0% found this document useful (0 votes)

444 views6 pagesFmea Example

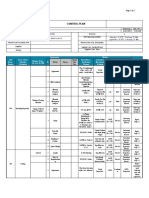

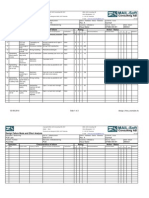

This Failure Mode and Effects Analysis (FMEA) document summarizes potential failures in the raw material receiving process for a automotive parts manufacturer. It identifies 10 potential failure modes including receiving the wrong grade of material, thickness variations, length variations, and material stored in open conditions. For each failure mode, it describes the potential effects on the product, next process, and customer. It also evaluates the severity, occurrence, detection rating and calculates the risk priority number to help prioritize issues. Current controls are listed to mitigate the risks.

Uploaded by

SandeepCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

444 views6 pagesFmea Example

This Failure Mode and Effects Analysis (FMEA) document summarizes potential failures in the raw material receiving process for a automotive parts manufacturer. It identifies 10 potential failure modes including receiving the wrong grade of material, thickness variations, length variations, and material stored in open conditions. For each failure mode, it describes the potential effects on the product, next process, and customer. It also evaluates the severity, occurrence, detection rating and calculates the risk priority number to help prioritize issues. Current controls are listed to mitigate the risks.

Uploaded by

SandeepCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

/ 6