Project Client Location

Delhi Metro MC1B

IMCC External slabs and walls

Early Age Thermal Crack Control Reinforcement Design Made by

abc

Date Page Job No

STS

Checked

17-Sep-2013

Revision

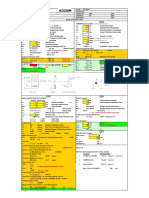

Ref 1: Ref 2: INPUT Type of Concrete: Ordinary Portland Cement (OPC) Sulphate Resisting Portland Cement (SRPC) Rapid Hardening Portland Cement (RHPC) Use of Pozzolanic or Latent Hydraulic Materials: Pulverised Fuel Ash (PFA) Ground Granulated Blastfurnace Slags (GGBS) Cement Content (OPC) = PFA Content =

OPC

SRPC RHPC

59120

Early-age thermal crack control in concrete - Ciria Report 91 BS 8007:1987 - Design of concrete structures for retaining aqueous liquids

PFA GGBS

280 120 0 35

kg/m kg/m

Concrete Grade = Dominant Movement = Type of Aggregate:

N/mm2

Quartzite

Type of Formwork:

Steel Formwork 18mm Plywood Formwork

STEEL PLYWOOD

Type of Steel: Diameter of Bars:

415 201

N/mm mm

Section Thickness = Expected Concrete Placing Temperature = Fall in Temperature due to Seasonal Variations (T2) = Maximum Allowable Crack Width (Wmax) = Maximum Thermal Expansion Coefficient (x 10-6/C) = Minimum Thermal Expansion Coefficient (x 10-6/C) = Average Thermal Expansion Coefficient (x 10-6/C) =

1200 25 15 0.2 14.6 11.7 9.2

mm C C mm

USE MAX USE MIN

USE AVERAGE

�Project Client Location

Delhi Metro MC1B

IMCC External slabs and walls

Early Age Thermal Crack Control Reinforcement Design Made by

abc

Date Page Job No

STS

Checked

17-Sep-2013

Revision

CALCULATIONS

Temperature Rise Above Mean Ambient Temperature (C) 35.57 Peak Temperature of Concrete Attributable to the Portland Cement (C) 50.57 Contribution to the Temperature Rise from PFA in Concrete (C) 4.80 Contribution to the Temperature Rise from GGBS in Concrete (C) 0.00 Contribution to the Temperature Rise Increased Placing Temperature (C) 5.34 Design Mix Tempeature (C) 60.71

59120

Maximum Spacing of Cracks (Smax) = (fct/fb) x (/2r) where fct/fb = 0.67 r = As/Ac rcrit = 0.0064 Maximum Crack Width (Wmax) = Smax x (a/2) x (T1 + T2) Rearranging these formulas gives As = (fct/fb) x a x (T1 + T2) x x Ac 4 W max a= T1 + T2 = Ac = Required Area of Steel: Data Checks: r= 0.0098 > rcrit = Smax = Steel to be used: or T16@ 80mm T16@ 82mm = 2513 mm2 = 2440 mm2 As = 12 60.71 250000 2440 0.0064 549 x 10-6 C mm2 mm2 OK mm

�Project Client Location

Delhi Metro MC1B

IMCC External slabs and walls

Early Age Thermal Crack Control Reinforcement Design Made by

abc

Date Page Job No

STS

Checked

17-Sep-2013

Revision

59120

Range of Temperature Rises Above Mean Ambient Temperature (C)

76 74 72 70 68 66 64 62 60 58 56 54 52 50 48 46 44 42 40 38 36 34 32 30 28 26 24 22 20 18 16 14 12 10 8 6 4 2 0 0 200 400 600 800

220 (kg/m) 290 (kg/m) 360 (kg/m) 400 (kg/m)

35.57

500 (kg/m) Design Values

1000

1200

�Project Client Location

Delhi Metro MC1B

IMCC External slabs and walls

Early Age Thermal Crack Control Reinforcement Design Made by

abc

Date Page Job No

STS

Checked

17-Sep-2013

Revision

Ref 1: Ref 2: INPUT Type of Concrete: Ordinary Portland Cement (OPC) Sulphate Resisting Portland Cement (SRPC) Rapid Hardening Portland Cement (RHPC) Use of Pozzolanic or Latent Hydraulic Materials: Pulverised Fuel Ash (PFA) Ground Granulated Blastfurnace Slags (GGBS) Cement Content (OPC) = PFA Content =

OPC SRPC RHPC

59120

Early-age thermal crack control in concrete - Ciria Report 91 BS 8007:1987 - Design of concrete structures for retaining aqueous liquids

PFA GGBS

300 120 0 45

kg/m kg/m

Concrete Grade = Dominant Movement = Type of Aggregate:

N/mm2

Quartzite

Type of Formwork:

Steel Formwork 18mm Plywood Formwork

STEEL PLYWOOD

Type of Steel: Diameter of Bars:

415 201

N/mm mm

Section Thickness = Expected Concrete Placing Temperature = Fall in Temperature due to Seasonal Variations (T2) = Maximum Allowable Crack Width (Wmax) = Maximum Thermal Expansion Coefficient (x 10-6/C) = Minimum Thermal Expansion Coefficient (x 10-6/C) = Average Thermal Expansion Coefficient (x 10-6/C) =

800 25 15 0.2 14.6 11.7 9.2

mm C C mm

USE MAX

USE MIN USE AVERAGE

�Project Client Location

Delhi Metro MC1B

IMCC External slabs and walls

Early Age Thermal Crack Control Reinforcement Design Made by

abc

Date Page Job No

STS

Checked

17-Sep-2013

Revision

CALCULATIONS

Temperature Rise Above Mean Ambient Temperature (C) 34.62 Peak Temperature of Concrete Attributable to the Portland Cement (C) 49.62 Contribution to the Temperature Rise from PFA in Concrete (C) 4.62 Contribution to the Temperature Rise from GGBS in Concrete (C) 0.00 Contribution to the Temperature Rise Increased Placing Temperature (C) 5.19 Design Mix Tempeature (C) 59.43

59120

Maximum Spacing of Cracks (Smax) = (fct/fb) x (/2r) where fct/fb = 0.67 r = As/Ac rcrit = 0.0064 Maximum Crack Width (Wmax) = Smax x (a/2) x (T1 + T2) Rearranging these formulas gives As = (fct/fb) x a x (T1 + T2) x x Ac 4 W max a= T1 + T2 = Ac = Required Area of Steel: Data Checks: r= 0.0096 > rcrit = Smax = Steel to be used: or T16@ 80mm T16@ 84mm = 2513 mm2 = 2389 mm2 As = 12 59.43 250000 2389 0.0064 561 x 10-6 C mm2 mm2 OK mm

�Project Client Location

Delhi Metro MC1B

IMCC External slabs and walls

Early Age Thermal Crack Control Reinforcement Design Made by

abc

Date Page Job No

STS

Checked

17-Sep-2013

Revision

59120

Range of Temperature Rises Above Mean Ambient Temperature (C)

76 74 72 70 68 66 64 62 60 58 56 54 52 50 48 46 44 42 40 38 36 34 32 30 28 26 24 22 20 18 16 14 12 10 8 6 4 2 0 0 200 400 600 Element Thickness

220 (kg/m) 290 (kg/m) 360 (kg/m)

34.62

400 (kg/m) 500 (kg/m) Design Values

800

1000

1200

�Project Client Location

Delhi Metro MC1B

IMCC External slabs and walls

Early Age Thermal Crack Control Reinforcement Design Made by

abc

Date Page Job No

STS

Checked

17-Sep-2013

Revision

Ref 1: Ref 2: INPUT Type of Concrete: Ordinary Portland Cement (OPC) Sulphate Resisting Portland Cement (SRPC) Rapid Hardening Portland Cement (RHPC) Use of Pozzolanic or Latent Hydraulic Materials: Pulverised Fuel Ash (PFA) Ground Granulated Blastfurnace Slags (GGBS) Cement Content (OPC) = PFA Content =

OPC SRPC RHPC

59120

Early-age thermal crack control in concrete - Ciria Report 91 BS 8007:1987 - Design of concrete structures for retaining aqueous liquids

PFA GGBS

320 80 0 35

kg/m kg/m

Concrete Grade = Dominant Movement = Type of Aggregate:

N/mm2

Granite

Type of Formwork:

Steel Formwork 18mm Plywood Formwork

STEEL PLYWOOD

Type of Steel: Diameter of Bars:

500 201

N/mm mm

Section Thickness = Expected Concrete Placing Temperature = Fall in Temperature due to Seasonal Variations (T2) = Maximum Allowable Crack Width (Wmax) = Maximum Thermal Expansion Coefficient (x 10-6/C) = Minimum Thermal Expansion Coefficient (x 10-6/C) = Average Thermal Expansion Coefficient (x 10-6/C) =

1200 25 10 0.2 10.3 8.1 9.2

mm C C mm

USE MAX

USE MIN USE AVERAGE

�Project Client Location

Delhi Metro MC1B

IMCC External slabs and walls

Early Age Thermal Crack Control Reinforcement Design Made by

abc

Date Page Job No

STS

Checked

17-Sep-2013

Revision

CALCULATIONS

Temperature Rise Above Mean Ambient Temperature (C) 40.43 Peak Temperature of Concrete Attributable to the Portland Cement (C) 55.43 Contribution to the Temperature Rise from PFA in Concrete (C) 3.80 Contribution to the Temperature Rise from GGBS in Concrete (C) 0.00 Contribution to the Temperature Rise Increased Placing Temperature (C) 6.06 Design Mix Tempeature (C) 60.29

59120

Maximum Spacing of Cracks (Smax) = (fct/fb) x (/2r) where fct/fb = 0.67 r = As/Ac rcrit = 0.0064 Maximum Crack Width (Wmax) = Smax x (a/2) x (T1 + T2) Rearranging these formulas gives As = (fct/fb) x a x (T1 + T2) x x Ac 4 W max a= T1 + T2 = Ac = Required Area of Steel: Data Checks: r= 0.0074 > rcrit = Smax = Steel to be used: T16@ 100mm = 2011 mm2 As = 9.2 60.29 250000 1858 0.0064 721 x 10-6 C mm2 mm2 OK mm

�Project Client Location

Delhi Metro MC1B

IMCC External slabs and walls

Early Age Thermal Crack Control Reinforcement Design Made by

abc

Date Page Job No

STS

Checked

17-Sep-2013

Revision

59120

Range of Temperature Rises Above Mean Ambient Temperature (C)

76 74 72 70 68 66 64 62 60 58 56 54 52 50 48 46 44 42 40 38 36 34 32 30 28 26 24 22 20 18 16 14 12 10 8 6 4 2 0 0 200 400 600 Element Thickness 800

220 (kg/m)

40.43

290 (kg/m) 360 (kg/m) 400 (kg/m) 500 (kg/m) Design Values

1000

1200