0% found this document useful (0 votes)

312 views18 pagesSystem Flow Pattern: Istat

COOLING SYSTEM

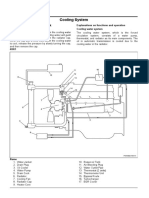

SYSTEM FLOW PATTERN

ISTAT

LOWER

6. COOLING SYSTEM

SYSTEM FLOW PATTERN

SERVICE INFORMATION TROUBLESHOOTING SYSTEM TESTING COOLANT REPLACEMENT 6-0 6- 1

6-2

THERMOSTAT RADIATOR WATER PUMP RADIATOR RESERVE TANK FAN CONTROL RELAY

6-6 6-8 6-13 6-16 6-17

6-3 6-4

SERVICE INFORMAT10N

GENERAL

Removing the radiator cap while the engine is hot can cause the coolant t o spray out, seriously scalding you. Always let the engine and radiator cool down before removing the radiator cap.

Uploaded by

genuineswedeCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

312 views18 pagesSystem Flow Pattern: Istat

COOLING SYSTEM

SYSTEM FLOW PATTERN

ISTAT

LOWER

6. COOLING SYSTEM

SYSTEM FLOW PATTERN

SERVICE INFORMATION TROUBLESHOOTING SYSTEM TESTING COOLANT REPLACEMENT 6-0 6- 1

6-2

THERMOSTAT RADIATOR WATER PUMP RADIATOR RESERVE TANK FAN CONTROL RELAY

6-6 6-8 6-13 6-16 6-17

6-3 6-4

SERVICE INFORMAT10N

GENERAL

Removing the radiator cap while the engine is hot can cause the coolant t o spray out, seriously scalding you. Always let the engine and radiator cool down before removing the radiator cap.

Uploaded by

genuineswedeCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 18