767 Electric Power System Modeling in

SysML

Authors:

John Finn

Mohammad Mostafizur Rahman Mozumdar

Alberto Sangiovanni Vincentelli

University of California, Berkeley

Version & Date:

Ver.02 April 19th, 2011

�Reviews:

Ver.01 02/09/2011: Preliminary version

Ver.02 04/19/2011: First Draft of Complete Power System

�Abstract

This document provides a preliminary description for SysML modeling of the 767

electrical power system, a part of the design methodology to the MuSyC/DSCS

avionics challenge problem. It starts with a short overview of the aircrafts electric

power system and then highlights the components that have been modeled. Rational

Rhapsody is used as a SysML modeling interface.

Description of Power System

The Electrical Power System (EPS) is an important subsystem of a typical avionics

vehicle management system. The scope of the EPS is to provide electrical power to

the different aircraft subsystems. Typically it consists of power generators, switches,

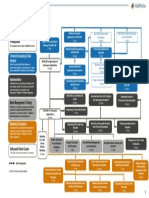

contactors and electrical loads. Figure 1 shows a simplified schema of the Boeing

767 Electrical Power System.

Figure 1 Simplified Boeing 767 Electrical Power System

There are two generators in the aircraft that serve as a primary power sources

(shown as L-Gen and R-Gen in Figure 1). Each of them provides power to their

respective AC Bus through a Generator Control Breaker (GCB), which is controlled

by a local Generator Control Unit (GCU). Next, each AC Bus powers the local DC Bus

through a Transformer Rectifying Unit (TRU). The Bus Power Control Unit (BPCU)

controls the Bus Tie Breakers (BTB), which in the event of main generator failure,

the BTB allows for the other generator, Auxiliary Power Unit (APU) or the External

Power (EXT) to compensate for the lost generator. Similarly, the DC Tie allows one

DC Bus to compensate the other in the event of a TRU failure. Lastly, the Left DC Bus

or the onboard batteries can power the Battery Bus. This primitive functionality was

incorporated into SysML as described in the next section.

�Modeling Electrical Power System in SysML

The EPS can be viewed as an interaction between three entities, the pilot, control

system and power system. The pilot has the ability to start/stop the right or left

engine. The control system controls the power system based upon its current status

and commands from the pilot. Finally, the power system generates power for the

various aircraft loads from passenger lighting to anti-ice devices for the wings. This

functionality is illustrated in the SysML use case diagram of Figure 2.

Figure 2 - Use Case Diagram of EPS

System Architecture

Figure 3 illustrates the top-level view of the EPS using a block diagram, which

consists of the pilot, control system, left/right side of the power system, Bus Tie

Breaker, DC Tie Breaker, External and APU Power Units, AC/DC Standby Buses,

Battery Bus, and the Battery. All these components contain ports by which they are

connected with each other. Using ports, components can communicate with each

other by means of events, which can carry specific data values.

As shown in the figure 3, the pilot sends the start/stop commands to the control

system. The engine control system consists of two GCUs (one for each engine) and

one BPCU (shown in figure 4). The GCU sends the start/stop command to each of the

engines and receives (measures) the current generator voltage level. Additionally,

the BPCU controls the BTB. In the current implementation, each side of the power

system contains blocks for engine, AC Bus and DC Bus (shown in figure 5).

�bdd [Pac k age] Arc h itec ture [Arc hitec ture ]

1

itsLeftSide_PowerSystem:LeftSide_PowerSystem

ACstandby

ACstandby

itsDC_BUS_BAT_COMPONENTS:DC_BUS_BAT_Components

Attributes

Attributes

LeftEngC omm

Operations

Operations

DCstandby

LeftSta rtSto p(c ommand:int=0 )

DCstandby

c ur rentVoltLev elLeft( c urr entVoltLev ...

LeftTR U_Status ( TR Us tatus :int= 1)

D C Tie

LeftAC bus Statu s (Bus Status :int)

OtherPow er Sourc e s Srv Left()

LeftSta rtSto p, c ur rentVoltLev elLeft

noPow er Sourc es ForLe ft()

AC TieLeft

1 itsControlPanelForPilot:ControlPanelForPilot

Attributes

EngineC omm_L

Operations

EngineC omm_R

D C Tie Left

1

TieLeft

1

itsControlSytem:ControlSytem

LeftEngC omm

itsDCTieBreaker:DCTieBreaker

Attributes

itsBTBs:BTBs

Attributes

1 itsExtPower_APUgen:ExtPower_APUgen

BPC U _L_BTB_ BUS

BPC U _L_BTB_ BUS

BPC U _R _BTB_BU S

BPC U _R _BTB_BU S

Operations

APU _Ex tPow er

Attributes

Operations

EngineC omm_L

LeftStar tStop (c ommand:i...

c ur rentVoltL ev elLeft( c urr ...

Operations

LeftDC bus Status ...

APU _Ex tPow er

BPC U _APU _EXPW R _BU S

Operations

Pow er FromR ig ht...

R ightD C bus Statu...

EngineC omm_R

TieR ig ht

R eqPow er From...

D C Tie Right

R ightEngC omm

BPC U _APU _EXPW R _BU S

R ightStar tStop, c urr entVoltL ev elRight

AC TieR igh t

1 itsRightSide_PowerSystem:RightSide_PowerSystem

Attributes

R ightEngC omm

Operations

D C Tie

R ightStar tStop( c ommand:int=0)

c ur rentVoltLev elRight(c urre ntVoltLev el:i...

OtherPow er Sourc e s Srv R ight()

noPow er Sourc es ForR ight()

Figure 3 - System Architecture

Control System

As mentioned earlier, the control system in Figure 4 has three components, a GCU

for each engine and a BPCU for the BTB. Each GCU is connected to its corresponding

engine through a flow port by which it sends and receives data and events. The GCU

can start/stop its corresponding engine based on commands from the pilot. In

addition, the GCU monitors the generators output voltage, and if this voltage is

outside a specified range, the GCU will shut down the engine. If an engine is shut

down by the GCU, the GCU signals the BPCU to configure the BTBs to compensate for

the lost engine. The configuration of the BTBs depends on the status of the available

power sources, which are EXT, APU or the other generator (in that priority order).

�ibd [bloc k] Cont rolSy tem [C ontrolSy st emInt ernal]

LeftGCU

Attributes

Lef t EngComm

Lef t EngineComm

Lef t EngComm

Operations

currentVoltLev elLef t(curr. ..

StartLef t Engine()

StopLef tEngine()

GCUsync

GCUSyncLeft

1

BPC U

Attributes

BPC U_L_BTB_BUS

APUs tat e:int

EXT_PWRst ate: int

EngineComm_L

BPC U_L_BTB_BUS

BPC U_R_BTB_BUS

BPC U_R_BTB_BUS

lef tEngineSt atus :int

rightEngineStatus: int

EXT_PWRst atus (st ate: int)

BPC U_APU_EXPWR _BU S

BPC U_APU_EXPWR _BU S

ext ernalPowerON()

EngineComm_R

APU_ON()

ext ernalPowerOFF()

APU_OFF()

clos eLef tBTB()

GCUSy ncRight

GCUsync

1

RightGCU

Attributes

RightEngComm

Operations

RightEngComm

currentVoltLev elRight(c urrentVolt Lev el:int )

RightEngineC omm

StartRight Engine()

StopR ightEngine()

Figure 4 - Internal Block Diagram of Control System

Left/Right Power System

Each side of the power system contains three blocks including the engine, AC Bus

and the DC Bus as shown in Figure 5, which illustrates the left side. These blocks

communicate through ports, which send and receive events. The engine acts as the

generator, which when active, generates an output voltage to power the AC bus,

which in turn powers the DC Bus through the TRU. The GCUs control the engines

(via the LeftEngComm port) based on the pilots commands and whether or not a

satisfactory voltage is being supplied. Additionally, both the AC and DC Buses have

ports to their respective Tie Buses in the event of a system failure.

�ACst andby

DCst andby

ibd [block] Lef tSide_PowerSystem [ Lef tSide_PowerSystemI nternal]

DCst andby

1

LeftDCBus

At tributes

DCPowerSupply

LeftTRU:int

ACst andby

1

LeftACBus

At tributes

O per ations

DCTie

PowerFromRight(Status:int )

BusStat us: int

LeftTRU_Status(TRUst atus:int=1)

LeftEngComm

ACPowerSupply

LeftACbusStat us(BusSt atus:int)

O per ations

St ableVoltage()

DCPowerSupply

LeftDCbusStat us(BusSt atus:int)

ReqPowerFromRight ()

VoltageDown()

LeftACbusStat us(BusSt atus:int)

1

LeftEngine

DCTie

OtherPowerSourcesSrvLef t()

noPowerSourcesForLeft ()

A ttributes

currentVolt Level:int

ACPowerSupply

LeftEngComm

ACTieLeft

O per ations

LeftStartSt op(command...

StableVoltage()

ACTieLeft

Figure 5 - Internal Block Diagram of Left Power System

Generator Control Unit- GCU

The state flow shown in the Figure 6 (left side) illustrates the operation of each GCU.

Initially, the GCU is in the idle state waiting for a start command from the pilot

(StartLeftEngine). Once the start command is issued, the GCU will transition to the

StartEngine(Left/Right) state. On entry to this state, the GCU sends the start

command to the engine. For example to send the start command from the left GCU, it

uses following action language of SysML,

OUT_PORT(LeftEngComm)->GEN(LeftStartStop(1))

Here, LeftEngComm is the flow port between the left GCU and the left side of the

power system (see Figure 3), and LeftStartStop is the event with argument value of

1 (1= start, 0=Stop). Once in the StartEngineLeft state, the GCU will transition to the

LeftEngineStarted state if the output voltage from the engine is acceptable. If not, the

statechart will transition to the StopEngine state. While in the LeftEngineStarted

state and the voltage suddenly become unacceptable or a stop command is received,

the statechart will transition to the StopEngine state. From here, the engine can

transition back to the StartEngineLeft state with the LeftStartStop event from the

pilot.

�Idle

StartLef tEngine

StartEngineLef t

Reactions

currentVoltLev elLef t[params->current VoltLev el==115]

currentVoltLev elLef t[

params->currentVolt Lev el<=110 | |

params->currentVolt Lev el>=120]

Lef t EngineStarted

StartLef tEngine

currentVoltLev elLef t[params->current VoltLev el==115]

StopLef tEngine

currentVoltLev elLef t[params->current VoltLev el<=110 ||

params->current VoltLev el>=120]

StopEngine

Reactions

Figure 6 - Statechart Implementation of Left GCU

Engine

Initially, each engine waits for the start command in the idle state. Once the GCU

sends the start command (for example, LeftStartStop(1) from the left GCU), the

engine will make transition to the EngineStarted state. Once started, the engine will

send its output voltage to the GCU every 1000ms via the LeftEngComm port. On

entry to the EngineStarted state, the engine sends an event to the AC Bus indicating

its operating voltage level, which based on its status; this event is either

StableVoltage or VoltageDown via the ACPowerSupply port. Lastly, if the GCU sends a

stop command (for example, LeftStartStop(0) from the left GCU), the engine will

transition to the idle state and send VoltageDown to the AC Bus.

�StatechartOfLeftEngine

Idle

LeftStartStop[params->command==0]/

OUT_PORT(ACPowerSupply)->GEN(VoltageDown);

currentVoltLev...

LeftStartStop

[params->command==1]

EngineStarted

currentVoltLevel=115...

tm(1000)/

OUT_PORT(LeftEngComm)->

GEN(currentVoltLevelLeft(currentVoltLevel))

Figure 7 - StateChart Implementation of Left Engine

AC Bus

The state flow in Figure 8 illustrates the Left AC Bus. In this state flow, the Left AC

Bus is initially in the NotInService state, which implies the AC Bus is not powered. On

entry to this state, the AC Bus sends an event to both the DC Bus and AC Standby

Bus, which indicates the AC Bus is not in service, and therefore, the DC Bus cannot

be in service either, but the AC Standby Bus can be in service from the Battery Bus.

Once the left generator produces a stable voltage, the AC Bus will transition to the

InService_PowerFromLeftGenerator state. If the engine fails, then the VoltageDown

event generated by the GCU will transition the AC Bus back to the NotInService state.

When the BPCU closes the BTBs, the OtherPowerSourcesSrvLeft event will transition

the AC Bus to the InService_PowerFromOtherSources state, which implies either the

EXT Power, APU or the Right AC Bus is supplying power to the Left AC Bus. When

the NotInService state is exited, the AC Bus sends an event to both the DC Bus and AC

Standby Bus, which indicates the AC Bus is in service, and therefore, the DC Bus and

AC Standby Bus can be in service as well.

�The same state flow was implemented for the Right AC Bus, except there is no

Standby Buses on the Right Side, and therefore, there is no need to report its status

to the Standby Bus.

StatechartOfLef tACBus

NotInService

StableVoltage

OtherPow erSourcesSrvLef t

VoltageDow n

noPow erSourcesForLeft

InService_Pow erFromLeftGenerator

InService_Pow erFromOtherSources

StableVoltage

Figure 8 - StateChart Implementation of AC Bus

DC Bus

The state flow in Figure 9 illustrates the Left DC Bus. The functionalities of the DC

Bus are implemented using two parallel state machines. The first state machine (left

side) represents the actual DC Bus, and the second one updates the TRU status.

Initially, the Left DC Bus is in the LeftDC_NotInService state. On entry to this state,

the Left DC Bus informs the DC Standby Bus and DC Tie Breaker that its status is

unpowered via the LeftDCbusStatus(0) event. The LeftACbusStatus(1) event

transitions the state flow to the CheckTRU state, which checks the status of the Left

TRU. If the Left TRU is functioning properly (i.e. LeftTRU = 1), then the Left DC Bus is

powered from the Left TRU, which is signified by the InServiceFromTRU state. In the

event of TRU failure (i.e. LeftTRU = 0), the Left DC Bus transitions back to the

LeftDC_NotInService state, and sends the ReqPowerFromRight event to the DC Tie

Breaker. The same event occurs if the TRU fails while in the InServiceFromTRU state.

When the DC Tie Breaker receives the request, it can close the DC Tie Breaker,

�which will allow the Right DC Bus to power the Left DC Bus. In this case, the DC Tie

Breaker will send the PowerFromRight(1) event, which signifies the DC Tie Breaker

is closed and the Left DC Bus will transition to the InServiceFromRight state. If the

Right DC Bus goes down, the PowerFromRight(0) event will transition back to the

LeftDC_NotInService state. On entry to either the InServiceFromTRU or

InServiceFromRight, the DC Bus informs the DC Standby Bus and DC Tie Breaker that

its status is powered via the LeftDCbusStatus(1) event.

On the right side of state flow, the Left TRUs status is determined. Initially, the Left

TRU is functioning properly, which is designated by the LeftTRU_ON state. This state

sets the LeftTRU variable mentioned above to one. The LeftTRU_Status(0) events

transitions the Left TRU to the failed state, LeftTRU_OFF state, which sets LeftTRU to

zero.

The same state flow was implemented for the Right DC Bus, except there is no

Standby Buses on the Right Side, and therefore, there is no need to report its status

to the Standby Bus.

s tm [C lass ] Lef t DC Bus

[ Statechart Of Lef tD CBus ]

LeftDC

LeftDC_NotInSevice

Lef t ACbusSt at us[ (param s->BusStatus==1)]

[ Lef tTRU == 0]/

OUT_POR T(DC Tie)->

GEN(ReqPowerF romRight);

CheckTRU

Reactions

LeftTRU_ON

PowerFromR ight [params ->St at us == 0]

Lef t TR U _St at us [ params ->TR Us t at us == 0]

[ Lef tTRU ==0]/

OUT_POR T(DC Tie)->

GEN(ReqPowerF romRight);

[ Lef tTRU ==1]

PowerFromR ight [params ->St at us == 1]

LeftTRU_OFF

Lef t ACbusSt at us[ params ->Bus St at us ==0]

InServiceFromTRU

OUT_POR T(...

InServiceFromRight

Figure 9 - StateChart Implementation of DC Bus

DC Tie Breaker

The DC Tie Breaker state flow is shown in Figure 10. The two state flows on the

right side, update the status of the Left and Right DC Buses. If the Right Bus is

powered, then the value of RightDC is one, otherwise zero. LeftDC is updated

�identically. These updates are triggered by the LeftDCbusStatus({0,1}) and

RightDCbusStatus({0,1}) mentioned in the DC Bus section above.

The state flow on the left allows the DC Tie Breaker to open and close based on the

requests and the status updates from Right and Left DC Bus. Initially, the DC Tie

Breaker is open. If the DC Tie Breaker receives the ReqPowerFromRight event, the

state flow transitions to the CheckRightDC state, which checks the status of the Right

DC Bus. If it is powered (i.e. RightDC = 1), then the state flow transitions to the

SendPowerFromRight state which sends the event PowerFromRight to the Left DC

Bus. However, if the Right DC Bus is unpowered (i.e. RightDC = 0) while in either the

SendPowerFromRight or CheckRightDC state, the DC Tie Breaker transitions back to

the Open state. The DC Tie Breaker behaves identically if the ReqPowerFromLeft is

received while in the Open state.

MainSt at e

Lef tD Cbus Status [params ->BusSt at us == 1] /

Lef tD C = 1;

Open

ReqPowerFromR ight

ReqPowerFromLef t

Lef tD Cupdat e

[R ightD C==0]

CheckRightDC

[Lef t DC ==0]

CheckLeftDC

Lef tD Cbus Status [params ->BusSt at us == 0] /

Lef tD C=0;

Right DC busSt atus[ params->Bus Status == 1]/

Right DC = 1;

[R ightD C==0]

[R ightD C==1]

[Lef t DC ==0]

SendPowerFromR ight

Right DC update

[Lef t DC ==1]

SendPowerFromLef t

Right DC busSt atus[ params->Bus Status == 0]/

Right DC = 0;

Figure 10 - StateChart Implementation of DC Tie Breaker

BPCU

The BPCU state flow implementation of Figure 11 consists of three parallel state

machines. The two statecharts on the right get the status of the APU and EXT Power.

These statuses are updated by events from the corresponding APU/EXT block

within the Architecture of Figure 3 via the BPCU_APU_EXPWR_BUS port. Figure 12

shows the APU status update state flow, which sets the variable APUstate according

to the status of the APU, which is either ON (APUstate = 1) or OFF (APUstate = 0).

Figure 13 shows the EXT Power status update state flow, which sets the variable

EXT_PWRstate according to the status of the EXT Power, which is either ON

(EXT_PWRstate = 2), OFF (EXT_PWRstate = 0) or AVAIL (EXT_PWRstate = 1). The

�AVAIL state indicates EXT Power is available, but not being used while the ON state

indicates the EXT Power is being used to power the AC Bus(s).

S tatec hartOfB P C

U

ex ternalP ow erON

NoAv ailablePowerSourc eForACBUS

A P U _ON

leftE ngine[params->s tatus==0]/

leftE ngineS tatus =0;

leftE ngine[params->s tatus==1]/

leftE ngineS tatus =1;

rightE ngine[params->status ==1]/

rightE ngineS tatus=1;

rightE ngine[params->status ==0]/

rightE ngineS tatus=0;

rightE ngine[params->status ==1]/

rightE ngineS tatus=1;

[APUstate !=1 && EXT_ PWRstate!=2 &&

( ri ghtEn gi ne Status ==1 || l eftEng in eSta tu s==1)]

l eftEng in e[pa ra ms->s tatus ==0 ]/

l eftEng in eSta tu s=0;

//No po we r at Le ft AC BUS

rig htEn gi ne [p arams ->statu s==0]/

rig htEn gi ne Status =0;

//No po we r at Ri gh t AC BUS

///N o gurad

leftE ngine[params->s tatus==1]/leftE ngineS tatus =1;

[EXT_PWRs ta te ==2]

CL OSE_BOTH_BTB_RIGHT_ PROVIDING_POWER

A P U _OFF

l eftEng in e[pa ra ms->s tatus ==1 ]/

l eftEng in eSta tu s=1;

[ri g htEng i neSta tus==0 ]

[le ftEngi n eStatu s==0]

APUs ta tu s[pa ra ms->s tate==1]/

APUs ta te =1 ;

GEN(APU_ ON)

APUs ta tu s[pa ra ms->s tate==0]/

APUs ta te =0 ;

GEN(APU_ OFF);

APU_ ON/

//OPEN RIGHT BTB

ex ternalP ow erOFF

CL OSE_BOTH_BTB_LEFT_PROVIDING_ POWER

CheckEngineFailur e

[le ftEngi n eStatu s==0 &&

rig htEn gi ne Status ==1 ]

ex ternal Powe rON/

//OPEN RIGHT BTB

[APUstate ==1 && EXT_ PWRstate!=2 ]

Po we rFro mEx te rnal So urce

[ri g htEng i neSta tus==0 &&

le ftEngi n eStatu s==1]

APU_ ON/

//OPEN LEFT BTB

ex ternal Powe rON/

//OPEN LEFT BTB

rig htEn gi ne [p arams ->statu s==1]/

rig htEn gi ne Status =1;

ex ternal Powe rON

[le ftEngi n eStatu s==0 &&

rig htEn gi ne Status ==0 ]

rig htEn gi ne [p arams ->statu s==1]/

rig htEn gi ne Status =1;

l eftEng in e[pa ra ms->s tatus ==1 ]/l eftEng i neStatus=1;

rig htEn gi ne [p arams ->statu s==1]/

rig htEn gi ne Status =1;

l eftEng in e[pa ra ms->s tatus ==1 ]/

l eftEng in eSta tu s=1;

rig htEn gi ne [p arams ->statu s==0]/

rig htEn gi ne Status =0;

l eftEng in e[pa ra ms->s tatus ==0 ]/

l eftEng in eSta tu s=0;

Po we rFro mAPU

EXT_ PWRstatus [p arams ->state==0 ]/

EXT_ PWRstate=0;

CheckEngineFailur e

EXT_ PWRstatus [p arams ->state==1 ]/

EXT_ PWRstate=1;

GEN(ex te rnal Po we rOFF);

[ri g htEng i neSta tus==0 &&

le ftEngi n eStatu s==1]

[le ftEngi n eStatu s==0 &&

ri g htEng i neSta tus==1 ]

[le ftEngi n eStatu s==0 &&

ri g htEng i neSta tus==0 ]

CL OSE_L EFT_BTB

EXT_ PWRstatus [p arams ->state==2 ]/

EXT_ PWRstate=2;

GEN(ex te rnal Po we rON);

rig htEn gi ne [p arams ->statu s==1]/

rig htEn gi ne Status =1;

l eftEng in e[pa ra ms->s tatus ==1 ]/

l eftEng in eSta tu s=1;

rig htEn gi ne [p arams ->statu s==0]/

rig htEn gi ne Status =0;

CL OSE_BOTH_BTB

l eftEng in e[pa ra ms->s tatus ==0 ]/

l eftEng in eSta tu s=0;

Figure 11 - StateChart Implementation of the BPCU

Figure 12 - StateChart Implementation of the APU Status Update within

the BPCU

�Figure 13 - StateChart Implementation of the EXT Power Status Update within

the BPCU

The large state flow on the left side of the entire BPCU state flow can be divided into

five states including three super states each indicating the flow of power and the

BTB configuration. Recall the priority to power a given AC Bus is EXT Power, local

engine, APU and opposite engine. The initial state, Both_BTB_Open, signifies both of

the BTBs are open and the local engine powers each AC Bus. In the event either

engine fails, the state flow will transition to the AlternativePowerSource, which is a

kind of junction state that enforces the priority mentioned above and based on the

statuses of the alternative power sources, determines which source will power the

lost channel. First, if no alternative power source is available, it will transition to the

NoAvailablePowerSourceForACBus state, which indicates the lost channel will

remain unpowered. Next, each of the super states represents alternative power

sources which will be explained in the following paragraphs.

As far as the BTBs are concerned, the APU and EXT Power have the same BTB

configuration for each of the given scenarios. Figure 14 shows the APU super

states of the BPCU state flow. The state flow of the EXT Power has modeled in

similar fashion. The initial state, CheckEngineFailure, checks the status of each

engine to determine which BTBs to close. An engine status of one indicates proper

operation while zero indicates failure. If only the Right Engine is lost, the Right BTB

will close as indicated by the Close_Right_BTB state. Similarly, if only the Left Engine

is lost, the Left BTB will close as indicated by the Close_Left_BTB state. However, if

both engines failed, both BTBs will close as indicated by the Close_Both_BTB state.

�Figure 14 - StateChart Implementation of the APU Alternative Source within the BPCU

Figure 15 shows the super state in which one engine compensates for the other. In

this case, both BTBs must close regardless of which engine fails. The only thing that

changes in this scenario is the direction of power flow. If the Left Engine fails, the

Right Engine provides power to the Left AC Bus and vice versa if the Right Engine

fails.

�Figure 155 - StateChart Implementation of the Other Engine Alternative Source

within the BPCU

When either the Left or Right BTB is command to be opened or closed, the

appropriate event (i.e. openLeftBTB, closeLeftBTB, etc.) is sent from the BPCU to the

Bus Tie Breaker in the Architecture (Figure 3) via the corresponding port(

BPCU_L_BTB_BUS, BPCU_R_BTB_BUS).

The last thing to note about the BPCU state flow is that there are transitions

between the five main states mentioned above. The transitions correspond to the

event when a source of higher priority is suddenly available in which there is a

transition from the lower priority source to the higher priority source.

Bus Tie Breakers Internal Block Diagram

The Bus Tie Breaker (BTB) internal block diagram is shown in Figure 16. As

previously mentioned, the BTB consists of two contactors, the Right BTB and the

Left BTB, shown in Figure 16. The ports BPCU_L_BTB_BUS and BPCU_R_BTB_BUS

receive open/close commands from the BPCU as mentioned in the BPCU section.

The TLeft(TieLeft) and TRight(TieRight) either send power to or receive from the

corresponding AC Bus. Lastly, the APU_ExtPower port receives power from the APU,

EXT Power or both, which can be distributed to one or both of the AC Buses.

�TieLeft

ibd [block] BT Bs [BTBsInternal]

TLeft

1

BPCU_L_BTB_BUS

BTB_left

BPCU_L_BTB_BUS

Attributes

APU_ExtPower

Operations

APU_ExtPower

closeLeftBT B()

OtherPowerSour...

openLeftBT B()

GEN_Power

GEN_Power

1

BPCU_R_BTB_BUS

BTB_right

BPCU_R_BTB_BUS

Attributes

Operations

APU_ExtPower

closeRightBTB()

OtherPowerSou...

openRightBTB()

TRight

TieRight

Figure 166 Internal Block Diagram of the Bus Tie Breaker

Right/Left Bus Tie Breaker State Flow

Figure 17 illustrates the simple state flow diagram of the Left BTB. Initially, the Left

BTB is open. It will close to the corresponding state on the closeLeftBTB event.

Likewise, the openLeftBTB event, will transition back to the initial state. The Right

BTB has an identical implementation.

OpenLeftBTB

openLeftBTB/OUT_PORT(TLeft)->

GEN(noPowerSourcesForLeft);

clos eLeftBTB/OU T_PORT(TLeft)->

GEN(OtherPowerSources SrvLeft);

Clos eLeftBTB

Figure 177 Right/Left Bus Tie Breaker State Flow

�External Power and Auxiliary Power Unit Internal Block Diagram

Figure 18 shows the internal block diagram of the ExtPower_APUgen block in the

Architecture (Figure 3). The BPCU_APU_EXPWR_BUS port allows the BPCU to receive

the status of both the APU and EXT Power. The APU_ExtPower port allows the Bus

Tie Breaker (in Architecture) to receive power from the APU or EXT Power.

ibd [block] ExtPower_APUgen [Ex tPowerAPUgenInternal]

External PowerController

Attributes

Ext Power

Operations

BPCU_APU_EXPWR_BUS

externalPowerCordConn()

Push_EXT_PWR_switch()

externalPowerCordDisCo...

APU_Ext Power

BPCU_APU_EXPWR_BUS

APU_Generator

Attributes

APUpower

Operations

APUstart ()

BPCU_APU_EXPWR_BUS

closeAPU_GenBreak er()

openAPU_GenBreaker()

APUstop()

APUstatus(state:int)

Figure 188 APU and External Power Internal Block Diagram

External Power

The transitions of states for External Power can be seen in Figure 19, in which it

updates the BPCU with the EXT Power status via the BPCU_APU_EXPWR_BUS port.

Initially, the state flow is in the NoExternalPower state, which indicates External

Power is not available and EXT_PWRstatus is set to zero and sent to the BPCU. The

event, externalPowerCordConn signifies the external power is available, but is not

supplying power to any of the aircrafts buses because it requires a pilot command

to supply power to the aircraft loads. This event reports EXT_PWRstatus=1 to the

BPCU. The state flow will transition back to the NoExternalPower state if EXT Power

is removed by the externalPowerCordDisConn event. When in the AVAIL state, If the

pilot pushes switch to supply external power (Push_EXT_PWR_switch) to the

required part of the power system buses, the EXT Power will be ready to supply

�power to the aircraft loads and EXT_PWRstatus=2 is sent to the BPCU. The EXT

Power state flow transitions to the ProvidePowerToEntireSystem state. If the pilot

sends the Push_EXT_PWR_switch event in this state, EXT Power will transition back

to the AVAIL state and send the BPCU EXT_PWRstatus=1.

NoE xternalPower

ext ernalP owerCordDisConn/

OUT_PORT(BP CU_A PU_E XPW R_BUS)

->GEN(E XT_PW Rstatus(0));

ext ernalP owerCordConn/

OUT_PORT(BP CU_A PU_E XPW R_BUS)

->GEN(E XT_PW Rstatus(1));

AV AIL

Pus h_EXT_PW R_switch/

OUT_PORT(BP CU_A PU_E XPW R_BUS)

->GEN(E XT_PW Rstatus(1));

Pus h_EXT_PW R_switch/

OUT_PORT(BP CU_A PU_E XPW R_BUS)

->GEN(E XT_PW Rstatus(2));

ProvideP owerToEntireSyst em

Figure 19 External Power State Flow

Auxiliary Power Unit

The APU state flow can be seen in Figure 20. This state flow has the responsibility to

update the BPCU with the APU status via the BPCU_APU_EXPWR_BUS port. Initially,

the state flow is in the Off state, which indicates the APU is not available and

APUstatus is set to zero and sent to the BPCU. The event APUstart, starts the APU by

transitioning the state flow to the On state and sending APUstatus=1 to the BPCU.

�Off

APUstart/

OUT_PORT(BPCU_APU_EXPWR_BUS)

->GEN(APUstatus(1));

APUstop/

OUT_PORT(BPCU_APU_EXPWR_BUS)

->GEN(APUstatus(0));

On

Figure 20 APU State Flow

AC/DC Standby Bus

The AC/DC Standby Bus has three modes. Mode 0 is off, which indicates the Standby

Buses are unpowered. Mode 1 is AUTO, which powers the AC/DC Standby Buses

from the Left AC and DC Buses, respectively. However, if the AC/DC Buses are

unpowered while in Auto Mode, the Battery Bus will power the DC and AC Buses

(via an inverter). Mode 2 indicates the Battery Bus must power the Standby Buses.

Figure 21 depicts implementation of the AC/DC standby Bus, which has four parallel

state flows on the right side and one on the left side. On the right side, the top two

get the status of the Left AC and DC Buses (one for powered and zero for

unpowered) via the LeftACbusStatus and LeftDCbusStatus events. The third updates

the operating mode, which is set by the pilot via the StandbyMode event. The last

one gets the status of the Battery Bus via the BatteryBusStatus event.

On the left state machine, initially it is in the NotInService state. If both the Left AC

and DC Buses are powered and mode is in AUTO, then the state flow transitions to

the InServiceFromLeft state. On entry and exit of this state, an event, ACDCbusPower,

is sent to the Battery Bus, which indicates whether or not the Left Side is providing

power to the Standby Buses. However, if any of these variables change, the state

flow will transition back to the NotInService state. If the Battery Bus is powered, and

the mode is BATT, then the state flow will transition to the InServiceFromBatBus

state. It will also transition to this state if in the AUTO mode and either the Left AC

or DC Bus is unpowered and the Battery Bus is powered. However, if the mode

changes to OFF or the Battery Bus becomes unpowered it will transition back to the

�NotInService state. Or, if the mode becomes AUTO and both the Left AC and DC buses

become powered, it will transition to the InServiceFromLeft state.

Standby

LeftAC busStatus[params-> BusStatus = = 1]/LeftAC = 1;

NotInService

LeftAC update

[LeftAC= =1 &&

LeftDC == 1 &&

Mode = = 1]

LeftAC busStatus[params-> BusStatus = = 0]/LeftAC = 0;

[LeftAC= =0 | |

LeftDC == 0 | |

M ode ! = 1]

LeftDCbusStatus[params-> BusStatus == 1]/LeftDC = 1;

LeftDCupdate

InServiceFromLeft

LeftDCbusStatus[params-> BusStatus == 0]/LeftDC = 0;

StandByMode[params-> mode== 1]/Mode = 1;

[ (BatBus = = 1) &&

((Mode == 2) | |

(Mode = = 1) &&

(LeftAC ! = 1 | | LeftD C ! = 1))]

StandByMode[params-> mode== 2]/Mode = 2;

ModeUpdate

[M ode == 1 &&

LeftAC = = 1 &&

LeftDC == 1]

[M ode == 0 | |

BatBus == 0]

StandByMode[params-> mode== 0]/Mode = 0;

BatteryBusStatus[params-> Status== 1]/BatBus = 1;

InServiceFromBatBus

BatteryBusUpdate

BatteryBusStatus[params-> Status== 0]/BatBus= 0;

Figure 191 AC/DC Standby Bus

Battery Bus

The Battery Bus can either be powered from the Left DC Bus or the Battery, but this

depends on the Standby Mode previously discussed. The state flow is shown in

Figure 22, which has three update state flows on the right side. The first one gets the

Standby Mode from the pilot via the StandbyMode event. The second update gets the

value ACDC from the AC/DC Standby Bus, which is one if the Left AC and DC Buses

power the Standby Bus. This update is triggered by the ACDCbusPower event from

the Standby Bus. The last update state flow gets the Battery Status from the Battery

via the BatteryStatus event. Batt = 1 if the Battery can supply power, and Batt = 0

otherwise.

Initially, the Battery Bus is not in service. If the Battery can supply power (i.e. Batt =

1) and Standby Mode is either OFF or BATT, then the Battery will power the Battery

Bus, and the state flow will transition to the InServiceFromBatt state. The state flow

will also transition to this state if in the AUTO mode and the Left AC/DC Buses are

not powering the Standby Buses (i.e. ACDC = 0). While in the InServiceFromBatt

state and the Battery becomes depleted (i.e. Batt = 0), it will transition back to the

�NotInService state. Once in either the InServiceFromBatt or NotInService states, if

Mode becomes AUTO and Left AC/DC Bus is providing power to the AC/DC Standby

Buses (i.e. ACDC = 1), then the Left DC Bus provides power to the Battery Bus, which

is indicated by transitioning to InServiceFromLeft. However, if the mode changes or

the Left Side no longer powers the Standby Buses, the state flow will transition back

to the NotInService state.

stm [Class] BatteryBus [StatechartOfBatteryBus]

BattBus

[Batt == 0]

StandByMode[params->mode == 1]/Mode = 1;

NotInService

ModeUpdate

[(Mode == 1)&&(ACDC == 1)]

InServiceFromLeft

[(Batt == 1)&&

(Mode = = 2 | | Mode = = 0 | |

(Mode = = 1)&&ACDC==0)]

[Mode ! = 1 | | ACDC ==0]

StandByMode[params->mode == 2]/Mode = 2;

StandByMode[params->mode == 0]/Mode = 0;

ACDCbusPower[params->Status == 1]/ACDC = 1;

ACDCupdate

InServiceFromBatt

ACDCbusPower[params->Status == 0]/ACDC = 0;

BatteryStatus[params->Status == 1]/Batt = 1;

BattUpdate

[(Mode == 1 && ACDC == 1)]

BatteryStatus[params->Status == 0]/Batt = 0;

Figure 202 Battery Bus

Battery

The Battery model (shown in Figure 23) has two update state flows. The first one

gets the status of the Battery Bus via the BatteryBusStatus event. This event sets

BattBus to one if the Battery powers the Battery Bus otherwise it is zero. If this is

the case, the Battery cannot be charged because the chargers would be supplying

power to a load, which could cause them to fail prematurely. The Left AC Bus

powers the Battery Chargers, and therefore, the second status update gets the status

of the Left AC Bus from the Battery Bus via the BattBusServiceFromLeft event. So if

the Left AC bus is powered, the variable LeftAC=1, otherwise it is zero.

Initially, the battery is Full as indicated by the Full state (charge = 100). If the

Battery Bus is providing power (i.e. BattBus = 1) then the Battery will transition to

the Discharging state, which decrements charge every 1000ms. If charge becomes

zero, the Battery will transition to the Depleted state. If the Battery Bus changes to

not supplying power and the Left AC Bus is powered (i.e. BattBus = 0 and LeftAC =

1) while in either the Discharging or Depleted states, then the Battery can transition

�to the Charging state where charge is incremented every 1000ms until it is 100. At

this point, it transitions back to Full. However, if the Battery suddenly starts to

supply power while in the Charging State (i.e. BattBus = 1), then it will transition

back to the Discharging state.

Battery Stat e

Battery BusStatus[params->St atus == 1]/ Bat tBus = 1;

Full

BattBusUpdate

[charge == 100]

charge ...

[Batt Bus==1 && Lef tAC == 0]

tm(1000)

Charging

tm(1000)

[Batt Bus==1 &&

Lef tAC==0]

Discharging

Battery BusStatus[params->St atus==0]/BattBus = 0;

charge ...

BattBusServ iceFromLef t [params->Stat us==1] /Lef tAC=1;

[Batt Bus == 0 &&

Lef t AC == 1]

[Batt Bus == 0 &&

Lef tAC == 1]

Deplet ed

Reactions

Lef tACupdat e

[charge == 0]

BattBusServ iceFromLef t [params->Stat us==0] /Lef tAC=0;

Figure 213 Battery