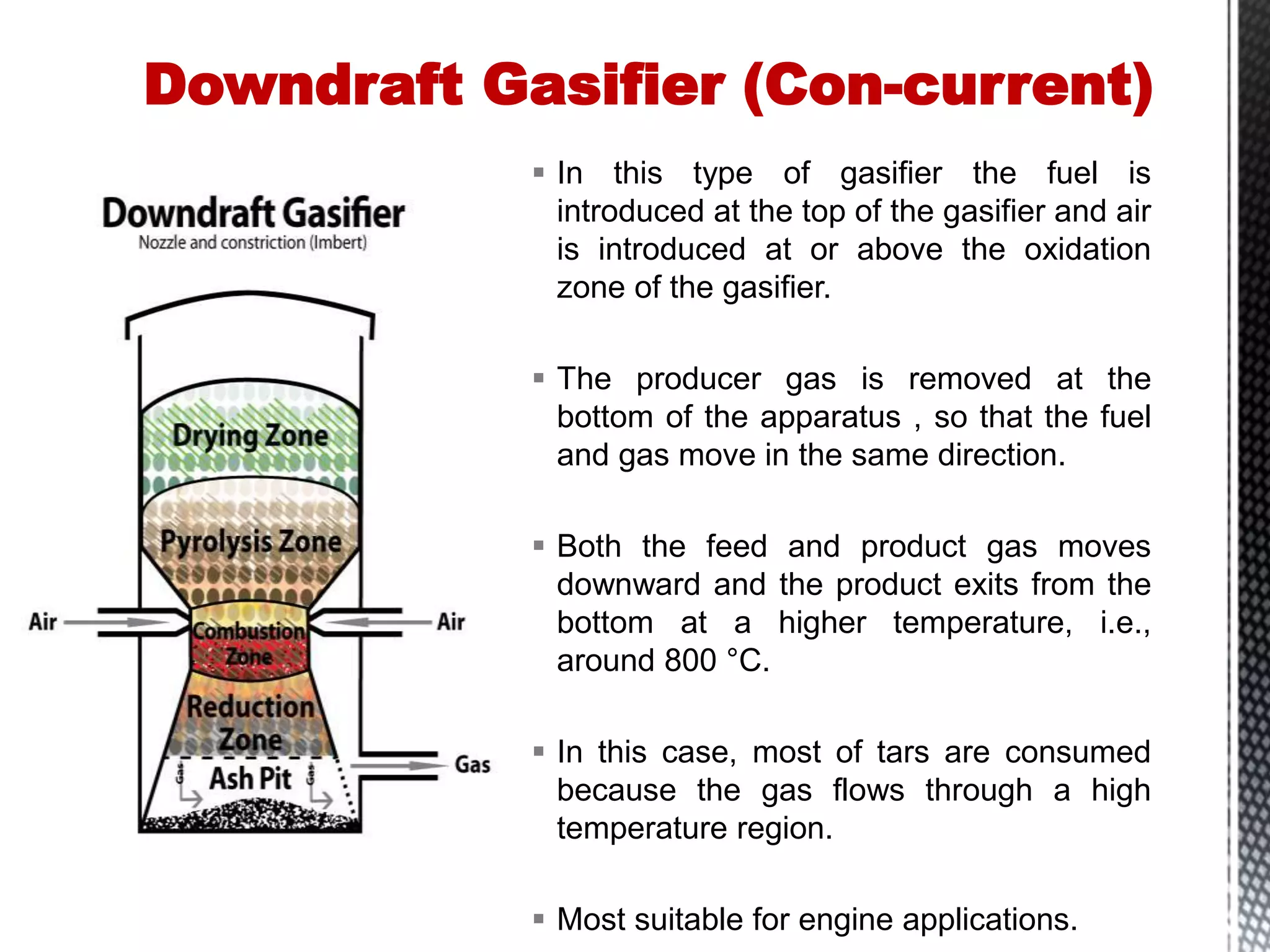

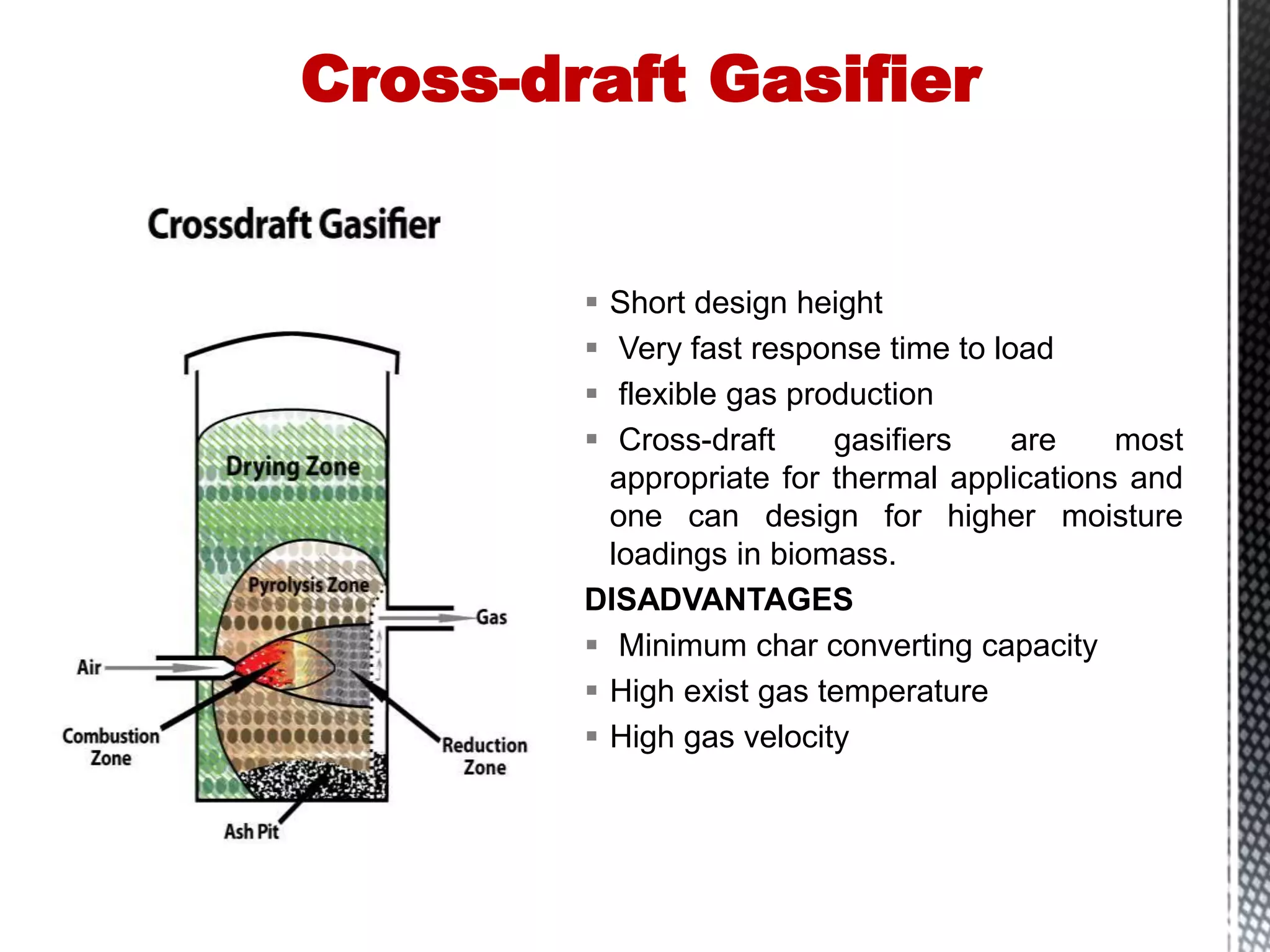

There are several types of gasifiers that are categorized based on flow direction and bed type. Updraft gasifiers have counter-current flow with fuel entering from the top and gasifying agents from the bottom, producing gas that exits at the top around 150°C and contains tar. Downdraft gasifiers have concurrent flow with fuel and gas moving downward and gas exiting at the bottom around 800°C where most tars are consumed. Crossdraft gasifiers introduce fuel at the bottom of a fluidized bed and produce gas with more particulates.

![Gasifiers are categorized as follows:

Basing on direction of flow (DRAFT) of gas [where we get output]

Up draft (Counter current)

Down draft (concurrent)

Cross draft

Based on type of bed

1. Fixed bed- updraft , downdraft and cross draft

2. Fluidized bed

Types of Gasifier](https://image.slidesharecdn.com/gasifiertypes-210525041137/75/Types-of-Gasifier-reactors-3-2048.jpg)