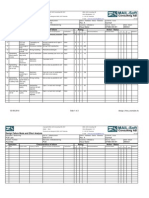

Supplier Standards Manual

Seat Heat Peel and Stick Heater PFMEA

Chapter 7 Quality Section

March 2008 Revision 1.0

Document #:

Program:

Model Year:

RFQ # / Basis #:

Back Office Chief / Manager

Back Office Lead

Program Manager

Phase:

ECO #:

273959762.xls

Rev:

A

1444480

Template - Peel and Stick Heater PFMEA

N/A

N/A

Deana Borghi

Joe Hebda

Robert Hicks

N/A

Change Description:

Date:

Initial Release

Page 1 of 14

�Supplier Standards Manual

Seat Heat Peel and Stick Heater PFMEA

Chapter 7 Quality Section

March 2008 Revision 1.0

CORE PFMEA SHEET - SEAT HEATERS

Item Date

1.

10/282003

2.

3.

4.

2/4/2004

9/14/2004

9/9/2005

273959762.xls

Revisions

Converted Document from MPACT to Excel.

Updated with Password Protections, Added Revision Tab, Updated PFMEA Instruction, Created

Separate Tabs for Peel N' Stick and Sewn-In Systems.

Updated document with Significant and Critical symbols - Sept 04

Updated to reflect revised operational procedures & new Design template.

Page 2 of 14

�Supplier Standards Manual

Seat Heat Peel and Stick Heater PFMEA

Chapter 7 Quality Section

March 2008 Revision 1.0

Process Failure Mode Effects and Analysis (Heater PFMEA)

Instructions

All 2007 model year and beyond programs must utilize Heater Template.

NOTE: Process FMEA's must be prepared for all programs (components, subassemblies and

assemblies) where Johnson Controls has full program design responsibility. (Refer to the AIAG

FMEA Manual and the AIAG APQP and Control Plan manual).

1.

Instructions for PEEL N' Sticker Heater PFMEA Template :

Process FMEA's are to be prepared using a cross functional team and the AIAG Potential Failure

Modes and Effects Analysis (FMEA) manual.

The cross-functional team should include:

* Advance Manuf. Engineer (Champion)......PFMEA from similar programs, DFM&A input

* Product Engineer .................................DFA items for similar programs

* Quality Engineer .........................

2.

Copy Information from the "Heater_Template" into your existing PFMEA.xls file where you

process the heater elements. Steps 1-5 should be copied into the area where the heater to foam

operation occurs. The remaining steps should be incorporated into the seat build process at the

appropriate operational step. (NOTE: REVIEW BOLD TEXT to determine if items apply to

processing)

3.

Occurrence numbers can be adjusted by the Cost Functional Team based on Customer Plant

Problems or Warranty Information. These items should be listed in the Recommended Actions

Column and used to re-calculate the RPN under the "Reaction Results"

4.

Detection numbers can be adjusted by the Cost Function Team based on Controls not listed

under the Detection/Prevention Columns. These items should be listed in the Recommended

Actions Column and used to re-calculate the RPN under the "Reaction Results"

273959762.xls

Page 3 of 14

�Supplier Standards Manual

Seat Heat Peel and Stick Heater PFMEA

Chapter 7 Quality Section

March 2008 Revision 1.0

273959762.xls

Page 4 of 14

�Supplier Standards Manual

Seat Heat Peel and Stick Heater PFMEA

Chapter 7 Quality Section

March 2008 Revision 1.0

CORE SEAT HEATER P F M E A

FAILURE MODE

AND EFFECTS ANALYSIS

FMEA no#:

Item/Component: PEEL N' STICK HEATERS

OEM

Model Year/Vehicle:

Prepared by:

CoE Organization

Key Date:

CoreTeam:

FMEA Date (Orig.)

FMEA Date (Last rev.)

Requirements

Failure

Effect(s) of

Mode

Failure

Standard

Process

Process

Controls

Controls

Prevention

Detection

Mechanism(s)

of Failure

Standard

RPN

Potential

Cause(s)/

DETECT

Potential

OCCUR

Potential

CLASS

Process Function/

SEV

Item

Responsibility

Actions

& Target

Actions

Completion

Taken

Date

1

Get components

wrong parts

improper heating

locations

5

a. Wrong components

stocked on line

a) Lineside racking with

designated lanes

2

b) Labeled containers

from supplier w/part

description

60

b. picked up from the

floor, another bin, etc

(other than the correct

location)

plant procedure for part

handling re. loose parts,

operator training

60

c. similar component used

in the same station

2

(picked up the wrong

component)

separation of LH & RH

seats/ components

60

10

50

d. Wrong components in

the correct shipping

1

container (Supplier Issue)

Obtain the correct

non-functioning heater or

components but not to the improper heating

required design standards locations

FBU PFMEA Heater Template / Rev 02 (15-December-2004)

a. box cutter cut through

element wire/ harness

when opening box

a) Prohibit opening box

with cutter/ caution label

added to packaging

EOL tester - Check

2 b) returnable packaging Current Draw (Applies to

c) special designed

Series System)

heater packaging (eggcrate) to prevent failure

48

b. Component picks up

foreign materials or

comes in contact with

(especially with the

adhesive tape)

1 ODS, (Reject procedures)

42

file name: 273959762.xls

Action Results

Recommended

S O

P.

N.

Page 5 of 14

R.

�Supplier Standards Manual

Seat Heat Peel and Stick Heater PFMEA

Chapter 7 Quality Section

March 2008 Revision 1.0

CORE SEAT HEATER P F M E A

FAILURE MODE

AND EFFECTS ANALYSIS

FMEA no#:

Item/Component: PEEL N' STICK HEATERS

OEM

Model Year/Vehicle:

Prepared by:

CoE Organization

Key Date:

CoreTeam:

FMEA Date (Orig.)

FMEA Date (Last rev.)

Requirements

Failure

Effect(s) of

Mode

Failure

Standard

Process

Process

Controls

Controls

Prevention

Detection

Mechanism(s)

of Failure

Standard

RPN

Potential

Cause(s)/

DETECT

Potential

OCCUR

Potential

CLASS

Process Function/

SEV

Item

Responsibility

Actions

& Target

Actions

Completion

Taken

Date

FIFO Procedures utilized

at facility, Change

100% visual inspection at

Management, Material

point of installation to a

Inventory management

master sample

procedures

c. FIFO is not conducted

d. previously used

component is used

1 ODS, (Reject procedures)

42

42

ODS, training

EOL tester - Check

Current Draw

24

Incoming part racking,

Proper material container

EOL tester - Check

Current Draw

48

63

72

84

e. carrying by harness

(peel & stick heater)

f. hanging parts to prestage at station

a. Box cutter when

opening box (If nick is

between module and

heater sensor in the

element)

a) Prohibit opening box

with cutter/ caution label

added to packaging

1 b) returnable packaging

c) specially designed

heater packaging (eggcrate) to prevent failure

Action Results

Recommended

S O

P.

N.

Hot Spot in the harness

Align heater pad to foam

pad.

Wrong sub-assembly

placed on seat (subasm

out of sequence)

Non-functional heater

No heater on seat

Installed off location/

mis-alignment

non-symmetrical heating

difficult to install hog

rings

FBU PFMEA Heater Template / Rev 02 (15-December-2004)

b. Dangling harness get

snagged by equipment,

2

tools fixtures causing nick

a) plant procedure for

part handling re. loose

parts

b) equipment design

No heater mat on heated

seat, or heater mat on

non-heated seat

ODS, Operator training

matrix,

a. ODS elements are not

followed.

Operator training matrix,

visual inspection for

notch alignment

63

b. ODS is not clearly

defined for operator to

follow

Operator training matrix,

visual inspection for

notch alignment

63

file name: 273959762.xls

EOL tester - Check

Current Draw

Page 6 of 14

R.

�Supplier Standards Manual

Seat Heat Peel and Stick Heater PFMEA

Chapter 7 Quality Section

March 2008 Revision 1.0

CORE SEAT HEATER P F M E A

FAILURE MODE

AND EFFECTS ANALYSIS

FMEA no#:

Item/Component: PEEL N' STICK HEATERS

OEM

Model Year/Vehicle:

Prepared by:

CoE Organization

Key Date:

CoreTeam:

FMEA Date (Orig.)

FMEA Date (Last rev.)

Requirements

Failure

Effect(s) of

Mode

Failure

Standard

Process

Process

Controls

Controls

Prevention

Detection

Mechanism(s)

of Failure

Standard

RPN

Potential

Cause(s)/

DETECT

Potential

OCCUR

Potential

CLASS

Process Function/

SEV

Item

Responsibility

Actions

& Target

Actions

Completion

Taken

Date

c. Lack of alignment

between heater element

Operator training matrix,

and foam pads

2 DFA Review, Safety Sign

(insufficient installation

off

reference points / datums)

visual inspection for

notch alignment

42

10

a. Wire positioning in

trench (too much causing

'bending' effect under

compression, not enough

causing strain, or

positioned such that

damage can occur during

hog ring installation)

ODS, training

EOL tester- ground

detection

70

a. ODS elements are not

followed.

Operator training matrix,

visual inspection for

notch alignment

63

b. ODS is not clearly

defined for operator to

follow

Operator training matrix,

visual inspection for

notch alignment

63

42

70

damage to heater wire

causing short or hot spot

Only Applies if Elements

Cross over Trenches in

local spots.

Remove tape backing from Installed off location/

adhesive.

mis-alignment

P.

N.

HIC

c. Lack of alignment

between heater element

Operator training matrix,

and foam pads

2 DFA Review, Safety Sign

(insufficient installation

off

reference points / datums)

damage to heater wire

causing short or hot spot

FBU PFMEA Heater Template / Rev 02 (15-December-2004)

S O

non-symmetrical heating

difficult to install hog

rings

Only Applies if Elements

Cross over Trenches in

local spots.

Action Results

Recommended

HIC

10

a. Wire positioning in

trench (too much causing

'bending' effect under

compression, not enough

causing strain, or

positioned such that

damage can occur during

hog ring installation)

ODS, training

file name: 273959762.xls

EOL tester- ground

detection

Page 7 of 14

R.

�Supplier Standards Manual

Seat Heat Peel and Stick Heater PFMEA

Chapter 7 Quality Section

March 2008 Revision 1.0

CORE SEAT HEATER P F M E A

FAILURE MODE

AND EFFECTS ANALYSIS

FMEA no#:

Item/Component: PEEL N' STICK HEATERS

OEM

Model Year/Vehicle:

Prepared by:

CoE Organization

Key Date:

CoreTeam:

FMEA Date (Orig.)

FMEA Date (Last rev.)

Requirements

Failure

Effect(s) of

Mode

Failure

Standard

Process

Process

Controls

Controls

Prevention

Detection

Mechanism(s)

of Failure

Standard

RPN

Potential

Cause(s)/

DETECT

Potential

OCCUR

Potential

CLASS

Process Function/

SEV

Item

Responsibility

Actions

& Target

Actions

Completion

Taken

Date

Heat elements not

adhered to the foam

properly

Attach heater pad to foam

pad.

Installed off location/

mis-alignment

element moves and may

bunch heater elements

causing hot spots

HIC

10

a. Reuse of heater

element (adhesive is one

time use)

ODS, training, reject

procedure

visual, seat appearance

70

b. All tape backing not

removed or partially

removed or torn

ODS, training

visual, seat appearance

210

c. Adhesive comes in

contact with foreign

materials (dust, dirt, oils,

etc)

1 ODS (Reject procedures)

70

d. Tape to felt adhesive

joint separates (as

operator removes tape

backing)

1 Operator training matrix,

70

a. ODS elements are not

followed.

Operator training matrix,

visual inspection for

notch alignment

63

b. ODS is not clearly

defined for operator to

follow

ODS approval procedure,

Operator training matrix,

visual inspection for

notch alignment

63

42

70

c. Lack of alignment

between heater element

Operator training matrix,

and foam pads

2 DFA Review, Safety Sign

(insufficient installation

off

reference points / datums)

damage to heater wire

causing short or hot spot

FBU PFMEA Heater Template / Rev 02 (15-December-2004)

Implement a tape backing

refer to product

design that has pull tabs

design template

for the operator.

S O

R.

P.

N.

10 1

70

non-symmetrical heating

difficult to install hog

rings

Only Applies if Elements

Cross over Trenches in

local spots.

Action Results

Recommended

HIC

10

a. Wire positioning in

trench (too much causing

'bending' effect under

compression, not enough

causing strain, or

positioned such that

damage can occur during

hog ring installation)

ODS, training

file name: 273959762.xls

EOL tester- ground

detection

Page 8 of 14

�Supplier Standards Manual

Seat Heat Peel and Stick Heater PFMEA

Chapter 7 Quality Section

March 2008 Revision 1.0

CORE SEAT HEATER P F M E A

FAILURE MODE

AND EFFECTS ANALYSIS

FMEA no#:

Item/Component: PEEL N' STICK HEATERS

OEM

Model Year/Vehicle:

Prepared by:

CoE Organization

Key Date:

CoreTeam:

FMEA Date (Orig.)

FMEA Date (Last rev.)

Requirements

Failure

Effect(s) of

Mode

Failure

Standard

Process

Process

Controls

Controls

Prevention

Detection

Mechanism(s)

of Failure

Standard

RPN

Potential

Cause(s)/

DETECT

Potential

OCCUR

Potential

CLASS

Process Function/

SEV

Item

Responsibility

Actions

& Target

Actions

Completion

Taken

Date

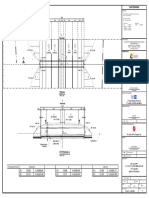

Heat elements not

adhered to the foam

properly

Heater element not

installed flat

Route wire harness through Improper routing

foam

Convey/ transport s/a

(ONLY APPLIES IF

FOAM/HEATER

ELEMENT IS NOT

INSTALLED AT THE

SAME STATION AS

TRIM COVER)

element moves and may

bunch heater elements

causing hot spots

wrinkling of element

causing hot spots

damage to harness,

causing improper heating

function

HIC

10

10

Components not properly damage to harness,

conveyed/ transported

causing improper heating

function

FBU PFMEA Heater Template / Rev 02 (15-December-2004)

a. Reuse of heater

element (adhesive is one

time use)

ODS, training, reject

procedure

b. not firmly pressed

down to engage adhesive

ODS, training

c. Adhesive comes in

contact with foreign

materials (dust, dirt, oils,

etc)

HIC a. ODS elements are not

followed.

70

visual, seat appearance

70

1 ODS, (Reject procedures)

visual, seat appearance

70

1 Operator training matrix,

visual, seat appearance

70

b. ODS is not clearly

defined for operator to

follow

1 Operator training matrix,

visual, seat appearance

70

c. Lack of alignment

between heater element

and foam pads

Operator training matrix,

1 DFA Review, Safety Sign

off

visual inspection for

notch alignment

70

d. Foreign object trapped

under heater mat

Operator training matrix,

scrap procedure

visual, seat appearance

70

e. Heater mat folds over

on itself (sticks to itself

once backings are

removed

Operator training matrix

visual, seat appearance

70

a. ODS elements are not

followed.

1 Operator training matrix,

visual, seat appearance

42

b. ODS is not clearly

defined for operator to

follow

1 Operator training matrix,

visual, seat appearance

42

a. Dangling harness

snagging equipment,

tools, fixtures

48

tucking harness into asm EOL tester - Check Amp

for transportation

draw

file name: 273959762.xls

Action Results

Recommended

S O

P.

N.

Page 9 of 14

R.

�Supplier Standards Manual

Seat Heat Peel and Stick Heater PFMEA

Chapter 7 Quality Section

March 2008 Revision 1.0

CORE SEAT HEATER P F M E A

FAILURE MODE

AND EFFECTS ANALYSIS

FMEA no#:

Item/Component: PEEL N' STICK HEATERS

OEM

Model Year/Vehicle:

Prepared by:

CoE Organization

Key Date:

CoreTeam:

FMEA Date (Orig.)

FMEA Date (Last rev.)

Requirements

Failure

Effect(s) of

Mode

Failure

Standard

Process

Process

Controls

Controls

Prevention

Detection

Mechanism(s)

of Failure

Standard

RPN

Potential

Cause(s)/

DETECT

Potential

OCCUR

Potential

CLASS

Process Function/

SEV

Item

Responsibility

Actions

& Target

Actions

Completion

Taken

Date

c. Heater element is used

as "handle" for carrying

bunching of heater

causing hot spots

Attach trim cover to foam

Heater off location/ misalignment

Heater moves during

assembly

damage to jumper wire/

heating element causing

short or hot spot

bunching of heater

causing hot spots

10

10

10

Only Applies if Using Back

Stuffer or Cushion Roller

to attach Trim Cover

Convey/ transport s/a

(ONLY APPLIES IF

FOAM/HEATER

ELEMENT/FOAM IS

NOT INSTALLED AT

THE SAME STATION

AS TRIM COVER IS

Components not properly damage to harness,

conveyed/ transported

causing improper heating

function

FBU PFMEA Heater Template / Rev 02 (15-December-2004)

ODS, training

EOL tester - Check Amp

draw

48

ODS, training

visual, seat appearance

80

b. Tape not firmly pressed

1

down to engage adhesive

ODS, training

visual, seat appearance

70

HIC a. Pulling on dangling

wire harness during

conveying

HIC a. Hogring nicks heater

wire (Applies only if

attaching trim cover with

Hog Rings)

ODS, training

EOL tester- ground

detection

80

b. Hog ring is not shot

through clearance hole in

heater mat

ODS, training

visual, seat appearance

160

HIC a. Pulling on wire

harness

ODS, training

visual, seat appearance

80

b. Excessive Finessing of

1

the trim cover

ODS, training

visual, seat appearance

80

c. Roller Stanchions

catch corners/edges of the 1

heater element

ODS, training

visual, seat appearance

80

d. Trim covers catches

corners/edges of the

heater element

ODS, training

visual, seat appearance

80

e. Poor adhesion between

pad and Element

ODS, training

visual, seat appearance

140

a. Dangling harness

snagging equipment,

tools, fixtures

48

b. Asm is folded or

bunched

ODS, Training

42

c. Heater element is used

as "handle" for carrying

ODS, training

48

tucking harness into asm EOL tester - Check Amp

for transportation

draw

file name: 273959762.xls

EOL tester - Check Amp

draw

Action Results

Recommended

Revise adhesive material

to meet current design

template pulloff

requirement

Engineering

S O

R.

P.

N.

10 1

70

Page 10 of 14

�Supplier Standards Manual

Seat Heat Peel and Stick Heater PFMEA

Chapter 7 Quality Section

March 2008 Revision 1.0

CORE SEAT HEATER P F M E A

FAILURE MODE

AND EFFECTS ANALYSIS

FMEA no#:

Item/Component: PEEL N' STICK HEATERS

OEM

Model Year/Vehicle:

Prepared by:

CoE Organization

Key Date:

CoreTeam:

FMEA Date (Orig.)

FMEA Date (Last rev.)

Requirements

Failure

Effect(s) of

Mode

Failure

Standard

Process

Process

Controls

Controls

Prevention

Detection

Mechanism(s)

of Failure

Standard

RPN

Potential

Cause(s)/

DETECT

Potential

OCCUR

Potential

CLASS

Process Function/

SEV

Item

Responsibility

Actions

& Target

Actions

Completion

Taken

Date

bunching of heater

causing hot spots

10

Route & secure wire

harness

Connect back element to

cushion element (ONLY

APPLIES IF SYSTEM

HEATS BOTH BACK

AND CUSHION)

HIC

10

a. Pulling on wire

harness during conveying

ODS, training

visual, seat appearance

80

b. Asm is folded or

bunched

ODS, training

visual, seat appearance

80

visual, seat appearance

42

84

84

Improper routing (places pinched / cut wire harness

harness between hard

causing short condition

points)

a. Exposure to hard

points

Operator training matrix,

DFA review

Not secured (which may

place harness in harms

way over time)

a. High insertion forces

on retaining clips

ODS sheets and Operator audible, tactile, or visual

Training.

indicator

b. Inadequate clearances

c. ODS Elements are not

followed

1 Operator training matrix,

42

d. ODS is not clearly

defined for operator to

follow

1 Operator training matrix,

42

a. ODS elements are not

followed. (wire routed

improperly)

1 Operator training matrix,

EOL tester - Check Amp

draw after full seat travel

24

b. ODS is not clearly

defined for operator to

follow

1 Operator training matrix,

EOL tester - Check Amp

draw after full seat travel

24

a. High insertion forces

ODS sheets and Operator audible, tactile, or visual

Training.

indicator

70

b. Inadequate clearances

to complete task

DfA Workshops,

Manufacturing Reviews

70

c. Lack of indication for

complete engagement

ODS sheets and Operator operator push-pull-push

Training.

connect method

40

d. ODS Elements are not

followed

1 Operator training matrix,

35

e. ODS is not clearly

defined for operator to

follow

1 Operator training matrix,

35

Not connected

pinched / cut wire harness

causing short condition

improper functioning

heater system

6

Not fully connected

FBU PFMEA Heater Template / Rev 02 (15-December-2004)

intermittent operation

DFA Workshops

file name: 273959762.xls

Action Results

Recommended

S O

P.

N.

Page 11 of 14

R.

�Supplier Standards Manual

Seat Heat Peel and Stick Heater PFMEA

Chapter 7 Quality Section

March 2008 Revision 1.0

CORE SEAT HEATER P F M E A

FAILURE MODE

AND EFFECTS ANALYSIS

FMEA no#:

Item/Component: PEEL N' STICK HEATERS

OEM

Model Year/Vehicle:

Prepared by:

CoE Organization

Key Date:

CoreTeam:

FMEA Date (Orig.)

FMEA Date (Last rev.)

Requirements

Failure

Effect(s) of

Mode

Failure

Standard

Process

Process

Controls

Controls

Prevention

Detection

Mechanism(s)

of Failure

Standard

RPN

Potential

Cause(s)/

DETECT

Potential

OCCUR

Potential

CLASS

Process Function/

SEV

Item

Responsibility

Actions

& Target

Actions

Completion

Taken

Date

11

Connect to seat wire

harness

Not connected

Not fully connected

Improperly connected to

mating connector

12

non-functioning heater

intermittent operation

non-functioning heater

Connect to seat wire

Not connected

non-functioning heater

harness to Heat Module or (APPLIES ONLY IF

switch

HEATER MODULE IS

ASSEMBLED AT THE

JIT)

FBU PFMEA Heater Template / Rev 02 (15-December-2004)

a. ODS elements are not

followed.

1 Operator training matrix,

EOL tester - Check Amp

draw after full seat travel

24

b. ODS is not clearly

defined for operator to

follow

1 Operator training matrix,

EOL tester - Check Amp

draw after full seat travel

24

a. High insertion forces

ODS sheets and Operator audible, tactile, or visual

Training.

indicator

70

b. Inadequate clearances

to make connection

DFA Workshops,

Manufacturing Reviews

70

c. Lack of indication for

complete engagement

ODS sheets and Operator operator push-pull-push

Training.

connect method

40

d. ODS Elements are not

followed

1 Operator training matrix,

35

e. ODS is not clearly

defined for operator to

follow

1 Operator training matrix,

35

a. similar connector on

seat harness (Lack of

poka-yoke of harness

connectors

48

b. ODS Elements are not

followed

1 Operator training matrix,

42

c. ODS is not clearly

defined for operator to

follow

1 Operator training matrix,

42

a. ODS elements are not

followed.

1 Operator training matrix,

EOL tester - Check Amp

draw after full seat travel

24

b. ODS is not clearly

defined for operator to

follow

1 Operator training matrix,

EOL tester - Check Amp

draw after full seat travel

24

DFA Workshops,

Manufacturing Reviews,

Design reviews

file name: 273959762.xls

EOL tester- amp draw

check

Action Results

Recommended

S O

P.

N.

Page 12 of 14

R.

�Supplier Standards Manual

Seat Heat Peel and Stick Heater PFMEA

Chapter 7 Quality Section

March 2008 Revision 1.0

CORE SEAT HEATER P F M E A

FAILURE MODE

AND EFFECTS ANALYSIS

FMEA no#:

Item/Component: PEEL N' STICK HEATERS

OEM

Model Year/Vehicle:

Prepared by:

CoE Organization

Key Date:

CoreTeam:

FMEA Date (Orig.)

FMEA Date (Last rev.)

Requirements

Failure

Effect(s) of

Mode

Failure

Standard

Process

Process

Controls

Controls

Prevention

Detection

Mechanism(s)

of Failure

Standard

RPN

Potential

Cause(s)/

DETECT

Potential

OCCUR

Potential

CLASS

Process Function/

SEV

Item

Responsibility

Actions

& Target

Actions

Completion

Taken

Date

Not fully connected

intermittent operation

(APPLIES ONLY IF

HEATER MODULE IS

ASSEMBLED AT THE

JIT)

Improperly connected to

mating connector

(APPLIES ONLY IF

HEATER MODULE IS

ASSEMBLED AT THE

JIT, Severity to be

confirmed by

Engineering)

Module is properly

connected but damaged

by process (APPLIES

ONLY IF HEATER IS

PART OF HEATER

SYSTEM, Severity to be

confirmed by

Engineering)

13

Function testing

not tested / tested

improperly

FBU PFMEA Heater Template / Rev 02 (15-December-2004)

non-functioning heater

and/or disables Heater

Module Functions (Over

Heats)

Non-Functioning heater

system and/or disables

Heater Module Functions

(Over Heats)

shipment of a nonfunctional heated seat

a. High insertion forces

ODS sheets and Operator audible, tactile, or visual

Training.

indicator

70

b. Inadequate clearances

to make connection

DFA Workshops,

Manufacturing Reviews

70

c. Lack of indication for

complete engagement

ODS sheets and Operator operator push-pull-push

Training.

connect method

40

d. ODS Elements are not

followed

1 Operator training matrix,

35

e. ODS is not clearly

defined for operator to

follow

1 Operator training matrix,

35

a. similar connector on

seat harness (Lack of

poka-yoke of harness

connectors

64

b. ODS Elements are not

followed

1 Operator training matrix,

56

c. ODS is not clearly

defined for operator to

follow

1 Operator training matrix,

56

a. Module is dropped

Reject Procedure, Repair

procedure

EOL tester- amp draw

check

64

b. Module comes in

contact with a Static

Discharge

Reject Procedure, Repair

procedure

EOL tester- amp draw

check

64

c. Module see a Voltage

Spike

Reject Procedure, Repair

procedure

EOL tester- amp draw

check

64

d. Module see a reverse

voltage polarity.

Reject Procedure, Repair

procedure

EOL tester- amp draw

check

64

a. Equipment failure

Operator training matrix

warning lights, current

draw (amperage)

24

DFA Workshops,

Manufacturing Reviews

file name: 273959762.xls

EOL tester- amp draw

check

Action Results

Recommended

S O

P.

N.

Page 13 of 14

R.

�Supplier Standards Manual

Seat Heat Peel and Stick Heater PFMEA

Chapter 7 Quality Section

March 2008 Revision 1.0

CORE SEAT HEATER P F M E A

FAILURE MODE

AND EFFECTS ANALYSIS

FMEA no#:

Item/Component: PEEL N' STICK HEATERS

OEM

Model Year/Vehicle:

Prepared by:

CoE Organization

Key Date:

CoreTeam:

FMEA Date (Orig.)

FMEA Date (Last rev.)

Requirements

Failure

Effect(s) of

Mode

Failure

Standard

Process

Process

Controls

Controls

Prevention

Detection

Mechanism(s)

of Failure

Standard

RPN

Potential

Cause(s)/

DETECT

Potential

OCCUR

Potential

CLASS

Process Function/

SEV

Item

Responsibility

Actions

& Target

Actions

Completion

Taken

Date

14

Transfer Seat to Ship Pallet Transfer

Equipment/Method

damages of heater

element/ harness

FBU PFMEA Heater Template / Rev 02 (15-December-2004)

b. Damage to connector

during the function test

ODS, training, Reject

Procedure, Repair

procedure, pogo pin

connectors

96

a. Improper handling of

seat

seat lift assist to transfer

seat from build line to

pallet

54

b. Lift assist tool is placed

in location where wire

1

harness / seat element is

routed

DFA Workshops,

Manufacturing Reviews

48

inoperable heater

6

file name: 273959762.xls

Action Results

Recommended

S O

P.

N.

Page 14 of 14

R.