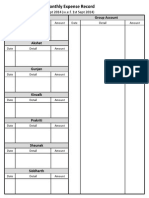

DEVELOPMENT CONTROL REGULATIONS

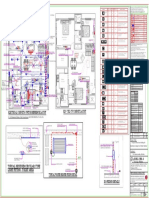

Southern Region Logistic Projects (Al Wakra Logistic Park, Birkat Al Aawamer, Aba Saleel)

LAND USE TYPE: Logistics and light Industrial Plots

PLOT COVERAGE

PLOT SIZE: Varies

WAREHOUSE BUILDING

* Up to 55% coverage * Maximum G + M

of the total Plot Area Height 20m

Basement allowable within the

approved floor coverage and

accounted in FAR unless utilised

for parking only.

FAR = 1.00

* Security guard function to be

accommodated in dedicated

guard house not exceeding 10m2

or within the main building

Minimum

Development

Obligation 25% of

plot area

Single or multiple

* Electrical Substations permitted

at sides, front or rear

* Maximum Substation height of

4.5m

* Parking canopy maximum height

Date: 30/08/2015

PLOT COVERAGE

OFFICE

LABOUR

ACCOMMODATION

Not Exceeding 10% Maximum of 4% of

of allowable Built plot area for the

Up Area

accommodation of

workers employed

within the plot

only

* Maximum height Maximum G +2

G + M, or G+1 or

mezzanine

level

within warehouse

(in accordance with

development

Guidelines)

Mezzanine shall not Mezzanine Level

exceed 80% of office not applicable

ground floor area

Compliant

SHOWROOMS

Rev. 1

LANDSCAPING

Maximum of 5% of * Minimum 3.5% of plot to

plot area

be covered with soft

landscaping

Maximum G+M

Mezzanine shall not Mezzanine

exceed

80%

of applicable

showroom

ground

floor area

Level

not

with

1

�Buildings

are

allowable subject to

MMUP approval

Mezzanine level shall

not exceed 4.0m in

height

Front

Sides

Rear

Additional

Requirements

BOUNDARY WALL

* Boundary wall

compulsory

compliant

with

design criteria. 2.5m

high rear and sides

and

subject

to

Manateq approval

3.5m

* Tensile structures preferred or

steel structures

Mezzanine shall not exceed 50%

of Warehouse ground floor area

MMUP

specification

guidelines

and

SETBACKS

WAREHOUSE BUILDING

WAREHOUSE

WAREHOUSE

PARKING

PLOT > 2000M2

BUILDING

BUILDING

2001M2 > PLOT >

5,001M2 > PLOT

5000M2

6 Meters

12 Meters

20 Meters

1.5 meters

3 meters

3 meters

6 meters

1.5 meters

3 meters

Not less than 3 6 meters

1.5 meters

meters

provided

combined front and

rear setback is not

less than 18m

All sites shall provide emergency access in accordance with Fire Safety Standards Minimum Requirements of the Qatar Ministry of

Interior Civil Defence Department and NFPA requirements.

FENCING

* Front and side fence compulsory

compliant with design criteria at

2.5m and 1.8m respectively in

height and subject to Manateq

approval

SITE DEVELOPMENT

SITE ACCESS

PARKING

1 or 2 access points 1 parking space per 50 m2 of Gross floor

permitted along plot

area (GFA) office and showroom and

frontage, Min. 2

120m2 for Warehouse area

meters from plot On plot truck and other operational

corners

required parking shall be incorporated

within the plot to ensure all requisite

operational needs are located within the

plot

MISCELLANEOUS

Refuse storage area shall be

screened from view in a

services Yard.

�AESTHETICS

FINISH MATERIALS

COLORS

SIGNAGE

PROHIBITED

All exterior finish Exterior of all buildings to be Free standing sign or sign on Building Temporary Buildings

materials compliant white, beige or other colours as compliant with design criteria and subject including but not

with design criteria

pre-approved by MMUP.

to Manateq Approval

limited to porta cabins

are prohibited.

DEVELOPMENT PLANNING REQUIREMENTS

1. Design of the project shall contribute to the cohesive and coherent with the Design criteria.

2. Approval of the preliminary Design required by Manateq and all other approvals by respective and prevailing Government Authority

Note: All plots comprise a minimum frontage of 20 metres or greater

�Design Criteria

1

The Tenants Works should be designed to comply with standards applicable in the State of

Qatar or such other international standards as will be notified by the Tenant to the

Landlord and will comprise the following minimum anticipated standards of construction

and design performance to be considered by the investors in developing the facilities:

1.1

General Planning

The following Design Performance Criteria for the facilities is considered as a minimum,

shall be designed to comply with latest editions of British Standards, EN Standards,

International Building Code (IBC) American Society for Testing and Materials (ASTM) and

National Fire Protection Association (NFPA) and must also be compliant to all latest local

codes, rules and regulations of the state and including latest edition of QCS.

Further to this, the facilities shall comprise the following minimum anticipated standard of

construction and design performance to be considered by the investors in developing the

facilities;

General Planning

The planning for the Project shall provide due consideration to all the required services

that are typically expected as best practice in an international/ regional project of this

nature and include the following facilities:

1. Appropriate Landscape with automated Irrigation

2. Appropriate perimeter fencing in compliance with Landlord guidelines

3. All essential Public amenities as required by MMUP requirements.

4. Security and Life Safety requirements as per local codes, especially MOI, Civil

Defense, and MMUP regulations

5. All Dry and Wet Utilities including appropriate cooling facilities as per Kahramaa,

QICT, all other relevant Standards and regulations as a minimum.

6. Air Conditioning System for all facilities (offices, Showrooms, labour

accommodation, amenities).

7. Compliance with GSAS in accordance with MOE requirements

8. Carparking for all visitors workers and trucks shall be accommodated on and within

the plot

9. Labour accommodation shall be compliant with MMUP codes and regulations

Architectural

1. Minimum design life of all the building structures shall be 50 years and for all other

facilities including infrastructure shall be 50 years

2. Clear height within the warehouses of 13m as a minimum unless otherwise

approved by MMUP

3. Grid spacing to be maximized with minimum grid not less than 9m spacing

4. Provision for mezzanine offices as required in compliance with MMUP guidelines

5. Provision of showroom not exceeding 5% of plot area as and if applicable

�6. Provision of labour accommodation solely for accommodating workers on the plot

in accordance with MMUP guidelines as and if required at a maximum of 4% of plot

area

7. Plot service SW & SS connection to be to PWA design standard.

8. Potable Water supply connection to be to KAHRAMAA design standard.

Building Material

Building

Material

Ventilated & AC Metal clad with color bond type material or

Warehouses

similar with min 50mm insulation

Alternate options to be provided

Chilled

& Spray

foam

Insulation

Refrigerated

(polystyrene/polyurethane) wall, ceiling and

warehouses

floor

finish

comprising

appropriate

flammability index, smoke developed index

and with U value as required by standards

and further dealt below.

Roads

Bitumen or concrete

Structure

Portal Steel Frame/ PREENGINEERED

STEEL

STRUCTURES

Portal Steel Frame/ PREENGINEERED

STEEL

STRUCTURES

Should be as per ASHGHAL

standards

and

specifications and so to

ensure future handover if

required

Open Storage Bitumen or concrete ground finish

yards

Perimeter Wall

2.5m high side and rear and 1.8m high front In

accordance

with

constructed from block work with steel Landlord specification and

grate comprising a render & painted finish guidelines

(refer details)

Circulation

Bitumen or concrete ground finish

Areas and roads

within sub plots

Should be as per ASHGHAL

standards

and

specifications and so to

ensure future handover if

required

PRE-ENGINEERED STEEL STRUCTURES (as a minimum)

Standard Accessories

No. Description

1 Double Steel Sliding Door Minimum opening size: To be specified

2

Wall Framed opening For windows and Doors

Sky light panels

4 Loading Docks for each warehouse facility compliant with relevant international

standards. The loading dock shall be sloped down so that the truck level matches with

the loading dock level which shall be the edge of the ware house.

5

�1. 0 Open Storage Yards (51 to 65 )

a) Panel Specifications

ROOF PANELS

Profile

Thickness (mm)

Material

Finish

Color

Single Skin Panels

As per manufacturer Profile

0.7 0.8(minimum)

Aluminum

Polyester Painted

Standard per client requirement

b) Paint Specifications

Primary Structural Members

The primary steel members shall be cleaned and sand blasted with SA 2.5 Swedish Standard

painted with multi coat 250 microns DFT epoxy paint system.

Secondary Structural Members

The secondary steel members such as purlins, girts, eave struts, base angles and gable angles shall

be cold formed pre-galvanized materials. The anchor bolts are galvanized.

2. 0 Enclosed Dry (ventilated) Warehouses (24 to 50 )

a) Panel Specifications

ROOF and WALL PANELS

Exterior

Skin

Sandwich Panels

P.U. Core

Interior

Skin

Profile

Minimum

Thickness

Material

Finish

Color

Density

Thickness

Profile

Thickness

Material

Finish

Color

As per manufacturer Profile

0.7 mm

Aluminum

Polyester Painted

Standard

35kg/m3(minimum)

50 mm minimum (excluding rib depth)

Flat

0.5 mm(minimum)

Aluzinc

Polyester Painted

Standard

6

�b) Paint Specifications

Primary Structural Members

The primary steel members shall be cleaned and sand blasted with SA 2.0 Swedish Standard

painted with one coat 75 microns DFT epoxy primer.

Secondary Structural Members

The secondary steel members such as purlins, girts, eave struts, base angles and gable angles shall

be cold formed pre-galvanized materials. The anchor bolts are galvanized.

3. 0 Enclosed Air Conditioned Warehouses (23 to 25)

a) Panel Specifications

ROOF and WALL PANELS

Exterior

Skin

Sandwich Panels

P.U. Core

Interior

Skin

Profile

Minimum

Thickness

Material

Finish

Color

Density

Minimum

Thickness

Profile

Thickness

Material

Finish

Color

As per manufacturer Profile

0.7 mm

Aluminum

Polyester Painted

Standard

35kg/m3

75 mm minimum (excluding rib depth)

Flat

0.5 mm

Aluzinc

Polyester Painted

Standard

b) Paint Specifications

Primary Structural Members

The primary steel members shall be cleaned and sand blasted with SA 2.0 Swedish Standard

painted with one coat 75 microns DFT epoxy primer.

Secondary Structural Members

The secondary steel members such as purlins, girts, eave struts, base angles and gable angles shall

be cold formed pre-galvanized materials. The anchor bolts are galvanized.

4. 0 Enclosed Chilled Warehouses (6 to 22)

7

�a) Panel Specifications

ROOF and WALL PANELS

Exterior

Skin

Sandwich Panels

P.U. Core

Interior

Skin

Profile

Minimum

Thickness

Material

Finish

Color

Density

Minimum

Thickness

Profile

Thickness

Material

Finish

Color

As per manufacturer Profile

0.7 mm

Aluminum

Polyester Painted

Standard

35kg/m3

100 mm minimum (excluding rib depth)

Flat

0.5 mm

Aluzinc

Polyester Painted

Standard

Chilled room shall be constructed separately from the main warehouse and shall be tested for

air/water tightness.

b) Paint Specifications

Primary Structural Members

The primary steel members shall be cleaned and sand blasted with SA 2.0 Swedish Standard

painted with one coat 75 microns DFT epoxy primer.

Secondary Structural Members

The secondary steel members such as purlins, girts, eave struts, base angles and gable angles shall

be cold formed pre-galvanized materials. The anchor bolts are galvanized.

5. 0 Enclosed Frozen Warehouses (0 to 5)

a) Panel Specifications

ROOF and WALL PANELS

Exterior

Skin

P.U. Core

Sandwich Panels

Profile

Thickness

Material

Finish

Color

Density

Minimum

Thickness

As per manufacturer Profile

0.7 mm

Aluminum

Polyester Painted

Standard

35kg/m3

100 mm minimum (excluding rib depth)

8

�Interior

Skin

Profile

Thickness

Material

Finish

Color

Flat

0.5 mm

Aluzinc

Polyester Painted

Standard

Freezer room shall be constructed separately from the main warehouse and shall be tested for

air/water tightness.

b) Paint Specifications

Primary Structural Members

The primary steel members shall be cleaned and sand blasted with SA 2.0 Swedish Standard

painted with one coat 75 microns DFT epoxy primer.

Secondary Structural Members

The secondary steel members such as purlins, girts, eave struts, base angles and gable angles shall

be cold formed pre-galvanized materials. The anchor bolts are galvanized.

Structure

1. Design load for the respective buildings and roads as per QCS

2. Roads - Shall not be less than 16m wide corridor with minimum 8m road width and

comprising a load bearing capacity AS PER Industrial standards and as mandated by

ASHGHAL

General (Codes, Loads and Material Specification)

Loading for warehouse super structures

CODE

: MBMA-2006, AISC 2005, AISI 2002,

AWS 2006

Design Live Load

: 0.75kN / m2 (On Roof)

: 0.75kN / m2 (On Frame)

Dead Load

: As per design STANDARDS (On Roof& Frame)

Collateral Load

Air conditioned

Cold Store

No Air Conditioned

: 0.50 kN / m2

: 1.00 kN / m2

: 0.10 kN / m2

Wind Speed

: 162 KPH (3-second gust), Exposure B,

Importance factor = 1.0, Refer to MBMA-2002,

Chapter 1, Section 1.4, Page 16

Seismic Loads

: Per IBC latest Edition

9

�Load Combination

: As per MBMA-2002

Rainfall Intensity

: 68 mm/Hr

Temperature load

: None

Deflection Limits

: In accordance with 2002 MSMN

The temperature design shall consider, but not be limited to, seasonal climatic variations, day/night

variations, internal/external variations, and exposed/shaded area variations.

Temperature Range (oC)

Cases

For

Steel

temperature

Section

Average

Restraint/Locked-in

Operational temperature (for controlled conditions)

Operational temperature (for uncontrolled conditions)

As per QCS

To be determined by the

consultant

Temperature load shall be combined with the appropriate load cases considering the followings:

1. For construction stage: Combine with applicable DL & SDL, construction LL and WL (with 5 yr

return period)

2. For operation stage: Combine with all load cases.

Imperfection loads shall be as per the codal requirement.

QCS applies for all structural aspects of the project. All structures will acceptable International

Design standards to Client.

Thermal Performance

Roof material is available in almost any construction depth to suit all building needs ranging from

65mm to 500mm with corresponding thermal performance. The table below gives average figures

for systems based on specific criteria.

Construction Depth

U Value

100mm

0.4 W/m2K

150mm

0.37 W/m2K

200mm

Appropriately to be designed based on local

requirements and conditions

250mm

Appropriately to be designed based on local

requirements and conditions

10

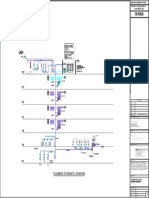

�MEP

MEP infrastructure and materials utilized on the Plot shall be fully compliant with and in

accordance with relevant Authorities design guidelines and specifications hence enable handover

to the Authorities for maintenance upon completion.

Generally the following additional provisions shall be incorporated;

1. Air Conditioning & Ventilation(as per regional , GCC and ASHRAE standards)

All air conditioning and refrigeration equipment shall operate using environmentally

friendly refrigerant. Ammonia as a refrigerant alternate can be utilized of refrigeration

system serving large cold and freezer rooms.

2. Electrical design shall be in accordance with Kahrama and QCS Specifications, British

Standards, SSL/CIBSE Lighting Guides and generally shall include the following;

a. 11kv network with 415V non-essential distribution systems

Equipment

Type

Form of

Construction

MV (11kV)

Panel

IP Rating

(main

enclosure)

Fault Level

Rating

Minimum

Thickness

As per Kahrama specification

LV (415V)MDB Panel

Form 4b,

Type 6

SMBD

Panel/MCCB

Panel Board

Form 3b,

Type 2

Final Dist.

Board

Form 2b

As per QCS specification

MCC

Form 3b

As per QCS specification

Outdoor

Feeder Pillar

Form 2b

As per Kahrama specification

IP 32

IP 56

As per QCS specification

10kA for 3 secs

if fed from

SMDB or

25kA for secs if

fed from main

LV panel

2.0 mm

Comment

Min. 25% spare

capacity on design

load.

Min. 25% spare

capacity on design

load.

Min. 25% spare

capacity on design

load.

Min. 25% spare

capacity on design

load.

Min. 25% spare

capacity on design

load.

Min. 10% spare

capacity on design

load.

b. 415V essential distribution systems (standby and emergency power)

As a minimum, standby/emergency generator power shall be provided for the

following:

Minimum code requirements for life safety

Additional loads required by projects operational requirements

Particular Client/End User/Operator requirements

11

�c. 415V essential distribution systems (uninterrupted power)

As a minimum the following shall be provided with UPS to feed the following:

MDF and IDF rooms

Critical IT and other installations as identified by Client/End User

Building Control Systems

Security, Access control system.

Particular Client/End User/Operator requirements

CCTV system including associated network switches as per Ministry of

Interior Security Guidelines

d.

e.

f.

g.

h.

i.

Maximum Demand Diversification as per Kahrama requirements.

Power factor correction of 95%

Energy efficient internal and external lighting and control systems.

Emergency Lighting and Exit Signage as per QCD requirements.

Lightning Protection as per BS EN 62305.

Cables and wires to be low smoke and fume type (LSF/LSOH), or fire rated where

required by QCD.

j. Conduits and cable trunking to be galvanized steel. PVC conduits only to be used

where embedded.

k. Street lighting minimum illumination of 5 lux as per ASHGAL and QCS requirements

and Qatar Highway Design Manual.

3. Fire and life safety shall be designed in accordance with NFPA and compliance with the civil

defense authority of the State of Qatar

4. Hydraulics

a. Provision of storm water drainage to the site

b. Potable water reticulation

c. Irrigation

Landscaping

All roads shall be landscaped and provided with appropriate Hard and Soft scapes, should aim to

reduce heat gain, minimize water consumption, provide suitable imageability for the project area,

provide adequate shade for pedestrians, include Native species and landscape strategies including

xeriscapesto mitigate sand storms, heats and prevailing winds.

Appropriate urban hardscape should be provided in the public realm where ever possible.

All of the above design specifications are provided as a minimum and are for purposes for guiding

the developer to achieve acceptable standards in the project as per best practice in the GCC region

on similar reputed projects.

B) DESIGN CODES:

12

�c) MATERIAL SPECIFICATIONS

No

Components

Built up

(Plates)

Angles

Hot

Rolled

Beams

Cold

Form

Galvanize

d

Roof panel

Specifications

ASTM A-572 Grade 50

Yst = 34.50 kN/cm (50 ksi)

ASTM A-36 (or equivalent)

ASTM A-572, Yst = 34.50 kN/cm (50 ksi)

EN-10025, S355 JR. Yst = 35.50 kN/cm OR

S275 Yst = 27.50 kN/cm

ASTM A-653 GR 50 (G90) or equipment

Zinc Aluminium Base

ASTM A792 Gr. 40/50

Minimum yield

strength

Fy = 34.5 kN/cm2

Fy = 23.5 kN/cm2

Fy = 34.5 kN/cm2

Fy=34.0kN/cm2

Fy = 30.0 kN/cm2

ASTM A36

5

XBracing

Rods

Anchor bolts

High strength Bolts

(or equivalent)

ASTM A36

(or equivalent)

ASTM A325 Type 1

(or equivalent)

Machine Bolts

ASTM A 307

(or equivalent)

Fy = 23.5 kN/cm2

Fu = 25.0 kN/cm2

Ft = 30.3 kN/cm2

Fu = 72 to 83 kN/cm2

Ft = 13.8 kN/cm2

Fu = 41.0 kN/cm2

13

�(A) STANDARD DEFLECTION LIMITS

DESCRIPTION

Frames: Columns and Rafter

Vertical Deflection

DEFLECTION LIMIT

Span / 180 for RF

Span / 90 for Cantilever

Height / 45

(for buildings without crane)

Drift Horizontal Sway

Height / 60

(for buildings with crane)

REFERENCES

As per UBC, 94 Vol.2.

Section 2349,862

As per MBMA, Section C 6,8,

Page 117 for crane building

frames

the

maximum

calculated bare frame drift

under

MBMA

loading

recommendations

commonly range from H/60

to H/100.

Roofs:

Span / 180

Eave Strut, Purlins & Sheeting.

Wall & Structural Framing :

Rails, Wall Sheeting

Span / 120

(for walls with flexible

finishes)

As per UBC, 94 Vol. 2,

Section 1643, Page 2-1203.

As per UBC 94 Vol. 2,

Section 1643.2 Page 2-1203.

Span / 240

(for wall with brittle

finishes)

Flat Roof / Mezzanine

Span / 360

(With Live Load Only)

Span / 240

(With Live Load +

Dead Load)

As per UBC, 94 Vol.2, Table

16-D, Page. 2-32.

14

�Aesthetic standards

COMPONENT

DESIGN STANDARD

In order to create an attractive,

functional

development,

aesthetic

standards have been established. These

standards will promote a consistent,

orderly appearance that will help

preserve property values and provide

assurance to tenants and investors

about the quality of development that

will occur around them.

Location

Offices

Offices shall be located at the front of the building facing the road. Where Mezzanine office are considered a dedicated and

separate entry shall be provided that is distinguished from warehouse structure and is commensurate with commercial office

aesthetics.

Any outdoor storage area (including garaged in storage areas and liquid waste storage tanks) shall not be located within

the Front setback. Any outdoor storage area must be screened from the road.

The

aesthetic

standards

address

components of a plot plan that will

affect the visual quality of the plot as

viewed from off-plot locations. In

addition, these components affect the

experience of on-plot workforce in their

everyday lives.

Figures 6-62 and 6-63 below illustrate

graphic guidelines for plot landscaping,

plot wall character and main signage for

the logistics, support, & light industrial

land Use Zone. For an attractive and

consistent appearance throughout the

logistics and industrial Zones, each plot

should have a distinct front side and

back side. In general, the front side

should contain the main office and

parking within a landscaped setting. The

sides and rear of the plot can be more

utilitarian and contain loading areas,

utility structures and other ancillary uses

that are generally screened from view of

public roads.

of

Outdoor

Storage Areas

Mechanical

Equipment &

Utility

structures

In general, mechanical equipment and utility structures shall be screened from offsite views:

At grade water tank and mechanical equipment shall be located to the side and rear of the building.

Roof-top water tank and mechanical equipment shall be screened from view and not be visible from the road.

landscaping

A landscaping strip with a minimum average width of 1.5 m shall be provided along all road frontages except across

vehicle crossings and where a guardhouse is located in the road boundary setback. the landscaping strip must contain:

Minimum 1 tree and one additional tree for every 10m of roads frontage.

Where three or more trees are required these trees shall be planted no more than 15m

apart or closer than 5m apart.

Trees shall be of a species capable of reaching a minimum height at maturity of 8m and

shall not be less than 1.5 m high at the time of planting.

Walls and fences are permitted under the following conditions:

On the read and side of the property, solid walls are allowed up to a height of 2.5m however, on the front of the property

and any external boundary solid walls only up to a height of 1.4m above which a tubular metal fence with minimum 80%

opacity may be erected. The total height of this barrier shall not be more than 2.5m.

The following types of fences shall not be permitted on any side of the plot:

Barbed wire fencing.

Corrugated metal sheet fencing.

Foundations of all walls and fences shall be located within the plot boundary

Signage and branding is permitted at designated locations within the plot boundary as follows:

Embedded within the boundary wall near the entrances to the plot.

On the vertical surface of the main building.

On a standalone independent pillar located within the plot (not exceeding the maximum height of the building).

Dimensions of the signage shall be restricted within a rectangular frame of 15m x 3m

Attractive building faade design is required. Architects are encouraged to create simple, timeless design solutions that

contribute to a high-quality character:

Buildings shall display variety in forms, material and colour to reflect a style consistent with modern logistics facilities.

The office or non-logistics components of the project shall be expressed differently from that of the warehouses.

Ancillary buildings and service buildings shall be architecturally treated with colours and materials appropriate to fit within

the architectural style of the main warehouse facilities

Walls

Fencing

Signage

Building

Faade

treatment

&

15

�Southern Region Logistic Projects

Figure 6-62: Typical Plot Boundary Wall (Front) with Signage Plot Identification Signage

Plot Identification Signage Elevation View

Plot Identification Signage 3D View

Figure 6-63: Typical Plot Boundary Wall (Side & Rear)

Side & Rear Fence Elevation View

Side & Rear Fence Street View

16