0% found this document useful (0 votes)

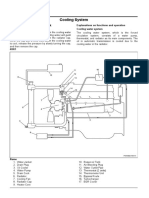

65 views30 pagesCooling System

SISTEMA DE REFRIGERACION MOTOR IZUSU HK1-3

Uploaded by

Andres GranadosCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

65 views30 pagesCooling System

SISTEMA DE REFRIGERACION MOTOR IZUSU HK1-3

Uploaded by

Andres GranadosCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 30